Chiltern Invadex WISPA 100 Plus User manual

User Guide

All 100 Plus models

WISPA 100 Plus

This user guide contains essential information in relation to safe use and troubleshooting and should

be retained with the hoist for reference

Unit 6C Thorpe Drive

Banbury OX16 4UZ UK

Issue 2.0

Contents

These products have been designed to the highest standards with safety, strength and quality in mind.

Follow the recommendations in this guide to ensure maximum benet from your Overhead Hoist. Should

you experience any diculties please consult the trouble shooting guide, prior to contacting your Overhead

Hoist supplier.

Your Chiltern Invadex hoist has been designed and tested to meet the highest standards of safety. Read the

safety section of this guide prior to use, this is contained on pages 1-2.

Intended use................................................ 1

Safety considerations .................................. 1-2

Using the controls........................................ 3-4

Emergency stop & reset procedure............. 5

Emergency lowering.................................... 5

Charging Wispa battery hoists..................... 6

Servicing and maintenance ......................... 7

Parts ............................................................ 7

Troubleshooting........................................... 8

Hoist specication........................................ 9

Installation notes.......................................... 10

Carry/Spreader bar installation.................... 11

Warranty ...................................................... 12

Wispa hoist service record .......................... 13-16

Declaration of Conformity............................ 17

WISPA 100 Plus

Page 1

HOIST 100 Series

Issue 2.0 Issue 2.0 June 2018

Prior to Use

• Ensure that all users read this guide before operating the hoist.

• Do not operate the hoist without training in the safe operation of the hoist and slings.

• Only use slings which have been assessed as suitable by a trained person.

• Read the relevant Sling User Guide, which is provided with each sling. It explains in detail how to

use slings correctly.

• Do not use the hoist if there is any doubt about wear to the carry bar or there is fraying or stitch

damage to the lifting tape or slings, or if the hoist itself is damaged in any way.

• Before using the hoist for the rst time ensure the batteries are fully charged (Battery models only).

• Do not exceed the maximum labelled load of the hoist*.

W, WB, WL, WLB models 130kgs (20 stone)

WT, WLT, WTB, WLTB models 200kgs (31 stone)

*Note: you must check the maximum load of the sling or any other lifting accessory,

where this diers from the hoist the lowest weight must not be exceeded.

When using the Hoist

• Ensure when the hoist is in use that the surrounding area is clear and the person being lifted is

clear of all objects.

• Hoists should only be used to lift vertically. Lifting at an angle will wear the lifting tape prematurely.

• Do not leave a user unattended in the sling.

Safety Considerations

Intended Use of the Product

The Wispa 100+ hoist has been designed to lift and transfer a disabled or sick person with the help of a carer. It

should be used with a Wispa sling or other lifting accessories, as assessed by a trained person.

Note: Not all slings and accessories are compatible with this hoist. A copy of our compatibility state-

ment can be viewed at www.chilterninvadex.co.uk/pdfs/sling-compatibility-statement.pdf

The correct and appropriate use of this product will reduce the risks associated with manual patient handling.

The lifting/transferring task should be assessed and planned by a trained person.

HOIST 100 Series

Page 2

Issue 2.0June 2018

Chiltern Invadex (UK) Limited do not encourage or recommend end users to self hoist due to the increased

risks associated with lack of help should assistance be required. That said, we are sensitive to the fact that

there are a large number of equipment users who choose to self hoist in order to maintain their independence.

Where it is known that an end user is self hoisting, ISO 10535 (Hoists for the transfer of disabled persons.

Requirements and test methods) states that an assessment of risk should be undertaken. This assessment

should be undertaken by a competent person and take into consideration factors such as; does the user

have the necessary training, skills and body strength to self hoist safely, are they able to use the emer-

gency lower/stop devices, would they be able to raise the alarm if necessary, and would they be placed

in unnecessary danger should a breakdown or other incident occur. Chiltern Invadex would recommend

that this risk assessment is reviewed at least annually, or where there is a change in user circumstance,

property or equipment.

ISO 10535 recommends that a ‘conveniently placed telephone’ or alarm system should be provided as

a safety control measure. As it is unlikely that the end user would be able to reach even a conveniently

placed telephone in an emergency situation, and a mobile phone may not be on the users person at all

times, we would recommend consideration be given to the provision of a remote pendant alarm system in

the form of a necklace or bracelet which may be a more suitable solution.

It is ultimately the responsibility of the user and healthcare professionals to make the necessary assessment

of risk where independent use of the system is required.

After use

• Return the hoist to the charging position when not in use (Battery models only).

• The outer case, mechanical parts and track should only be removed by a qualied service engi-

neer.

• Do not touch any of the moving parts in the hoist unit or in the track. Contact Chiltern Invadex for

assistance.

• Take care when attaching or removing a sling as the carry bar could cause injury if the user is hit in

the face.

• Do not try and lift using the emergency lowering device as this can damage the hoist.

Independent Hoisting

User Guide Page 3

HOIST 100 Series

Issue 2.0 Issue 2.0 June 2018

wisp

a

100 Plus

Using the controls

Overload Reset Button

In event of overload press button

to re-set

Product Identication Label

(serial number, model, SWL)

Carry/Spreader Bar

Lifting Tape

Handset Cable

Retaining Socket

Emergency Stop

Emergency Lower

Soft Touch Handset

(colour coded direction indication)

