Chiltern Invadex OHWLTRK-1 User manual

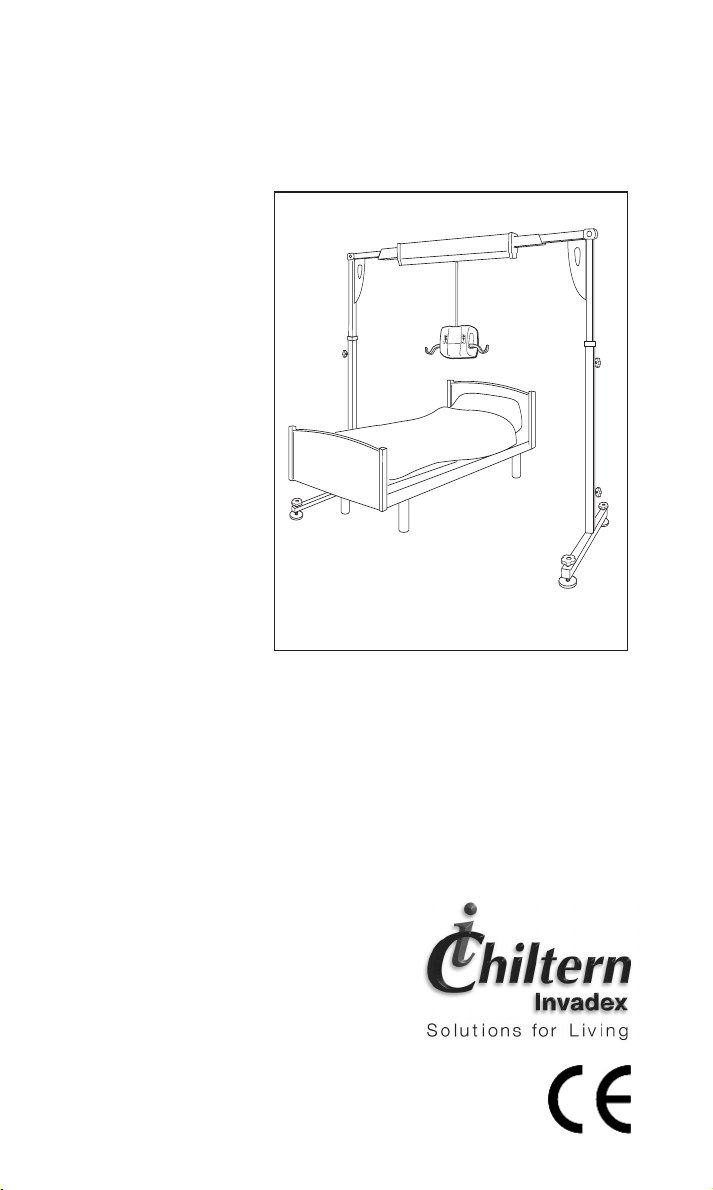

Portable Gantry

Wispa

LiteTrack

LiteTrack

user guide

Gantry System

FM 40009

FM 21085

Q

U

A

L

I

T

Y

•

S

A

F

E

T

Y

•

S

E

R

V

I

C

E

•

LiteTrack

Chiltern Invadex Ltd

6Wedgwood Road

Bicester Oxfordshire

OX26 4UL

Tel: 01869 246470

Fax: 01869 247214

Overseas Enquiries

Tel: +44 (0) 1869 365545

Fax: +44 (0) 1869 365567

Web: www.chilterninvadex.co.uk

Chiltern Invadex (NI) Ltd

5Balloo Way

Balloo Industrial Estate

Bangor County Down

BT19 7QZ

Tel: 028 9145 0497

Fax: 028 9127 0046

Chiltern Invadex Ltd

Unit 16 Evans Business Centre

68-74 Queen Elizabeth Avenue

Hillington Industrial Estate

Glasgow G52 4NQ

Tel: 0141 880 9986

Fax: 0141 880 9990

Copyright © Chiltern Invadex Ltd. The design of the product shown in this User Guide is vested in Chiltern Invadex Ltd and should not be copied or

reproduced in anyway whatsoever without the express permission in writing of Chiltern Invadex Ltd.

Published by: Chiltern Invadex Ltd 6 Wedgwood Road Bicester Oxon OX26 4UL Registered in England No: 1182024

In Ireland: Chiltern Invadex (NI) Ltd 5 Balloo Way Balloo Industrial Estate Bangor County Down BT19 7QZ Registered No: 19958

CINV435.01 08/05

23

User Guide

1

Contents

Portable Gantry System

This product has been designed to the highest

standards with safety, strength and quality in

mind.

Follow the recommendations in this guide to

ensure maximum benefit from your Wispa

LiteTrack Gantry system. Should you

experience any difficulties please consult the

trouble shooting guide, prior to contacting your

LiteTrack Gantry supplier.

Read the safety section of this guide prior to

use, this is contained on page 2.

Intended use of the Product .............................. 2

Things to consider before using the

Gantry ................................................................ 2

Assembly Guide ................................................ 4

Disassembly guide .......................................... 11

Servicing & maintenance ................................ 15

Parts ................................................................. 15

Troubleshooting ............................................... 16

Gantry Specification ........................................ 17

Warranty .......................................................... 18

Gantry Service Record ................................... 19

Chiltern Invadex LiteTrack Portable Gantry

20

Gantry Service Record

Serviced By

(company) .......................................................................................

Telephone no....................................................................................

Engineers training cert. no. Signature

................................................................ .................................

Date: .............................. Load Tested To: .............................Kgs

Comments..........................................................................................

...........................................................................................................

Serviced By

(company) .......................................................................................

Telephone no.......................................................................................

Engineers training cert. no. Signature

...................................................................... .................................

Date: .............................. Load Tested To: ..........................Kgs

Comments .........................................................................................

...........................................................................................................

Serviced By

(company) .......................................................................................

Telephone no.......................................................................................

Engineers training cert. no. Signature

...................................................................... .................................

Date: .............................. Load Tested To: ..........................Kgs

Comments .........................................................................................

...........................................................................................................

Chiltern Invadex LiteTrack Portable Gantry

2

•

Only a single hoist should be attached to the gantry at

any one time

•

Do not operate the WispaLite Portable Hoist and gantry

without training in the safe operation of the hoist,

gantry and slings. The gantry should only be assembled

by a competent person.

•

Only use slings which have been assessed as

suitable by a competent person.

•

Read the Wispa Lite Portable hoist User Guide in

conjunction with this guide.

•

Read the relevant Sling User Guide, which is

provided with each sling. It explains in detail how to

use slings correctly.

•

Do not use the Gantry if there is any doubt about the

integrity of the gantry, wear to the hoist carry bar or

there is fraying or stitch damage to the lifting tape or

slings, or if the gantry or hoist itself is damaged in any way.

•

Do not exceed the Maximum load of the gantry or hoist.

Wispa LiteTrack Gantry 210kgs (33 Stone) (460 lb)

WispaLite Portable Hoist 200kgs (31 Stone) (440 lb)

•

Ensure when the gantry and hoist are in use that

the surrounding area is clear and the person being

lifted is clear of all objects.

•

Always ensure the gantry is assembled and

adjusted for level using the spirit levels on the end beams.

•

There are only 3 width adjustment holes per end

beam. The pin must always be located in one of these.

Safety

Safety Considerations

Intended Use of the Product

The Wispa LiteTrack gantry sytem has been designed to lift and transfer

aless able person with the help of a carer. The gantry is portable and

can easily be relocated and reassembled wherever required. It should be

used with the WispaLite Portable Hoist and a Wispa sling or other lifting

accessories from the Chiltern Invadex range, as assessed by a trained person.

Note: Not all slings and accessories are compatible with the Wispa Lite hoist.

If you are unsure please contact your nearest Chiltern Invadex Office.

The correct and appropriate use of this product will reduce the risks

associated with manual patient handling. The lifting/transferring task should

be assessed and planned by a trained person.

User Guide

19

Gantry Service Record

Serviced By

(company) .......................................................................................

Telephone no....................................................................................

Engineers training cert. no. Signature

................................................................ .................................

Date: .............................. Load Tested To: .............................Kgs

Comments..........................................................................................

...........................................................................................................

Serviced By

(company) .......................................................................................

Telephone no.......................................................................................

Engineers training cert. no. Signature

...................................................................... .................................

Date: .............................. Load Tested To: ..........................Kgs

Comments .........................................................................................

...........................................................................................................

Serviced By

(company) .......................................................................................

Telephone no.......................................................................................

Engineers training cert. no. Signature

...................................................................... .................................

Date: .............................. Load Tested To: ..........................Kgs

Comments .........................................................................................

...........................................................................................................

User Guide

3

•

Always ensure the gantry track is directly above

the clients centre of gravity. Hoists should only be

used to lift vertically. Lifting at an angle will wear

the lifting tape prematurely and affect the stability

of the gantry.

•

Always ensure the top beam is horizontal and the

leg adjustment pin is located in the same position

on each side.

•

All fixings should be checked on a regular basis.

•

The cassette case and mechanical parts should

only be removed by a qualified service engineer,

trained by Chiltern Invadex.

