CHINT TNDZ Series Installation instructions

TNDZ,TNSZ

AC AUTOMATIC VOLTAGE REGULATORS

SERIES PILLAR TYPE

User Instruction

NO:2020.10

Safety Warning

1

2

3

4

5

6

Only professional technicians are allowed for installation and maintenance;

Installation in any damp, condensation environment with inflammable and explosive gas is

forbidden;

When the product is being installed or maintained, the power must be switched off;

You are prohibited from touching the conductive part when the product is operating;

Do not install the product in a place where the gaseous medium can corrode the metal or

damage the insulation.

Column AC automatic voltage regulators are prohibited from being used in parallel.

TN Z -

Rated capacity: kVA

Pillar iron core

Number of phase: D means single phase and S means three phases.

Automatic voltage regulator

01

1

General Use

TNDZ and TNSZ series pillar type AC automatic voltage regulators (hereinafter referred to as the voltage regulator) are

mainly used in various places where the load voltage needs to be stablized. When the supply voltage fluctuates, the voltage

regulator can automatically stabilize the load voltage within the deviation range of the rated value. They are suitable for the

areas with large fluctuation of grid voltage or large seasonal variation of grid voltage (long-term low or high grid voltage), by

providing stable power supply for load to ensure the normal operation of powered devices.

TNDZ、TNSZ series pillar type AC automatic voltage regulators

2

Type Designation and Implications

3

Use Conditions, Installation and Transportation and Storage Conditions

3.1 Environmental conditions

3.1.1 The altitude of the installation site must not exceed 2,000m.

3.1.2 Ambient temperature

40 °C,and the average temperature within 24 hours shall not exceed 35 °C

°C.

3.2 Installation conditions

3.2.1 For indoors use, and the products cannot be used in parallel; the inclination of the mounting surface to the horizontal

plane must not exceed 5°; the installation site should be free from shaking and shock.

3.2.2 The waveform of the supply voltage should be approximately sinusoidal. For a three-phase regulator, the three-phase

input supply voltages should be approximately symmetrical.

3.3 Transportation and storage conditions

During the transportation, the the product shall not be placed upside down, placed on the side or exposed to rain, and

shall not be subject to severe vibration and impact.

The voltage regulator must be stored in an environment where there is no rain or snow, the air circulation is good, there is

no exposure to sunlight or corrosive gases, the relative humidity (at 25 ° C) is not greater than 95%, and the temperature is

between -25 ° C and 55 ° C.

a. The upper limit of ambient air temperature is .

b. The lower limit of ambient air temperature -5

4

Main Technical Parameters and Performance

4.1 For the basic specifications and performance parameters of the voltage regulator, please refer to Table 1

Bmax Dmax

Emax

Dmax

Bmax

Emax

TNDZ-30

TNDZ-50

TNSZ-30

TNSZ-50

TNSZ-75

TNSZ-100

TNSZ-150

TNSZ-180

TNSZ-200

TNSZ-225

TNSZ-250

TNSZ-300

TNSZ-320

TNSZ-350

TNSZ-400

TNSZ-450

TNSZ-500

TNSZ-600

TNSZ-800

TNSZ-1000

30

50

30

50

75

100

150

180

200

225

250

300

320

350

400

450

500

600

800

1000

136

227

46

76

114

152

228

273

304

342

380

456

486

532

608

684

760

912

1215

1519

150

503

176~264 220 ±5

304~456 380 ±5

02

TNDZ、TNSZ series pillar type AC automatic voltage regulators

Specifications

and models Rated

capacity (kVA) Rated output

current (A) Number

of phase Frequency

(Hz) Input voltage

range (V) Output voltage

(V) Voltage-stabilized

precision (%)

Technical

Parameters

Table 1 Main Technical Parameters

5

Structural Features and Working Principle

5.1 This series of voltage regulators consists of a column regulator, a compensating transformer and a controller or a

control circuit, which constitute a closed-loop control system. It is an electrical device that can stabilize the output voltage

through automatic regulation.