Colour coded directional arrows

match handset buttons

HOIST 100 Series

Page 4

Issue 2.0June 2018

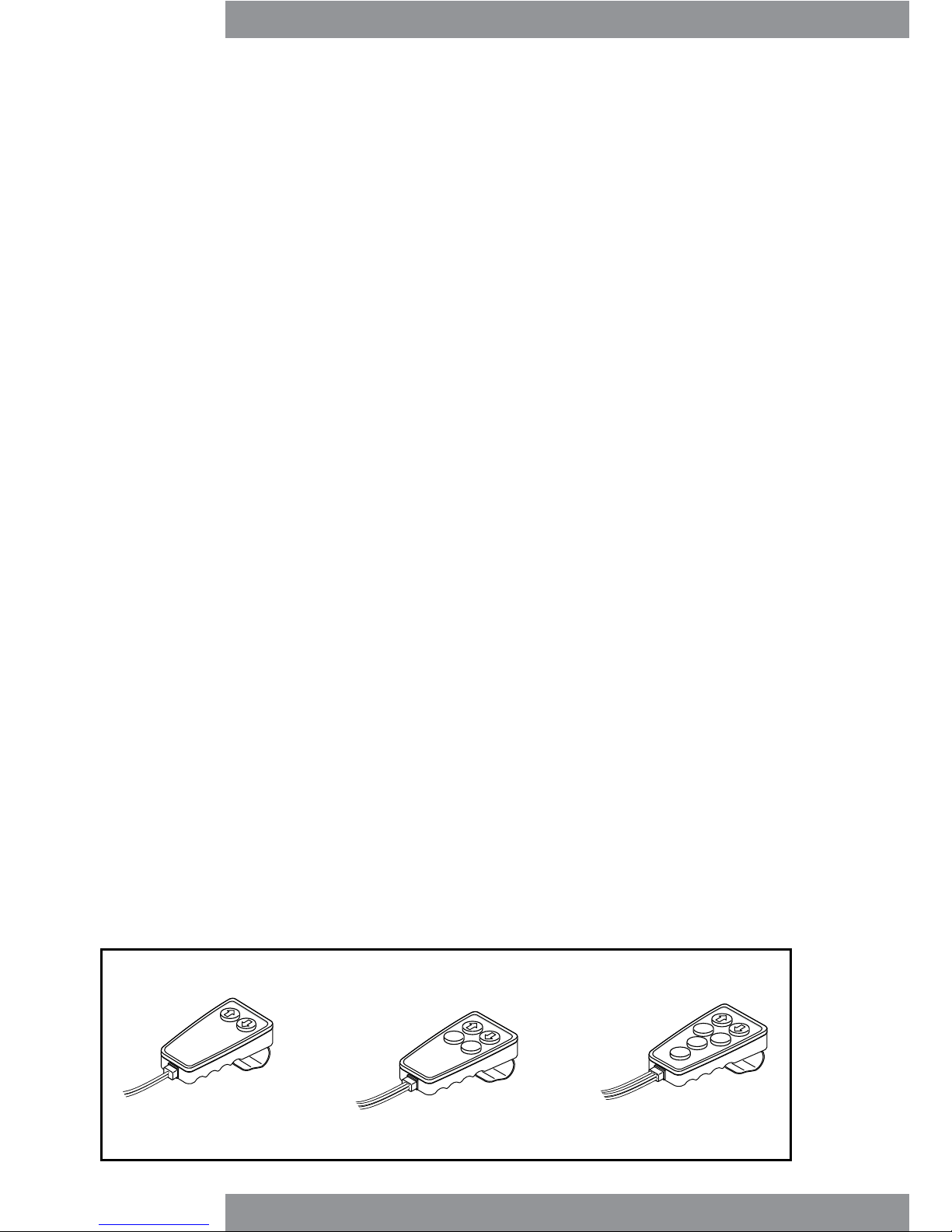

Four Button Hand Control used on ‘Wispalong’ (WL) Hoist Models

The four button handset is used to control the raising and lowering of the carry bar and the powered

traversing along the ceiling track on

Wispalong models.

The traversing function is controlled by the or buttons, on the handset. The buttons are colour

coded with blue and yellow. These colours correspond to the blue and yellow direction travel arrows

on the underside of the hoist case.

To control the direction of the hoist, view the coloured direction arrows mounted on the hoist and press

the button on the hand control which corresponds in colour to the arrow on the hoist.

Six Button Hand Control used on X-Y Models

The 6 button hand control has the same function buttons as the four button hand control, with the

addition of the tracking for the X-Y system.

The tracking X-Y function is controlled by the bottom buttons on the handset. The buttons are colour

coded with red and green. These colours correspond to the red and green direction travel arrows on

the underside of the track ends.

To control the direction of the hoist, view the coloured direction arrows mounted on the hoist and track

ends and press the button on the hand control which corresponds in colour and direction to the arrows.

Two Button

Hand Control

Four Button

Hand Control

Six Button

Hand Control

Two Button Hand control used on Wispa (W) Hoist Models

The two button hand control is used to control the lifting and lowering of the carry bar on Wispa hoist

models. The lifting and lowering are controlled by the or buttons.

PLEASE NOTE: For all battery powered models, the hoist must be moved away from

the charging point at the end of the track before the lifting and lowering functions will

operate. Lifting and lowering functions are inoperable whilst the green charging LED

is lit.

Hand controls

The controls use air to operate the hoist and are therefore completely safe to use with wet hands.