•

Do not touch any of the moving parts in the hoist

unit or in the track. Call Chiltern Invadex for assistance.

•

Always ensure the legs are positioned as shown

in Fig 13 of this user guide

•

Take care when moving around the gantry to avoid

trip hazards such as the legs, handwheels and

potential injury from the corner quadrant.

•

Take care when attaching or removing a sling as a

swinging carry bar or hoist could cause injury.

•

For maximum comfort always move the user in one

movement and avoid stop/starting the hoist.

Some occupants are reassured if the carer holds

them whilst the hoist is traversing across the track.

•

Never leave a client unattended on the gantry.

•

Keep this user guide readily available for other users.

•

Always ensure there is sufficient clearance width

and height to erect/dismantle the gantry.

•

If the gantry is to be dismantled always remove the

Wispa Lite portable hoist from the gantry before

attempting to dismantle the gantry. The hoist should

be lowered onto a bed, chair or a Chiltern Invadex

transportation trolley before it is disconnected from

the gantry track.

•

Always follow the assembly/dissassembly

instructions contained in this guide.

After use

Chiltern Invadex LiteTrack Portable Gantry

18

Warranty

Your Chiltern Invadex Wispa LiteTrack Gantry carries a 2 year warranty

from the date of purchase, subject to the following :-

1. Should you experience any problems with our workmanship

or materials within the first 2 year period please contact

your point of purchase.

2. Repairs made during the warranty period will be carried out

free of charge, provided the product has been used strictly

in accordance with the guidelines set out in this user guide.

3. Our warranty does not cover replacements, adjustments or

repairs which may be required as a result of normal wear

and tear, wilful or accidental damage, misuse, neglect or

any other cause which is beyond the control of

Chiltern Invadex.

4. Modifications and repairs made to this product by

unauthorised persons will render the warranty void.

5. Only parts manufactured or approved by Chiltern Invadex

shall be used to repair this product. Use of unauthorised parts

will invalidate all warranties and remove all liability from

Chiltern Invadex for the safety of this product.

6. Chiltern Invadex shall in no event be liable for any damages,

costs or expenses arising from any claim made under this

warranty (save for any legal liability of Chiltern Invadex for

death or personal injury resulting from the company’s

negligence in respect of its products).

7. This warranty does not affect your statutory consumer rights.

Chiltern Invadex LiteTrack Portable Gantry

4

Check all components are available prior to assembly.

Notes:

If the gantry is to be assembled over a bed

The gantry can be assembled over a bed unless it is occupied. If the

bed is occupied assemble the gantry away from the bed and then

position afterwards (as a guide this would be approximately 900mm

from the head board but always ensure the gantry track is directly

above the clients centre of gravity).

1. Preparation

1. Unpack all components and lay on the floor ready for assembly.

2. Check all parts are available (see Fig 1) and for damaged components.

3. Safety note: The corner quadrant located on the end beam (see Fig 1)

should always have tension. Check to ensure it does not swing freely

and there is tension.

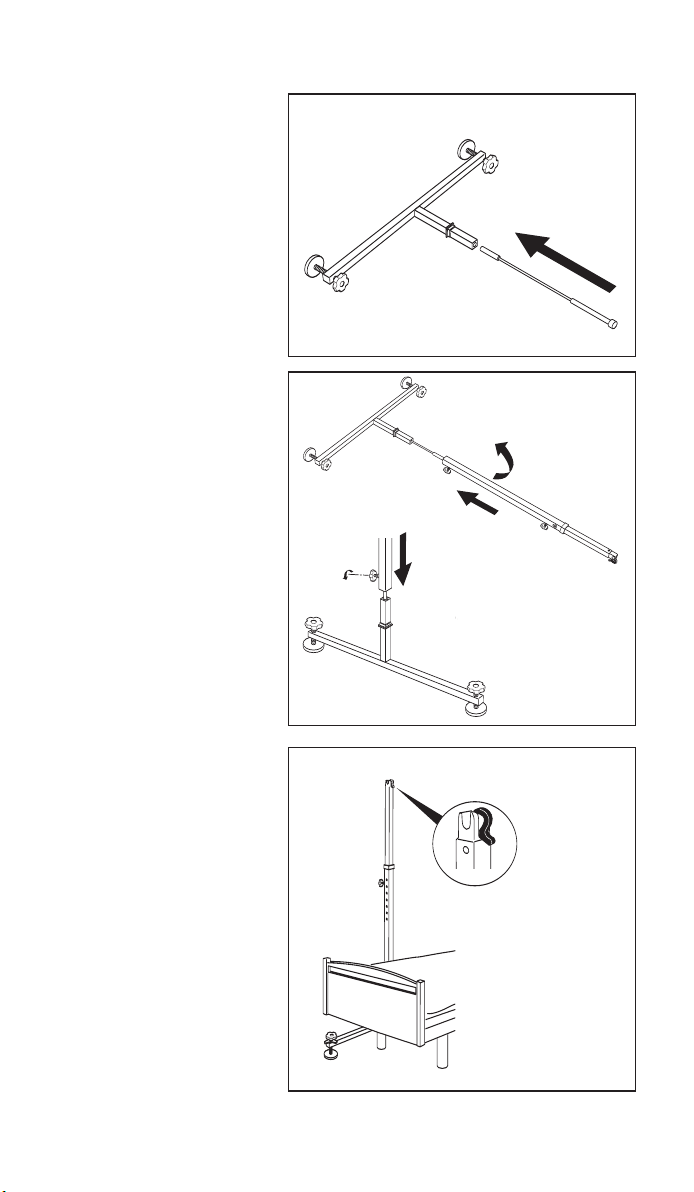

2. Leg assembly

Loosen both black handwheels on the leg as Fig 2 (C & D). Push both

release levers in with one hand as Fig 2 (A), pull out the inner leg

section to the first position as Fig 2 (B) having let go of the release

levers. This should then ‘click’ into place (the pin will be flush with the

top of the block when in the correct position). Secure the leg with the

locking knob Fig 2 (C). Note: The height of the unit can be adjusted later

when the gantry is fully assembled.

AA

A

B

C

D

LiteTrack Gantry Assembly

Instructions

Fig 2

Foot section x 2

Leg section x 2

Cassette x 1

End beam x 2

Foot section x 2

Leg section x 2

Cassette x 1

Gas strut x 2

Corner

quadrant x 2

Fig 1

User Guide

17

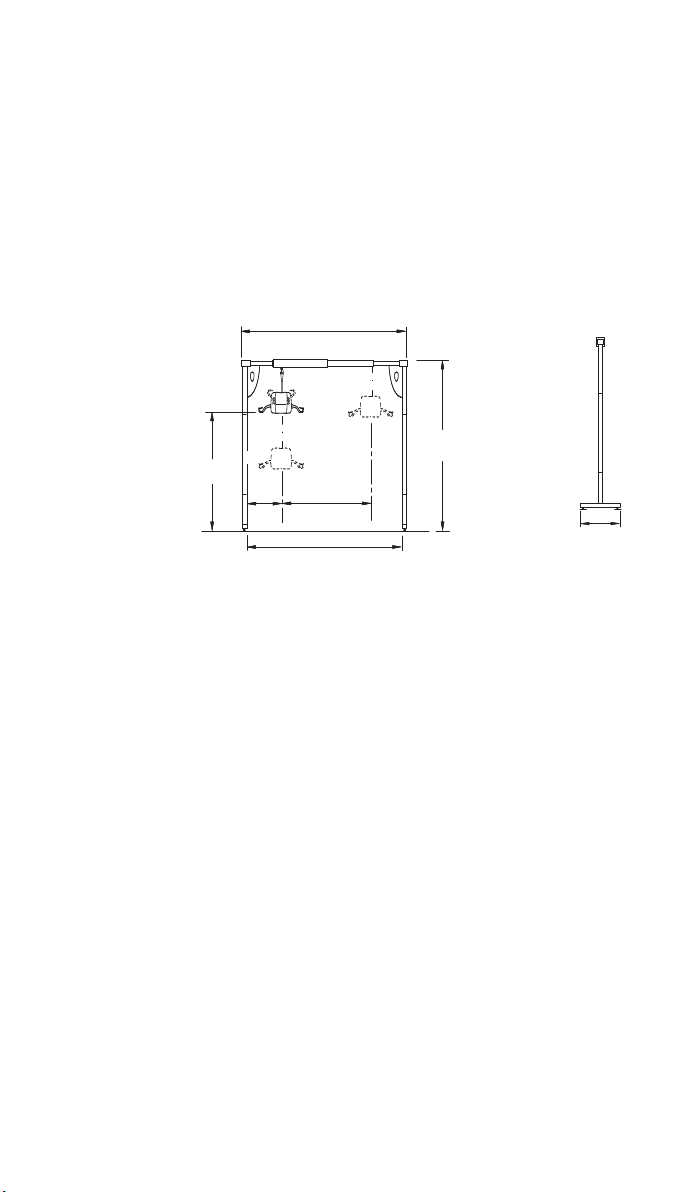

Lifting capacity 210 Kg (33 stone)(460 lb)

including hoist

Construction Legs - steel

Track - Aluminium

Cassette - Aluminium with ABS cover

Lifting Range Approximately 1525mm - 1825mm

Maximum loading per foot 100kg (16 stones) (220lb) (provided that the gantry is used in

accordance with the instructions in this user guide)

Assembled component weights:

Lower Leg section (x2) 7kg each (15.5lb)

Upper Leg section 8kg each (18lb)

Cassette (x1) 11kg (24lb)

End section/corner quadrant (x2) 5kg each (11lb)

Gas strut (x2) 1kg each (2.2lb)

Total weight of gantry 53kg (116lb)

CE MARK

The Chiltern Invadex Wispa LiteTrack Gantry carries the CE mark and complies with EC Directives:

Medical Device Directive(93/42/EEC)

Further assistance

Please telephone any Chiltern Invadex Office for further assistance.

