CHINT NQ2 Series Installation instructions

NO:2020.04

Standard: IEC/EN 60947-4-1

User Instruction

NQ2 Series

Electromagnetic Starter

Safety Warning

1

2

3

4

Only professional technicians are allowed for installation and maintenance;

Installation in any damp, condensed-phase environment with inflammable

and explosive gas is forbidden.

When the product is being installed or maintained, the power must be

switched off.

You are prohibited from touching the conductive part when the product is

operating.

1

2

Main Use Purpose and Application Scope

NQ2 series electromagnetic starter (hereinafter referred to as starter) is mainly used in electric circuits

with AC frequency of 50Hz (or 60Hz), rated operating voltage up to 660V and rated operating current up to

68A for controlling the direct start and stop of electric motor. Starter with thermal overload relay

(hereinafter referred to as thermal relay) can be used to protect the overload and phase loss of electric

motor.

Key Technical Parameters

01

NQ2 Series Electromagnetic Starter

Table 1 Ambient Conditions

Ambient temperature (℃)

Hot and humid atmospheric conditions

Altitude

Pollution class/installation category

-5℃~+40℃, average temp. not exceeding +35℃ within 24h

+40℃, RH not exceeding 50% and may reach 90% at +20℃

No influence below 2,000m

Class 3/Ⅲ

Table 2 Key Technical Parameters of Starter (I)

AC-3

660V 380V 220V

Model

Conventional

free air

thermal

current of

shell frame,

Ith (A)

Rated

operating

current

of shell

frame,

Ie (A)

Rated power control of

shell frame, Pe (kW) AC

contactor

model

assembed

Thermal

relay

model

assembled

Setting

current

range of

thermal

relay (A)

Button

type of

starter

with

button

0.1~0.16

0.16~0.25

0.25~0.4

0.4~0.63

0.63~1

1~1.6

1.25~2

1.6~2.5

2.5~4

4~6

5.5~8

7~10

9~13

12~18

17~25

23~32

28~36

NQ2-15□/1

NQ2-15□/2

NQ2-15□/3

NQ2-15□/4

13

18

25

36

12

18

25

32

7.5

10

15

18.5

5.5

7.5

11

15

3

4

5.5

7.5

NC1-12

NC1-18

NC1-25

NC1-32

NR2-25

NR2-36

NP2-EA31

(start)

NP2-EA42

(stop)

NQ2 Series Electromagnetic Starter

02

AC-3

660V 380V 220V

Model

Conventional

free air

thermal

current of

shell frame,

Ith (A)

Rated

operating

current

of shell

frame,

Ie (A)

Rated power control of

shell frame, Pe (kW) AC

contactor

model

assembed

Thermal

relay

model

assembled

Setting

current

range of

thermal

relay (A)

Button

type of

starter

with

button

23~32

30~40

37~50

48~65

55~70

63~80

80~93

NQ2-33□/1

NQ2-33□/2

65

95

52

68

33

37

25

33

15

25

NC1-65

NC1-95

NR2-93

NP2-EA31

(start)

NP2-EA42

(stop)

Table 3 Key Technical Parameters of Starter (II)

Model

Use type

Rated insulation voltage, Ui (V)

Rated impluse withstand voltage, Uimp (kV)

NQ2-15/1~4

NQ2-15N/1~4

NQ2-15NB/1~4

NQ2-15P/1~4

NQ2-33/1~2

NQ2-33P/1~2

(85%~110%)Us

(20%~75% Us)

50

IP40

Eight-hour duty, Uninterrupted duty, Intermittent periodic duty

Main circuit: AC-3, AC-4; auxiliary circuit: AC-15

690

6

1200

300

600

300

50

10

100

20

1000

50

10

100 600 100

AC-3

AC-4

AC-3

AC-4

Operational frequency

(times/h)

Electrical life

4

( 10 times)×

Mechanical life ( times)

4

×10

Pull-in voltage

Release voltage

Operating range

Rated conditional short-circuit current, Iq(kA)

(corresponds to 380V testing voltage)

Enclosure protection class

Rated duties

Table 2 (contintued)

03

NQ2 Series Electromagnetic Starter

3

Installation

1) See Fig. 1-Fig. 4 and Table 4 for the outline and installation size of the starter.