Page 5

HOIST 100 Series

Issue 2.0 Issue 2.0 June 2018

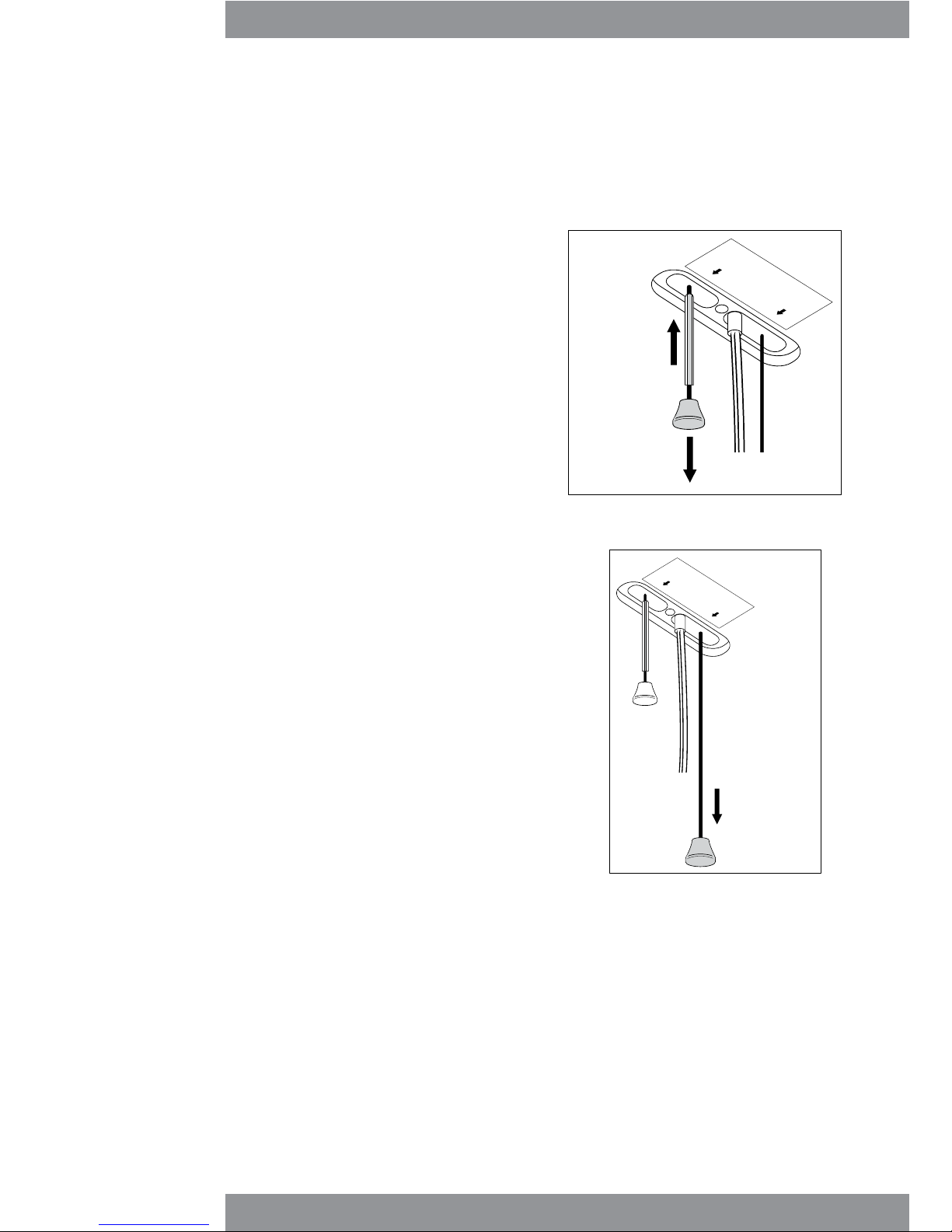

Emergency Lowering

In the unlikely event of a power failure or hoist malfunction the

hoist occupant may be lowered using the emergency lowering

cord.

To operate, pull the white cord gently until 2 clicks are heard/

felt. The occupant will then be slowly lowered.

In certain circumstances the cord may need to be pulled more

gently for just one click, to lower the occupant. If this occurs

refer to the troubleshooting guide on page 8.

Do not try and lift using the emergency lowering device as this

can damage the hoist.

EMERGENCY

STOP LOWER

Emergency lowering

pull cord

Emergency Stop

To operate in case of an emergency, pull the red cord to switch o the hoist completely.

EMERGENCY

STOP LOWER

Emergency stop

pull cord

RESET

Reset Procedure

Once the emergency stop or overload device have been

activated, the hoist will need to be reset.

To reset slide the plastic tube on the red cord upwards through

the hole in the case and push to reset the switch. A click will

be hear when the switch resets.

The hoist should now operate normally.

Please Note: The emergency lowering device uses a PP3 battery to allow the occupant

of the hoist to be lowered in the event of an emergency. Frequent testing of this device

in non-emergency situations will quickly discharge the battery. The battery should be

renewed at each service and after use.

HOIST 100 Series

Page 6

Issue 2.0June 2018

Charging Wispa Battery Hoists

When not in use it is VERY important to return Wispa Battery hoists to the end of the track where the

charging unit for the batteries is housed. To engage the hoist with the charger, simply push or traverse

the hoist to the end of the track. Correct engagement is signalled when the charging light glows green.

Once the hoist is engaged, charging is automatic. No further actions are required to charge the batteries.

The batteries cannot be overcharged. When the Hoist is on charge the lifting and lowering functions will

not operate, unless pre-set software is enabled - contact the sales oce for further information.

Battery Low Indicator Light (Wispa Battery Hoists Only)

The battery low indicator light will glow red when the hoists batteries are in need of charging. This is unlikely

to happen unless the hoist is used for long periods of time (approximately 60 lifts) without charging, or the

hoist has not been properly ‘parked’ in its charger, to recharge the batteries. Should the light ash red,

batteries are critically low and the hoist should be returned to the charging dock immediately.

Warning Buzzer (Wispa Battery Hoists Only)

If the battery low warning buzzer sounds, then the batteries need recharging before use.

Overload Reset

This device safeguards the hoist against overload, the connection between the power supply and the

control unit is deliberately broken to prevent the safe working load of the unit being exceeded. Should

the hoist not respond to the handset controls and the the buzzer sounds three times, the hoist has been

overloaded. The reset procedure on page 5 will need to be performed to resume normal hoist function.

If the hoist fails to respond contact Chiltern Invadex or your supplier.

Page 7

HOIST 100 Series

Issue 2.0 Issue 2.0 June 2018

Servicing and maintenance

ISO10535 requires that all equipment used to lift people must be fully serviced, including a load test, at

least every 12 months. The frequency of servicing should be increased in areas where the environment

or heavy usage may cause deterioration of the equipment. Chiltern Invadex recommend that in these

circumstances hoists are serviced every 6 months. An orange indicator light will show on the hoist when

a service is due.

In addition to servicing, the Lifting Operations and Lifting Equipment Regulations (LOLER) require 6 six

monthly inspections of any device and accessories (including slings) which are used as work equipment.

This includes in a private home where a carer is employed.

Additional services and LOLER inspections should be carried out where the scheme has been unused

for long periods, subject to modication or at point re-installation.

Information regarding LOLER requirements can be seen at http://www.hse.gov.uk/pubns/hsis4.pdf.

Maintenance of this equipment should only be conducted by engineers trained and certied by Chiltern

Invadex.

Keep the service record (at the back of this booklet) up to date.

DO NOT USE IF:

1. There is any damage to the hoist.

2. There is fraying or stitch damage to the lifting tape or slings.

To ensure maximum cleanliness

Wipe with a dry cloth (track and hoist). For stubborn marks use a damp cloth and a mild cleanser. Always

read the manufacturers instructions prior to applying the cleanser. To prevent damage the hoist and

handset must never be submerged in water.