Remember that service calls made after the guarantee period will be

chargeable. If the maintenance of the equipment is the responsibility of a

third party, for example the Social Services, please contact them in the first

instance.

Gantry Specification

2165 - 2465

(50mm intervals)

1010 - 1530440

Gantry at highest position 1825

Gantry at lowest position 1525

2040 - 2560

1890 - 2410 (Internal)

1100

User Guide

5

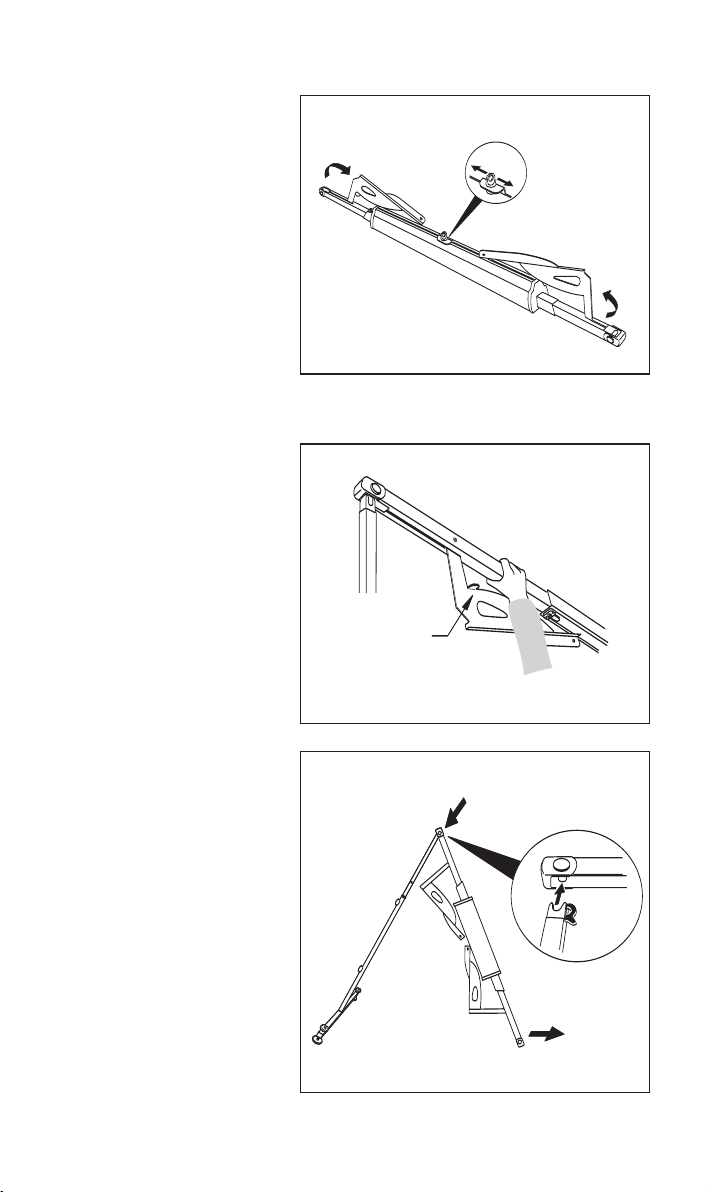

3. Locating the leg

and foot sections

and inserting the

gas strut

Where there is limited

head room it is

recommended that

the foot section is

laid on its side for

assembly as Fig 3.

Insert the gas strut in

the orientation shown

in Fig 3.

Place the leg section

over the gas strut as

Fig 3 (B) (Note:

Orientate the leg to

ensure the top catch

bracket is pointing

towards the floor),

while raising the leg

at the same time

(taking care not to

damage the gas

strut), compressing

the gas strut and

pushing down as far

as the moulding on

the foot section as

Fig 3 (C). Note: The

bottom handwheel

needs to be almost

all the way out.

4. The top catch

bracket should be

located on the inside

as Fig 4. Tighten the

lower handwheel to

secure in place.

Safety note: The

leg is not yet free

standing. Do not

leave the leg

unattended. Lay it

on the floor, against

abed or wall.

Repeat for other leg.

Fig 3

Fig 4

Top catch bracket on

leg section facing inward

B

A

Fig 3B

Fig 3C

Chiltern Invadex LiteTrack Portable Gantry

16

symptom suggested cause solution

Troubleshooting

Cassette travels

further in one direction

along the beam than

the other

Pins do not click into

position on the leg

Pins do not click into

position on the end

beam/cassette

Spring mechanism is

stuck on the leg/end

beam section

Spring mechanism has

failed on the leg/end

beam section and will

not push in manually

Height of feet cannot

be adjusted

Cannot check gantry is

level

Lifting eye on cassette

will not come down

Corner quadrant will

not fold back against

the leg

There is no tension in

the corner quadrant

Leg does not raise

easily/falls under gravity

Gas strut will not

compress

Cable tension is

incorrect

Leg section is

incorrectly positioned

End beam section is

incorrectly positioned

Push pin in manually

Spring mechanism is

damaged

Thread on feet is

damaged or twisted

Spirit levels are

damaged or broken

Spring mechanism is

defective/damaged

Gantry leg not positioned

correctly to accept the

corner quadrant.

Corner quadrant is

defective/damaged

Washers in the corner

quadrant are damaged/

defective.

Adjust grub screws

Gas strut is damaged

Gas strut is damaged

Contact Chiltern

Invadex for assistance

Adjust leg position

Adjust end beam

position

If problem persists

contact Chiltern

Invadex for assistance

Contact Chiltern

Invadex for assistance

See replacement parts

list in this booklet.

Contact Chiltern

Invadex for parts.

Contact Chiltern

Invadex for

replacement parts.

Contact Chiltern

Invadex for assistance

Reposition gantry leg

at 90 degrees.

Contact Chiltern

Invadex for assistance

Contact Chiltern

Invadex for assistance.

Check tension

Contact Chiltern

Invadex for assistance

Contact Chiltern

Invadex for assistance

Chiltern Invadex LiteTrack Portable Gantry

6

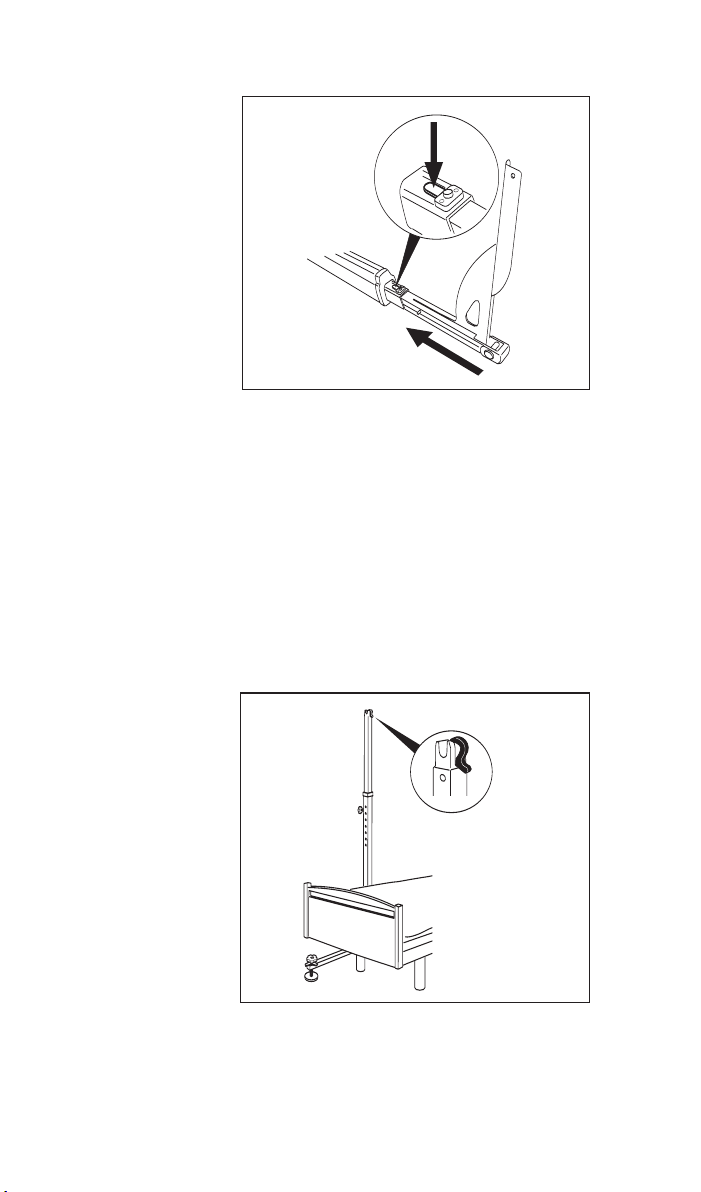

6. Attaching beam

to leg section

Please note prior to

assembly:

Top catch bracket on

the leg section should

be on the inside to

accept the beam as

Fig 6.