Table 4 Outline and Installation Size

Model

Maximum

outline size

(A×B×C)

NQ2-15 NQ2-15N NQ2-15NB NQ2-15P NQ2-33 NQ2-33P

Unit: mm

n×Φ

Reference picture

Installation size

(D×E)

116×207×127

60×150

176×207×127

130×150

176×207×127

130×150

116×207×138

60×150

167×296×162

105×205

167×296×172

105×205

3× 6

See Fig. 1

Φ3× 6

See Fig. 2

Φ4× 6.2

See Fig. 3

Φ4× 6.2

See Fig. 4

Φ

n×

A

D

C

B

E

B

CA

Dn×φ

E

φ

Figure 1 Outline and installation size of

NQ2-15, 15N, 15NB

Figure 2 Outline and installation size of

NQ2-15P

Figure 3 Outline and installation size of

NQ2-33

Figure 4 Outline and installation size of

NQ2-33P

n×

n×φφ

B

CA

D

E

B

CA

D

E

CA

D

B

E

NQ2 Series Electromagnetic Starter

04

2) Inspection of operating flexibility of the thermal relay inside the starter

Open the cover of the thermal relay. Press the blue Reset button using a small screwdriver and rotate it

90° clockwise so that the relay is in the Automatic Reset status (Letter A on the Reset button is in vertical

alignment with the reference point). Then, use the small screwdriver to press the red Test button beside

TEST downward vertically. You can hear the operating sound of the contact, and the indicator column is

red. Loosen your hold on the screwdriver, you can hear the sound of the reset contact and the indicator

column resumes its original status (Alternatively, you can use a multimeter). If any abonormality occurs

during the testing, replace it immediately. The panel layout of the thermal relay is shown in Fig. 5.

Current dial Indicator column Cover

Stop button

Reset button

Test button

2/T1

98 97 96 95

NCNO

4/T2 6/T3

Reference point

Manual reset

Automatic reset

Figure 5 Panel layout of the thermal relay

3) Starter wiring diagram

When the product leaves the factory, the control circuits are wired on the premises that the voltage of

the starter is the same as that of the main circuit. Once the main circuit is powered on, the starter can

operate without additional wiring. The starter cannot control single-phase motor unless the main circuits of

any two of its phases are connected in series. In case the control circuit voltage is different from the main

circuit voltage, disconnect the two wires on the main circuit and connect them to the control power supply.

See Fig. 6 – Fig. 9 for the starter wiring diagram.

Figure 6 Control circuit voltage same as

main circuit voltage (three-phase)

Figure 7 Control circuit voltage different from

main circuit voltage (three-phase)

L1 L3 L5

FU1

1 3 5

246

1 3 5

246

UV W

M

3~

KM

FR KM

FR

95

96

A1

A2 13

14

KM

L1 L3 L5

FU1

1 3 5

246

1 3 5

246

UV W

M

3~

KM

FR KM

FR

95

96

A1

A2 13

14

KM

additional power supply

NQ2 Series Electromagnetic Starter

05

Figure 8 Control circuit voltage same as

main circuit voltage (single-phase)

Figure 9 Control circuit voltage different from

main circuit voltage (single-phase)

4) Starter installation procedure and method

See Fig. 10 for starter installation instructions.

Cover

Base

Grounding

screws

Connecting

screws

1 4

2

1.Unscrew connecting screws on the base and

cover counterclockwise, and open the cover;

2.Use some tool to pierce the rubber seal rings

on both sides for later wiring;

3.Connect the main circuit, control circuit and

grounding screws, adjust the setting current

value of the thermal relay; and install the

product according to the requirements;

4.Put the cover on and tighten the connecting

screws clockwise.