Slings should be washed in accordance with the instructions on the label, sewn into the sling.

Parts

2 Button 4 Button 6 Button

Please note: hand controls are the only spare part which can be safely replaced by untrained persons

all other works should be carried out by a competent engineer.

A full list of replacement parts can be obtained on request from Chiltern Invadex or your local dealer.

OHHS350 OHHS351 OHHS352

HOIST 100 Series

Page 8

Issue 2.0June 2018

Troubleshooting

Further assistance

Please telephone Chiltern Invadex on 01869 365500 further assistance. Remember that service calls made

after the warranty period will be chargeable. If the maintenance of the equipment is the responsibility of a

third party, for example the Social Services, please contact them in the rst instance.

Battery models only

Hoist lacking power Battery is low Charge batteries

Hoist make beeping sound Battery is low

Hoist is left o charge

Charge batteries

Return to charge point

Red light is on Battery is low Charge batteries

Red light is ashing Batteries are critically low Charge immediately

Green light is on Batteries charging Will turn o when charged

Red & Green lights are

ashing

Hoist idle Return to charge

Hoist will not function Hoist is charging Remove hoist from charging dock and

wait for green LED to turn o

Powered models only

No hoist function No power Ensure mains power is connected,

check fuse box

All models

Hoist will not function Hoist has been overloaded

Emergency stop has been

activated

Thermal fuse requires reset see page

3

Reset hoist, see page 5

Hoist stops when lifting Tape is twisted Ensure tape is vertical

Orange light is on Service is due Arrange service call

Orange light is ashing Service is overdue Arrange service call

Hoist lifts when down button

is pressed

Airline incorrectly installed

Lifting tape may be reversed

on the spool

Black line on handset must align with

the raised edges on the hoist connec-

tion when inserted into the grommet on

the hoist box

To correct press up button to lower

carry bar whilst pulling lift tape down

gently to the end of its travel. Tape will

then rewind itself correctly, or the lower

cutout will operate. If lower cutout

operates the tape is wound correctly.

Symptom Suggested cause Solution

Page 9

HOIST 100 Series

Issue 2.0 Issue 2.0 June 2018

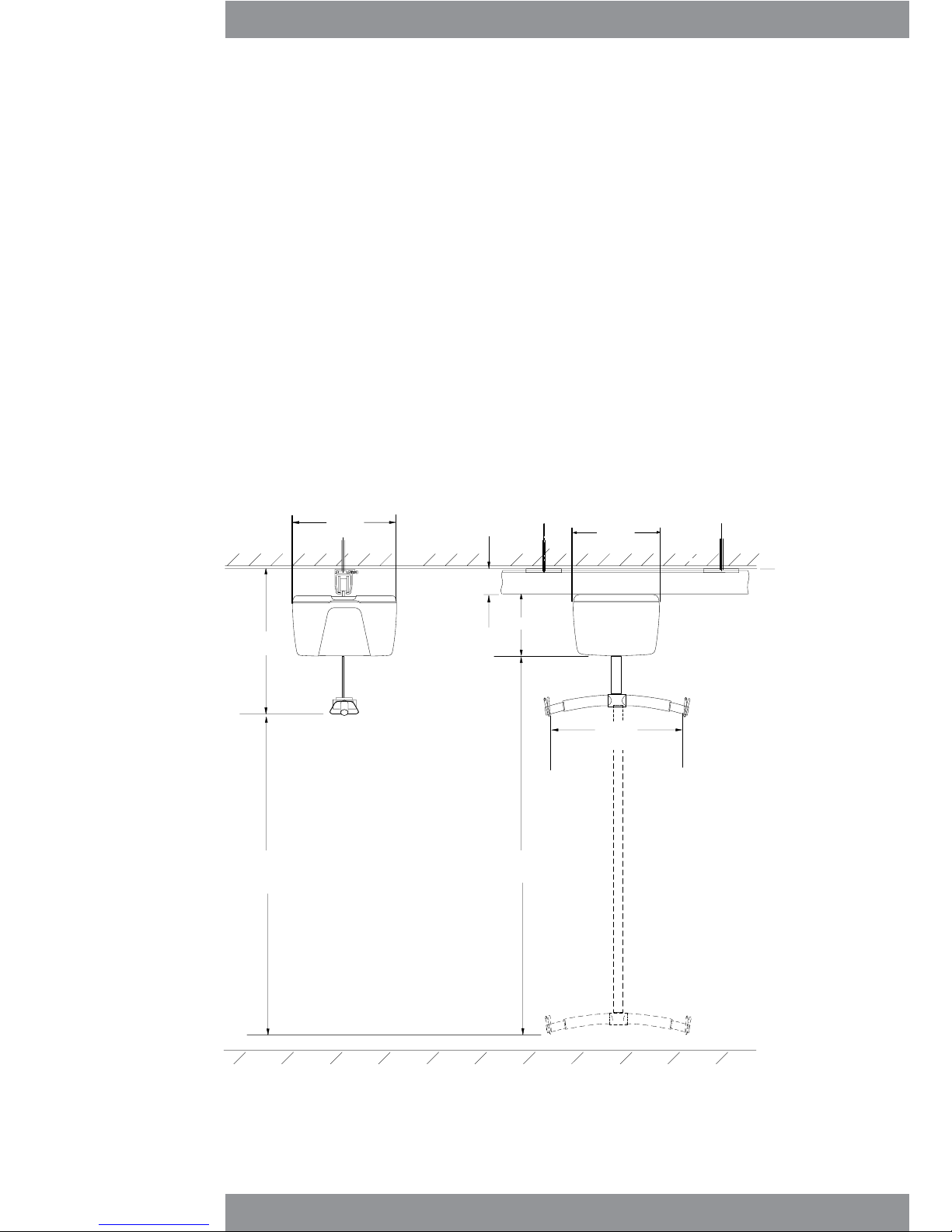

Hoist Specication

Lifting capacity WP, WBP, WLP, WLBP models - 130 Kg (20 stone)

WTP, WLTP, WTBP, WLTBP models - 200 Kg (31 stone)