5.2 The voltage regulator has a mains function and a voltage regulation function. For details on functions, please refer to

7.4 Commissioning.

5.3 For the working principle diagram of the voltage regulator, please refer to Appendix 1 Electrical Schematic Diagram

10~14.

6

Overall Size

6.1 The overall sizes of TNSZ series are shown in Fig. 1 and Fig. 2.

Figure 1 Overall Size of TNSZ-30~320 Product Figure 2 Overall Size of TNSZ-350~1000

6.2 Refer to Table 2 for the overall sizes of the products

DmaxBmax Emax

TNDZ-30

TNDZ-50

TNSZ-30

TNSZ-50

TNSZ-75

TNSZ-100

TNSZ-150

TNSZ-180

TNSZ-200

TNSZ-225

TNSZ-250

TNSZ-300

TNSZ-320

TNSZ-350

TNSZ-400

TNSZ-450

TNSZ-500

TNSZ-600

TNSZ-800

TNSZ-1000

610

650

570

610

650

650

760

1400

1400

1400

1400

1420

1150X3

1150X3

900

900

900

900

900

900

820

880

790

820

880

880

1100

1070

1070

1070

1070

1090

970

970

1190

1190

1190

1190

1190

1190

1150

1210

1050

1150

1210

1210

1300

2250

2250

2250

2250

2300

2300

2300

1550

1550

1550

1550

1550

1550

Input and output line entrance hole Input power terminal

Output

terminal Neutral wire common terminal,must

be connected to the neutral wire

a

b

c

N

input

(Directly connected to the

inputerminal of the circuit breaker)

(i.e. the input power is

three-phasefour-wire system)

03

TNDZ、TNSZ series pillar type AC automatic voltage regulators

Table 2 Overall Sizes of TNDZ (DBW) and TNSZ (SBW) Series Products

Model Overall Size (mm)

Note: The overall and installation sizes are subject to the change without further notice. The data in the table are

for reference only.

7

Installation, Commissioning and Operation

7.1 Appearance inspection

7.1.1 The parts of the voltage regulator should be intact and the fixtures should be firm and reliable.

7.1.2 The electric brush and the coil should be in good contact with no shortage or damage.

7.1.3 Remove the spare parts from the product and keep them properly.

7.2 Wiring description (see the wiring diagram of Figs. 3, 4, 5and6 )

Figure 3 TNSZ-30 150 Wiring Diagram~

Input terminal Output terminal

TNSZ-Column type AC automatic voltage regulator

(input must be

connectedto the

neutral wire, ie.

theinput power

supply isthree-phase

four-wire system)

04

TNDZ、TNSZ series pillar type AC automatic voltage regulators

Figure 4 TNSZ-180 320 Wiring Diagram~

Figure 5 Tnsz-350 600wiring Diagram~

Input and output line entrance hole

Input power terminal

Output

terminal

Neutral wire common terminal,must

be connected to the neutral wire

(Directly connected to the

inputerminal of the circuit breaker)

(i.e. the input power is

three-phasefour-wire system)

(input must be

connectedto the

neutral wire, ie.

theinput power

supply isthree-phase

four-wire system)

Output terminal

TNSZ-Column type AC automatic voltage regulator

TNSZ-Column type AC automatic voltage regulator

TNSZ-Column type AC automatic voltage regulator

Input terminal

Figure 6 TNSZ-800 1000 Wiring Diagram~

7.2.1 Select the cable with appropriate wire diameter, connect the power supply to the input terminal of the voltage

regulator, and the neutral wire must be connected.

7.2.2 The enclosure must be reliably grounded.

7.3 Inspection before power connection

7.3.1 The input supply voltage of the voltage regulator should be consistent with the input voltage range on the nameplate.

