CHINT NS2-80B Installation instructions

NO:2020.04

Standard: IEC/EN 60947-2

IEC/EN 60947-4-1

NS2-80B

AC Motor Starter

User Instruction

Only professional technicians are allowed for installation and

maintenance.

Installation in any damp, condensed-phase environment with

inflammable and explosive gas is forbidden.

When the product is being installed or maintained, the power

must be switched off.

You are prohibited from touching the conductive part when the

product is operating.

1

2

3

4

Safety Warning

01

Environmental conditions

Ambient temp. (℃)

Hot and humid

atmospheric conditions

-5℃ 40℃, average temperature should not

exceed +35℃ within 24h

~+

Relative humidity should not exceed 50% at

+40℃; up to 90% at +20℃;

Pollution class/installation category

Altitude No influence below 2000m,

Class 3/Ⅲ

Main technical parameters

The Purpose of Use

1

NS2-80B AC motor starter is applicable to circuits with frequency of AC

50Hz or 60Hz, rated operating voltage up to 415V and current up to 80A. It

is used for infrequent start control of 3-phase squirrel cage asynchronous

motor and it can protect motor from short circuit, overload and loss of

phase. The product can also be used for distribution line protection and

infrequent load transfer or used as isolator.

NS2-80B AC motor starter can be added with a set of side mounted

auxiliary contacts: AU11(1NO+1NC) or AU20(2NO). See product catalog or

product itself for technical parameters of auxiliary contacts.

Main Technical Parameters

2

Table 1 Main technical parameters

No

Frame

size

rated

current

Inm

A

Release

rated

current

In

A

Adjustment

range of

thermal

element

setting

current

A

Release

setting

current

value for

short

circuit

current

Ir A

Rated ultimate short

circuit breaking capacity

Icu, Rated operating

short circuit breaking

capacity Ics kA

Arcing

distance

mm

400/415V

1

2

3

4

80 50

25

40

63

80

16-25

25-40

40-63

56-80

350

560

882

1120

Icu

15

15

15

15

Ics

7.5

7.5

7.5

7.5

02

Table 2 Technical parameters and performance

Content

Rated insulation voltage Ui(V)

Rated voltage Ue(V)

Rated frequency (Hz)

Rated impulse withstand voltage Uimp(kV)

Enclosure protection class

Rated duty system

Conductor (wire/conducting bar) strip length

before being inserted into terminal (mm)

Conductor (wire/conducting bar)

2

sectional area mm

Allowable maximum number of conductor

(wire/conducting bar) to be inserted

Size of fixing screws (or bolts) at wiring end

Tightening torque for fixing screws at wiring end

(N.m)

Operation frequency (times/hour)

690V

400/415

50/60Hz

6kV

IP20

Long term duty system

15

4~25

2

M8

6

≤25

No. Parameters

1

2

3

4

5

6

7

8

9

10

11

12

03

x times of setting current

Time(s)

10000

1000

100

10

1

0.1

0.01

0.001

11

22

33

11.5 210 100

(1) Start from cold state, 3-pole

(2) Start from cold state, 2-pole

(3) Start from thermal state, 3-pole

Figure 1 Time – current characteristic curve (20℃)