Case construction Injection moulded Flame Retardant ABS

Lifting Range Approximately 1800mm*

No of Lifts per Charge 60** (Battery models)

Battery voltage 24 vdc

Overload cut out <150% maximum load (All models)

Hand control Pneumatic hand control

Track Aluminium extruded track

Low battery indication Audible and visual warning device on hoist (On battery models only)

Clearance dimension Top of track to bottom of carry bar hook at max height is 442mm

*This is adjustable and should be set by the installer to meet the requirements of the user. Typically the carry bar would stop about 300mm from

the oor. Extended tapes are available to accommodate high ceilings

**600mm up and down cycle with average 70kg (11 stone) patient weight.

CE Mark

The Chiltern Invadex Wispa 100Plus Hoist carries the CE mark and complies with the Medical Devices Directive (93/42/EEC) as amended

2007/47/EC

1782mm

maximum lifting range

with standard tape

1922mm

with standard tape

480mm

between pick up points

442mm

minimum

370mm

82mm

220mm

270mm

Standard single track conguration, for details of other congurations please contact us at [email protected]

HOIST 100 Series

Page 10

Issue 2.0June 2018

Important Information - Transformer Powered Models

Please note that the brown and blue wires on the hoist curly cable

can be connected to either of the two blue wires in the transformer.

Installation Notes

Important Information - Battery Powered Models

Where this hoist is to be a replacement unit on an existing track

installation, the charging unit included in the box MUST be used.

This hoist is NOT compatible with the old RED charging unit.

Use of this hoist with the old RED charger may result in damage

to the PCB and WILL invalidate the product warranty.

For further information please contact our Technical team on

01869 365500.

Page 11

HOIST 100 Series

Issue 2.0 Issue 2.0 June 2018

Carry/Spreader Bar Installation

9

8

4

5

6

7

3

11

2

d

c

b

a

Carry Bar/Lift Tape Replacement

Using a 2.5mm allen key remove the security screw (1) and set

aside for re-use

Push down firmly through the carry bar to remove the component

parts (2). Parts should include;

PTFE bearings x2 (a)

Lift tape retainer housing (b)

Lift tape retainer dowel (c)

Cap (d)

Should any of these parts be missing the installation should be postponed

until the necessary replacement parts have been obtained.

Note: where an existing lift tape is being removed it may be necessary

to cut along the base of the lift tape (as shown) to facilitate removal of

the retainer dowel.

Push the new lift tape through the slot in the top of the carry bar (3).

Slide the two PTFE bearings over the lift tape and position them

at the top of the carry bar (4).

Note: to ensure that the carry bar can swivel smoothly care

should be taken to ensure that the PTFE bearings are flat against

the top of the carry bar.

Place the retainer housing over the lift tape (5) and insert the dowel through the hole provided into

the lift tape loop (6). Pull the tape tight through the slot in the top of the carry bar (7).

Note: be aware of finger trap hazard.

If the tape is fitted correctly the carry bar should rotate freely, if this is not the case ensure that PTFE

bearings are installed correctly and that the dowel sits flush within the retainer housing.

Insert the cap (8) and re-insert the security screw (9).

For safety reasons a lift tape should be renewed if any sign of wear is visible

or every two years regardless of condition.

This procedure should only be carried out by qualified service personnel.

Please ensure that this guide is read thoroughly prior to commencement

Chiltern Invadex (UK) Limited, 126 Churchill Road, Bicester, Oxfordshire OX26 4XD Tel: 01869 365500 Fax: 01869 365588 Email: [email protected] Registered in England No: 04704248

CINV 576.02 October 2012

HOIST 100 Series

Page 12

Issue 2.0June 2018

Warranty

Your Chiltern Invadex (UK) Limited Overhead Hoist carries a 12 month warranty from the date of purchase,

subject to the following :-

1. Should you experience any problems with your product within the rst 12 months period please

contact your point of purchase.

2. Repairs made during the warranty period will be carried out free of charge, provided the product

has been used strictly in accordance with the guidelines set out in this user guide.

3. Our warranty does not cover replacements, adjustments or repairs which may be required as a

result of normal wear and tear, wilful or accidental damage, misuse, neglect or any other cause

which is beyond the control of Chiltern Invadex (UK) Limited.

4. Modications and repairs made to this product by unauthorised persons will render the warranty void.

5. Only parts manufactured or approved by Chiltern Invadex (UK) Limited shall be used to repair this

product. Use of unauthorised parts will invalidate all warranties and remove all liability from Chiltern

Invadex (UK) Limited for the safety of this product.

6. Chiltern Invadex (UK) Limited shall in no event be liable for any damages, costs or expenses arising

from any claim made under this warranty (save for any legal liability of Chiltern Invadex (UK) Limited

for death or personal injury resulting from the company’s negligence in respect of its products).

7. This warranty does not aect your statutory consumer rights.

Life Expectancy Statement

Based upon 25 years experience in the manufacture, installation and service of overhead hoists, Chiltern

Invadex (UK) Ltd conrm a life expectancy of at least 8 - 10 years in relation to ceiling mounted hoists.

The life expectancy of any hoist can be vastly increased or decreased dependant upon the frequency of

use, the loads applied, correct operation and of course regular servicing and maintenance as detailed

within this guide.

A full statement of life expectancy can be obtained from Chiltern Invadex.

