HISAKA UX-005A User manual

Plate Heat Exchanger

5 “Slit-In” Type Gasketting Manual

Introduction

About this document

In addition to this document, the Manuals for HISAKA PHEs consist of the following six documents. Read them thoroughly and

understand the precautions regarding the safety of the equipment and its functions before handling the equipment.

1 Installation Manual, 2 Operation and Maintenance Manual, 3 Gasketting Manual, 4 Plate Cleaning Manual,

6 Mixed Gasket Materials Manual, 7 Strainer Maintenance Manual.

You can also download these documents on our company website. http://www.hisaka.co.jp/english/

This document is the operation and maintenance manual for “Slit-in” type plates of plate heat exchangers (PHE) to which gaskets

are installed without adhesives. Refer to the separate operation and maintenance manual for food product PHE

(FX-A Series).

This document is created for a person who fully understands the language it is written in. If a person, who is not able to understand

the language written herein, will handle the equipment, please provide safety instructions to the personnel/operators.

The PHE supplied may differ from the drawings and pictures in this document depending on the optional parts if any. Also, for the

purpose of explanation, the drawings and pictures in this document may omit the details, accessories, or the like.

Changing the contents of this document, in part or in whole, or using this document for anything other than its intended purpose is prohibited.

About gasket use

To prevent injury and damages, do not use the gaskets other than for their intended purpose and specifications. Also, during

maintenance, follow the instructions of related documents.

About worker limitations

PHE maintenance should be carried out by a worker who has received training in safety and danger prevention.

Work in high places should be carried out by a worker who fully understands the danger of the work and has received training in

safety and danger prevention.

Export Regulations on the Equipment

In case of export of HISAKA PHE and its component parts such as plate, gasket and so on, please follow the local law and

regulations.

Disposal of the Equipment

Do not incinerate gaskets. Incinerating gaskets releases toxic gas and is extremely dangerous.

Any unnecessary gasket should be disposed as industrial waste in accordance with international, national, prefectural, and

municipal regulations.

Disclaimer

HISAKA accepts no liability for any failures in the function or performance of the equipment caused by use of any other than

genuine parts.

HISAKA accepts no liability for any injuries or damage borne by the user, caused by use of any other than genuine parts.

HISAKA accepts no liability for any failures in the function or performance of the equipment caused by use of this equipment in a

manner that does not adhere to the procedures indicated in this manual.

“Slit-in” Manual

Table of Contents

1 Safety Precautions P1

2 “Slit-in” Plates and Gaskets P2

3 “Slit-in” Gasketting Procedures P2 to 4

4 “Slit-in” Gasket Removal Procedures P4

5 Plate Disassembly and Assembly P4

6 D-Plate Gasket Installation Procedures P4

7 Other Precautions P4

8 Inquiries P5 to 7

P1

1 Safety Precautions

Read through this manual carefully before use and use the PHE properly as indicated.

If you have any questions, please inquire with our company.

Precautions are categorized using the following symbols.

WARNING

This symbol indicates content where mishandling could result in death or severe injury.

CAUTION

This symbol indicates content where mishandling could result in injury or property damage.

NOTE This symbol indicates important matters and/or useful information.

Meanings of Symbols

Indicates items that are

"prohibited (something that you must NOT do)".

Indicates items that are

"mandatory (something that you must do)".

WARNING

Do NOT loosen PHE's tightening bolts/nuts except for maintenance work.

The PHE could come apart if tightening bolts/nuts are loosened before installation.

Do NOT use tightening bolts with loosened bolt heads.

If the bolt head loosens and the bolt head (nut) comes off the bolt, it could fly off at high

speed. This is dangerous and contact could cause serious injury or property damage.

Do NOT use a flange gasket for the nozzle of heat exchangers with synthetic

rubber covering.

Sealing performance could be decreased and it could be a cause of leaking.

(Flange gaskets are required for nozzles with metal covering.)

Do NOT incinerate gaskets.

Incinerating gaskets releases a toxic gas and is very dangerous.

Any unnecessary gaskets should be disposed as industrial waste in accordance

with international, national, prefectural, and municipal regulations.