Top catch bracket on

leg section facing inward

Fig 6

B

A

5. Assembling the

cassette and end

beams

Notes:

1. The end beams

which attach to the

cassette are identical.

2. The cassette can be

positioned either way

round.

3. Assemble the

cross beam as close

to the legs as

possible.

Rotate the corner

quadrant to the

position shown in Fig

5. Push the release

lever down with one

hand as Fig 5 (A) and

slide the end beam

into the cassette as

Fig 5 (B) having let go

of the release lever

as the end beam

begins to slide, and

select the appropriate

hole (depending on

lifting task - see p14

for Width calculation

guide). The end beam

will then ‘click’ into

place (the pin will be

flush with the top of

the block when in the

correct position).

Repeat for other side.

Fig 5

User Guide

15

Servicing and Maintenance

Based upon EN10535:1998 and Health and Safety Executive guidance

Chiltern Invadex recommend that hoists and gantry systems are fully

serviced, including a load test, at least every 12 months with an interim

six monthly inspection to LOLER requirements. Prices are available from

Chiltern Invadex Service Offices. The frequency of servicing should be

increased in areas where the environment or heavy usage may cause

deterioration of the equipment. Further details can be obtained from any

Chiltern Invadex Office, shown on the back of this booklet.

Chiltern Invadex and its Authorised Dealers are able to carry out all

aspects of servicing and maintenance work.

Maintenance of this equipment should only be conducted by engineers

trained and certified by Chiltern Invadex.

Keep the service record (at the back of this booklet) up to date.

DO NOT USE IF:

1. There is any damage to the hoist or gantry.

2. There is fraying or stitch damage to the lifting tape, or slings.

3. Any of the gantry parts are missing or damaged

To ensure maximum cleanliness

Wipe with a dry cloth (Gantry and hoist). For stubborn marks use a damp

cloth and a mild cleanser. Always read the manufacturers instructions

prior to applying the cleanser. Avoid using cleaning agents which contain

chlorine, carbolic acid or other strong chemicals as these may damage

the metalwork and plastic components.

Parts

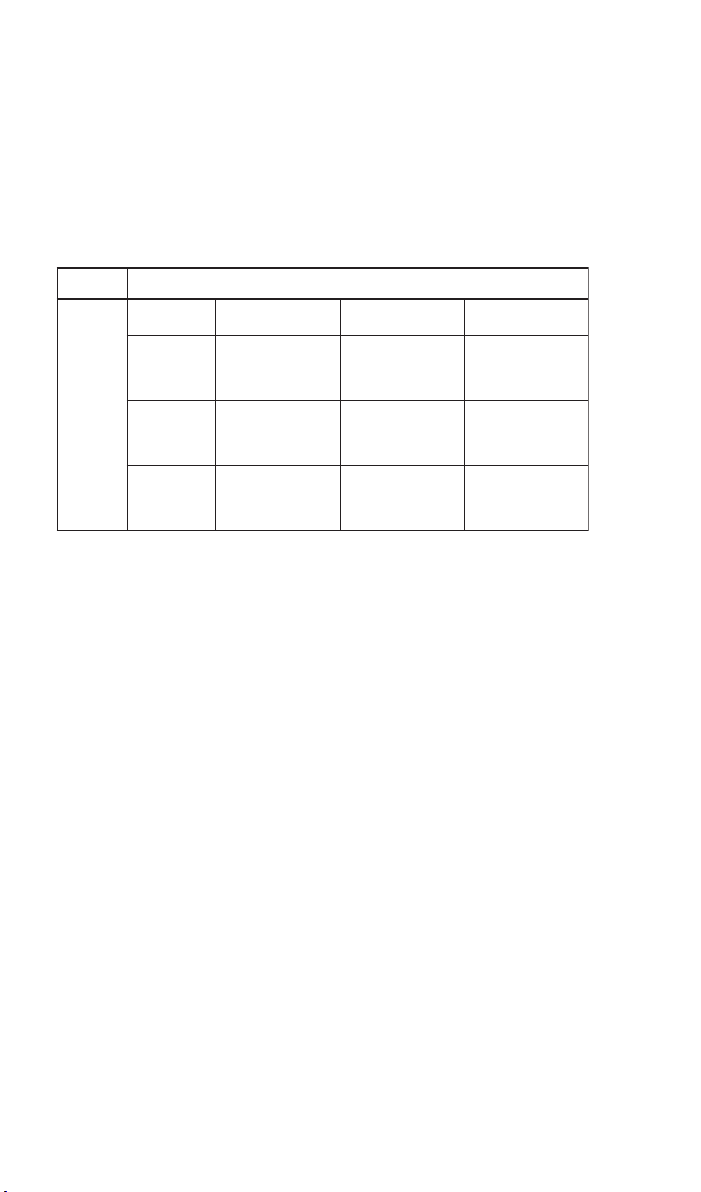

item description qty part no

1 Upright mouldings kit (all mouldings for legs) 1 360-80001

2 Beam mouldings kit (all mouldings for horizontal beam) 1 360-80002

3 Hand Wheel (Black) 1 COM0081

4 Levelling Foot Kit 1 360-80011

5 Spirit Level spares kit (x4 spirit levels) 1 360-80003

6 Gas strut assembly spares kit (x1) 1 360-80004

1

4

Note: Replacement parts should only be installed by trained personnel.

The gantry then needs testing once parts have been replaced.

6

5

2

3

Chiltern Invadex LiteTrack Portable Gantry

14

THGIR

TFEL

eloH

noitisop

123

10981

debelgnislacipyT(

)riahcrewohsot

0

202

debelgnislacipyT(

renilcer/resirot

)riahc

0

512

citsemodlacipyT(

otdebelbuod

)riahcrewohs

20202

debelgnislacipyT(

renilcer/resirot

)riahc

0512

citsemodlacipyT(

otdebelbuod

)riahcrewohs

0822

gnisrunlacipyT(

otdebelbuod

)riahcrewohs

30512

citsemodlacipyT(

otdebelbuod

)riahcrewohs

0822

gnisrunlacipyT(

otdebelbuod

)riahcrewohs

0142

elbuodlacipyT(

otdeb

riahcrenilcer/resir

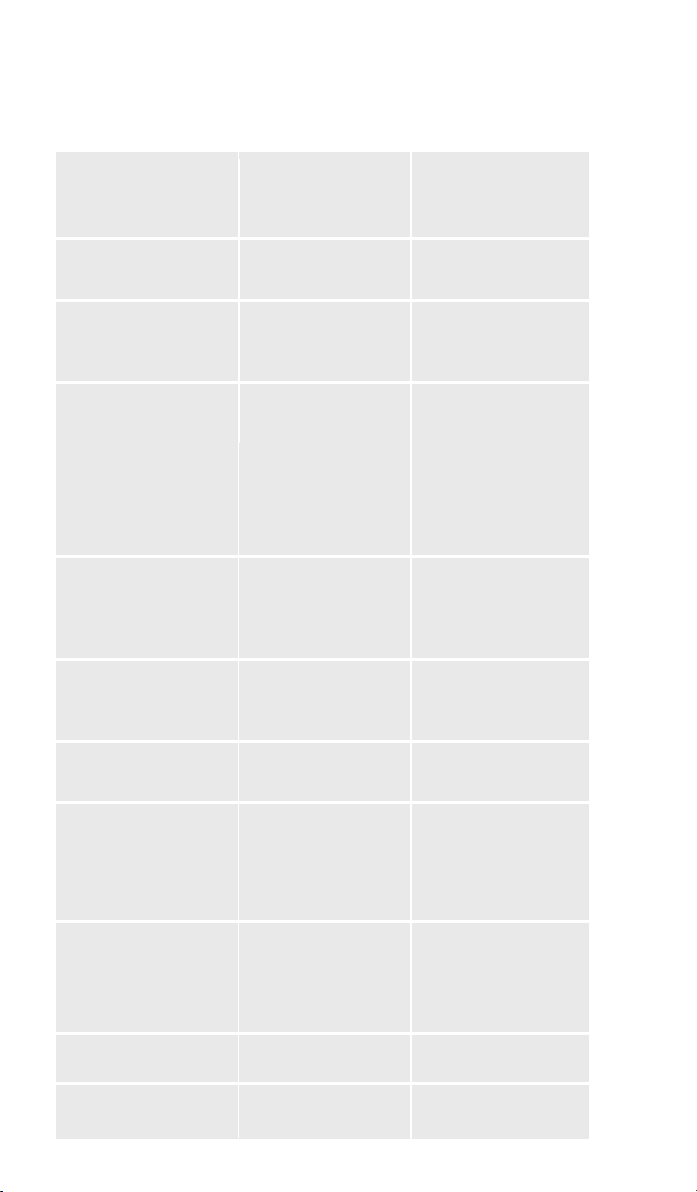

Width calculation guide

The table below can be used as a quick reference guide to help

determine the internal width of the gantry (depending on the hole position

which has been selected). For example - when the first hole position is

selected on the end beam and the same on the right end beam the internal

width is 1890mm, which will typically allow the transfer of a client from a

single bed to a shower chair).

