CHINT Astronergy CHSM6610M User manual

1

Crystalline Silicon PV

Module Installation

Manual

Rev1.2,Released in August 2021.

2

Directory

1Introduction....................................................................................................................................................... 3

1.1 Purpose.................................................................................................................................................... 3

1.2 Limitation of Liability............................................................................................................................. 3

2Regulations and regulations............................................................................................................................. 3

3Safety measures................................................................................................................................................. 4

3.1 General safety measures.......................................................................................................................... 4

3.2 Operational safety measures.................................................................................................................... 5

4Handling and unpacking .................................................................................................................................. 7

4.1 Transport ................................................................................................................................................. 8

4.2 Unpack .................................................................................................................................................... 8

5Mechanical installation..................................................................................................................................... 9

5.1 Installation conditions ............................................................................................................................. 9

5.2 Installation angle selection.................................................................................................................... 10

5.3 Installation Method ............................................................................................................................... 10

6Electrical Installation...................................................................................................................................... 15

6.1 Electrical properties............................................................................................................................... 15

6.2 Electrical connection............................................................................................................................. 16

6.3 Grounded............................................................................................................................................... 18

7Maintenance..................................................................................................................................................... 19

7.1 Routine inspection................................................................................................................................. 19

Modified version and date...................................................................................................................................... 20

3

1Introduction

First of all, thank you very much for using

Chint Solar Technology Co., Ltd. (hereinafter

referred to as Chint Solar) production of

photovoltaic modules.

Please read all the instructions in this manual

carefully before installation, as well as electrical and

mechanical requirements.

The installation and operation of photovoltaic

modules requires professional skills that only

professionals can do. The installation process is strictly

observed with all safety precautions in this manual and

the manual is kept for further reference. At the same

time, the installer must inform the end customer (or

consumer) of the above accordingly.

1.1 Purpose

This manual provides detailed instructions and

important safety precautions for the installation,

electrical connection and maintenance of single-sided

crystalline silicon photovoltaic modules (hereinafter

referred to as photovoltaic modules) produced by

Chint Solar. Covers photovoltaic module models such

as Table 1.

Table 1 This manual applies to photovoltaic module types

CHSM6610M

CHSM6610M(BL)

CHSM6610M/HV

CHSM60M-HC

CHSM60M(BL)-H

C

CHSM6610P

CHSM6610P/HV

CHSM60P-HC

CHSM6612M

CHSM6612M/HV

CHSM72M-HC

CHSM60M/LV-HC

CHSM6612P

CHSM6612P/HV

CHSM72P-HC

CHSM72M/LV-H

C

CHSM54M-HC

CHSM54M(BL)-H

C

1.2 Limitation of Liability

Since the use of this manual and the installation,

operation, use and maintenance of photovoltaic

modules are beyond the control of Chint Solar, this

manual does not have any warranty meaning, whether

express or implied. Chint will not be responsible for

any form of injury, including, but not limited to,

damage, damage, loss of life or additional expenses

caused by incorrect installation, operation, use and

maintenance of photovoltaic modules and systems.

Chint Solar reserves the right to update this

manual without prior notice. If there are

inconsistencies in the descriptions between different

language versions of this manual, the Chinese version

will prevail.

2Regulations and regulations

The mechanical and electrical installation of

photovoltaic modules should be carried out in

accordance with applicable laws and regulations,

including electrical law, building law and electrical

connection requirements. These regulations vary

depending on the installation location, such as the roof

4

of the building, the surface of the water, etc., or may

vary depending on the installation system voltage, dc

usage, or AC. Please contact your local authority for

specific terms.

3Safety measures

Chint solar modules are designed to meet the

requirements of IEC 61215 and IEC 61730,

application class A.

Modules rated for use in this application class may

be used in system operating at greater than 50V DC

or 240W, where general contact access is

anticipated. Class C fire rating(IEC61730)and

Category 4 fire rating (UL61730) are available

!warn

All safety rules should be read and understood

before installing, wiring, etc. / maintaining

photovoltaic modules. When the photovoltaic module

is exposed to sunlight or other light sources, direct

current is generated. Direct contact with the live part

of the photovoltaic module, such as terminals, whether

or not a photovoltaic module is connected, can result

in loss of life.

3.1 General safety measures

Before installation, please contact the

relevant local authority to determine the

installation permit and installation inspection

requirements that meet the local

requirements. The installation process should

comply with the safety rules applicable to all

components in the system, including cables,

terminals, charging monitors, batteries,

inverters, etc.

If you install or operate photovoltaic

modules on a rainy day or in the morning

with dew, you need to take appropriate

protective measures to prevent water vapor

from penetrating into the connector.

Unauthorized personnel are prohibited from

approaching the installation area or

photovoltaic module storage area.

It is forbidden to install or use damaged

photovoltaic modules.

It is forbidden to repair photovoltaic

modules by yourself, including but not

limited to replacing any components of

photovoltaic modules (diodes, junction

boxes, connectors, etc.).

It is forbidden to plug in connectors of

different types and models.

It is forbidden for photovoltaic modules to

be used or exposed to the following

substances in an environment containing the

following substances: grease or organic ester

compounds (such as DOP, plasticizers),

aromatics, phenols, ketones, halogenated

5

substances, mineral oil, alkanes (Such as

gasoline, cleaning lubricants, electronic

resurrection agents), alcohol, certain drugs

(white flower oil, active oil, bone-setting

water, thinner), adhesive sheets that can

generate oxime gas and potting glue (only

for connectors) (Such as KE200,

CX-200/chemlok, etc.)), TBP (plasticizer),

detergent, etc., to avoid chemical damage

and affect the electrical safety performance

of photovoltaic modules.

It is forbidden to install photovoltaic

modules in windy weather.

It is forbidden to focus sunlight on

photovoltaic modules.

It is forbidden to use photovoltaic modules

in relevant places such as movable platforms

(except for tracking brackets).

It is forbidden to disassemble and move any

part of the photovoltaic module; if the

connector of the photovoltaic module is wet,

do not perform any actions to avoid the risk

of electric shock.

Do not connect or disconnect the

photovoltaic module when there is current or

external current from the photovoltaic

module.

The cover of the junction box should always

be kept closed.

Avoid partial shading of photovoltaic

modules for a long time. Otherwise, the

temperature of the shaded solar cells will

rise (hot spot effect), and in severe cases, the

photovoltaic modules may be burned, or

even a fire may occur.

For photovoltaic modules used in deserts or

windy and sandy areas, it is recommended to

use connector dust caps before installation,

or take other measures to prevent sand and

dust from entering the connectors, otherwise

it may cause insertion problems or electrical

safety hazards.

3.2 Operational safety measures

During transportation and storage, avoid

damage or fall of the packaging; ensure that

the packaging box is ventilated, rain-proof

and dry; after arriving at the installation site,

carefully open the outer packaging to

prevent scratches and bumps on the

photovoltaic modules due to improper

unpacking Such phenomena; when stacking

photovoltaic modules, the stacking

requirements must be strictly followed.

Avoid impact or scratches on any part of the

photovoltaic module, otherwise the

reliability and safety of the photovoltaic

6

module will be affected; standing or walking

on the photovoltaic module is prohibited; at

the same time, in order to avoid glass

damage, it is forbidden to apply excessive

load or Distorted photovoltaic modules.

Do not install or carry photovoltaic modules

by one person. It is forbidden to pick up,

drag, or move photovoltaic modules by

grabbing the junction box (including the box

body, cables, and connectors); when placing

a photovoltaic module on a flat surface, It

must be operated carefully and be aware of

bumps in the corners.

When installing or repairing the photovoltaic

system, do not wear any metal accessories to

avoid the risk of electric shock; if it is

installed far above the ground, please wear a

seat belt.

When operating photovoltaic modules in the

sun, please use insulated tools, and wear

rubber gloves and protective clothing. At the

same time, in order to avoid the risk of arc

and electric shock, do not directly touch the

junction box and the end of the output cable

(connector) with your hands.

When the photovoltaic modules are

electrically connected, choose a dry and

weak morning or evening; or use opaque

materials to completely cover the surface of

the photovoltaic modules to prevent current

generation.