05

TNDZ、TNSZ series pillar type AC automatic voltage regulators

OUTPUT

VOLTAGE

INPUT

VOLTAGE

Ua Uab OUTPUT

CURRENT(a)

v

~A

~

v

~A

~

Ub Ubc OUTPUT

CURRENT(b)

Uc Uca OUTPUT

CURRENT(c)

v

~A

~

UNDER

VOLTAGE

OVER

VOLTAGE

7.3.2 It is prohibited from phase loss during using.

7.4

7.4.1 Commissioning of TNSZ-30~320 product

a)TNSZ-30~320:Do not load the product for the time being after it is powered on as required. Turn the “Mains/Voltage

Stabilization" switch to the "Voltage Stabilization" position and close the circuit breaker switch on, then the voltage regulator will

automatically output the regulated voltage; press the "Voltage Conversion" button on the instrument panel to switch and check

the input voltage, which should be within the input voltage range specified on the nameplate; if the mains function is required,

turn the“Mains/Voltage Stabilization" buttonto the “Mains” position, then the voltage regulator will directly output the mains

voltage.

b)TNSZ-150~320:Turn the “Manual/Automatic Transfer” switch to the “Manual”position, Turn the “Mains/Voltage

Stabilization" switch to the "Voltage Stabilization" position and close the circuit breaker switch on . The voltage regulator delays

the output, press the “Step up” or “Step down” button to adjust the output voltage of the voltage regulator. When you

select the manual voltage regulation mode, the product has no voltage regulation function and the output voltage may be

higher or lower than the rated value. Please pay attention to the influence ofoutput voltage change on the load. When you turn

the “Manual/Automatic Transfer” switch to the “Automatic” position, the voltage regulator returns to the automatic

regulation state.

TNSZ-30~320 For the schematic diagram of the LCD display of product, please refer to Figure 7.