Dimensions are in mm and for guidance only

User Guide

7

8. General safety

note: When placing

the top beam on the

legs always position

hand behind the

corner quadrant as

Fig 8.1.

Corner quadrant

Note hand grasp point for safety

when assembling beam

Fig 8.2

A

B

Do not lift the whole

cassette section. With

one end of the

cassette resting on

the floor hold the

assembled leg with

one hand, raise the

beam section and

place on top of the leg

as Fig 8.2 (A).

Fig 8.1

7. Fold over the

corner quadrant on

both end beams in

preparation for

connecting to the leg

as Fig 7 (A).

Ensure the cassette is

centralised in the

correct position

(latched). To achieve

this slide along until it

clicks into position in

the centre of the rail

as Fig 7 (B).

Fig 7

A

A

B

Chiltern Invadex LiteTrack Portable Gantry

8

9. Securing the

cross beam to the

cassette

Adjust the position of

the leg as Fig 8.2 (B)

to allow the corner

quadrant to be

connected (this

should be at 90

degrees to the leg and

cross beam).

Pull the corner

quadrant back against

the leg and hold with

one hand against the

leg as Fig 9 (A).

Check the cross

beam has been

locked in position on

the legs. Be aware of

finger trapping hazard

when pulling corner

quadrant back

against the leg.

Secure in position

using the handwheel

as Fig 9 (B).

Fig 9

10. Place the second

leg within easy reach

and raise the end of

the beam. Place on

top of the second leg

as Fig 10. Note:

Check the pin on the

cross beam sits on

top of the moulding on

the legs as Fig 10.

Fig 10

Pull the corner

quadrant back against

the leg (at 90 degrees

to the leg and cross

beam) and hold with

one hand against the

leg as Fig 11 (A).

Secure in position

using the handwheel

as Fig 9 (B).

Fig 11

A

B

A

Pin should sit

on top of the

moulding

User Guide

13

B

A

C

B

C

A

Fig 19

19. Fold back the

corner quadrant as

Fig 19 (A), depress

the release lever as

Fig 19 (B) and slide

out the end beam

section as Fig 19 (C).

Repeat for other side.

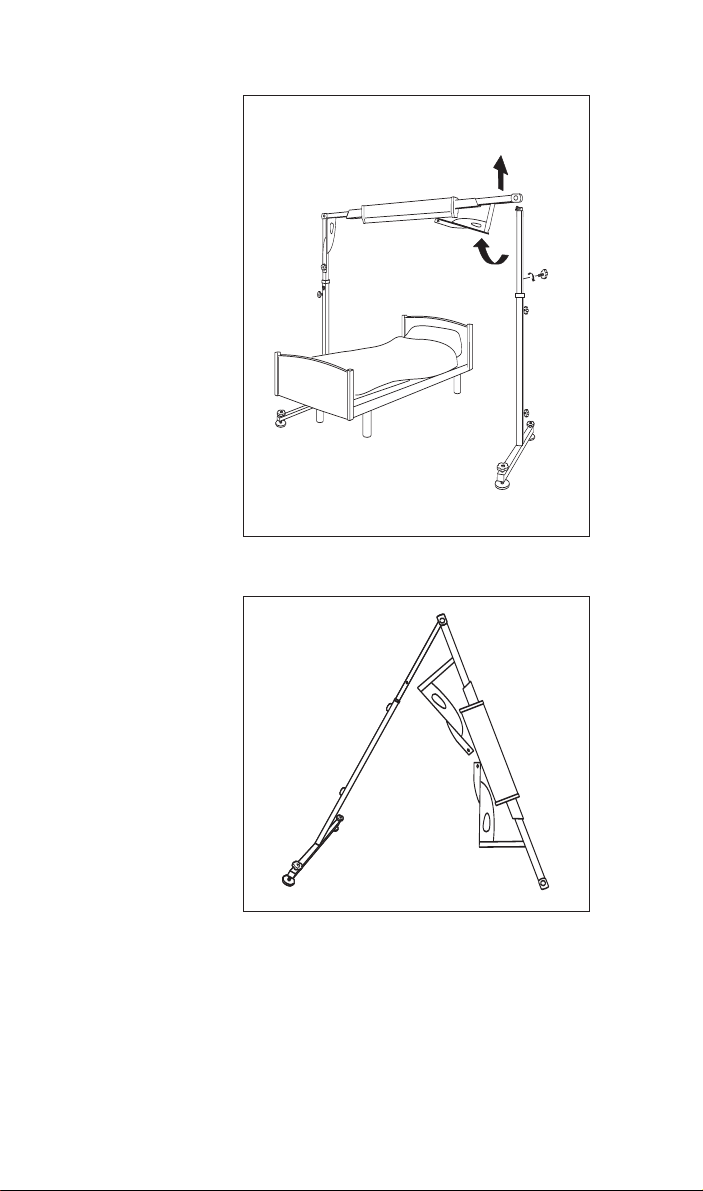

20. Leg

disassembly

Where there is limited

head room it is

recommended that

the leg section is laid

on its side for

disassembly as Fig 20.

Loosen the lower

black handwheel as

Fig 20 (A). The gas

strut and leg section

will then slide apart.

Safety note: The

gas strut is

compressed and

will spring out. Pull

the leg section apart

from the gas strut as

Fig 20 (B) and remove

the gas strut from the

foot section (C).

Repeat for other side. Fig 21

Fig 20

B

C

AA

A

21. Ensure top

handwheel is loose

and depress the

release levers as Fig

21 (A) and push the

leg section down to

the lowest position

as Fig 21 (B). Fasten

both handwheels (C)

for safe transportation.

Repeat for other side.

Chiltern Invadex LiteTrack Portable Gantry

12

17. Important safety

note:

1. Completely

remove one leg

BEFORE releasing

the second leg.

2. Ensure there is

sufficient space to

lower the gantry.

Remove the upper

handwheel which

locks the corner

quadrant in place as

Fig 17 (A)

Fold back the corner

quadrant against the

cassette as Fig 17 (B)

one leg at a time.

Push the beam

upwards as Fig 17 (C).

Fig 17

C

BA

Fig 18

Safety note: The

leg is not free

standing. Do not

leave the leg

unattended. Lay it

on the floor,

against a bed or

wall.

18. Lower the beam

to the floor as Fig 18

whilst retaining the

leg with the other

hand.

Repeat for other side.

User Guide

9

Lever NOT correctly

engaged

Lever correctly

engaged

BA

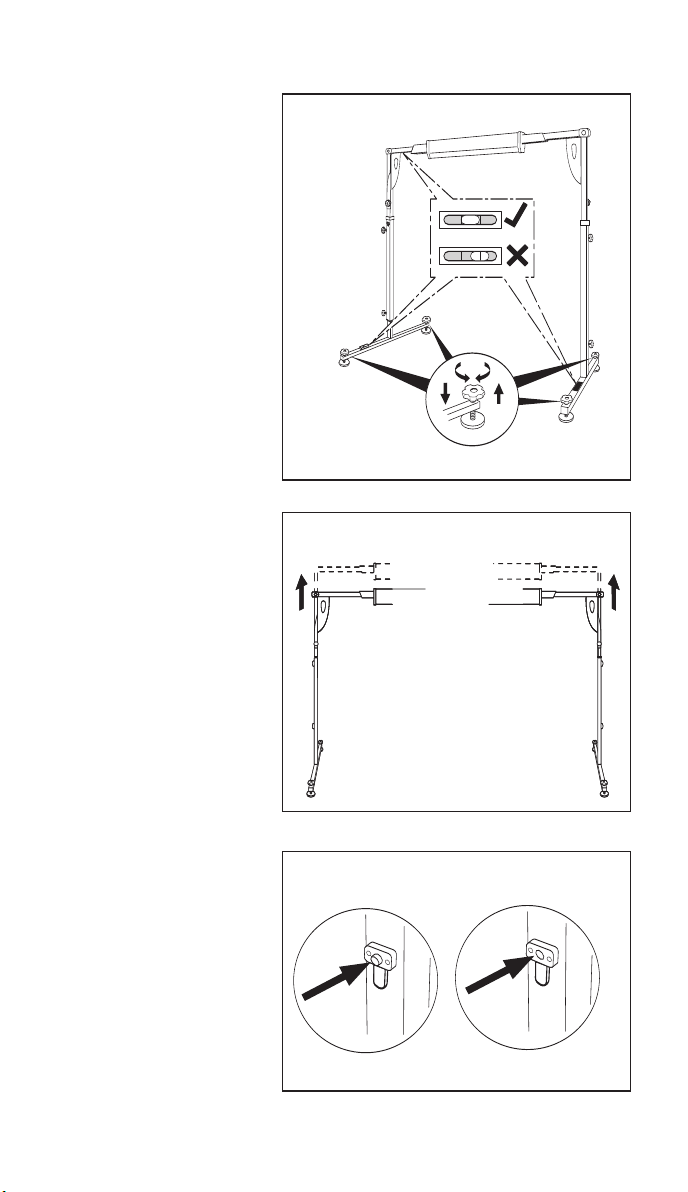

12. Adjusting the

height of the gantry

Position the gantry in

its required location

prior to adjusting the

height and checking

level. Take care when

moving the gantry to

the desired location.