Page 13

HOIST 100 Series

Issue 2.0 Issue 2.0 June 2018

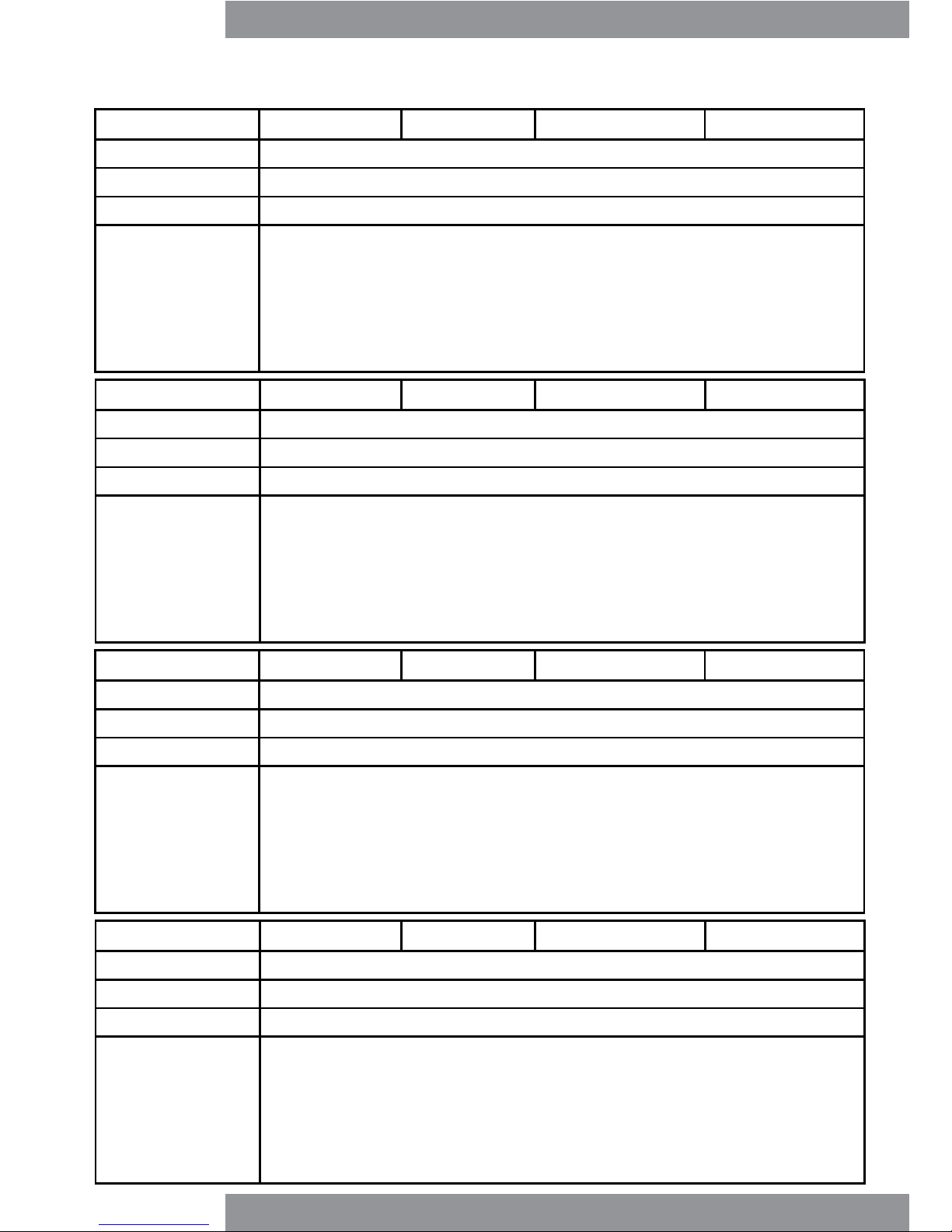

Year 1 Date of Service Load tested to kg

Serviced by

Address

Engineer name

Comments

Year 2 Date of Service Load tested to kg

Serviced by

Address

Engineer name

Comments

Year 3 Date of Service Load tested to kg

Serviced by

Address

Engineer name

Comments

Wispa Hoist Service Record

Year 4 Date of Service Load tested to kg

Serviced by

Address

Engineer name

Comments

HOIST 100 Series

Page 14

Issue 2.0June 2018

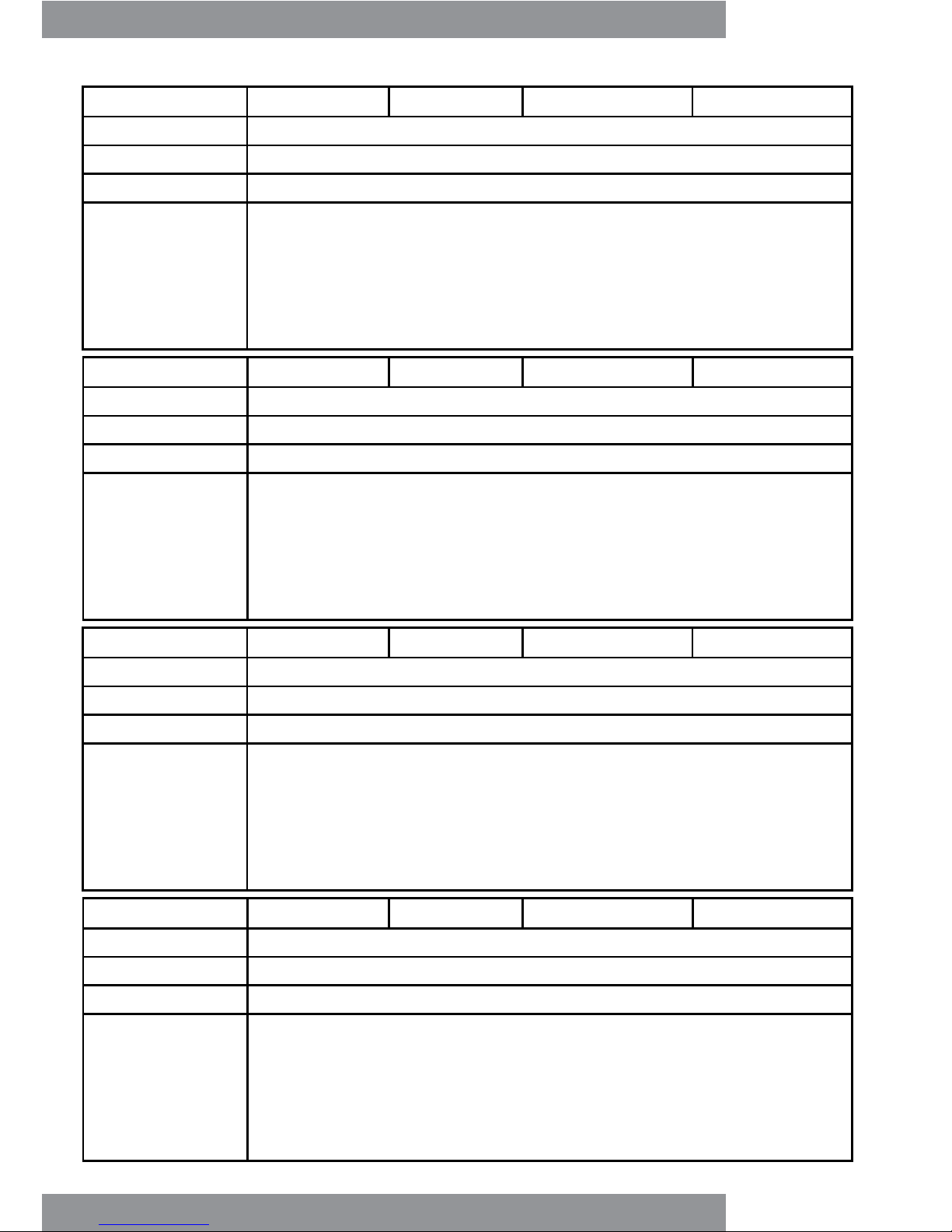

Year 5 Date of Service Load tested to kg

Serviced by

Address

Engineer name

Comments

Year 6 Date of Service Load tested to kg

Serviced by

Address

Engineer name

Comments

Year 7 Date of Service Load tested to kg

Serviced by

Address

Engineer name

Comments

Year 8 Date of Service Load tested to kg

Serviced by

Address