Figure 10 Starter installation diagram

Note 1: The connecting wires of the incoming and outgoing lines of the main circuit must

be single-core PVC insulated copper cables with prefabricated terminal, whose cross-

sectional area is specified in Table 5; the cross-sectional area of connecting wires of the

auxiliary circuit should be 1mm². Tighten all the screws during wiring to prevent the starter

from slipping and fall due to vibration. Remove the residual of foreign objects to prevent

the moving parts of the contactor from getting stuck and the occurrence of short-circuit

accidents.

Note 2: Choose screws no smaller than M5 according to the size of the mounting hole.

Add seal ring to the screw to ensure enclosure protection class.

L

FU1

1 3 5

246

1 3 5

246

U1

M

1~

KM

FR KM

FR

95

96

A1

A2 13

14

KM

N

U2

L

FU1

1 3 5

246

1 3 5

246

U1

M

1~

KM

FR KM

FR

95

96

A1

A2 13

14

KM

N

U2

additional power supply

3

NQ2 Series Electromagnetic Starter

06

Table 5 Cross-sectional area of connecting wires of the main circuit

0 I≤8

8 I≤12

12 I≤20

20 I≤25

25 I≤32

32 I≤50

50 I≤65

65 I≤85

85 I≤100

<

<

<

<

<

<

<

<

<

Rated operating current of motor, I (A) Cross-sectional area of connecting wires of main circuit (mm²)

1

1.5

2.5

4

6

10

16

25

35

4

Maintenance

Check whether the thermal relay inside the starter operates reliably on a regular basis (once a month)

by adjusting the current dial and reducing the setting current until the relay operates. Then, restore the

current dial to the original position.

Note: Do not dismantle and repair the product at will. Once the product is found damaged, replace it

immediately.

Table 6 Examples of Fault Analysis and Troubleshooting

Cause anaylsis Troubleshooting method and precautionsSymptoms

Fine tune the current dial so that the product’s set

current matches the actual current of the motor.

The setting current value of thermal relay is smaller

than the actual operating current of the motor.

Inspect the installation site and troubleshoot to

prevent the product from being placed in an

environment where there is strong shock or

viberation.

Strong shock or viberation

The motor start requires a certain interval, with

frequency no more than 30 times per hour.

Frequent starts of the motor

Choose standard wires according to Table 5.

The cross-sectional area of connecting wires of the

main circuit is too small.

The starter

mis-operates

before being

overloaded

The setting current value of thermal relay is bigger

than the actual operating current of the motor.

Fine tune the current dial so that the product’s set

current matches the actual current of the motor.

The cross-sectional area of connecting wires

of the main circuit is too big. Choose standard wires according to Table 5.

The starter

fails to

operate after

being

overloaded

The wiring of the starter becomes loose or falls

The coil voltage is too low or voltage fluctuation is

too big.

The setting current value of thermal relay is too

small which leads to the failure of product reset.

Tighten the connecting screws and check whether

the screws are loosen before use.

Increase the power supply voltage or add stabilized

voltage equipment.

Fine tune the current dial toward the bigger current

direction.

The starter

fails to

operate

QC PASS

Test date: Please see the packing

ZHEJIANG CHINT ELECTRICS CO., LTD.

NQ2 Series

Electromagnetic Starter

IEC/EN 60947-4-1

Check 18

07

NQ2 Series Electromagnetic Starter

5

Environmental Protection

In order to protect the environment, the product or product parts should be disposed of according to

the industrial waste treatment process, or be sent to the recycling station for assortment, dismantling and

recycling.

NQ2 Series

Electromagnetic Starter

User Instruction

Zhejiang Chint Electrics Co., Ltd.