Move one leg at a time

in small increments.

The gantry should be

level in all directions.

Check this using the

spirit levels on the

feet and end beams.

Centre the bubble in

the spirit level

window as Fig 12.

Use the large

handwheels on the

feet to adjust level, as

required as Fig 12.

Fig 12

13. If the height of the

gantry needs to be

raised release the

middle handwheel.

Hold onto the top

handwheel with one

hand, pressing the

release levers in on

the leg with the other

hand, and push the

leg up to the required

height one hole at a

time,raising one leg

and then repeating by

the same increment

on the other side.

Ensure it ‘clicks’ into

position and the pin is

flush with the block

as Fig B. Secure with

the middle handwheel

and check for level

using the spirit levels

on the end beam.

Repeat for other side.

If the leg height is

raised always ensure

adequate clearance

overhead.

Fig 13

Chiltern Invadex LiteTrack Portable Gantry

10

15. Final safety check

Prior to hoisting a client check:

- All handwheels are in place (3 per upright) and they have

been securely tightened

- The gantry is level in all directions

- The height and width of the gantry are appropriate for the

task eg. there is sufficient space to position a wheelchair or

shower chair at the side of the bed for transfer

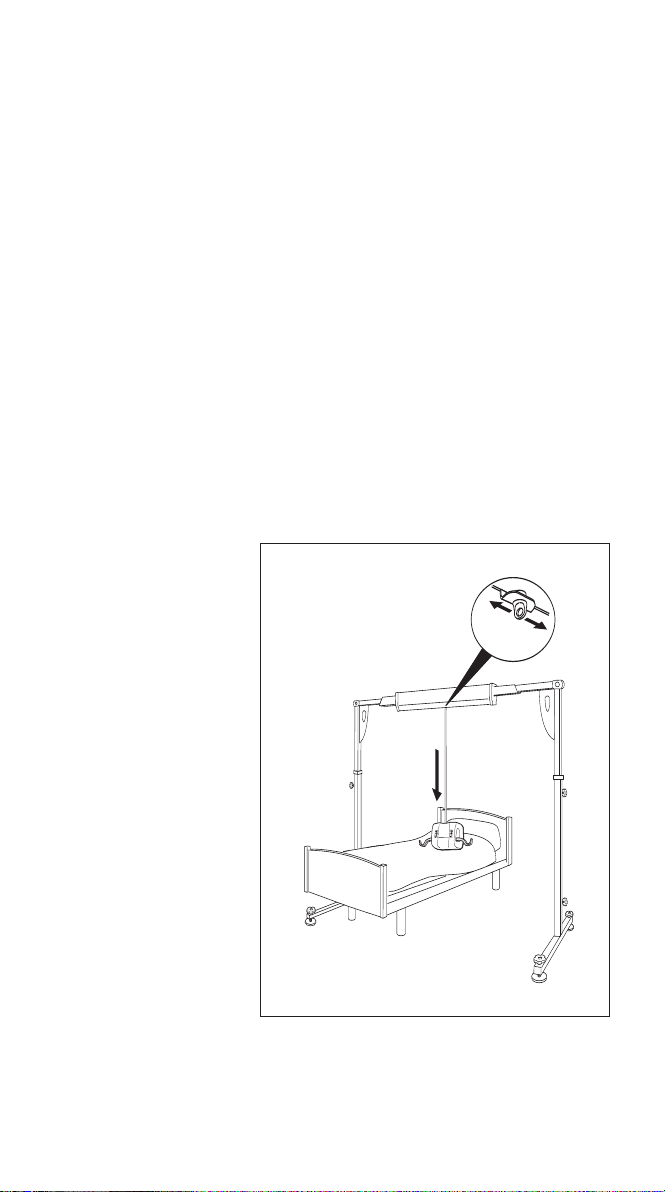

The gantry is now

ready for use. The

weight of the hoist will

release the cassette

and allow it to travel

freely along the beam

as Fig 15. Slide the

hoist across the

gantry to the desired

position ready to lift/

transfer the client.

Take care when

moving around the

gantry to avoid

trip hazards such as

the legs, handwheels

and potential injury

from the corner

quadrant or cassette.

14. Attaching the

Wispa Lite Portable

hoist

Rest the Portable hoist

on the bed or trolley

ready for attaching to

the eye on the gantry.

Release sufficient

tape to connect the

carabena on the hoist

to the eye on the

gantry as Fig 14. Do

not lift the hoist to

attach it to the gantry.

Fig 14

Fig 15

Final positioning

User Guide

11

16. Disassembly of the gantry

1. Do not lift the hoist. Lower the hoist by releasing sufficient

tape to disconnect the carabena on the hoist from the eye on the

gantry as Fig 16 (B). Remove the hoist from the gantry.

2. Always ensure the cassette is locked in the central position

before disassembling the gantry. To achieve this slide the

cassette along until it clicks into position in the centre of the rail

as Fig16 (A).

If the height of the gantry needs to be lowered release the

middle handwheel. Hold onto the top handwheel with one hand,

pressing the release levers in on the leg with the other hand,

and push the leg down to the required height one hole at a

time,lowering one leg and then repeating by the same

increment on the other side.

3. If the bed is occupied, relocate the gantry to a suitable place

ready for disassembly.

Disassembly of the gantry

A

B

Disassembly of the gantry

Fig 16

Chiltern Invadex LiteTrack Portable Gantry

10

15. Final safety check

Prior to hoisting a client check:

- All handwheels are in place (3 per upright) and they have

been securely tightened

- The gantry is level in all directions

- The height and width of the gantry are appropriate for the

task eg. there is sufficient space to position a wheelchair or

shower chair at the side of the bed for transfer

The gantry is now

ready for use. The

weight of the hoist will

release the cassette

and allow it to travel

freely along the beam

as Fig 15. Slide the

hoist across the

gantry to the desired

position ready to lift/

transfer the client.

Take care when

moving around the

gantry to avoid

trip hazards such as

the legs, handwheels

and potential injury

from the corner

quadrant or cassette.

14. Attaching the

Wispa Lite Portable

hoist

Rest the Portable hoist

on the bed or trolley

ready for attaching to

the eye on the gantry.

Release sufficient

tape to connect the

carabena on the hoist

to the eye on the

gantry as Fig 14. Do

not lift the hoist to

attach it to the gantry.

Fig 14

Fig 15

Final positioning

User Guide

11

16. Disassembly of the gantry

1. Do not lift the hoist. Lower the hoist by releasing sufficient

tape to disconnect the carabena on the hoist from the eye on the

gantry as Fig 16 (B). Remove the hoist from the gantry.

2. Always ensure the cassette is locked in the central position

before disassembling the gantry. To achieve this slide the

cassette along until it clicks into position in the centre of the rail

as Fig16 (A).

If the height of the gantry needs to be lowered release the

middle handwheel. Hold onto the top handwheel with one hand,

pressing the release levers in on the leg with the other hand,

and push the leg down to the required height one hole at a

time,lowering one leg and then repeating by the same

increment on the other side.

3. If the bed is occupied, relocate the gantry to a suitable place

ready for disassembly.

Disassembly of the gantry

A

B

Disassembly of the gantry

Fig 16

Chiltern Invadex LiteTrack Portable Gantry

12

17. Important safety

note:

1. Completely

remove one leg

BEFORE releasing

the second leg.

2. Ensure there is

sufficient space to

lower the gantry.

Remove the upper

handwheel which

locks the corner

quadrant in place as

Fig 17 (A)

Fold back the corner

quadrant against the

cassette as Fig 17 (B)

one leg at a time.

Push the beam

upwards as Fig 17 (C).

Fig 17

C

BA

Fig 18

Safety note: The

leg is not free

standing. Do not

leave the leg

unattended. Lay it

on the floor,

against a bed or

wall.

18. Lower the beam

to the floor as Fig 18

whilst retaining the

leg with the other

hand.

Repeat for other side.

User Guide

9

Lever NOT correctly

engaged

Lever correctly

engaged

BA

12. Adjusting the

height of the gantry

Position the gantry in

its required location

prior to adjusting the

height and checking

level. Take care when

moving the gantry to

the desired location.

Move one leg at a time

in small increments.

The gantry should be

level in all directions.

Check this using the

spirit levels on the

feet and end beams.

Centre the bubble in

the spirit level

window as Fig 12.