For the industrial waste treatment company, use a company that has received

permission from the prefectural governor.

In general, do NOT perform pneumatic test for medium and large size PHE.

For small size PHE, do NOT perform pneumatic test at the same pressure as

hydrostatic test pressure.

If a leak occurs during a pneumatic test using compressed air or nitrogen, it is extremely

dangerous as, in addition to the test pressure, volume expansion causes an impact.

In general, do NOT perform a pneumatic test in excess of 0.75 MPaG.

Install a protective cover on heat exchangers that handle high temperatures,

high pressure, or dangerous fluids such as strong acids or strong alkalies.

If a dangerous fluid leaks, it could cause a serious accident.

Make sure that the operation is stopped, the internal pressure is "0", and the

fluid temperature has sufficiently dropped before disassembling the PHE.

If a fluid sprays out from the heat exchanger interior during disassembly, it could

cause burns or lacerations.

Do NOT operate in excess of the design conditions

(temperature, flow rate, pressure, etc.).

It may cause deformation of the heat transfer plates or leakage. Also, the required

performance may not be achieved.

Do NOT loosen the thermometer, pressure gauge, tightening bolts and nuts, or

any other accessories during operation and when the PHE are pressurized.

If fluid splashes from the PHE during disassembly, it may cause burns or lacerations.

Perform gasket replacement in a well-ventilated area or area with ventilation

equipment.

The gasket dedicated adhesives "S-1" and "F-2" contain organic solvents. Breathing

the volatile ingredients for a long time may cause symptoms such as headache,

dizziness, and nausea. Should these symptoms occur, move somewhere with fresh

air and rest, stay calm and warm, and seek medical attention.

Do NOT use tightening bolts with damage such as significant rust or cracks.

If a tightening bolt breaks during operation or during disassembly, not only will the

fragments fly off, but there is also danger of the fluid in the heat exchanger interior

spraying out.

CAUTION

Do NOT touch the side of the heat exchanger element (edge of the heat

transfer plates).

The edge of a heat transfer plate is very sharp and may cut you.

Be sure to wear cut-resistant gloves whenever touching the heat transfer plates.

Request an expert to perform piping work, and review the assembly drawings

with them beforehand to ensure that connections are properly made.

Work performed by inexperienced personnel can result in a faulty or improper

connection. An improper connection can result in failure to provide the specified

performance or an equipment malfunction.

Do NOT place objects on the heat exchanger.

Doing so may cause deformation of heat transfer plate or a falling object may

cause injury during operation.

Do NOT touch anything the side of the heat exchanger element (edge of the

heat transfer plates).

Deformation of the heat transfer plate may cause damage to the plate gasket and

result in leakage.

Secure working space around the PHE.

Installation and piping design must take into account the working space required

for using disassembly and installation tools.

In general, do NOT remove the stud bolts on the heat exchanger nozzles.

Removing the stud bolts may cause damage on the threads.

If it is absolutely necessary to remove them, remove them carefully so as not to

damage the screw threading on the stud bolt and the frame. Also, stud bolt removal

shall be done at the customer's liability.

Clean the piping interior before connecting.

Clean piping thoroughly so that no debris enters the PHE.

Select flange gasket material that is suitable for the fluid specifications.

Flange gaskets are required for tube flange and metal boot types.

Do NOT weld or attach any piping support to the frame, guide bar, or guide

bar support.

Such welding may cause thermal damage to gaskets, or the attached part may

cause interference that prevents parts from fulfilling their function. Furthermore, the

installed part will be an obstacle and will prevent disassembly.

Install sufficient support for piping connected to the PHE.

A large piping load to the PHE may cause the frame to become deformed or

leakage.

Do NOT allow debris or foreign material to get inside the PHE.

The clearance of the PHE is quite narrow, such that it can be easily clogged by

debris or foreign material. When flushing the piping, take measures such as

installing a temporary strainer at the inlet piping or bypassing the PHE in order to

prevent debris or foreign materials from entering the PHE.

