Morgana UFO Manual

Other Morgana Folding Machine manuals

Morgana

Morgana Square fold 104 User manual

Morgana

Morgana MB300 XL Pro User manual

Morgana

Morgana Digifold 5000P User manual

Morgana

Morgana DigiFold Pro User manual

Morgana

Morgana AutoFold Pro User manual

Morgana

Morgana TF MEGA-S User manual

Morgana

Morgana AutoFold Pro User manual

Morgana

Morgana DIGIFOLD User manual

Morgana

Morgana DocuFold Pro User manual

Morgana

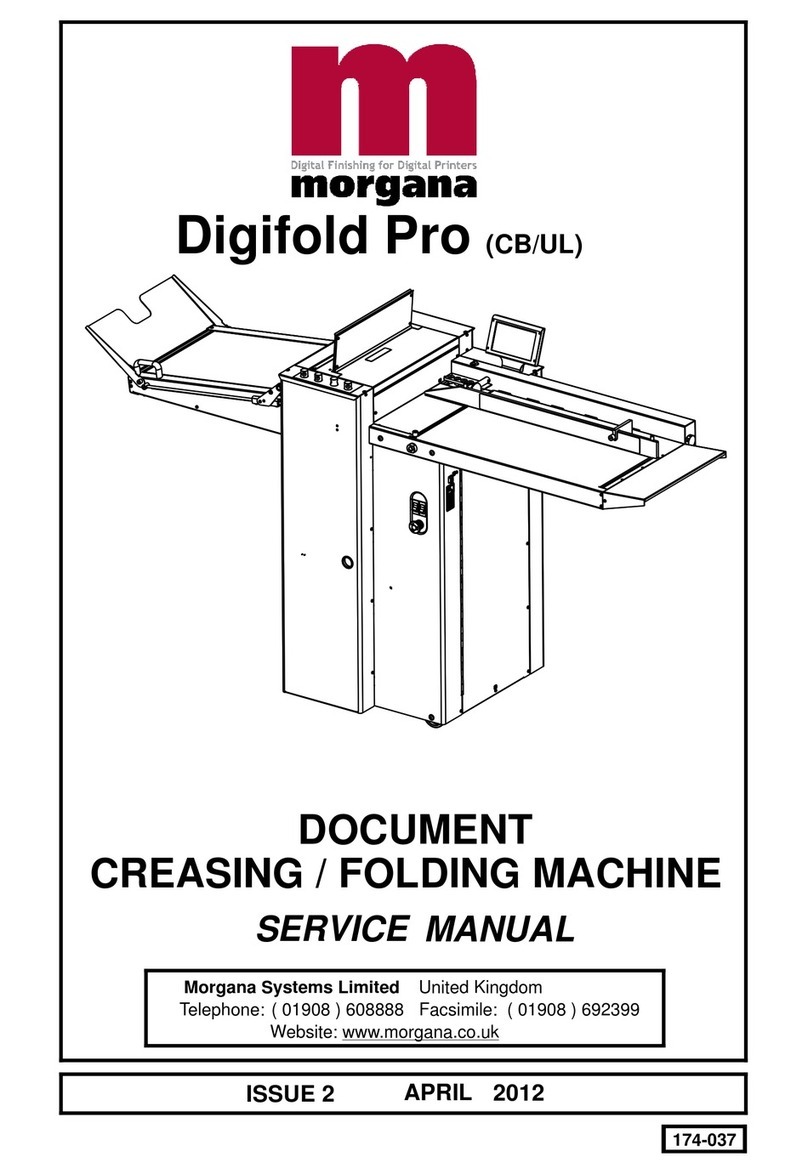

Morgana Digifold Pro CB User manual

Popular Folding Machine manuals by other brands

Mathias Bauerle

Mathias Bauerle Multipli 35 Operator's manual

Intelli-Fold

Intelli-Fold DF-304C user manual

Pitney Bowes

Pitney Bowes DI425 FastPac Operator's guide

Hwasung

Hwasung COMPODIS HMK-830 Series Technical manual

KRUG+PRIESTER

KRUG+PRIESTER IDEAL 8306 operating instructions

XPOtool

XPOtool 61574 Operation manual