A certain distance between the photovoltaic

module and the installation surface should be

kept to prevent the installation surface from

touching the junction box.

When installing on the roof, comply with the

fire protection requirements of the building.

It is recommended to install photovoltaic

modules on a fireproof and insulated roof

covering, and ensure adequate ventilation

between the photovoltaic modules and the

installation surface. In order to ensure the

fire rating on the roof, the minimum distance

between the frame of the photovoltaic

module and the roof surface is 10 cm.

The connector must be fully mated when

wiring. If the cable is too long, it is

recommended to fix the cable to the

installation system with a UV resistant nylon

cable tie. When fixing the cable to the

bracket, the bending radius of the cable

should not be less than 60mm.

Avoid directly exposing cables and

connectors to sunlight. Please use

anti-ultraviolet cables.

Do not disconnect the electrical connection

7

when there is a load.

It is strictly forbidden to try to disassemble

the photovoltaic module, and it is strictly

prohibited to remove the nameplate of the

photovoltaic module or other parts on the

photovoltaic module; it is strictly forbidden

to paint or apply any adhesive on the surface

of the photovoltaic module;

It is strictly forbidden to drill holes in the

frame of the photovoltaic module.

It is strictly forbidden to scratch the

anodized layer on the surface of the

aluminum alloy frame, except when it is

connected to the ground. Scratches may

cause corrosion of the frame, affecting the

frame's load-bearing capacity and long-term

reliability.

If the photovoltaic module glass or other

packaging materials are damaged, please

wear personal protective equipment to

separate the photovoltaic module from the

site or the circuit. It is strictly forbidden to

touch wet photovoltaic modules, unless you

are wearing electric shock protection

equipment that meets the requirements.

When professionals replace or repair

photovoltaic modules, do not damage the

surrounding photovoltaic modules or their

support structures.

When cleaning photovoltaic modules, you

must follow the cleaning requirements of

photovoltaic modules.

The connectors must be kept dry and clean

to ensure that they are in good working

condition. Do not insert other metal objects

into the connector or make electrical

connections in any other way.

4Handling and unpacking

If the photovoltaic module is not in use, please

do not open the product packaging. The goods should

be stored in a dark, dry and ventilated place. If the

photovoltaic modules are stored in an uncontrollable

environment, the storage time must be less than 3

months when the outer packaging of the photovoltaic

modules is kept intact.

It is recommended to take appropriate amount of

photovoltaic modules for unpacking according to the

project progress every day, and the unpacked

photovoltaic modules should be installed within a day.

After unpacking, the photovoltaic modules are stacked

on the ground. In severe weather such as heavy rain,

the photovoltaic modules may be immersed in water

for a long time and affect the reliability of the product.

In severe weather such as typhoons, photovoltaic

modules that have not been installed may also be

scraped away.

8

4.1 Transport

When the photovoltaic modules are transported

to the project site, they must be transported in the

packaging box provided by Chint Solar, and should be

stored in the original packaging box before installation.

Please protect the packaging from damage.

It is necessary to protect the safety of

photovoltaic modules when unloading, especially

when hoisting roof projects. It is forbidden to use

lifting straps directly on the pallet for hoisting. The

photovoltaic modules should be placed in a protective

device and then hoisted to the roof to prevent the

packing box from deforming and bumping against the

wall during the hoisting process.

!Special instructions

Due to the limitation of the height of the

container, when the photovoltaic modules are removed

from the container, the distance between the upper

surface of the forklift tines and the ground should be

less than 80mm, otherwise collisions may easily occur,

which may damage the photovoltaic modules.

4.2 Unpack

When unpacking, you need to tear the stretch

film first, then use a knife to cut the binding tape, and

remove the packing box cover.

If the inner packaging is fixed with anti-falling

tape, a group of two should hold the frame with both

hands in the same direction to take out the

photovoltaic module one piece/time, and remove the

photovoltaic module by tearing off a piece of fixing

glue. The photovoltaic modules in the box are dumped;

if the internal packaging is fixed by the internal

packing belt, first cut the internal packing belt, use

anti-inverted sticks and other non-sharp and reliable

items to hold one side of the long side frame, and then

cut the other side Two people move and take out the

photovoltaic modules one by one around the frame; the

whole handling process needs to be handled with care,

and must not collide with hard objects or any part of

the frame touches the ground and drags.

4.3 Stacking of photovoltaic modules

When taking out the photovoltaic module from

the packing box, you need to lay the cardboard on the

ground first to prevent the photovoltaic module from

colliding and scratching with the cement surface/hard

object on the ground, color steel tile, metal corrugated,

etc.

When the photovoltaic modules are stacked, they

must be neatly and stably stacked on a horizontal

surface, and stacked with the glass side facing down

and the back side facing up. At the same time, there

must be cardboard bedding under the photovoltaic

modules. For example, when installing photovoltaic

modules on the roof, the number of piles should not

exceed 20. For roofs with poor load-bearing capacity,

9

it is recommended that the designer or installer

evaluate the load-bearing capacity of the roof and

reduce the load-bearing unit area of the roof by

reducing the number of piles. At the same time, avoid

installation tools and other objects on the surface of

the photovoltaic module.

Chint PV modules adopt high and low current

bins, and the handlers need to place them separately

and mark them according to the markings on the

power list of the PV module outer packaging (for

example, 270W-L means low current gear; 270W-H

means high current Gear position; the current division

method required by other customers is similar);

According to the system design requirements, the same

current gear position is usually required in the same

array during installation.

If the customer requires PV modules to be

distinguished by color, the outer packaging box shall

be marked accordingly, and the PV modules shall be

marked to prevent confusion when they are taken out

of the packaging box and stacked. According to the

system design requirements, the color of photovoltaic

modules in the same row or square array should be the

same.

5Mechanical installation

5.1 Installation conditions

Recommended ambient temperature: -20°C to

+50°C; extreme working environment

temperature of photovoltaic modules: -40°C to

+85°C.

Photovoltaic module mechanical load: Under

standard installation conditions, the maximum

test snow/wind load is 5400Pa/2400Pa, and the

design load (considering a safety factor of 1.5) is

3600Pa/1600Pa. For specific installation methods

and mechanical load values of photovoltaic

modules, please refer to Table 2 for detailed

installation instructions for photovoltaic modules.

Photovoltaic modules are strictly prohibited to be

installed and used in excessive environments such

as hail, snow, hurricane, sandstorm, dust, air

pollution, and soot. It is strictly forbidden to

install or use photovoltaic modules in a closed

environment with strong corrosive substances

(such as salt, salt spray, salt water, active

chemical vapor, acid rain, strong steam, or any

other substances that will corrode photovoltaic

modules and affect the safety or performance of

photovoltaic modules. ) In the environment.

If photovoltaic modules will be installed in

special environments such as high temperature

and high humidity environment, wet salt fog

environment (C3 and above areas specified in

ISO 9223), water and breeding farms, etc., the

purchaser or user must inform Chint in advance.

The types of photovoltaic modules, BOM, and

10

quality assurance issues shall be decided by the

two parties through a joint re-agreement.

If the above precautions are not followed, the

Chint Solar Warranty will be invalid.