Perform maintenance of PHE that handle dangerous fluids, such as a strong

acids or alkalies, in an environment that has wastewater treatment equipment.

Process waste fluid in accordance with the law and regulations. Be careful not to drain

liquid into a river or ocean area. If untreated liquid leaks, take measures in accordance

with the "Material Safety Data Sheet (MSDS)" for the treatment liquid you used.

Do NOT allow the fluid to freeze.

In cold areas, remove the fluid inside the heat exchanger and empty the equipment

before storing it.

P2

2 “Slit-in” Plates and Gaskets

“Slit-in” plates are indicated by the letter "A" at the end of the model number indication. (Examples: UX-016A and UX-216A)

“Slit-in” plates have slits (holes) that are used for fixing gaskets to the plate.

These slits (holes) are located on the outside of the plate gasket groove and in the port holes (excluding UX-005A and

UX-01A).

“Slit-in” gaskets are indicated by the letter "A" in front of the material indication. (Examples: A-NBR and A-EPDM)

“Slit-in” gaskets have protrusions for fixing the gasket to a plate.

Handle gaskets with care because a protrusion can be cut easily.

3 “Slit-in” Gasketting Procedures

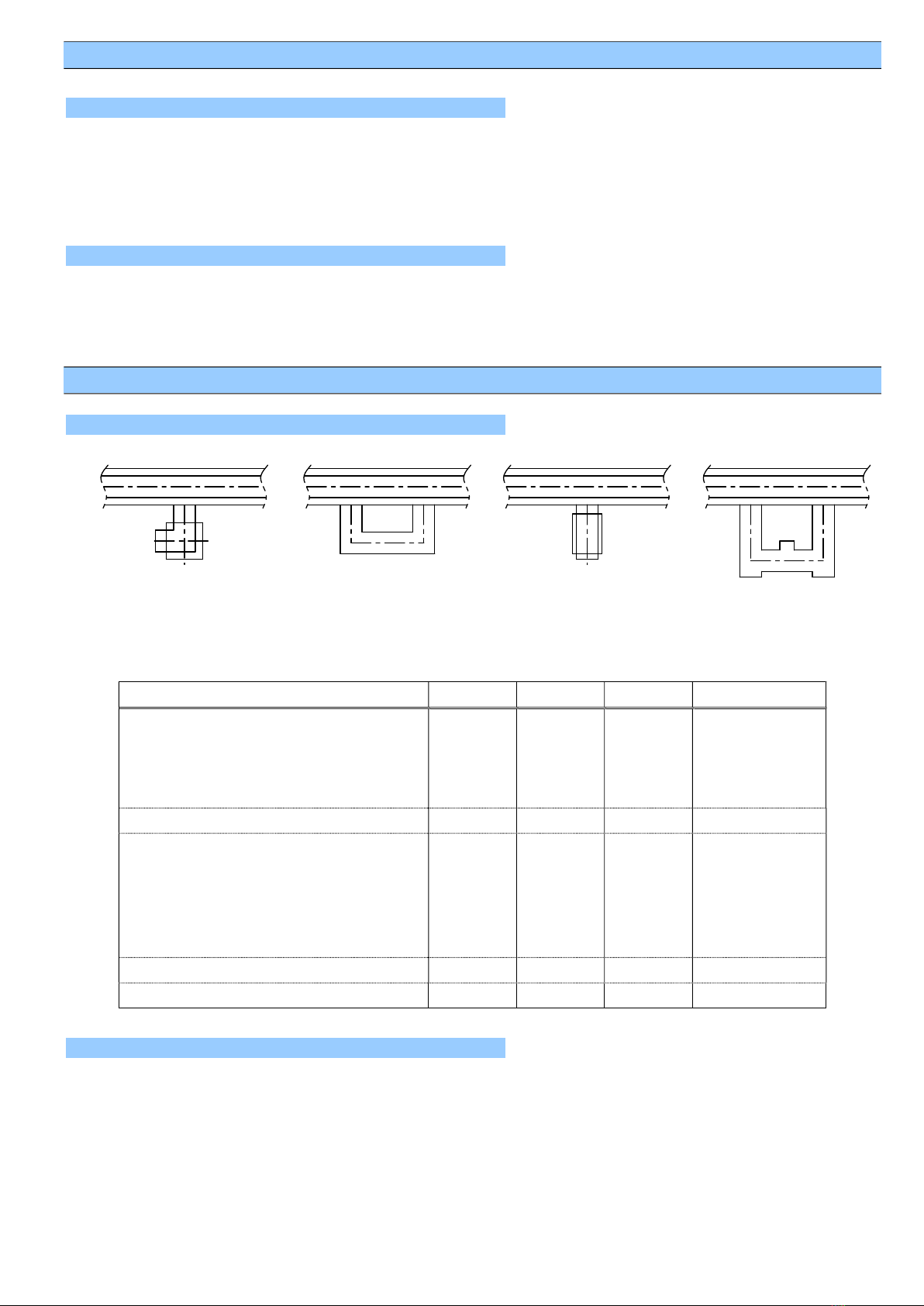

There are four type of protrusions depending on each PHE model (Fig.1).

Fig. 1 Type of Gasket-Fixing Protrusions

Table 1 Type of Gasket-Fixing Protrusions by Model

Model L-type O-type I-type Hook-lock type

UX-005A

RX-01A

WX-10A

CX-10A

- - -

UX-01A, 20A, 40A -

UX-10A, 30A

RX-10A, 30A, 50A

SX-10A, 30A, 30SA, 40A, 70A

LX-00A, 10A, 20A, 30A, 40A, 50A

GX-20A

- -

EX-11A, 15A - - -

CX-01A - - -

1) Press the gasket protrusion at point A by hand for inserting into the slit (hole) on the plate as shown in Fig. 2.

2) Keep pressing at point A by hand, press point B to the plate surface.

It is more effective and secure to use a flat-blade screwdriver or similar tool than by hand.