Use the large

handwheels on the

feet to adjust level, as

required as Fig 12.

Fig 12

13. If the height of the

gantry needs to be

raised release the

middle handwheel.

Hold onto the top

handwheel with one

hand, pressing the

release levers in on

the leg with the other

hand, and push the

leg up to the required

height one hole at a

time,raising one leg

and then repeating by

the same increment

on the other side.

Ensure it ‘clicks’ into

position and the pin is

flush with the block

as Fig B. Secure with

the middle handwheel

and check for level

using the spirit levels

on the end beam.

Repeat for other side.

If the leg height is

raised always ensure

adequate clearance

overhead.

Fig 13

Chiltern Invadex LiteTrack Portable Gantry

8

9. Securing the

cross beam to the

cassette

Adjust the position of

the leg as Fig 8.2 (B)

to allow the corner

quadrant to be

connected (this

should be at 90

degrees to the leg and

cross beam).

Pull the corner

quadrant back against

the leg and hold with

one hand against the

leg as Fig 9 (A).

Check the cross

beam has been

locked in position on

the legs. Be aware of

finger trapping hazard

when pulling corner

quadrant back

against the leg.

Secure in position

using the handwheel

as Fig 9 (B).

Fig 9

10. Place the second

leg within easy reach

and raise the end of

the beam. Place on

top of the second leg

as Fig 10. Note:

Check the pin on the

cross beam sits on

top of the moulding on

the legs as Fig 10.

Fig 10

Pull the corner

quadrant back against

the leg (at 90 degrees

to the leg and cross

beam) and hold with

one hand against the

leg as Fig 11 (A).

Secure in position

using the handwheel

as Fig 9 (B).

Fig 11

A

B

A

Pin should sit

on top of the

moulding

User Guide

13

B

A

C

B

C

A

Fig 19

19. Fold back the

corner quadrant as

Fig 19 (A), depress

the release lever as

Fig 19 (B) and slide

out the end beam

section as Fig 19 (C).

Repeat for other side.

20. Leg

disassembly

Where there is limited

head room it is

recommended that

the leg section is laid

on its side for

disassembly as Fig 20.

Loosen the lower

black handwheel as

Fig 20 (A). The gas

strut and leg section

will then slide apart.

Safety note: The

gas strut is

compressed and

will spring out. Pull

the leg section apart

from the gas strut as

Fig 20 (B) and remove

the gas strut from the

foot section (C).

Repeat for other side. Fig 21

Fig 20

B

C

AA

A

21. Ensure top

handwheel is loose

and depress the

release levers as Fig

21 (A) and push the

leg section down to

the lowest position

as Fig 21 (B). Fasten

both handwheels (C)

for safe transportation.

Repeat for other side.

Chiltern Invadex LiteTrack Portable Gantry

14

THGIR

TFEL

eloH

noitisop

123

10981

debelgnislacipyT(

)riahcrewohsot

0

202

debelgnislacipyT(

renilcer/resirot

)riahc

0

512

citsemodlacipyT(

otdebelbuod

)riahcrewohs

20202

debelgnislacipyT(

renilcer/resirot

)riahc

0512

citsemodlacipyT(

otdebelbuod

)riahcrewohs

0822

gnisrunlacipyT(

otdebelbuod

)riahcrewohs

30512

citsemodlacipyT(

otdebelbuod

)riahcrewohs

0822

gnisrunlacipyT(

otdebelbuod

)riahcrewohs

0142

elbuodlacipyT(

otdeb

riahcrenilcer/resir

Width calculation guide

The table below can be used as a quick reference guide to help

determine the internal width of the gantry (depending on the hole position

which has been selected). For example - when the first hole position is

selected on the end beam and the same on the right end beam the internal

width is 1890mm, which will typically allow the transfer of a client from a

single bed to a shower chair).

Dimensions are in mm and for guidance only

User Guide

7

8. General safety

note: When placing

the top beam on the

legs always position

hand behind the

corner quadrant as

Fig 8.1.

Corner quadrant

Note hand grasp point for safety

when assembling beam

Fig 8.2

A

B

Do not lift the whole

cassette section. With

one end of the

cassette resting on

the floor hold the

assembled leg with

one hand, raise the

beam section and

place on top of the leg

as Fig 8.2 (A).

Fig 8.1

7. Fold over the

corner quadrant on

both end beams in

preparation for

connecting to the leg

as Fig 7 (A).

Ensure the cassette is

centralised in the

correct position

(latched). To achieve

this slide along until it

clicks into position in

the centre of the rail

as Fig 7 (B).

Fig 7

A

A

B

Chiltern Invadex LiteTrack Portable Gantry

6

6. Attaching beam

to leg section

Please note prior to

assembly:

Top catch bracket on

the leg section should

be on the inside to

accept the beam as

Fig 6.

Top catch bracket on

leg section facing inward

Fig 6

B

A

5. Assembling the

cassette and end

beams

Notes:

1. The end beams

which attach to the

cassette are identical.

2. The cassette can be

positioned either way

round.

3. Assemble the

cross beam as close

to the legs as

possible.

Rotate the corner

quadrant to the

position shown in Fig

5. Push the release

lever down with one

hand as Fig 5 (A) and

slide the end beam

into the cassette as

Fig 5 (B) having let go

of the release lever

as the end beam

begins to slide, and

select the appropriate

hole (depending on

lifting task - see p14

for Width calculation

guide). The end beam

will then ‘click’ into

place (the pin will be

flush with the top of

the block when in the

correct position).

Repeat for other side.

Fig 5

User Guide

15

Servicing and Maintenance

Based upon EN10535:1998 and Health and Safety Executive guidance

Chiltern Invadex recommend that hoists and gantry systems are fully

serviced, including a load test, at least every 12 months with an interim

six monthly inspection to LOLER requirements. Prices are available from

Chiltern Invadex Service Offices. The frequency of servicing should be

increased in areas where the environment or heavy usage may cause

deterioration of the equipment. Further details can be obtained from any

Chiltern Invadex Office, shown on the back of this booklet.

Chiltern Invadex and its Authorised Dealers are able to carry out all

aspects of servicing and maintenance work.

Maintenance of this equipment should only be conducted by engineers

trained and certified by Chiltern Invadex.

Keep the service record (at the back of this booklet) up to date.

DO NOT USE IF:

1. There is any damage to the hoist or gantry.

2. There is fraying or stitch damage to the lifting tape, or slings.

3. Any of the gantry parts are missing or damaged

To ensure maximum cleanliness

Wipe with a dry cloth (Gantry and hoist). For stubborn marks use a damp

cloth and a mild cleanser. Always read the manufacturers instructions

prior to applying the cleanser. Avoid using cleaning agents which contain

chlorine, carbolic acid or other strong chemicals as these may damage

the metalwork and plastic components.

Parts

item description qty part no

1 Upright mouldings kit (all mouldings for legs) 1 360-80001

2 Beam mouldings kit (all mouldings for horizontal beam) 1 360-80002

3 Hand Wheel (Black) 1 COM0081

4 Levelling Foot Kit 1 360-80011

5 Spirit Level spares kit (x4 spirit levels) 1 360-80003

6 Gas strut assembly spares kit (x1) 1 360-80004

1

4

Note: Replacement parts should only be installed by trained personnel.

The gantry then needs testing once parts have been replaced.

6

5

2

3

User Guide

5

3. Locating the leg

and foot sections

and inserting the

gas strut

Where there is limited

head room it is

recommended that

the foot section is

laid on its side for

assembly as Fig 3.

Insert the gas strut in

the orientation shown

in Fig 3.

Place the leg section

over the gas strut as

Fig 3 (B) (Note:

Orientate the leg to

ensure the top catch

bracket is pointing

towards the floor),

while raising the leg

at the same time

(taking care not to

damage the gas

strut), compressing

the gas strut and

pushing down as far

as the moulding on

the foot section as

Fig 3 (C). Note: The

bottom handwheel

needs to be almost

all the way out.

4. The top catch

bracket should be

located on the inside

as Fig 4. Tighten the

lower handwheel to

secure in place.

Safety note: The

leg is not yet free

standing. Do not

leave the leg

unattended. Lay it

on the floor, against

abed or wall.

Repeat for other leg.

Fig 3

Fig 4

Top catch bracket on

leg section facing inward

B

A

Fig 3B

Fig 3C

Chiltern Invadex LiteTrack Portable Gantry

16

symptom suggested cause solution

Troubleshooting

Cassette travels

further in one direction

along the beam than

the other

Pins do not click into

position on the leg

Pins do not click into

position on the end

beam/cassette

Spring mechanism is

stuck on the leg/end

beam section

Spring mechanism has

failed on the leg/end

beam section and will

not push in manually

Height of feet cannot

be adjusted

Cannot check gantry is

level

Lifting eye on cassette

will not come down

Corner quadrant will

not fold back against

the leg

There is no tension in

the corner quadrant

Leg does not raise

easily/falls under gravity

Gas strut will not

compress

Cable tension is

incorrect

Leg section is

incorrectly positioned

End beam section is

incorrectly positioned

Push pin in manually

Spring mechanism is

damaged

Thread on feet is

damaged or twisted

Spirit levels are

damaged or broken

Spring mechanism is

defective/damaged

Gantry leg not positioned

correctly to accept the

corner quadrant.