04

Installation

3

3.1 Installation

14 .8±0 .35

5±0. 12

72 .5±0 .43

78±0 .4 3

35 .7

OFF

1/L1 3/L2 5/L3

2/L1 4/L2 6/L3

63 .5±0 .3 7

11 2. 5±0. 57

IEC 60947-2 60947-4-1

2004/08/04-010

Test

NS2-80B

56-80A

68

56

80

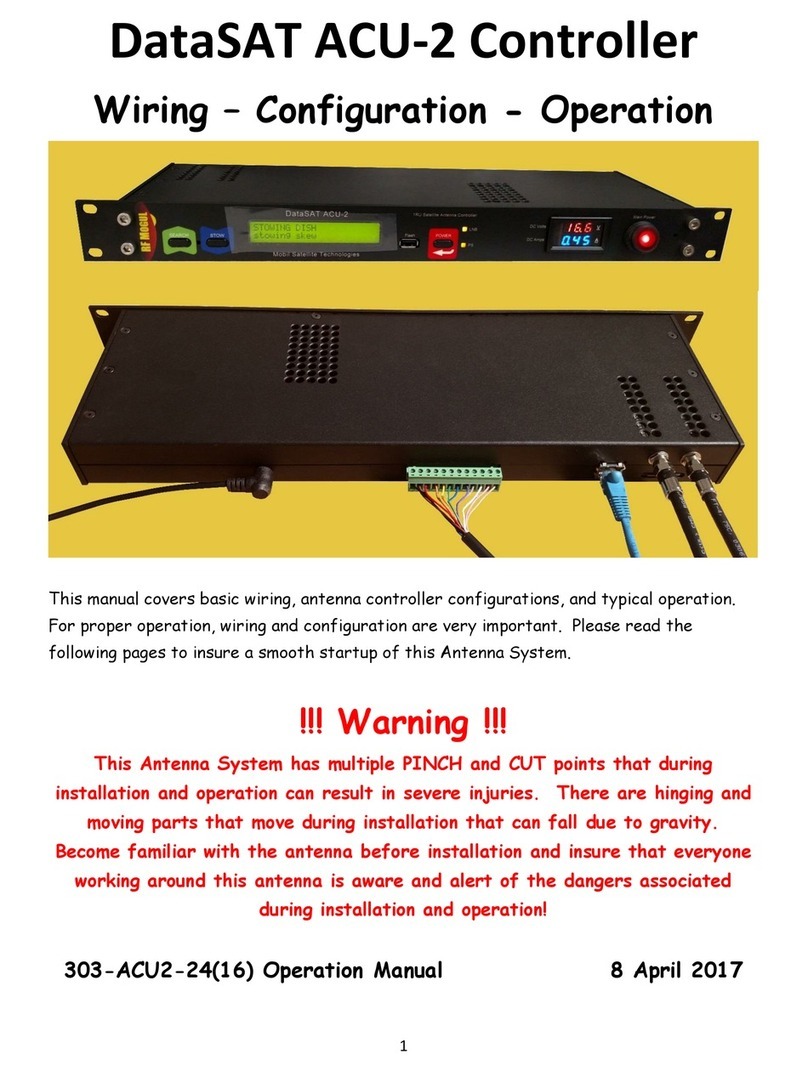

Figure 2 Overall and installation dimensions of NS2-80B

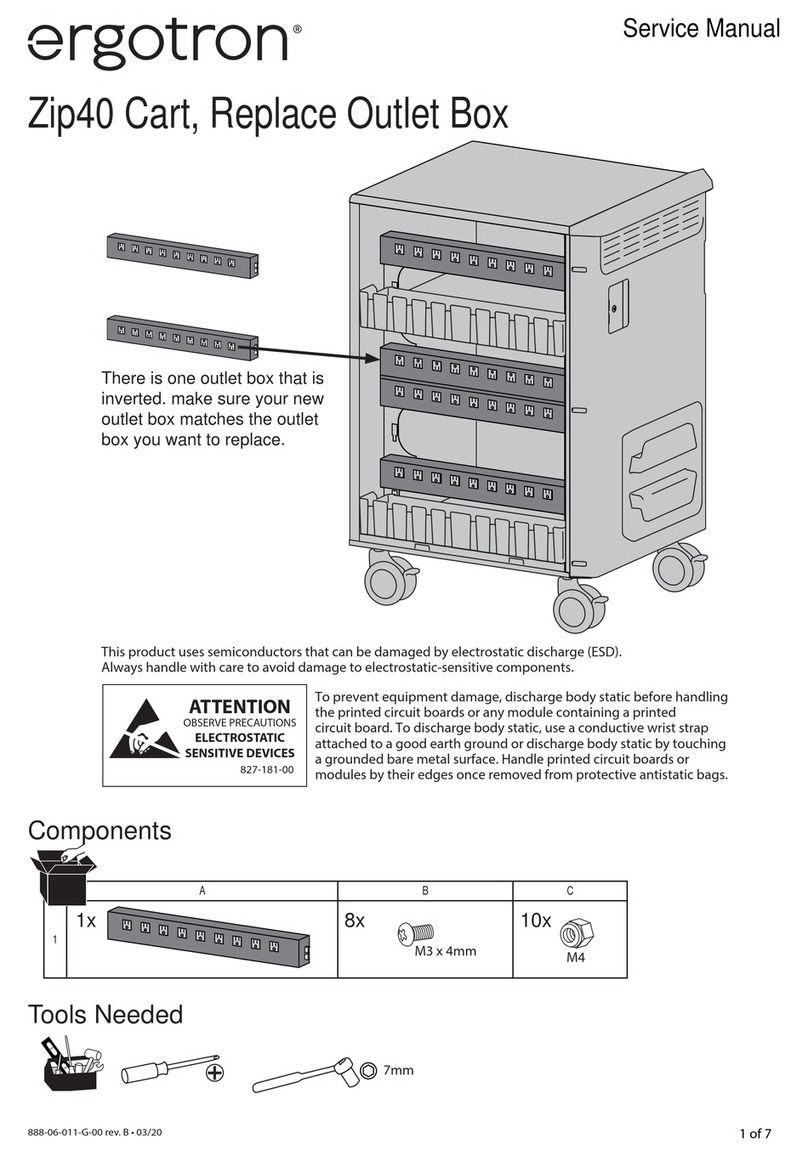

See Figure 3 for assembly procedure of starter and auxiliary contacts

when the starter is disconnected:

a) Confirm the starter is disconnected (the red OFF button is press

down);

b) Hang the front end of the auxiliary contacts on the slot at the left

front of the starter and move the auxiliary contacts towards the starter;