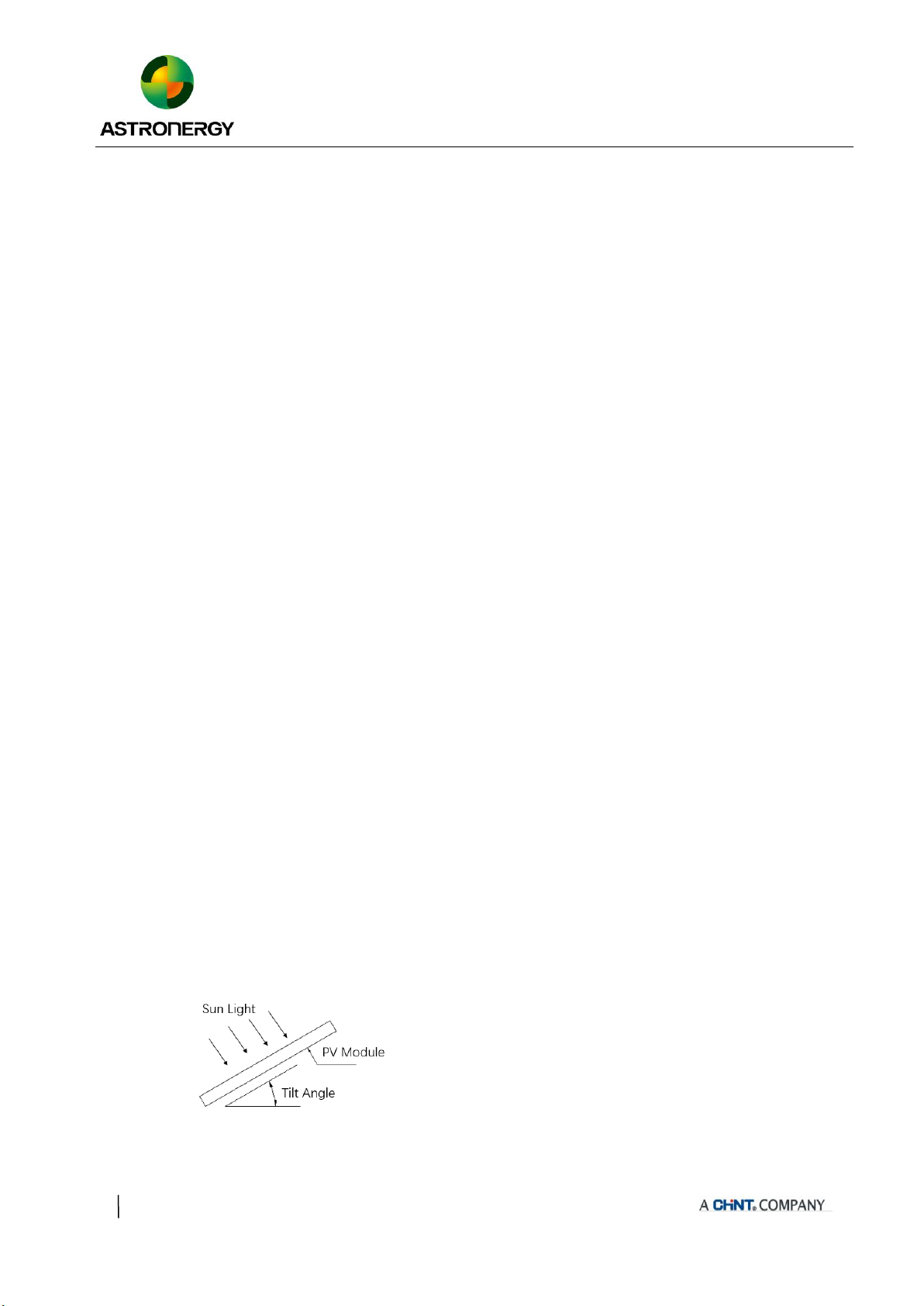

5.2 Installation angle selection

The tilt angle of the modules is measured between

the surface of modules and a horizontal

grounding face, as shown in figure 1. The

modules generate maximum power output when it

faces the sun directly.

In the northern hemisphere, modules should

typically face south, and in the southern

hemisphere, modules should typically face north.

Dust building up on the surface of the modules

can impair module performance, Chint Solar

recommends installing the modules with a tilt

angle of at least 10 degrees, making it easier for

dust to be washed off by rain. At the same time, it

is conducive to the flow of accumulated water on

the surface of the module, and avoids long-term

large amounts of accumulated water leaving

marks on the glass surface, thereby affecting the

appearance and performance of the module.

Figure a Schematic diagram of tilt angle

PV modules connected in series should be

installed in the same orientation and angle. If the

orientation and angle are different, the solar

radiation received by each module may be

different, resulting in power loss.

5.3 Installation Method

The photovoltaic module mounting bracket must

be made of durable, corrosion-resistant, and

UV-resistant materials. The mounting bracket

must be inspected and tested by a third-party

testing organization with static mechanical

analysis capabilities to meet the country, region,

or corresponding international standards.

The photovoltaic module must be firmly fixed on

the mounting bracket. If the photovoltaic module

is installed in a snow-covered area, the height of

the support should ensure that the lowest point of

the photovoltaic module will not be covered by

snow. In addition, it should be ensured that the

lowest point of the photovoltaic module will not

be blocked by surrounding trees or other plants.

When the photovoltaic module is installed on a

bracket parallel to the roof, the minimum gap

between the frame of the photovoltaic module

and the roof is 10cm, and air circulation is

required to prevent damage to the wiring of the

photovoltaic module.

The frame of the photovoltaic module will have

11

the effect of thermal expansion and contraction,

and the spacing between the two adjacent

photovoltaic module frames should not be less

than 10mm during installation.

For specific installation methods, please refer to

the following installation specifications.

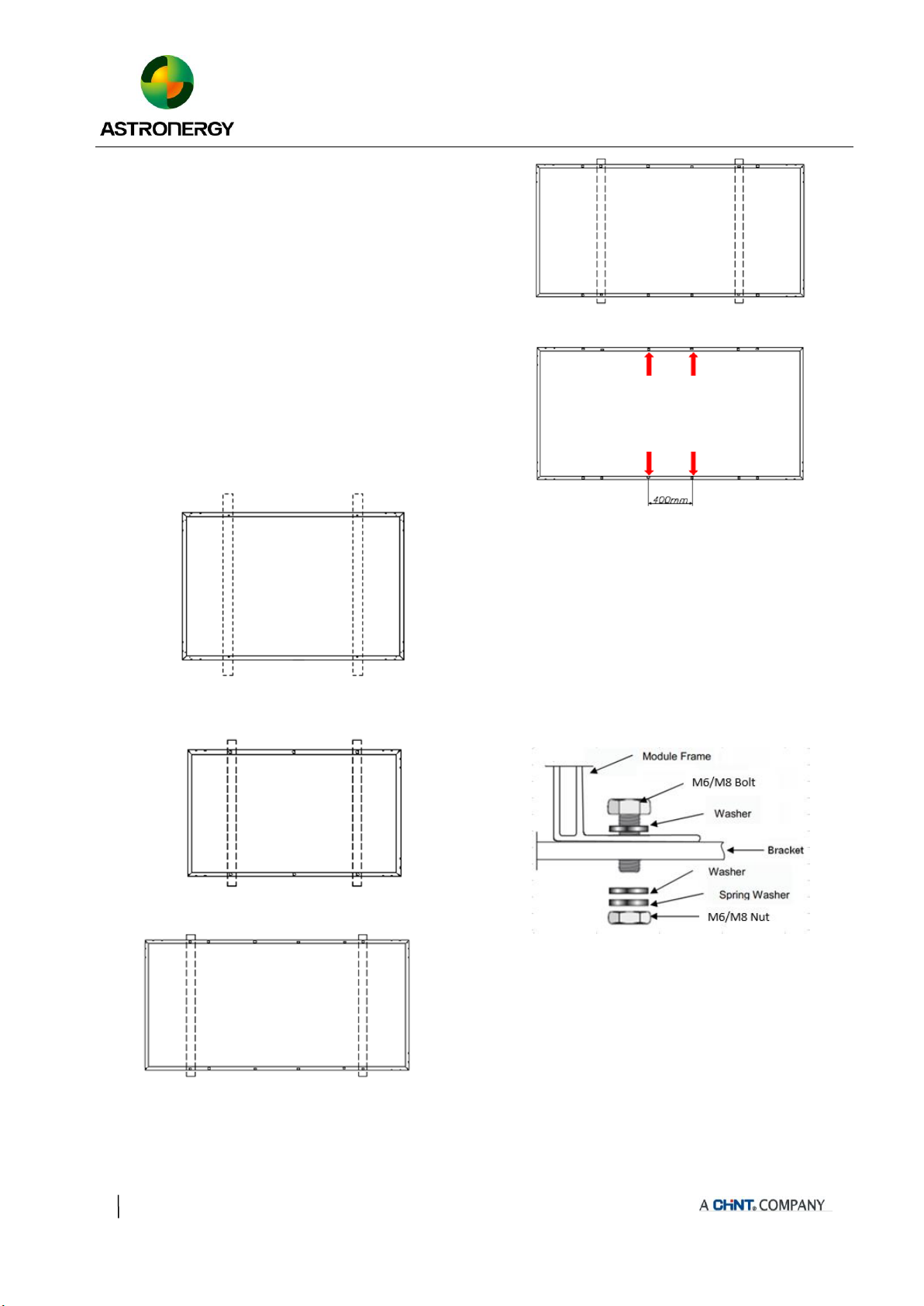

5.3.1 Bolting through the mounting holes

All modules must be securely fastened with at

least 4 bolts (As shown in Figure 2, Figure 3, Figure 4 ,

Figure 5 and Figure 6).

