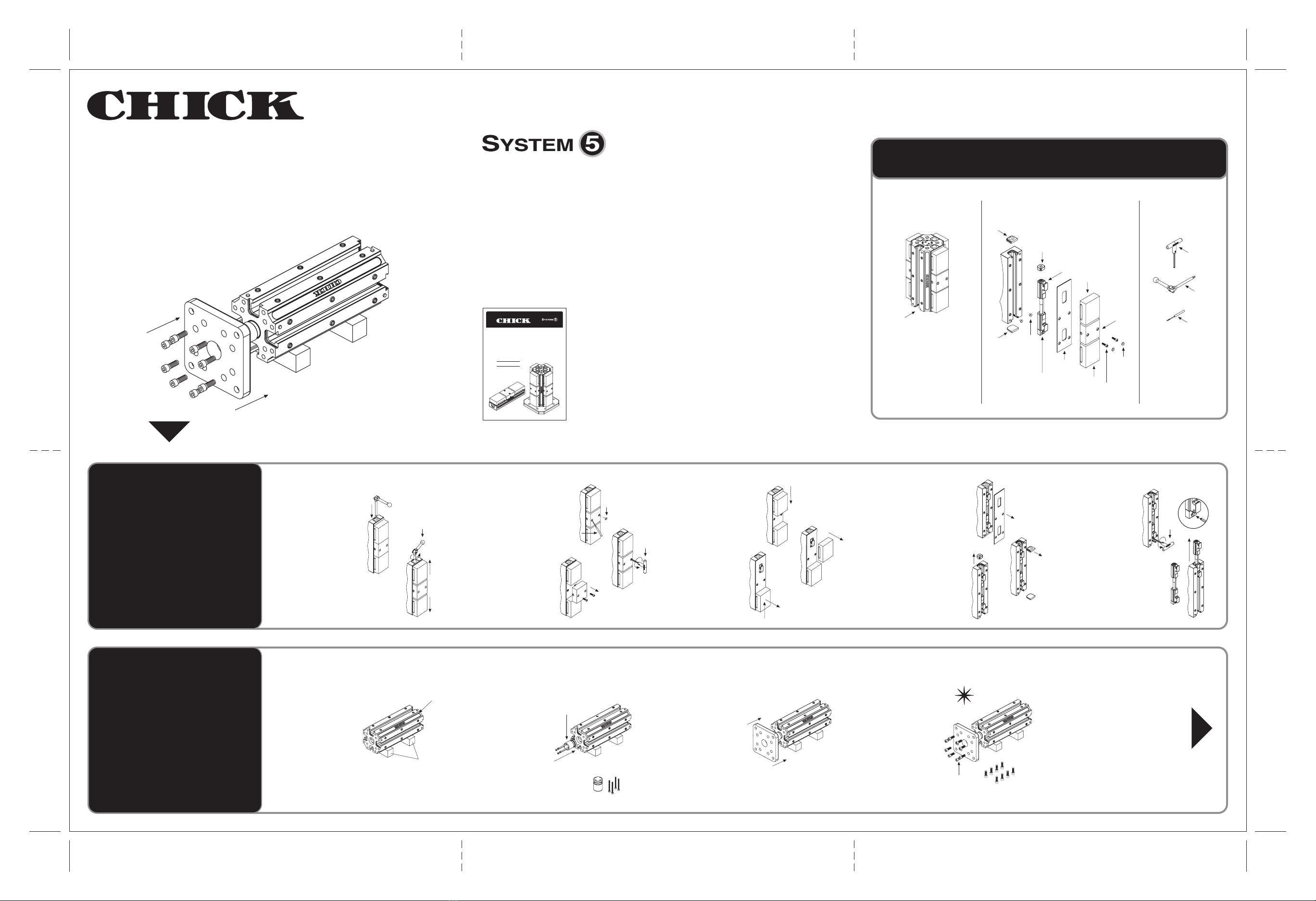

CHICK Multi-Lok User manual

Open the

Moveable Jaws

Allentare le

ganasce mobili

STEP 1

Remove the Fixed

Center Jaw

Rimuovere la ganascia

centrale fissa

STEP 2

Remove the

Moveable Jaws

imuovere le

ganasce mobili

STEP 3

Remove the Coverplate,

Seal Caps and andle Guide

Rimuovere la piastra di

coprimento ed i cappucci

laterali di protezione

STEP 4

Remove the

Slide Assembly

Rimuovere la slitta

centrale

STEP 5

Multi-Lok

Workholding Systems

QwikStart

Setting up your Multi-Lok Workholding System

takes just minutes.