Engineer name

Comments

Page 15

HOIST 100 Series

Issue 2.0 Issue 2.0 June 2018

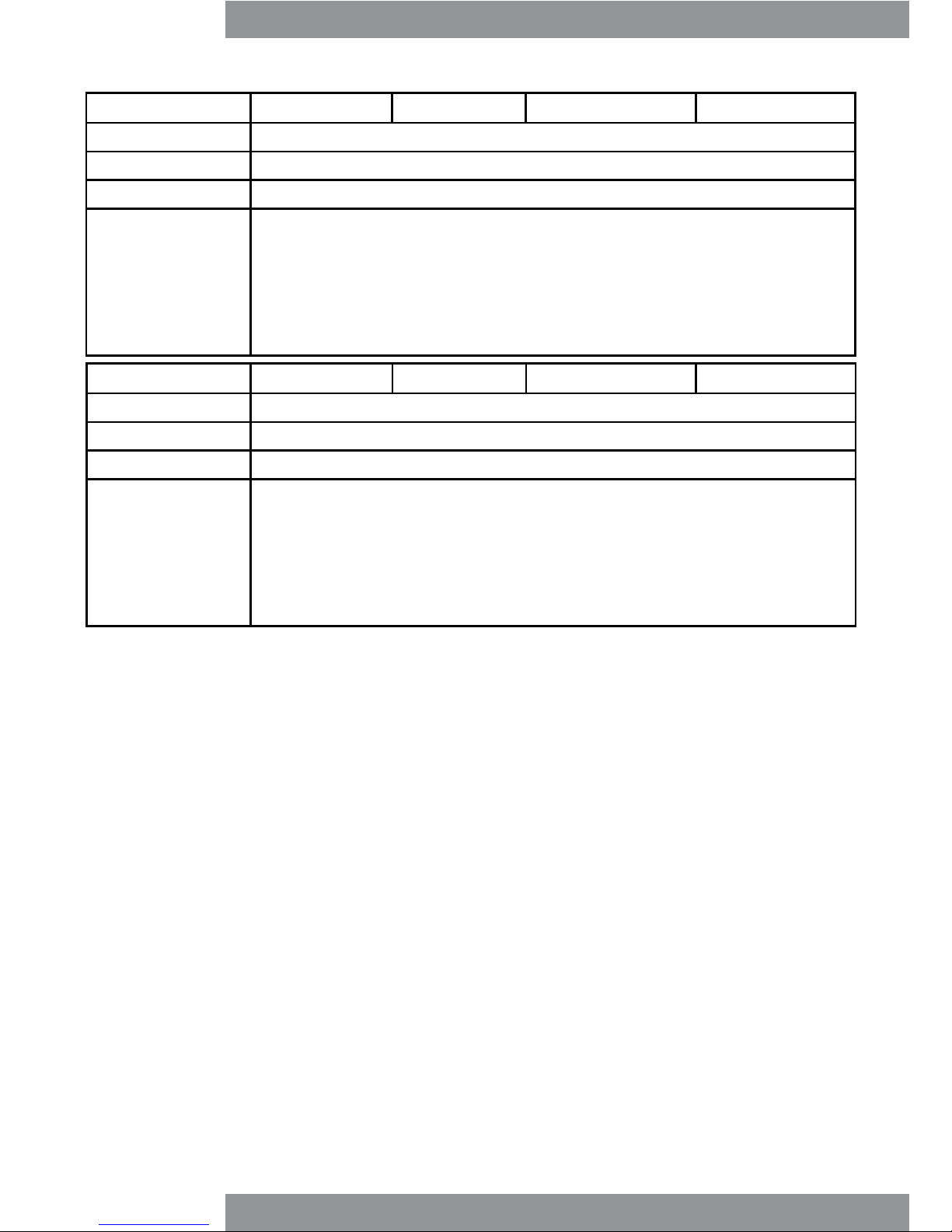

Year 9 Date of Service Load tested to kg

Serviced by

Address

Engineer name

Comments

Year 10 Date of Service Load tested to kg

Serviced by

Address

Engineer name

Comments

In addition to regular service and maintenance a requirement to provide 6 monthly LOLER inspections

may apply. Refer to page 7.

HOIST 100 Series

Page 16

Issue 2.0June 2018

Contractor name:

Contact number:

Address:

Contract/warranty/account number:

Notes:

The below space can be used to store details of your service contractor, if the equipment

has been provided by a third party for example the Local Authority, this information will be

available from them.

Refer to page 17 for details unique to your hoist. This information may be required when contacting your

service provider.