Commissioning (See Appendix I Electrical Schematic Diagrams )9 ~ 14

Figure 7 Schematic Diagram of the LCD Display of NSZ-30~320

7.4.2 Commissioning of TNSZ-350~600 product

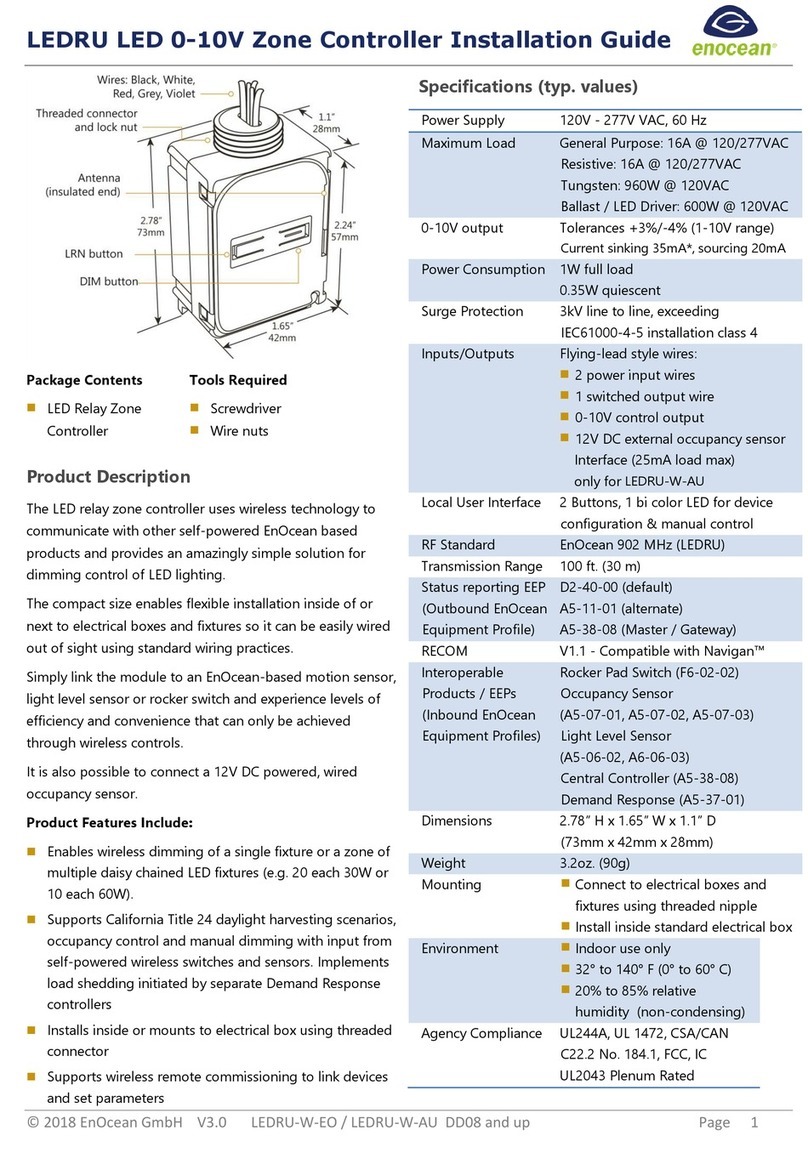

Figure 8 Schematic Diagram of TNSZ-350~600 Panel

Input voltage Output current Output voltage

MANUAL AUTOMATIC

AUTOMATIC VOLTAGE STABILIZATION

STOP

MAINS

SELF-RESET

MANUAL/AUTOMATIC Transfer

Power Supply Indicator

VOLTAGE STABILIZATION INDICATOR FAULT INDICATION

MAINS INDICATOR

STEP UP STEP DOWN STOP

VOLTAGE STABILIZATION

MAINS

Voltage Conversion

AB C

AB C

06

TNDZ、TNSZ series pillar type AC automatic voltage regulators

a)Do not load the product for the time being after it is powered on as required. First, stop the “Self-reset” switch on the

panel at the “Stop” position, and stop the “Manual/Automatic” switch at the “Automatic” positon (the arrow points to the

automatic position), as shown in Figure 8 Schematic Diagram of TNSZ-350~600 Panel.

b)Open the panel (front door), first close the small circuit breaker on the control panel, then close the circuit breaker switch

on the input side, and the “Power Supply Indicator” light is on.

c)Press the "Mains" button on the panel, the “Mains Indicator" light is on, the mains contactor and the output AC

contactor are connected, and the mains is directly output (without the voltage regulation function). At this time, the product has

no overvoltage, under-voltage and delay protection; press the “Stop” button on the panel, the mains contactor and the

output AC contactor are disconnected, the mains indicator light is off; press the “Voltage Stabilization” button, the voltage

stabilization contactor is closed, after 4s~8s, the output AC contactor is closed. At this time, the “Voltage Stabilization

Indicator” light is on, the voltage regulator outputs the voltage after regulation, and the output voltage meter displays the

voltage after voltage regulation.

d)After the voltage stabilization is started, stop the "Manual/Automatic" knob at the "Manual" position (the

arrow points to the manual position), then press the "Step up" button on the panel, at this time, the output voltmeter shows that

the voltage should rise. When the voltage reaches (418 ± 3.8) V, the output AC contactor is disconnected within 4s-8s without

output voltage by this time, and meanwhile the "Fault Indicator" gives a sound-light alarm and the product is in an overvoltage

protection state. Then press the "Step down" button, to a certain degree, the output AC contactor is closed, the voltage regulator

should be able to automatically start the output, continue to press the “Step down" button, the output voltmeter displays the

voltage to drop, until the limit switch is disconnected and the motor power supply is cut off, press the “Step down" button again,

and then the output voltage will no longer drop. If the product is equipped with the under voltage protection function, the

under-voltage protection will start when the output reaches the protection value at the time of buck, and "Fault Indicator"

sends out a sound-light alarm.

e)After completing the above steps, turn the "Manual/Automatic" switch tothe "Automatic Voltage Stabilization" position,

and then the voltage regulator realizes the automatic voltage stabilization.

f)Turn the “Self-reset” switch to the “Automatic Voltage Stabilization” position and then press the “Stop” button.

The product will restart after the output is cut off; turn on the voltage regulator again after the input breaker is turned off, the

voltage regulator should be able to automatically start the output.