2-1 Plates

2-2 Gaskets

3-1 Type of “Slit-in” Gasket Protrusions

3-2 Procedures for Setting L-type Protrusions

L-type O-type I-type Hook-lock type

P3

Fig. 2 Procedures for Setting L-type Protrusions

Set the gasket body into the plate groove properly. Press the gasket in point C as shown in Fig. 3 and 4 with pressing the

protrusion in point A and B for O-type / point A for I-type.

Fig. 3 O-type Protrusion Setting Procedures Fig. 4 I-type Protrusion Setting Procedures

Set the gasket body into the plate groove properly. Press the gasket in point C as shown in Fig. 5 with pressing the protrusion in

point A and B.

Fig. 5 Procedures for Setting Hook-Lock Type Protrusions

1) In case of no slit on plate, cut the protrusion of Gasket (* part in Fig.6) with scissors as below Fig.6 and 7.

Fig. 6 Part Names Fig. 7 Cutting Procedures

3-3 Procedures for Setting O-type/ I-type Protrusions

3-4 Procedures for Setting Hook-Lock Type Protrusions

3-5 Procedures for Setting Gaskets without Port Hole (Excluding UX-005A and UX-01A)

Before Cutting

After Cutting

O-type Protrusion

I-type Protrusion

A

C

A

B C

A

C B

L-type Protrusion

Gasket Body

Slit

Plate

A

A

B

L

-

type

Protrusion

Plate

a-a Cross-section

a

a

Hole

No Hole

Double-Seal Side

Plate

Gasket

Protrusion*

Double Seal Connection

Double Seal of Transfer Surface Side

P4

2) After cutting the protrusion of the port hole for UX-30A, UX-40A or SX-40A, Peel back one side only of Sekisui Double-Faced

Tape No. 575. Fix double seal connection to the plate by the tape. Refer to below Fig. 8.

Fig. 8 Procedures for fixing by Tape

Check the setting of all gasket protrusions properly.

4 “Slit-in” Gasket Removal Procedures

Push up gasket protrusion from the backside of the plate. Pay attention not to cut protrusions. Wear cut-resistant gloves while

working this procedure to prevent injury.