05

c) Before the extension bar at the center of the auxiliary contacts

touches the starter, use a screwdriver to push the central slot of the auxiliary

contacts so it stays at the top;

d) Push the auxiliary contacts towards the starter, press and hold the

blue button at the end of the auxiliary contacts and fit it into the starter;

e) After fitting the auxiliary contacts, break and make the starter for 5 –

10 times, check if the slot at the center of the auxiliary contacts can move

together with the starter reliably. In the meantime, check if the auxiliary

contacts are powered-on normally; if there is any abnormality, repeat step a)

– step d).

a)b)

c)d)

Figure 3 Assembley method for NS2-AU(80B)

06

Table 3 Connecting wire for operating current

3.2 Wiring

Use single core PVC insulated copper conductor for wiring, see Table 3

for sectional area of the wire.

12 I≤20<

20 I≤25<

2.5

4.0

25 I≤32<

32 I≤50<

50 I≤65<

65 I≤80<

6.0

10

16

25

Rated current

(setting current value of thermal element)

Ie A

Sectional area of

connecting wire

2

mm

3.3 Adjustment and inspection

3.3.1 Check if the rated voltage of the starter Ue is consistent with the actual

control voltage of power.

3.3.2 Check if the rated operating current of the starter is within its setting

current range.

3.3.3 Check if the starter can operate smoothly: press down the green

button of the starter or turn the knob to ON position, flip the guide plate

beside the TEST mark on the cover according to the direction shown by the

arrow. You can hear the operation sound of the contact, and the green

button will bounce back or the knob will be turned to OFF position. Replace

the starter if there is any abnormality.

3.3.4 The operating current of the starter (setting current value of thermal

element) should be determined by the rated current of the motor. If the

setting current value between two scales is required, turn the cam slightly

accordingly. User can make adjustment during operation.

07

Table 4 Model and melt current of the backup fuse of starter

3.4 Coordination of protection

If the short-circuit current is not bigger than the rated ultimate short

circuit breaking capacity of the starter, the protection should be provided by

the starter; if the short circuit current is bigger than the rated ultimate

short-circuit breaking capacity of the starter, the protection should be

provided by the fuse or circuit breaker. See Table 4 for model and melt

current of the backup fuse of starter.

1

2

3

4

25

40

63

80

16-25

25-40

40-63

56-80

250

250

315

315

315

315

400

400

No.

Rated

current

In A

Rated operating

current (adjustment

range of thermal

element setting

current)

Melt current

(backup fuse is only needed when Isc>Icu)

400/415V

aM A gL/gG a

Maintenance

4

Clean the dust on the motor starter timely. Conduct product test and

maintenance every half a year to ensure the smooth operation of the

product and the good contact of NO and NC contacts. Tighten the terminal

screws with specified torque and align the load protection capability of the

motor starter according to commissioning requirements.

Be careful when handling and installing the starter. It is prohibited to

move the product by crane with strong impact so that the product will not

be damaged and its protection characteristics will not change.

08

Environmental Protection

5

In order to protect the environment, the product or product parts

should be disposed of according to the industrial waste treatment process,

or be sent to the recycling station for assortment, dismantling and recycling

according to local regulations

Table 5 Analysis and Troubleshooting of Faults

Symptoms Cause analysis Troubleshooting method and precautions

Misoperation

of starter

Starter

does not

operate

The setting current value

of the starter is smaller

than the actual operating

current of the motor.

Strong shock or vibration

Fine tune the cam to match the set current

matches the actual motor current.

Check installation status and conduct

troubleshooting. Do not place the product in

environment with strong shock or vibration.

Frequent start of motor The start frequency of the motor should not

exceed 25 times per hour.

The sectional area of the

connecting wire is too

small.

Use standard wire according to Table 4.

The setting current value

of the starter is bigger

than the rated current

value of the motor.

Fine tune the cam to match the set current

matches the actual motor current.

The sectional area of the

connecting wire is too

big.

Use standard wire according to Table 3.

QC PASS

Test date: Please see the packing

ZHEJIANG CHINT ELECTRICS CO.,LTD.

NS2-80B

AC Motor Starter

IEC/EN 60947-2

IEC/EN 60947-4-1

Check 28

09

NS2-80B

AC Motor Starter

User Instruction

Zhejiang Chint Electrics Co., Ltd.

Add: No.1, CHINT Road, CHINT Industrial Zone,North Baixiang,

Yueqing, Zhejiang 325603,P.R.China

E-mail: global-sales@chint.com

Website: http://en.chint.com

Table of contents

Other CHINT Controllers manuals