Corner quadrant is

defective/damaged

Washers in the corner

quadrant are damaged/

defective.

Adjust grub screws

Gas strut is damaged

Gas strut is damaged

Contact Chiltern

Invadex for assistance

Adjust leg position

Adjust end beam

position

If problem persists

contact Chiltern

Invadex for assistance

Contact Chiltern

Invadex for assistance

See replacement parts

list in this booklet.

Contact Chiltern

Invadex for parts.

Contact Chiltern

Invadex for

replacement parts.

Contact Chiltern

Invadex for assistance

Reposition gantry leg

at 90 degrees.

Contact Chiltern

Invadex for assistance

Contact Chiltern

Invadex for assistance.

Check tension

Contact Chiltern

Invadex for assistance

Contact Chiltern

Invadex for assistance

Chiltern Invadex LiteTrack Portable Gantry

4

Check all components are available prior to assembly.

Notes:

If the gantry is to be assembled over a bed

The gantry can be assembled over a bed unless it is occupied. If the

bed is occupied assemble the gantry away from the bed and then

position afterwards (as a guide this would be approximately 900mm

from the head board but always ensure the gantry track is directly

above the clients centre of gravity).

1. Preparation

1. Unpack all components and lay on the floor ready for assembly.

2. Check all parts are available (see Fig 1) and for damaged components.

3. Safety note: The corner quadrant located on the end beam (see Fig 1)

should always have tension. Check to ensure it does not swing freely

and there is tension.

2. Leg assembly

Loosen both black handwheels on the leg as Fig 2 (C & D). Push both

release levers in with one hand as Fig 2 (A), pull out the inner leg

section to the first position as Fig 2 (B) having let go of the release

levers. This should then ‘click’ into place (the pin will be flush with the

top of the block when in the correct position). Secure the leg with the

locking knob Fig 2 (C). Note: The height of the unit can be adjusted later

when the gantry is fully assembled.

AA

A

B

C

D

LiteTrack Gantry Assembly

Instructions

Fig 2

Foot section x 2

Leg section x 2

Cassette x 1

End beam x 2

Foot section x 2

Leg section x 2

Cassette x 1

Gas strut x 2

Corner

quadrant x 2

Fig 1

User Guide

17

Lifting capacity 210 Kg (33 stone)(460 lb)

including hoist

Construction Legs - steel

Track - Aluminium

Cassette - Aluminium with ABS cover

Lifting Range Approximately 1525mm - 1825mm

Maximum loading per foot 100kg (16 stones) (220lb) (provided that the gantry is used in

accordance with the instructions in this user guide)

Assembled component weights:

Lower Leg section (x2) 7kg each (15.5lb)

Upper Leg section 8kg each (18lb)

Cassette (x1) 11kg (24lb)

End section/corner quadrant (x2) 5kg each (11lb)

Gas strut (x2) 1kg each (2.2lb)

Total weight of gantry 53kg (116lb)

CE MARK

The Chiltern Invadex Wispa LiteTrack Gantry carries the CE mark and complies with EC Directives:

Medical Device Directive(93/42/EEC)

Further assistance

Please telephone any Chiltern Invadex Office for further assistance.

Remember that service calls made after the guarantee period will be

chargeable. If the maintenance of the equipment is the responsibility of a

third party, for example the Social Services, please contact them in the first

instance.

Gantry Specification

2165 - 2465

(50mm intervals)

1010 - 1530440

Gantry at highest position 1825

Gantry at lowest position 1525

2040 - 2560

1890 - 2410 (Internal)

1100

User Guide

3

•

Always ensure the gantry track is directly above

the clients centre of gravity. Hoists should only be

used to lift vertically. Lifting at an angle will wear

the lifting tape prematurely and affect the stability

of the gantry.

•

Always ensure the top beam is horizontal and the

leg adjustment pin is located in the same position

on each side.

•

All fixings should be checked on a regular basis.

•

The cassette case and mechanical parts should

only be removed by a qualified service engineer,

trained by Chiltern Invadex.

•

Do not touch any of the moving parts in the hoist

unit or in the track. Call Chiltern Invadex for assistance.

•

Always ensure the legs are positioned as shown

in Fig 13 of this user guide

•

Take care when moving around the gantry to avoid

trip hazards such as the legs, handwheels and

potential injury from the corner quadrant.

•

Take care when attaching or removing a sling as a

swinging carry bar or hoist could cause injury.

•

For maximum comfort always move the user in one

movement and avoid stop/starting the hoist.

Some occupants are reassured if the carer holds

them whilst the hoist is traversing across the track.

•

Never leave a client unattended on the gantry.

•

Keep this user guide readily available for other users.

•

Always ensure there is sufficient clearance width

and height to erect/dismantle the gantry.

•

If the gantry is to be dismantled always remove the

Wispa Lite portable hoist from the gantry before

attempting to dismantle the gantry. The hoist should

be lowered onto a bed, chair or a Chiltern Invadex

transportation trolley before it is disconnected from

the gantry track.

•

Always follow the assembly/dissassembly

instructions contained in this guide.

After use

Chiltern Invadex LiteTrack Portable Gantry

18

Warranty

Your Chiltern Invadex Wispa LiteTrack Gantry carries a 2 year warranty

from the date of purchase, subject to the following :-

1. Should you experience any problems with our workmanship

or materials within the first 2 year period please contact

your point of purchase.

2. Repairs made during the warranty period will be carried out

free of charge, provided the product has been used strictly

in accordance with the guidelines set out in this user guide.

3. Our warranty does not cover replacements, adjustments or

repairs which may be required as a result of normal wear

and tear, wilful or accidental damage, misuse, neglect or

any other cause which is beyond the control of

Chiltern Invadex.

4. Modifications and repairs made to this product by

unauthorised persons will render the warranty void.

5. Only parts manufactured or approved by Chiltern Invadex

shall be used to repair this product. Use of unauthorised parts

will invalidate all warranties and remove all liability from

Chiltern Invadex for the safety of this product.

6. Chiltern Invadex shall in no event be liable for any damages,

costs or expenses arising from any claim made under this

warranty (save for any legal liability of Chiltern Invadex for

death or personal injury resulting from the company’s

negligence in respect of its products).

7. This warranty does not affect your statutory consumer rights.

Chiltern Invadex LiteTrack Portable Gantry

2

•

Only a single hoist should be attached to the gantry at

any one time

•

Do not operate the WispaLite Portable Hoist and gantry

without training in the safe operation of the hoist,

gantry and slings. The gantry should only be assembled

by a competent person.

•

Only use slings which have been assessed as

suitable by a competent person.

•

Read the Wispa Lite Portable hoist User Guide in

conjunction with this guide.

•

Read the relevant Sling User Guide, which is

provided with each sling. It explains in detail how to

use slings correctly.

•

Do not use the Gantry if there is any doubt about the

integrity of the gantry, wear to the hoist carry bar or

there is fraying or stitch damage to the lifting tape or

slings, or if the gantry or hoist itself is damaged in any way.

•

Do not exceed the Maximum load of the gantry or hoist.

Wispa LiteTrack Gantry 210kgs (33 Stone) (460 lb)

WispaLite Portable Hoist 200kgs (31 Stone) (440 lb)

•

Ensure when the gantry and hoist are in use that

the surrounding area is clear and the person being

lifted is clear of all objects.

•

Always ensure the gantry is assembled and

adjusted for level using the spirit levels on the end beams.

•

There are only 3 width adjustment holes per end

beam. The pin must always be located in one of these.

Safety

Safety Considerations

Intended Use of the Product

The Wispa LiteTrack gantry sytem has been designed to lift and transfer

aless able person with the help of a carer. The gantry is portable and

can easily be relocated and reassembled wherever required. It should be

used with the WispaLite Portable Hoist and a Wispa sling or other lifting

accessories from the Chiltern Invadex range, as assessed by a trained person.

Note: Not all slings and accessories are compatible with the Wispa Lite hoist.

If you are unsure please contact your nearest Chiltern Invadex Office.

The correct and appropriate use of this product will reduce the risks

associated with manual patient handling. The lifting/transferring task should

be assessed and planned by a trained person.

User Guide

19

Gantry Service Record

Serviced By

(company) .......................................................................................

Telephone no....................................................................................

Engineers training cert. no. Signature

................................................................ .................................

Date: .............................. Load Tested To: .............................Kgs

Comments..........................................................................................

...........................................................................................................

Serviced By

(company) .......................................................................................

Telephone no.......................................................................................

Engineers training cert. no. Signature

...................................................................... .................................

Date: .............................. Load Tested To: ..........................Kgs

Comments .........................................................................................

...........................................................................................................

Serviced By

(company) .......................................................................................

Telephone no.......................................................................................

Engineers training cert. no. Signature

...................................................................... .................................

Date: .............................. Load Tested To: ..........................Kgs

Comments .........................................................................................

...........................................................................................................

This manual suits for next models

1

Table of contents

Other Chiltern Invadex Medical Equipment manuals