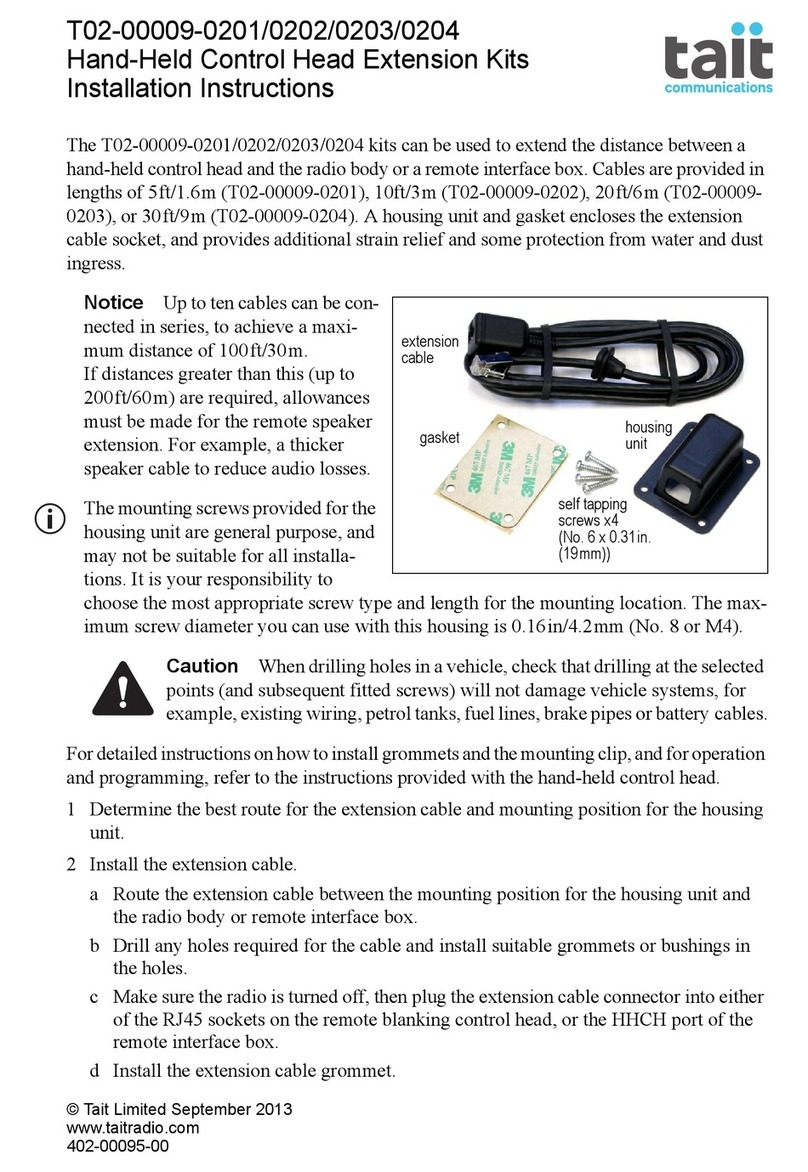

Fig 2 Bolt installation for 54cell

Fig 3 Bolt installation for 60cell

Fig 4 Outer four-hole bolt installation for 72cell

Fig 5 Internal four-hole bolt installation for 72cell

Fig 6 400mm pitch bolt installation for 72cell

!note :In order to achieve maximum safety

precautions against wind and snow loads, it is

recommended that all available mounting holes should

be used.Bolts are inserted as described in the process

below (Sketch figure 7).

Figure 7 Schematic diagram of bolt installation process

①Place the module on the supporting bars

underneath.

②Insert the four stainless-steel bolts (M6) through

the holes (7x11.5mm) or stainless-steel bolts (M8)

through the holes (9x14mm) in the frame

according to the Figure 2, Figure 3 & Figure 4.

The 400mm pitch mounting hole size is 7x10mm,

12

and 4 M6 stainless steel bolts are required (Figure

5).

③Secure each bolt to the frame with stainless-steel

washers, one for each side of the mounting

structure; and screw on either a stainless-steel

spring washer or a toothed lock washer. Finally,

secure with a stainless steel nut.

④The reference value of tightening torques should

be within 9~12Nm & 17~23 Nm respectively for

M6 & M8 bolts, depending on bolt class. For the

bolt grade, the technical guideline from the

fastener suppliers should be followed. For the

torque value, recommendations from specific

clamping hardware suppliers should prevail.