5 Plate Disassembly and Assembly

When disassembling plates, some gasket protrusions might slip out of the slits. Reset the slipped out protrusions into their slits

before assembly and tighten frame.

6 D-Plate Gasketting Procedures

Each model has different gasketting procedures. Refer to "3. Gasketting Manual" of your PHE model for gasket names and

installation positions.

This section indicates the gasketting procedures for D-gasket, “Slit-in” type. Models not indicated in table-2 are regardless of

“Slit-in” type, adhesive is necessary for D-gasket setting. Refer to "3. Gasketting Manual" for gasketting by adhesive.

Table 2 D-Plate Gasketting Procedures for “Slit-in” type

Models: UX-005A, UX-30A, SX-40A and SX-70A

[NOTE]

The figure shows model UX-005A. Plate type and

protrusion position are different depending PHE model.

Refer to "3. Gasketting Manual" of your PHE for gasket

names and type.

7 Other Precautions

1) Wash and remove solid scales and/or other foreign material before assembly.

2) Long period use make double seal of transfer surface side (refer to Fig. 6) insufficient fit to plate groove.

Existing gasket still can be re-used. Fix it as same procedure as 3-5 2)

3-6 Set Checking

Gasket (Port Hole Side)

Gasket (Heat Transfer Side)

Fixed by Tape

Double Seal Connection

Slit Adhesive

P5

8 Inquiries

Contact info for inquiries

HISAKA WORKS, LTD., Heat Exchanger Div., Sales Department

Osaka: 2-1-48, Higashi-Konoike-cho, Higashi-Osaka, Osaka, 578-0973, Japan Tel : +81-(0)72-966-9601

Fax : +81-(0)72-966-8923

Tokyo: KYOBASHI OM BLDG. 1-19-8, Kyobashi, Chuo-Ku, Tokyo, 104-0031, Japan Tel : +81-(0)3-5250-0760

Fax : +81-(0)3-3562-2759

Nagoya: Fujifilm Nagoya Bldg. 12th Floor, 1-12-17, Sakae, Naka-Ku, Nagoya,

Aichi 460-0008, Japan

Tel : +81-(0)52-217-2491

Fax : +81-(0)52-217-2494

Hokkaido: Sapporo Shiraishi Daiichi Seimei Bldg. 6-1-20, Higashi Sapporo 3jo,

Shiraishi-Ku, Sapporo, Hokkaido 003-0003, Japan

Tel : +81-(0)11-868-8010

Fax : +81-(0)11-868-8011

Onomichi: 14-15, Nishigosho-cho, Onomichi, Hiroshima, 722-0037, Japan Tel : +81-848-21-2750

Fax : +81-848-21-2751

URL : http://www.hisaka.co.jp/english/

Global Network

HISAKAWORKS S.E.A. SDN. BHD. (MALAYSIA)

No.2, Jalan TP2. Taman Perindustrian SIME UEP, 47600 Subang Jaya, Selangor,

Malaysia

Tel : +60-3-8081-4185

E-mail : [email protected] Fax : +60-3-8081-7185

HISAKAWORKS S.E.A. SDN. BHD. PENANG BRANCH (MALAYSIA)

No 2680, 2nd Floor, Jalan Chain Ferry, Taman Inderawasih, 13600 Perai, Penang,

Malaysia

Tel : +60-16-203-2527

Fax : +60-4-390-8588

E-mail : [email protected]

HISAKAWORKS S.E.A. SDN. BHD. JOHOR BRANCH (MALAYSIA)

30-02, JalanMolek 1/10, Taman Molek, 81100 Johor Bahru, Johor, Malaysia Tel : +60-16-228-4209

E-mail : [email protected]

HISAKA WORKS(THAILAND)CO., LTD. (THAILAND)

12th Floor, 825 PhairojKijja Tower, Debaratana Road, Bangna-Nua, Bangna, Bangkok

10260, Thailand

Tel : +66-2-744-3287

E-mail : [email protected] Fax : +66-2-744-3286

HISAKA WORKS(THAILAND)CO., LTD. SATTAHIP SALES OFFICE (THAILAND)

