Assembly and Operating Manual

2 Safety

2.1 Symbol

2.2 Intended purpose

2.3 Environmental and operating conditions

2.4 Safety indication

Dangers may arise from the unit, if:

•

the product is not installed or inserted properly,

•the system is not used for its intended purpose,

•the safety and installation notes are not observed.

CAUTION! Never operate the hand lever when the load is suspended!

Rev. 1.04 2

NOTICE!

The unit may only be operated if the machine in which the unit is installed complies with the

relevant provisions of the machinery directive 2006-42-EC.

This symbol indicates possible hazards to persons or the SHW

Connector.

Everyone who is responsible for assembly, commissioning and maintenance must read and

understand the complete operating instructions. Improper use, which affects the function und

operational safety of the SHW Connector, is prohibited.

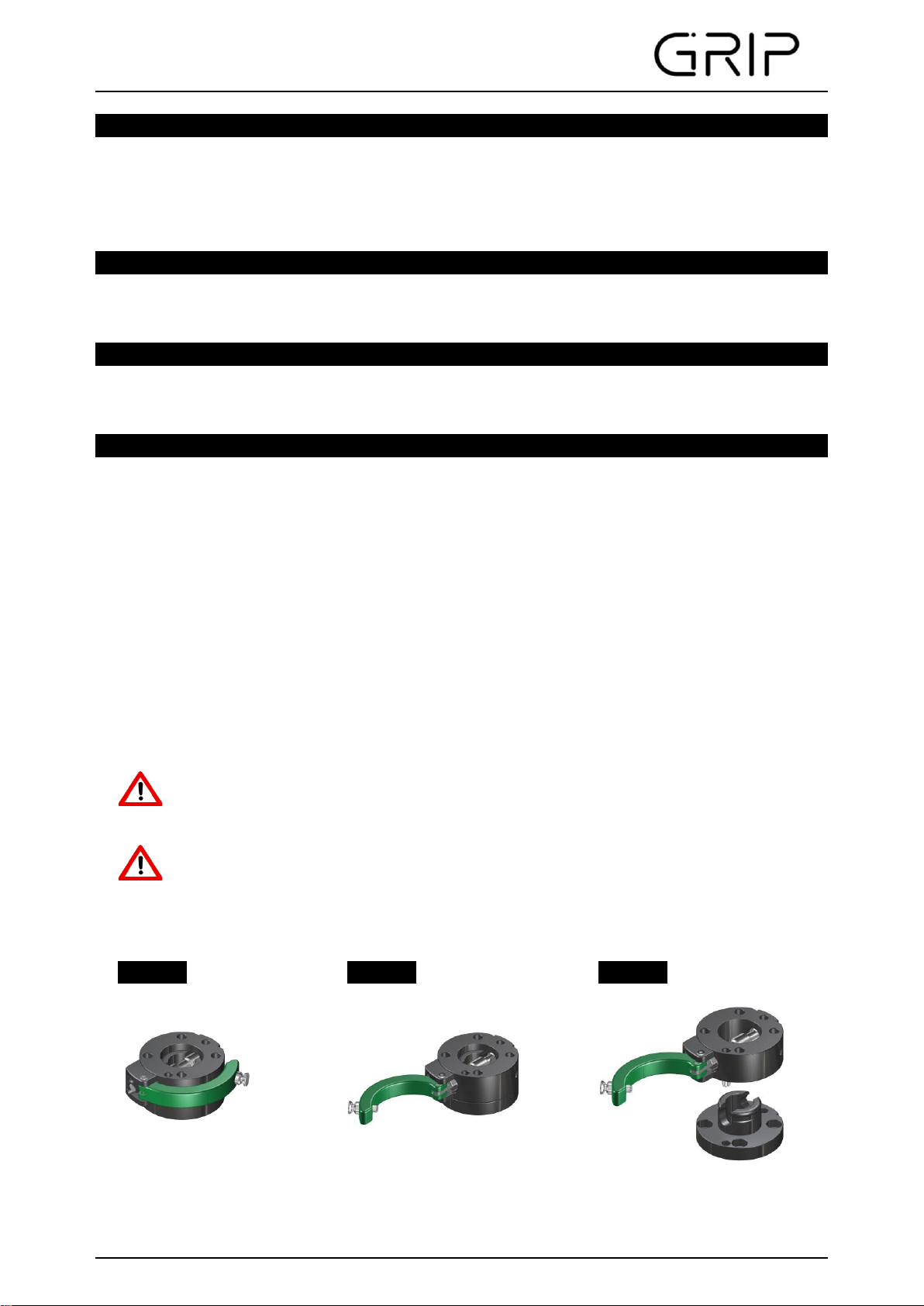

To open the change system, pull the locking pin on the hand lever. As a result, the crossway bolt

is displaced radially and releases the force-locked crimp connection in the bore of the lower

assembly. The upper and lower assembly can now be pulled apart.

Use this unit only in dry and splash-proof environments at room temperature as well as within the

application parameters defined in the technical specifications. If this is not the case, warranty

cannot be accepted. Exceptions are units designed especially for the respective conditions.

In order to prevent damage to the connector as well as injuries to the operator, the

lower assembly or the tool must be secured by hand or other devices before opening

the change system. Otherwise there is a risk that irreparable damages to the tool or

injury to the operator are caused by the unit falling down.

The SHW Connector has been designed as an interface between handling device and tool (e.g. gripper).

Furthermore, the SHW can also be used in special solutions, automation and also as a general

mechanical standard interface. The unit may only be used in the context of its technical specifications.

The system is intended for the installation in a machine. The requirements of the applicable instructions

must be considered and adhered to.