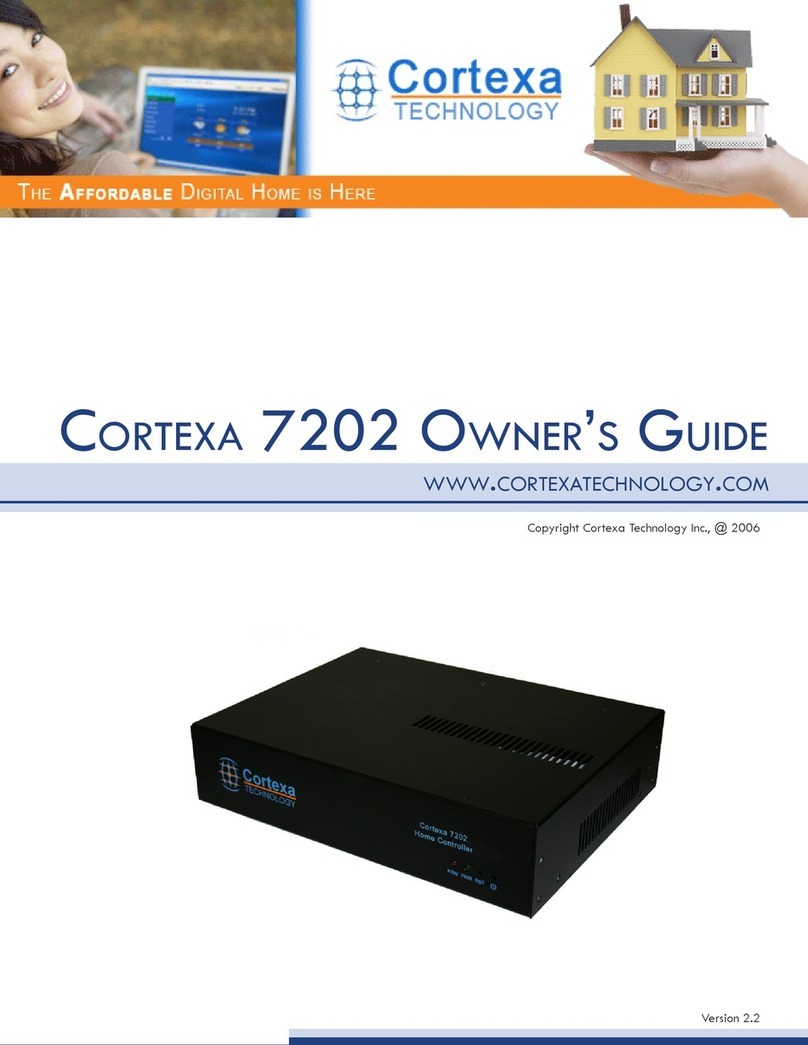

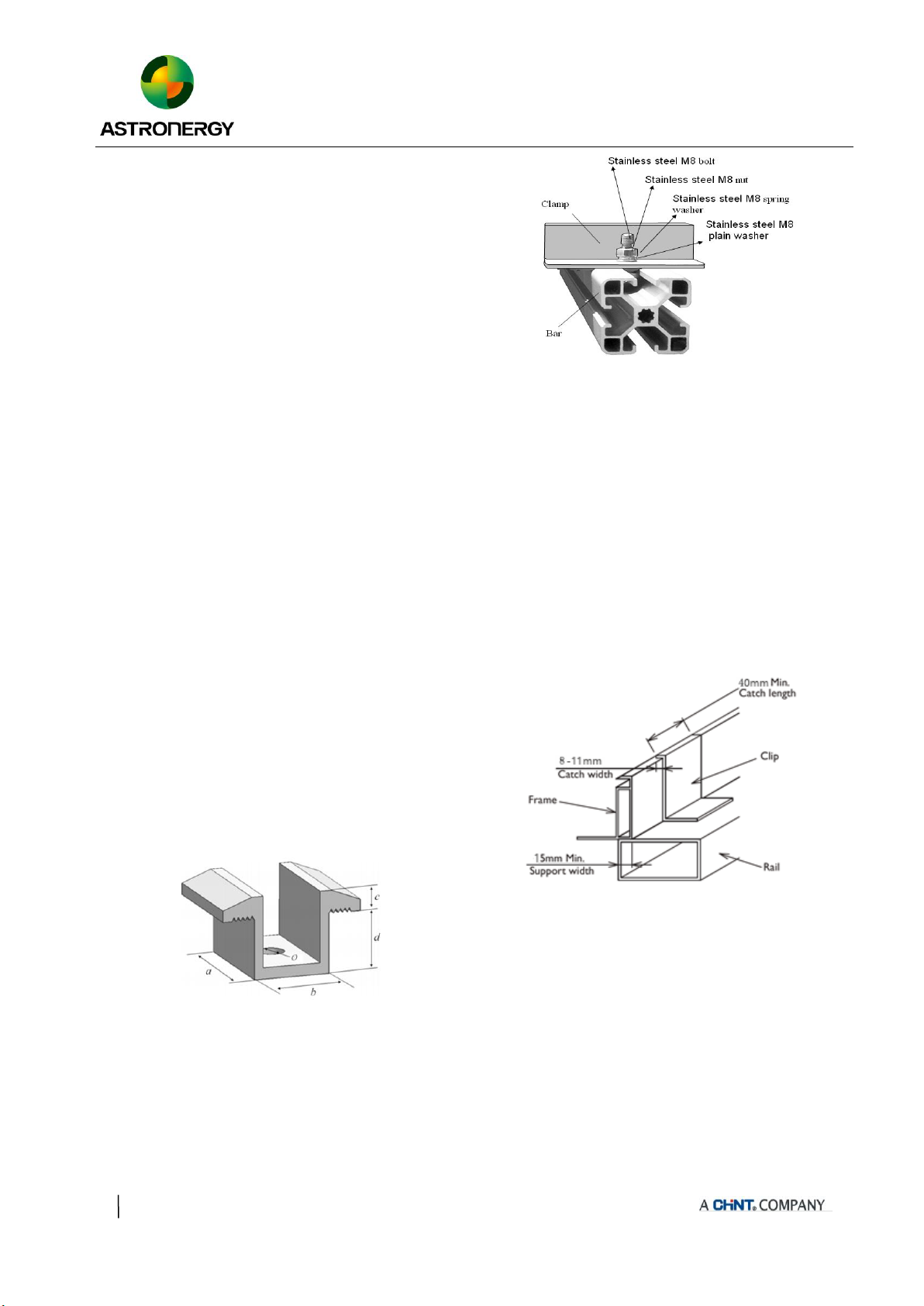

5.3.2 Clamping on the frame surface

Photovoltaic modules can be installed across the

support frame (Figure 8) or parallel to the frame of the

photovoltaic module (Figure 9). When using clamps to

install, each photovoltaic module must be fixed with at

least 4 clamps.

Figure 8 Rail vertical long frame installation

Figure 9 Installation of rails coincident with short frame

!note:

The length of supporting bars must be longer than

the length of module frame, otherwise please

confirm with our product team to get approval.

The above two diagrams show the installation

method using aluminum clamps (also called

fixtures). "D" indicates the allowable installation

range of the aluminum press block. Please refer to

4.3.3 for the specific recommended installation

location and corresponding load ("---" indicates

that the photovoltaic module does not apply to the

above installation methods).

Each aluminum pressure block is equipped with an

M8 bolt, a flat washer, a spring washer and an M8

nut. The fixing steps are as follows:

①Place the module on the two supporting bars (not

provided). The bars should be made with stainless

material and treated with an anti-corrosion process

(e.g., hot dipped galvanizing). Each PV module

needs at least four clamps to fix. Do not make the

clamp contact the glass directly or make the

aluminum frame deformation in the installation

process, and avoid the shadow of solar PV modules,

otherwise may break the modules.

②Be sure to avoid shadowing effects from the

module clamps. Weep holes on the module frame

must not be closed or obscured by the clamps. The

clamp must overlap the module frame by at least

13

8mm but no more than 11mm (The clamp section

can be changed under the premise of ensuring the

reliable installation of the components).

③The bar’s top surface contacted with module frame

should come with grooves compatible with an M8

bolt.

④If the bars do not come with grooves, holes of a

suitable diameter may need to be drilled to allow

bolts to be attached to the bars at the same locations

as mentioned above.

⑤Secure each clamp by attaching plain washer,

spring washer, and nut, in that order.

⑥Both of close-ups of Figure 10, indicating the

middle clamps and Figure 11, indicating the side

clamps for reference. Suggest the dimensions for

middle clamps are: a≥40mm, b≥26mm, c≥5mm,

d≥28mm, and Ø=9mm. The torque for tightening

the nut and bolts are recommended 17~23Nm when

the property class of bolts and screws is Class 8.8.

Figure 10 Schematic diagram of intermediate pressing block

Figure 11 Schematic diagram of side pressing block

⑦For the installation method shown in Figure 9, the

modules need to be fixed with professional solar

pressure blocks (as shown in Figure 12), and the

overlap between the C surface of the module and

the guide rail should be ≥15mm. If improper

fixtures or incorrect installation methods are used,

the Chint Solar limited warranty will be invalid.