222/28, Moo.10, Eastiny Park 5 Village, Bang Saray, Sattahip, Chonburi 20250, Thailand

Tel : +66-3-819-9819

E-mail : [email protected] Fax : +66-3-819-9820

HISAKAWORKS SINGAPORE PTE LTD. (SINGAPORE)

No.18, Boon Lay Way, #02-118, Trade Hub 21, Singapore 609966 Tel : +65-6-897-8489

E-mail : heatex@hisaka-sing.com Fax : +65-6-686-4579

PT.HISAKA WORKS INDONESIA (INDONESIA)

Ruko Grand Aries Niaga, Jalan Taman Aries Blok E1 No.3H, Jakarta Barat, Jakarta

11620, Indonesia

Tel : +62-21-2931-9235

E-mail : [email protected] Fax : +62-21-2931-9235

P6

HISAPINO Manila Representative Office (PHILIPPINES)

20th Floor, One Global Place, Office Business Center, 5th Avenue & 25th Street,

Bonifacio Global City, Taguig 1632, Philippines

Tel : +63-2-224-4129

Fax : +63-2-224-4130

E-mail : [email protected]

HISAVINA Ho Chi Minh Representative Office (VIETNAM)

4th Floor, Hoang Dan Building, 47-49, Hoang Sa Street, Da Kao Ward, District 1, Ho Chi

Minh City, Vietnam

Tel : +84- 8-3910-7355

Fax : +84-8-3910-7356

E-mail : [email protected]

HISAVINA Hanoi Representative Office (VIETNAM)

8th Floor, Sannam Building, Duy Tan Street, Dich Vong Hau Ward, Cau Giay District,

Hanoi, Vietnam

Tel : +84-4-3795-9900

Fax : +84-4-3795-9911

HISAKA WORKS(CHINA)CO., LTD. (CHINA)

No.117 Xiangyuan Road, Changshu National New & Hi-tech Industrial Development

Zone, Changshu City, Jiangsu Province 215542, P.R. China

Tel : +86-512-5213-3000

Fax : +86-512-5213-3008

HISAKA WORKS(CHINA)CO., LTD. SHANGHAI BRANCH (CHINA)

Room 1603, Shanghai Oriental Center, 699 West Nanjing Road,

Shanghai 200041, P.R. China

Tel : +86-21-5211-0701

Fax : +86-21-5211-0720

E-mail : [email protected]

HISAKA WORKS(CHINA)CO., LTD. GUANGZHOU BRANCH (CHINA)

Room 1208, R&F Tianhe Commercial Building No.4 Huanting Road,

Tianhe District, Guangzhou 5106t10,P.R. China

Tel : +86-20-3810-5515

Fax : +86-20-3847-7539

HISAKA MIDDLE EAST CO., LTD.

P.O. Box 7102, Building No.3861, Al Khudhariya Industrial Area, Dammam 32435,

Kingdom of Saudi Arabia

Tel : +966-13-838-4700

Fax : +966-13-838-5800

URL : www.hisaka-me.com

HISAKA KOREA CO., LTD.

15th Floor, Gwanghwamun Building, 149 Sejong-daero, Jongno-gu, Seoul 03186, South

Korea

Tel : +82-2-739-8861/2/3

HISAKA KOREA CO., LTD. BUSAN BRANCH

13th Floor, Kyowon Building, 216 Jungang-daero, Dong-gu, Busan 48733, South Korea

Tel : +82-51-747-0265

Fax : +82-51-747-0266

P7

For more information

Hisaka Works, Ltd. official homepage (http://www.hisaka.co.jp/english/).

Customer's memo

Please fill in the table below with PHE information.

Item Number

MFG. Number

Model

Qty

Date MFG.

Maintenance

records

Memo

[NOTE]

Please inform us the "MFG. Number" and "Model" described on the nameplate or Plate

Arrangement Drawing and Assembly Drawing.

Hisaka Works, Ltd., Heat Exchanger Division acquires both ISO9001 and ISO14001 certification.

HE-ME003700R4

This manual suits for next models

26

Table of contents

Other HISAKA Industrial Equipment manuals