7.4.3TNSZ-800 ~1000 product commissioning is the same as 7.4.2commissioning method but the product does not

have "SELF-RESET" switch, other methods are the same ,

.

7.5 Run

After the above commissioning is completed, disconnect the power supply, turn off the input breaker or knife switch of the

voltage regulator, and then connect the load. Then choose a reasonable operation mode according to the different

requirements of users.

7.5.1 Automatic voltage stabilization operation

Turn the “Manual/Automatic Transfer” switch to the “Automatic” position, turn the “Self-reset” switch to the

“Automatic Voltage Stabilization” position, and close the switch at the input end. Then the voltage regulator realizes the fully

automatic voltage stabilization operation.

7.5.2 Manual voltage regulation operation (TNSZ-350 ~ 600 products have this function)

Turn the “Manual/Automatic Transfer” switch to the “Manual” position, turn the “Self-reset” switch to the “Stop”

position, and close the circuit breaker switch on . Press the “Voltage Stabilization” button. The voltage regulator delays

the output, press the “Step up” or “Step down” button to adjust the output voltage of the voltage regulator. When you

select the manual voltage regulation mode, the product has no voltage regulation function and the output voltage may be

higher or lower than the rated value. Please pay attention to the influence ofoutput voltage change on the load. When you

turn the “Manual/Automatic Transfer” switch to the “Automatic” position, the voltage regulator returns to the automatic

regulation state.

7.5.3 Fully automatic mains operation

Turn the “Self-reset” button to the “Mains” position and close the power switch at the input end to achieve the mains

operation.

07

TNDZ、TNSZ series pillar type AC automatic voltage regulators

7.6 Notes

7.6.1 You should understand the operating conditions of the voltage regulator before it is put into operation, and the

requirements provided in Section 3 should be met.

7.6.2 The input wiring of the three-phase voltage regulator must be connected strictly in accordance with the three-phase

four-wire system. The input must be connected to the neutral wire, otherwise the voltage regulator and the powered device will

be damaged.

7.6.3 The imbalance of input power supply voltage and load will lead to the imbalance of the output voltage.

7.6.4 During the operation of the voltage regulator under load, the load should be added step by step in case of power

recovery after power failure, otherwise the excessive impulse current will damage the voltage regulator.

8 Maintenance, Lifting and Storage Precautions

8.1 Maintenance: The maintenance cycle varies greatly depending on the environment in which it is used, but the

maximum period should not exceed six months. During maintenance, the switch at the front end of the voltage regulator

should be turned off. You must ensure that there is no voltage at the upper end of the power switch at the input end of the

voltage regulator. At the same time, the power switch at the input end should be turned off.

8.1.1 Thoroughly clean all parts of the voltage regulator to avoid dust and dirt, especially the electric brush, the coil surface

of the voltage regulator, the sliding guide rail of the electric brush and the transmission parts.

8.1.2 Apply appropriate amount of N320 gear oil to the mechanical transmission parts on a regular basis, such as the

reducer and the drive chain; it is recommended to replace the oil in the reducer every 3 months.

8.1.3 Replace the worn or damaged electricbrush in time to ensure reliable contact. When the product is working, the

movement of the electric brush will cause a weak point spark in the contact area. In case of large spark, cut off the power for

maintenance and clean the voltage regulator according to 8.1.1 of the maintenance requirements. If there is a gap between the

electric brush and the coil, put the 0# sandpaper between the electric brush and the coil and pull it up and down to ensure the

reliable contact between the electric brush and the cylindrical slide rail.

8.1.4 Repair or replace the broken-down or damaged components in time.

8.1.5 For the maintenance of the control motor, the wiring should be strictly consistent with the regulations and a wrong

phase sequence of the motor is strictly prohibited. After maintenance, perform the commissioning according

to 7.4 and the put the product into operation again after successful commissioning.

8.2 Lifting and storage period precautions

8.2.1 The product should be packaged and stored indoors. The room should be well-ventilated, dry, and free of vibration

and corrosive gas (liquid).