Figure 12 Requirements for mounting clamps when the guide

rails coincide with the long frame

14

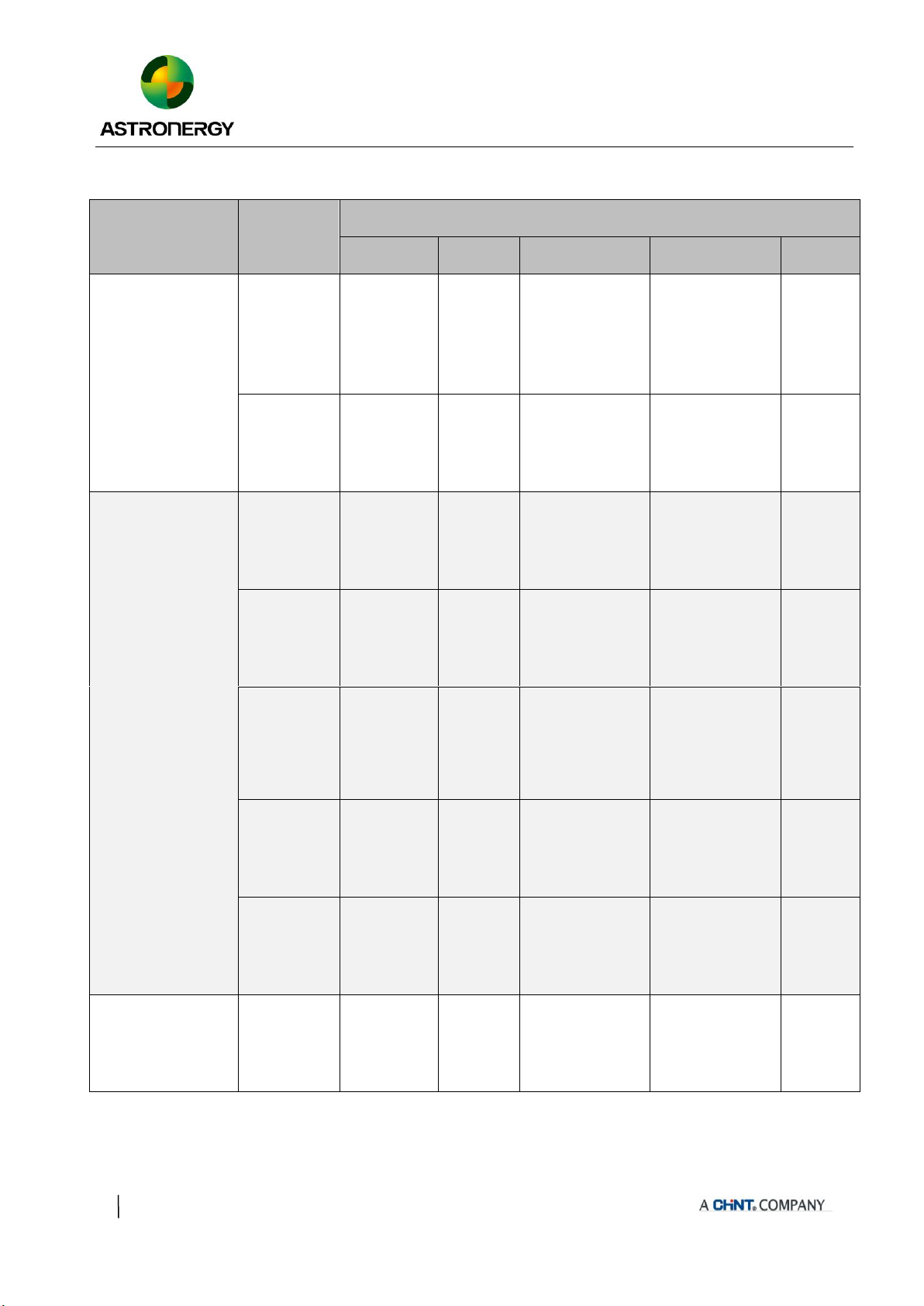

Table 2 Installation range and corresponding values

Module type

Dimensions

L*W*H (mm)

Installation method

Fig b & Fig C

Fig d

Fig g

Fig h

Fig e

CHSM6610M

CHSM6610M/HV

CHSM6610P

CHSM6610P/HV

CHSM6610M(BL)

1648*990*35

1648*990*40

+5400Pa

-2400Pa

---

+5400/-2400Pa

Installation scope

198~408mm

+2400/-2400Pa

Installation scope

50~200mm

---

1650*992*35

1650*992*40

+5400Pa

-2400Pa

---

+5400/-2400Pa

Installation scope

198~408mm

+2400/-2400Pa

Installation scope

50~200mm

---

CHSM60M-HC

CHSM60P-HC

CHSM60M(BL)-HC

CHSM60M/LV-HC

1666*992*35

+5400Pa

-2400Pa

---

+5400/-2400Pa

Installation scope

207~408mm

+2400/-2400Pa

Installation scope

50~200mm

---

1675*992*35

+5400Pa

-2400Pa

---

+5400/-2400Pa

Installation scope

215~415mm

+2400/-2400Pa

Installation scope

50~200mm

---

1692*1002*35

+5400Pa

-2400Pa

---

+5400/-2400Pa

Installation scope

350±50mm

+2400/-2400Pa

Installation scope

50~200mm

---

1755*1038*35

1765*1048*35

+5400Pa

-2400Pa

---

+5400/-2400Pa

Installation scope

400±50mm

+1800/-1800Pa

Installation scope

200±50mm

---

1755*1038*30

+5400Pa

-2400Pa

---

+5400/-2400Pa

Installation scope

350±50mm

+1800/-1800Pa

Installation scope

200±50mm

---

CHSM54M-HC

CHSM54M(BL)-HC

1708*1133*30

+5400Pa

-2400Pa

---

+5400/-2400Pa

Installation scope

359±50mm

+1400/-1400Pa

Installation scope

200±50mm

---

15

Table 2 (continue)

Module type

Dimensions

L*W*H (mm)

Installation method

Fig b & Fig C

Fig d

Fig g

Fig h

Fig e

CHSM6612M

CHSM6612M/HV

CHSM6612P

CHSM6612P/HV

1954*990*40

1954*990*35

+5400Pa

-2400Pa

+5400Pa

-2400Pa

+5400/-2400Pa

Installation scope

299~498mm

---

+2400Pa

-2400Pa

+Bumper

1960*992*40

1960*992*35

+5400Pa

-2400Pa

+5400Pa

-2400Pa

+5400/-2400Pa

Installation scope

299~498mm

---

+2400Pa

-2400Pa

+Bumper

CHSM72M-HC

CHSM72P-HC

CHSM72M/LV-HC

1986*992*40

1986*992*35

+5400Pa

-2400Pa

+5400Pa

-2400Pa

+5400/-2400Pa

Installation scope

315~505mm

---

+2400Pa

-2400Pa

+Bumper

2000*992*40

2000*992*35

+5400Pa

-2400Pa

+5400Pa

-2400Pa

+5400/-2400Pa

Installation scope

315~505mm

---

+2400Pa

-2400Pa

+Bumper

2018*1002*40

2018*1002*35

+5400Pa

-2400Pa

+2400Pa

-2400Pa

+5400/-2400Pa

Installation scope

350±50mm

---

+2400Pa

-2400Pa

+Bumper

2108*1048*35

2094*1038*35

+5400Pa

-2400Pa

+2400Pa

-2400Pa

+5400/-2400Pa

Installation scope

400±50mm

---

+2400Pa

-2400Pa

+Bumper

2256*1133*35

+5400Pa

-2400Pa

+2400Pa

-2400Pa

+5400/-2400Pa

Installation scope

400~450mm

---

+1800Pa

-1800Pa

+Bumper

6Electrical Installation

6.1 Electrical properties

For details of the electrical performance

parameters of Chint Solar PV modules, please refer to

the PV module product manual.

Rated electrical characteristics such as Isc is

within ±5% and Voc within ±3% and Pmpp within

±3% of tolerance values at Standard Test Conditions.

Standard Test Conditions: 1000W/m2 Irradiance, 25℃

Cell Temperature and 1.5Air Mass.

The IEC & UL standard maximum system

voltage for the regular module series is 1000V, the

1500V standard products are also available according

to the requirements. The IEC & UL standard

16

maximum system voltage for half-cell module series is

1500V (except for black modules). The maximum

voltage of the system must be less than the maximum

certified voltage and the maximum input voltage of the

inverter and of the other electrical devices installed in

the system. To ensure that this is the case, the open

circuit voltage of the array string needs to be

calculated at the lowest expected ambient temperature

for the location. This can be done using the following

formula.

Max System voltage ≥ N * Voc * [1 + TCvoc x (Tmin-25)]

Among them: N-the number of photovoltaic

modules in a single string; Voc-the open circuit voltage

of each photovoltaic module (refer to the photovoltaic

module nameplate or product brochure); TCvoc-the

temperature coefficient of the photovoltaic module

open circuit voltage (refer to the photovoltaic module

product brochure); Tmin -Minimum ambient

temperature.

!note

Under normal conditions, a photovoltaic module is

likely to experience conditions that produce more

current and/or voltage than reported at standard test

conditions. Accordingly, the value of Isc marked on

this module should be multiplied by a factor of 1.25

when determining component conductor ampacities,

fuse sizes, and size of controls connected to the PV

output.

Refer to Section 690-8 of the National Electrical

Code for an additional multiplying factor of 125%

(80% derating)which may be applicable. That

means, when determining the voltage rating,

conductor capacity, fuse rating, and photovoltaic

output control size, the parameters need to be

multiplied by the square of 1.25.

According to the max fusing rate of modules and

local electical installation standard, the parallel

connection of PV module arrays should use the

proper fuse to protect the circuit.