Page 17

HOIST 100 Series

Issue 2.0 Issue 2.0 June 2018

Chiltern Invadex (UK) Ltd

Issue a Issue Date Sept 2017

CI 2.10 Declaration of Conformity –Patient hoists Page 1 of 1

Author Authorisation

M Adamou

V Cartwright

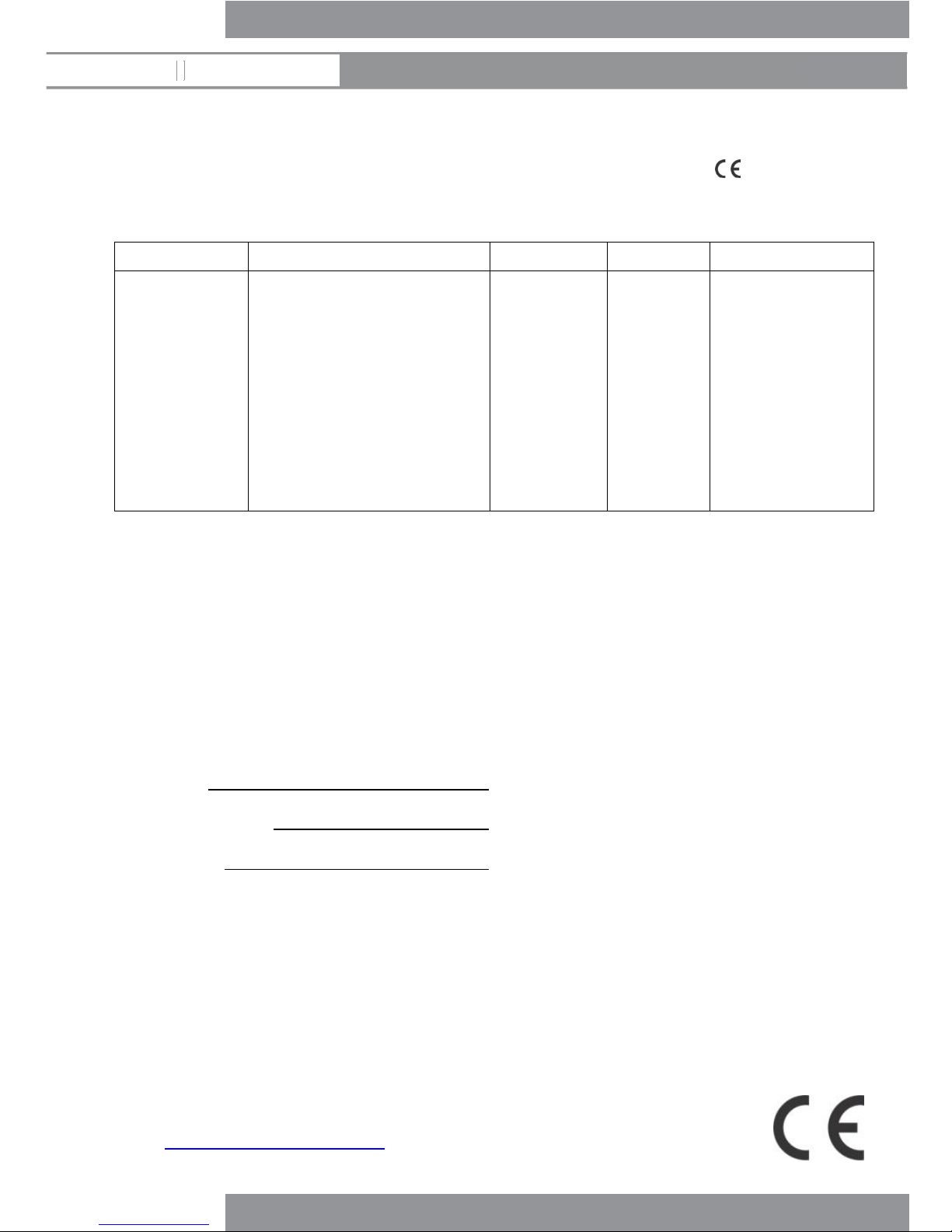

Chiltern Invadex (UK) Limited hereby declare the products identified below are Class 1 Medical

Devices as defined by the Medical Devices Directive 93/42/EEC and carry the mark.

Wispa branded patient hoist models;

Portable hoist 100Plus 200 Series 300 Series Mobile Hoist

WP

Transformer powered models

W

WT

WL

WLT

Battery powered models

WB

WTB

WLB

WLTB

200L

200LT

200LTR

200LTX

200LTXR

300L

300PT

300PTR

300P

300PR

MHWMEHUKEL

We hereby certify that the products listed have been designed, assessed, manufactured,

labelled and packaged to conform with the specifications which apply to them under

International Standard ISO10535:2006 and confirm compliance with the provisions applied

under the Medical Devices Directive 93/42/EEC (as amended by 2007/47/EC)

The necessary technical files are available for inspection by the relevant enforcement

authorities.

Registered Manufacturer Number: CA005328

E4: Patient/Hoist/Transfer Aids and Accessories

Hoist model:

Date of manufacture:

Serial number:

Unit 6C

Thorpe Drive

Banbury

OX16 4UZ

UK

Email: [email protected]

Manufactured by;

Chiltern Invadex (UK) Limited

Unit 6C

Thorpe Drive

Banbury

OX16 4UZ

UK

01869 365500

Overseas Enquiries

+44(0)1869 365500

www.chilterninvadex.co.uk

FM553189

.

The crossed wheelie bin symbol shown on this product indicates that

the item must not be disposed of with general household waste. Proper

recovery of your waste electronic and electrical equipment will ensure

safety of human health and the environment.

For more information where the product can be safely disposed of

please contact your Local Authority, the dealer from where the product

was purchased or Chiltern Invadex (UK) Limited.

WEEE producer number

WEE/JD1274RU

To request a copy of this guide in large print

please contact

customer services on 01869 365500 opt 1 or

email: [email protected]

Co p yr i ght © C hil t er n In v ad e x (UK) Ltd The design of the product shown in this guide is vested in Chiltern Invadex (UK) Ltd and should not be copied or reproduced in anyway

whatsoever without the express permission in writing of Chiltern Invadex (UK) Ltd.

Pu b li s hed by : Ch i lt e rn I nv a dex (UK) Ltd Unit 6C, Thorpe Drive, Banbury OX16 4UZ Registered in England No: 04704248 OH0014 Issue 2.0

June 2018

WISPA 100 Plus

Table of contents

Other Chiltern Invadex Medical Equipment manuals