8.2.2 This product cannot be hoisted and can only be handled by forklift. Keep it dry and upright during handling.

9

Analysis and Troubleshooting of Common Faults

Table 3 Analysis and Troubleshooting of Common Faults

Symptons Cause analysis Troubleshooting method

The voltage regulator fails to start

after power connection.

Input power phase loss

Product is not connected to

the neutral wire

Mains button and voltage stabilization

button failure

Open circuit of contactor coil leads to

failure of pull-in

Fuse fault

Poor contact of control circuit

Check if the input power supply is

normal or has phase loss

Connected to the neutral wire

Replace the buttons

Replace the contactor coil

Replace with the fuse of the same

specification

Check if all connectors are securely

connected

Travel protection caused by low input

power voltage or out of control power

phase sequence

Check whether the brush plate slides

to the bottom of the voltage regulating

coil and causes the travel switch to be

disconnected.Adjust the reducer.

Move the brush plate to the middle

position of the voltage regulating coil

and restart the voltage regulator.

(TNSZ-150 or above)

08

TNDZ、TNSZ series pillar type AC automatic voltage regulators

Symptons Cause analysis Troubleshooting method

The voltage regulator can regulate the

voltage normally but has no output.

Output contactor KM1 fault

Protection circuit board fault

Control transformer fault or open

circuit in wiring

Relay failure

Temperature protector (θ4 or θ5 or θ6)

fault

Replace the AC contactor

Change to the spare board for

TNSZ-100 or below;

Replace the protection circuit board

for TNSZ-150 or above

Check or replace the control

transformer

Replace the relay K1 or K2

Replace the temperature protector

(TNSZ-150 or above)

The small capacity of the user's power

supply leads to large input voltage

drop

The self-reset switch is in the “Mains”

position

Reduce the load or increase the power

supply capacity

Set the self-reset switch to the “Stop”

position, press the “Stop” button and

then start voltage stabilization

Voltage regulation becomes abnormal

after a period of use.

Motor fault

Failure or falling off of the coupling

(cross joint) of the motor and reducer

Gearbox gear is broken

Excessive resistance of voltage

regulation mechanism

Failure of the relay or contactor

controlling buck-boost

Control circuit board failure

Poor contact of control transformer

wiring

Internal motor protection circuit

breaker QF2 trips

Replace the motor

Replace the coupling (cross joint)

Replace the reducer

Adjust the voltage regulation

mechanism (remove dirt and dust, add

lubricating oil)

Replace the relay or contactor

Change to the spare board for

TNSZ-100 or below;

Replace the protection circuit board

for TNSZ-150 or above

Check the wiring of the control

transformer

Close the circuit breaker (TNSZ-150 or

above)

The voltage regulator is too noisy

after a period of use.

Sundries on the contactor core surface

Contactor core is damaged

A friction sound during voltage

regulation

Clean the core surface

Replace the contactor

This is normal

Correct the grid voltage to match the

input voltage range of the voltage

regulator

Turn the manual/automatic transfer

switch to the automatic state (voltage

stabilization light on)

The input voltage exceeds the rated

service range of the voltage regulator

The product does not switch to

automatic voltage stabilization state

The output voltage is too high or too

low when the voltage regulator is just

installed.

Without load, the fan starts for a long

time. Thermostat (θ1 or θ2 or θ3) fault Replace the thermostat

Turn the transfer switch to the

“Manual” position

Detecting circuit board failure

Open circuit of contactor coil or poor

contact of normally closed contact

point

Travel switch fault or open circuit of

motor control line

Open circuit of Fu1 fuse

Control transformer fault or open

circuit in wiring

Turn the transfer switch to the

“Automatic” position

Replace the detecting circuit board

Replace the contactor or replace the

contactor auxiliary contact

Replace or adjust the travel switch and

check the motor wiring

Check or replace the fuse FU1

Check or replace the control

transformer

The voltage regulator can’t regulate

the voltage automatically after start.