Add: No.1, CHINT Road, CHINT Industrial Zone,North Baixiang,

Yueqing, Zhejiang 325603,P.R.China

E-mail: global-sales@chint.com

Website: http://en.chint.com

Table of contents

Other CHINT Controllers manuals

Popular Controllers manuals by other brands

Distech Controls

Distech Controls DA-088N Series Hardware installation guide

Galcon

Galcon 7001D Installation and operating instructions

Schaudt

Schaudt EBL 99 L instruction manual

Leviton

Leviton Decora HCC2D installation instructions

Erreka

Erreka ATLAS G 605 Installer manual

AES

AES e-DIAGNOSTIC quick start guide

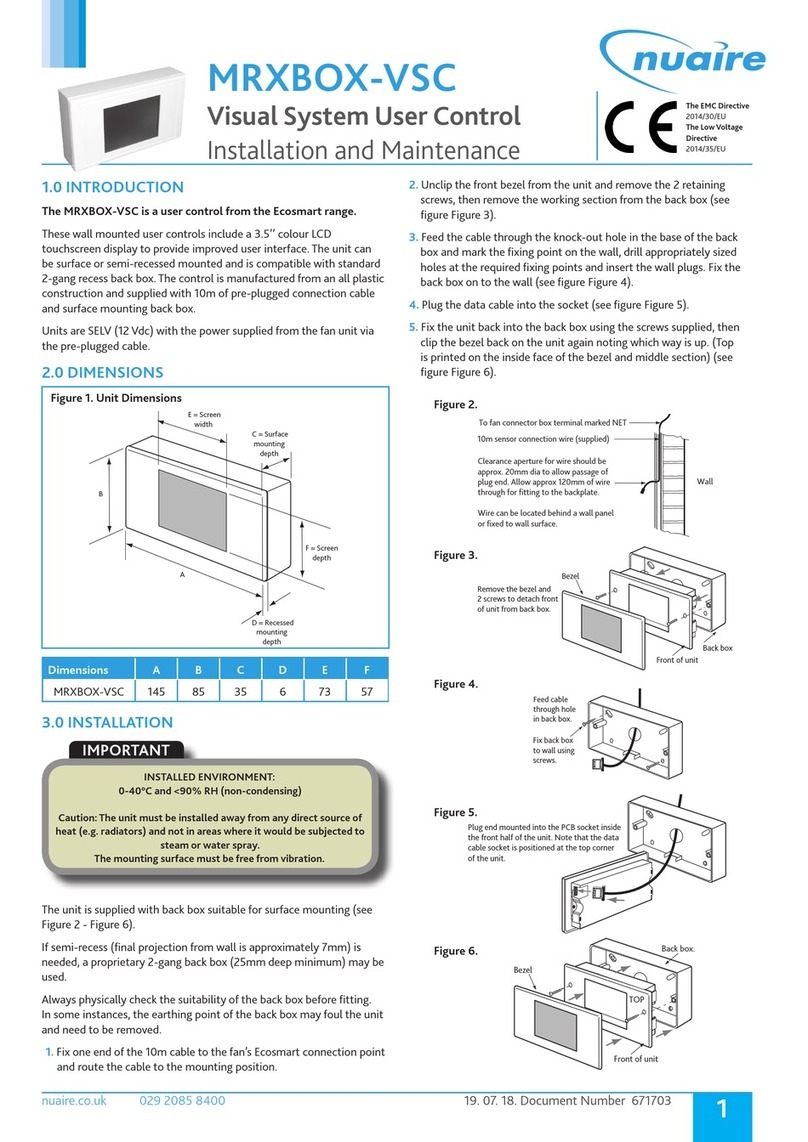

NuAire

NuAire MRXBOX-VSC Installation and Maintenance

Philips

Philips Dynalite DDLE802 installation instructions

Johnson Controls

Johnson Controls VMA1200 Series Troubleshooting

Nuvoton

Nuvoton ARM Cortex-M user manual

GAUGEMASTER

GAUGEMASTER TECH 6 quick start guide

Samson

Samson 42-37 Mounting and operating instructions