The following STEPS will help guide you through the setup

procedure and show you how you can load and unload

two workpieces independently.

UsingYour CHICK

Workholding Systems

VMC and HMC Models

USER GUIDE

Refer to the User Guide for more detailed

information on how to use your Workholding System.

To download a pdf of the User Guide go to:

English: www.chick-workholding.com/support/support.html

Deutsch: www.chick-workholding.com/german.html

For more information, please call CHICK at:

1-800-33-CHICK

Workholding System Breakdown

Column Face Components Tools Needed

START HERE!

Maximizing Milling Profitability

Disassemble

1

One System...

Endless Opportunities

Secure the

Multi-Lok Column

Sichere den

Multi-Lok-Turm

Prendete il cubo

Multi-Lok

Secure the

Multi-Lok Column

Protêger la colomne

Multi-Lok

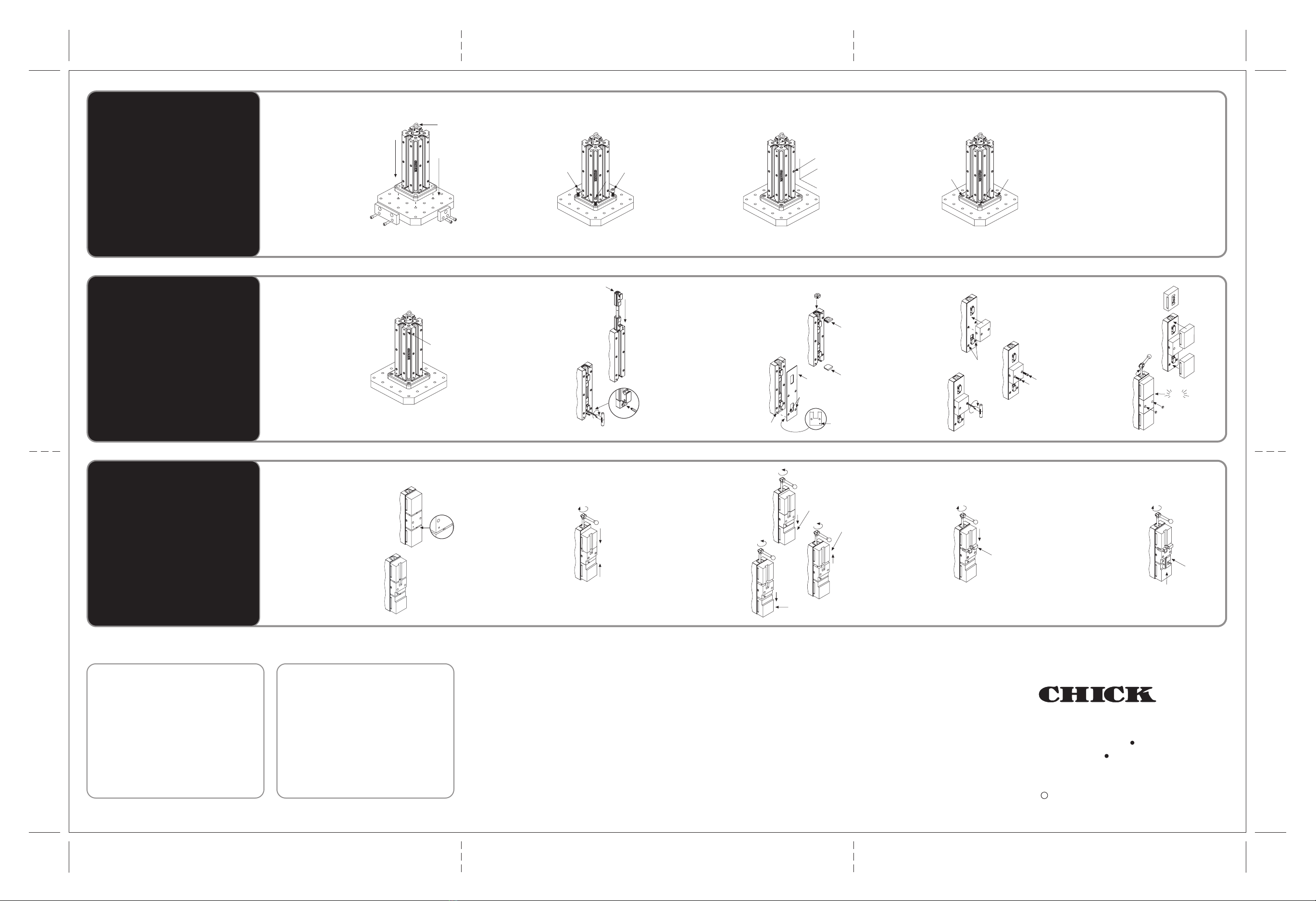

STEP 1

Attach Pilot Plug

to Column

Befestige den

Zentrierzapfen am Turm

Inserite il pilota neel

cubo

Attach Pilot Plug

to Column

Fixer le pilote de guidge

a la colonme

STEP 2

Attach Column to

Baseplate

Befestige die

Grundplatte am Turm

Collegate il cubo

alla base

Attach Column to

Baseplate

Fixer la colonme á la

plaque de base

STEP 3

Mounting to a

Baseplate

2

Befestigung auf einer

Grundplatte

Montare su una

Base

Mounting to a

Baseplate

Montage sur la

Plaque de base

Smontaggio

*

A

B

A

B

C

A

B

C

A

B

C

A

B

OVER

Swivel Handle Front

Moveable Jaw

Rear

Moveable Jaw

Chip Plugs

T-wrench

Screwdriver

Fixed Center

Jaw Mounting

Screws

Slide

Assembly

Multi-Lok Column-41

has 4 faces

Serial Number

Parallels

Pilot Plug

Abra las quijadas

móviles

Retire la quijada fija

central

Retire las quijadas

móviles

Retire la cubierta metálica y los

capuchones de sello

Retire la base del

conjunto

Desarmar

T-wrench

Square and Align

Column to Baseplate.

Coverplate

Handle Guide

Front

Seal Cap

Rear

Seal Cap

Chip

Plugs

Fixed Jaw

Mounting

Screws

Fixed

Center

Jaw

Front

Moveable

Jaw

Rear

Moveable

Jaw

Handle

Guide

Slide

Assembly

Coverplate

T-wrench

Rear

Seal Cap

Chip

Plugs

Front

Seal Cap

Screwdriver

Swivel

Face

Third-Hand

mechanism

Assembly

One MPP50 Column Pilot Plug