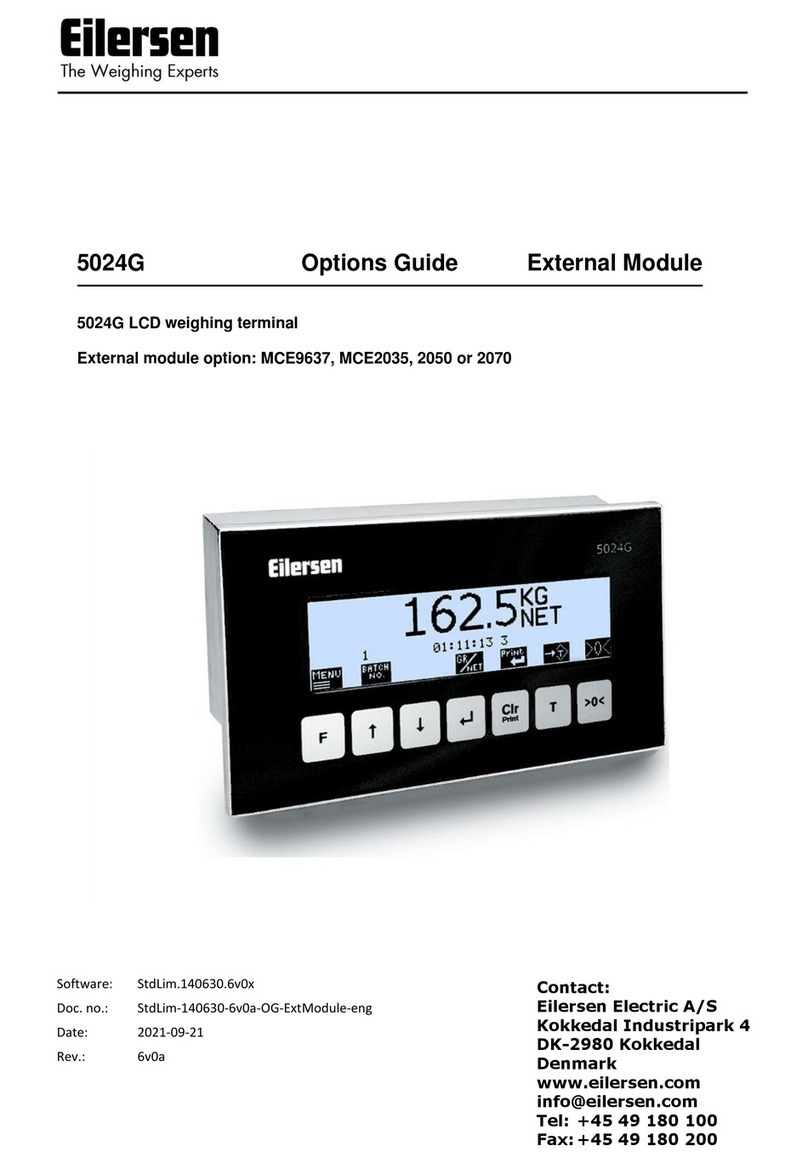

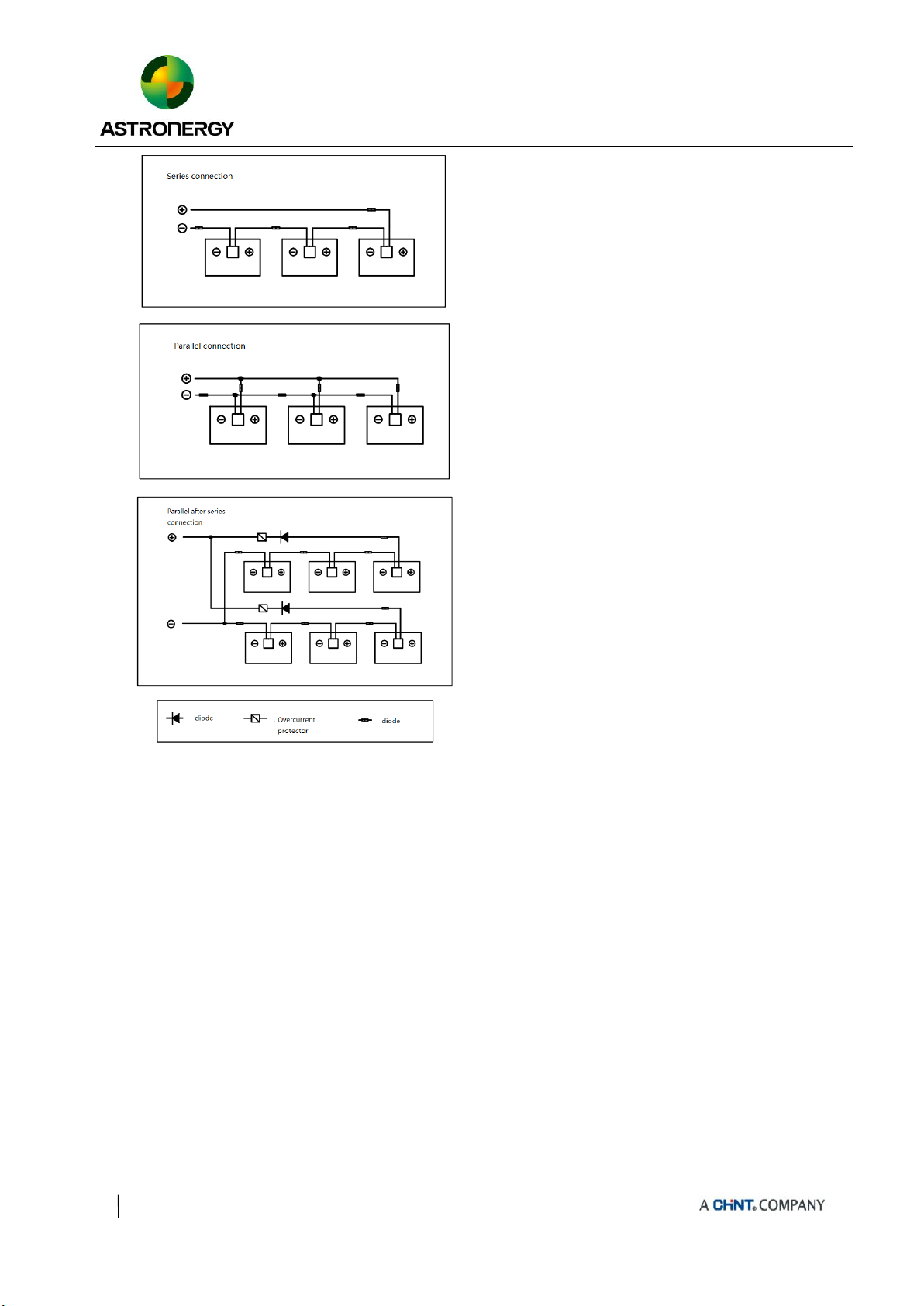

6.2 Electrical connection

In order to ensure the normal operation of the

system, when connecting photovoltaic modules or

connecting loads (such as inverters, batteries, etc.),

observe to ensure that the polarity of the cable is

connected correctly. If the PV module is not connected

correctly, the bypass diode may be damaged. Figure 12

shows the connection of photovoltaic modules in

series and parallel. PV photovoltaic modules can be

wired in series to increase the voltage. The series

connection is to connect the wiring from the positive

terminal of one photovoltaic module to the negative

terminal of the next photovoltaic module. PV

photovoltaic modules can be connected in parallel to

increase current. Parallel connection is to connect the

wiring from the positive terminal of one photovoltaic

module to the positive terminal of the next

photovoltaic module. If the PV module is not

connected correctly, the bypass diode may be

damaged.

17

Figure 12 Schematic diagram of electrical connection

!note

If one set of arrays is connected to another with the

opposite polarity, it will cause irreparable damage

to the product. Before connecting in parallel, be

sure to confirm the voltage and polarity of each

column. If the measurement finds that the polarity

between the columns is reversed or the voltage

difference is greater than 10V, you must check the

structure and configuration before making the

connection.

The number of photovoltaic modules in series and

parallel must be designed reasonably according to

the system configuration.

Photovoltaic modules of different electrical

performance models cannot be connected in a

string.

Special solar cables and connectors should be used

in the system, and all connections should be

securely tightened. The cable size should be 4mm2

(12 AWG) and must be able to withstand the

maximum open circuit voltage of the photovoltaic

system.