with four M6-1x70 Pilot Plug

Mounting Screws

Secure Baseplate to

Column

Verschraube die

Grundplatte mit dem Turm

Fissate la base al

cubo

Protêger la plaque de

base de la colonme

STEP 4

Secure Baseplate to

Column

Eight M12-1.75x35

Column Mounting Screws.

Tighten in

Star Pattern.

1

2

34

5

6

7

8

Ouvrir les mors

mobiles

Enlever le mors fixe Enlever les mors

mobiles

Enlever la paque detancheite

et les bouchons

Enlever lensemble

coulissean

Dimontage

Öffne die

beweglichen Backen

Entferne die feste

Mittelbacke

Nimm die beweglichen

Backen ab

Entferne die Stahlgleitplatte, die

Abdeckkappen und die

Spannkurbelführung

Ziehe den Spanntrieb

heraus

Demontage

www.chick-workholding.com

500 Keystone Drive Warrendale, PA 15086 USA

Phone: (724) 772-1644 Fax: (724) 772-1633

(800) 33-CHICK (800) 332-4425

***

Position Column/Baseplate

Assembly to Pallet

Positioniere den Turm mit

Grundplatte auf der Palette

Posizionare il cubo con la

base sul pallet

Position Column/Baseplate

Assembly to Pallet

Posikiommer la colonme et la

plaque de base sur la palette

STEP 1

Attach Assembly

to Pallet

Fixiere den Turm mit

Grundplatte auf der Palette

Collegare questo al pallet

Attach Assembly

to Pallet

Fixer sur la palette

STEP 2

Align Assembly

to Pallet

Richte den Turm mit

Grundplatte auf der Palette aus

Fare lallineamento

al pallet

Align Assembly

to Pallet

Degauchir sur la

palette

STEP 3

Secure Assembly

to Pallet

Befestige den Turm mit

Grundplatte auf der Palette

Serrare la base al pallet

Secure Assembly

to Pallet

Protêger l'ensemble

STEP 4

Mounting to a

Pallet

3

Befestigung auf einer

Palette

Montare su una

Pallet

Mounting to a

Pallet

Montage sur la

Palette

Properly Position

your System

Posizionare

lattrezzo

STEP 1

Insert Slide Assembly,

tighten Third- and Screw

Inserire la slitta

assemblata

STEP 2

Install andle Guide,

Seal Caps and Coverplate

Inserire i cappucci di

protezione e la piastra di

STEP 3

Install the Fixed

Center Jaw

Installare la ganascia

centrale fissa

STEP 4

Install Moveable Jaws

and Chip Plugs

Installare le ganasce

mobili

STEP 5

Reassemble

4Riassemblaggio

Machine Jaws

using a spacer

PriorTo:

Close the

Moveable Jaws

STEP 1

Set the System to

hold Workpieces

STEP 2

Load the Front

Workpiece

STEP 3

Load the Rear

Workpiece

STEP 4

Set Third-Hand

5

**

***

Swivel Handle

Bottom View

of Jaw

Front

Moveable

Jaw

Rear

Moveable

Jaw

Fixed

Center Jaw

Mounting

Screws

T-wrench

Handle Guide

Slide

Assembly

T-wrench

Chip Plugs

Rear

Moveable Jaw

Front

Moveable

Jaw

Rear

Moveable Jaw

*

A

B

A

B

C

A

B

A

B

AA

B

C

Made in the USA

Copyright 2003 800-0247 May 2003

c

B

Optional

Hoist Ring

Y

X

Z

Indicate

Mounting

Screws

Female

Hex

Front

Rear

CLICK

Prima...Lavorare le ganasce

bloccate su uno spaziatore

Serrare le ganasce mobili Preparare lattrezzo al

ricevimento dei pezzi

Montare il pezzo sulla

ganascia frontale

Montare laltro pezzo

sulla ganascia più lontana

Attivare la ter a mano

Repeat STEPS on every face of your workholding

system.

Auf jeder Seite des Werkst ck-Spannsystems m ssen

die SCHRITTE wiederholt werden.

Ripetete le procedure per ogni faccia del vostro sistema

di bloccaggio.

Repita LOS PASOS en cada cara de sus sistema de

sujecion.

Repeter les etapes sur chaque faces de votre systeme

de serrage.

Make sure the Third-Hand screw was tightened in

STEP 2B of Reassemble.

Es muß sichergestellt sein, dass die 3te-Hand-Schraube

im Schritt 2B der Montagebeschreibung angezogen

wurde.

Accertarsi che il dispositivo della terza mano sia serrato

al punto 2B del Riassemblaggio.

Asegurese que el tornillo de la tercera mano ha sido

apretado en el proceso de rearmado 2B.

Sassurer que la vis troisième main sort serre sufiamen

(dans letape 2B du remantage).

Maquine las quijadas usando un

espaciador

Cierre las quijadas

móviles

Ajuste el sistema para

colocar dos piezas

Cargar la pieza de trabajo Cargar la pieza de trabajo

trasera

Colocando la tercera mano

Posicione adecua

damente su sistema

Inserte la base del

ensamble

Inserte los capuchones de sello y

la placa metálica de protección

Instale la quijada

central fija

Instale las quijadas

móviles

Rearmado

Front

Seal Cap

Rear

Seal Cap

Coverplate

Guide

Single Station

Holes

Blind

Hole

Coverplate

Single Station

Locating Holes

Baseplate

Mounting Screws

Either

M12-1.75X35 (1/2-13)

M16-2x35 (5/8-11)

Finger Tighten

Third-Hand Mechanism

Serial Number

Remettre en position le

systeme

Mettre densemble

coullisseau

Mettre les bouchons et la

plaque detancheite

Mettre le mors

durs

Mettre les mors

mobiles

Remontage

Avant dusiner les mors

uholeser une cale

Fermer les mors mobiles Regler le systeme pour

serrer une pieces

Charger la piece avant Charger la piece arriere

Regler lensemble troisieme main

Befestige das System

sorgfältig

Setze den Spanntrieb ein und

fixiere die 3te- and

Installiere die Spannkurbelführung,

die Abdeckkappen und die

Stahlgleitplatte

Befestige die feste

Mittelbacke

Montiere die beweglichen

Backen

Montage

Benutze zur Bearbeitung

ein Distanzstück

Schließe die

beweglichen Backen

Stelle die

3te- and ein

Spanne das vordere

Werkstück

Spanne das hintere

Werkstück

Einstellen der 3ten-Hand

Popular Industrial Equipment manuals by other brands

Siemens

Siemens simovert EMC-Filter Compact PLUS operating instructions

Armstrong

Armstrong ASF Series Operation manual

SCHUNK

SCHUNK ROTA NCK plus Assembly and operating manual

ABB

ABB HT609588 Operation manual

Graco

Graco Series A Instructions-parts list

SUHNER MACHINING

SUHNER MACHINING BEM 20 Technical document