When the cable is fixed on the bracket, it is

necessary to avoid mechanical damage to the cable

or photovoltaic module, and do not press the cable

with force. To fix the cable through the proper way,

a specially designed tying coil and wire clip must

be used to fix it on the bracket. Avoid direct

sunlight and water soaking cables.

Please keep the connector dry and clean, and make

sure that the nut of the connector is tightened

before connecting. Do not connect the connector

when it is found that the connector is wet, dirty, or

in other bad conditions. Avoid direct sunlight and

immersion of the connector in water. Avoid the

connector falling on the ground or roof.

When the photovoltaic module is in a live state,

18

please do not plug or unplug the connector. When it

is necessary to open the connector, ensure that the

photovoltaic module is in a non-working state, and

must use professional unlocking tools and safety

protection measures. It is forbidden to pull or

damage the locking structure.

The junction box of the photovoltaic module

contains bypass diodes connected in parallel to the

battery string of the photovoltaic module. The

bypass diode in the junction box can avoid the

degradation of photovoltaic module performance

caused by shading or covering. Please refer to the

junction box diode specifications provided in the

relevant product specifications.

When a local hot spot phenomenon occurs due to

partial shading or covering of the photovoltaic

module, the diode in the junction box will start to

work, so that the photovoltaic module current will

no longer flow through the hot spot cell, thereby

limiting the heating and performance loss of the

photovoltaic module. When you suspect or find that

the diode is malfunctioning, please contact Chint,

please do not try to open the junction box cover by

yourself.

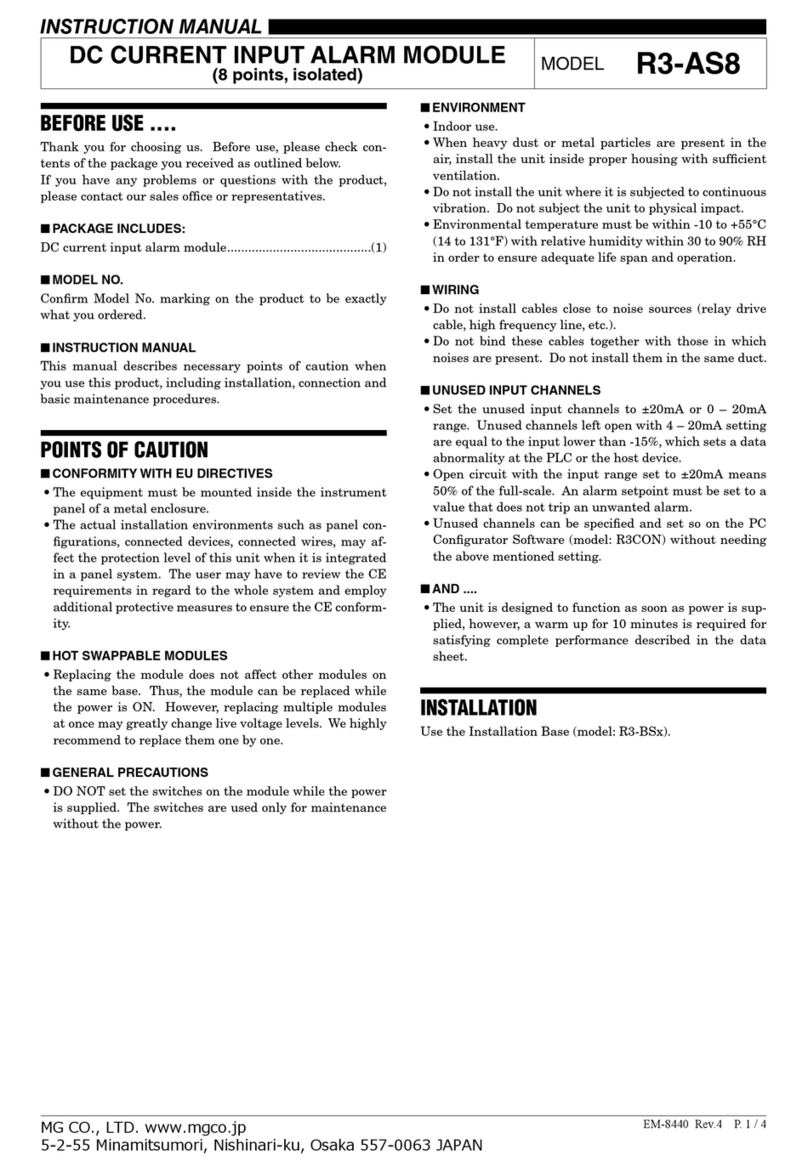

6.3 Grounded

Chint Solar modules use an anodic oxidized

aluminum frame to resist corrosion. So the frame of

modules should be connected to the equipment

grounding conductor to prevent thunder and electrical

shock. The grounding device should fully contact with

the inside of the aluminum alloy, and penetrate the

surface of the frame oxidation film.

The following is the specific grounding method,

as shown in Figure 13.

Figure 13 Use copper cables to ground the aluminum frame

The grounding requirements must be checked in

accordance with the applicable regulations and

standards before work is started.

Use the marked 5.5 mm grounding holes to ground

the anodized frame. Use one M5 nut, two M5 cut

washers, one M5 plain washer, one M5 spring

washer, and one M5 bolt and the copper wire. All

nuts, bolts, and washers are type M5 and should be

made of stainless steel.

Put the bolt through the cup washer and wrap the

copper wire around the bolt. (Note that the copper

wire cannot be attached directly to the aluminum.)

Put the bolt through the cut washer and then

19

through the hole in the aluminum frame.

Add the spring washer and nut on the other side of

the bolt and tighten to secure all parts. The

tightening torque should be 4~4.5 N•m.

!note

Approve the use of UL-467 certified bonding and

grounding devices, including Burndy (formerly

Wiley Electronics) Washer Electrical Equipment

Bonding (WEEB) and similar devices, such as

barbed washers, that meet the requirements of

UL-467 as suitable for electrical bonding and

grounding PV modules to PV mounting systems.

Other grounding methods may be allowable when

tested with the racking system per UL 2703

requirements.

Please don’t drill any additional grounding hole on

the frame of the modules.

The frame rails have pre-drilled holes marked with

a grounding sign. These holes should be used for

grounding purposes and should not be used for

mounting the modules.

7Maintenance

It is required to perform regular inspection and

maintenance of the modules, especially within

warranty scope. It is the user’s responsibility to the

report to the supplier regarding the damages found in

time.

7.1 Routine inspection

Regular inspections should be made to see if the

photovoltaic modules in the photovoltaic array are

damaged, such as glass breakage, cable breakage,

junction box damage, cell damage, backplane breakage

and other factors that lead to functional and safety

failures of photovoltaic modules. When the above

problems occur, the supplier must be notified in time

to replace the same type of photovoltaic modules.

It is recommended to perform a preventive

inspection every 6 months, and do not replace the

components of the photovoltaic module without

authorization. If electrical or mechanical performance

inspection or maintenance is required, it is

recommended that qualified professionals perform the

operation to avoid electric shock or personal injury.

Routine maintenance measures should be taken

to keep the photovoltaic modules free of snow, bird

droppings, seeds, pollen, leaves, branches, dust, stains,

etc.

7.2 Photovoltaic module cleaning

If the PV module has a sufficient tilt angle (at

least 15°), it is usually not necessary to clean the PV

module (rain will have a self-cleaning effect). If there

is a lot of dirt on the surface of the photovoltaic

module, which has seriously affected the power

generation, use water without detergent and a soft

sponge or brush to rinse the photovoltaic module array

when it is cool throughout the day. Do not scratch or

wipe the dust when it is dry, otherwise it will cause

20

tiny scratches. If there is snow, you can use a brush

with soft bristles to clean the surface of the

photovoltaic module.

For more detailed instructions related to cleaning

and maintenance, please refer to the "Photovoltaic

Module Cleaning Manual".

Modified version and date

Rev1.0, released in June 2018.

Rev1.2, released in August 2021.

Other manuals for Astronergy CHSM6610M

1

This manual suits for next models

17

Table of contents

Other CHINT Control Unit manuals