The voltage regulator can only start

the mains but can't start the voltage

stabilization.

When the voltage regulator starts with

the motor, the contactor keeps repeating

the action of closing and releasing.

09

TNDZ、TNSZ series pillar type AC automatic voltage regulators

Symptons Cause analysis Troubleshooting method

The voltage regulator works properly,

but stops automatically sometimes.

Product overvoltage protection

(with a sound-light alarm)

Poor contact of product fuse

Poor contact of relay (K1 or K2)

Poor contact of connecting wires

Protection circuit board failure

Poor contact of control transformer

wiring

Check if the input voltage is too high

Check if the elasticity of fuse holder is

too loose

Replace the relay

Tighten all connecting wires

Replace the protection circuit board

Check the wiring of the control

transformer

10

Ordering Instructions

Please specify the following items when placing an order:

10.1 Please specify the product model, capacity, rated output voltage, input voltage variation range, voltage regulation

accuracy, incoming and outgoing line position and load when you place an order.

10.2 Special requirements can be determined through consultation with the manufacturer.

10.3 Model selection guide

Choose a reasonable load when you install and use this product. Select a proper voltage regulator according to the rated

power, inductive or capacitive load of the electrical equipment. Its output capacity should be left with sufficient margin, which

should be larger for the impact load selection. See Table 4 for the specific safety factors in model selection.

Load

characteristics

Pure resistant

load

Inductive,

capacitive load

Select the voltage

regulator capacity

≥1.3 times of the

total load power

≥2 times of the

total load power

Table 4

Safety factor

1.3~2

2~3

Device type

Incandescent lamp, resistance wire, electric furnace, etc.

Elevator, air conditioner, electric motor, compressor, computer

room, factory, office building, etc.

Safety factor selection principle reference: In the case of inductive or capacitive load environment, the starting current of

the load is large and will cause impact on the voltage regulator. In order to ensure reliable operation of the product, the safety

factor must be carefully selected in model selection. The safety factor should be chosen according to the load. In case of few

types of loads, large power, continuous long-term running or repeated short-term running (frequent start), and no additional

starting equipment, the larger value should be taken, otherwise the smaller value should be taken.

11

Environmental Protection

In order to protect the environment, the product or product parts should be disposed of according to the industrial waste

treatment process, or be sent to the recycling station for assortment, dismantling and recycling.

Figure 9 Electrical Schematic Diagram of TNDZ

Figure 10 Electrical Schematic Diagram of TNSZ-30-100

Figure 11 Electrical Schematic Diagram of TNSZ-150-320

Figure 12 Electrical Schematic Diagram of TNSZ-350-500

Figure 13 Electrical Schematic Diagram of TNSZ-600

Figure 14 Electrical Schematic Diagram of TNSZ-800~1000

12

Appendix 1 Electrical Schematic Diagrams (subject to change without prior notice)

10

TNDZ、TNSZ series pillar type AC automatic voltage regulators

Figure 9 Electrical Schematic Diagram of TNDZ

T1

A101 102

QF1

N000

QC QC

103

111

QC

T2

104

KM1

TA

PA1

810

800

741

742

a

731

732

N

000

M

XT

000

K2 K3

502 501

000 423

103

000

FU3 0.5A

220V

TC2 721

722

701

702

711

710

712

11V

17V

12V

12V

9V

9V

9V

731

732

741

742

751

752

PCB1 CONTROL BOARD PCB1 SPARE CONTROL BOARD

422 000 451 511 423 521

1234 5678

422 000 451 511 423 521

1234 5678

PV1

COMPONENT NAME

COMPENSATION TRANSFORMER EMERGENCY STOP BUTTON

AC CONTACTOR RELAY TRAVEL SWITCH

FUSE

COMBINATION SWITCH

CONTROL BOARD

COMPONENT NAME CONTROL BOARD MOTOR

CONTROL TRANSFORMER

CODE

CODE

CIRCUIT BREAKER

T1 SE KM1

K1 K2

K3、

、

ST1

ST2

、

QC PCB1

QF1 FU1、

FU2

VOLTAGE REGULATOR

T2

AP 1

CURRENT TRANSFORMER

TA1 PCB1 MTC2

THE CORRESPONDENCE TABLE OF COMPONENT NAME AND CODE:

N102

104

SB1

PUSHBUTTON

SB1

AMMETER

000 QF1

KM1

000

030

410

SE EMERGENCY STOP

QC

K1 401

401

303

FU1 4A

QC FU2 4A

500

423

423

423

111

511

521

512

522

ST1

ST2

513

523

K3

K2

K2

K3

000

451 K1

CIRCUIT BREAKER

LCD DISPLAY CONTROLLER

T1 SE

KM1

K1 K2

K3、 、 ST1

ST2、

QC PCB1

QF1 FU1 、

FU2

VOLTAGE REGULATOR

T2

AP 1

CURRENT TRANSFORMER

TA1 TA2

TA3

、 、

PCB1 MTC2

THE CORRESPONDENCE TABLE OF COMPONENT NAME AND CODE:

CODE

CODE

COMPENSATION TRANSFORMER

EMERGENCY STOP BUTTON

AC CONTACTOR

RELAY

TRAVEL SWITCH

FUSE

COMBINATION SWITCH CONTROL BOARD

COMPONENT NAME CONTROL BOARD

MOTOR

CONTROL TRANSFORMER

COMPONENT NAME

QF1

304

N

000 QF1

KM1

000

030

410

SE

EMERGENCY STOP

QC

K1 401

401

303

FU1 4A

QC

FU2 4A

500

423

423

423

111

511

521

512

522

ST1

ST2

513

523

K3

K2

K2

K3

000

451 K1

a

b

c

n

PA1 LCD DISPLAY CONTROLLER

810 811 820 821 830 831 901 902

000102 202 302 104 204 304

QC

QCQC

T2 T2 T2

111

211

311

QC

204

TA1

TA2

TA3

000

N

M

502 501

K2 K3

423000

313

312

T1 303

213

212

T1 203

113

112

301

202

302

201

B

C

810

811

820

821

830

831

Figure 10 Electrical Schematic Diagram of TNSZ-30100~

A101 102 T1 103 KM1 104

7.5V 901

902

000 000

PCB1 CONTROL BOARD

PCB1 SPARE CONTROL BOARD

12V

422 000 451 511 423 521

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8

422 000 451 511 423 521

TC2 721

722

701

702

711

710

712

11V

17V

12V

.

FU305A

380V

103

203

11

TNDZ、TNSZ series pillar type AC automatic voltage regulators

12

TNDZ、TNSZ series pillar type AC automatic voltage regulators

SO1、SO2

AP 1

COMPONENT NAME

COMPENSATION TRANSFORMER

THERMOSTAT AC CONTACTOR RELAY TRAVEL SWITCH

FUSE

PROTECTION BOARD

COMPONENT NAME MOTOR

CONTROL TRANSFORMER

CODE

CODE

CIRCUIT BREAKER

T1 φ1~φ6

K1~K3

ST1~ST4

PCB2

QF1

FU1 、

FU2

VOLTAGE REGULATOR

T2

CURRENT TRANSFORMER

TA1~TA3

MTC2

THE CORRESPONDENCE TABLE OF COMPONENT NAME AND CODE:

KM1~KM5

CHANGE-OVER SWITCH

PUSHBUTTON

SB1、SB2 SO1 SO2

、

FAN

AF

DETECTION BOARD

PCB1

CALL RESET SWITCH

HR1

FAULT INDICATION

LCD DISPLAY CONTROLLER

810 811820821 830831 901 902

000102202302104 204

304

PA1 LCD DISPLAY CONTROLLER

103

203 380V

FU3 0.5A

TC2 701

702

711

710

712

721

722

17V

12V

11V

12 11 10 987654321

12V

441

000

000

451

102

202

302

12 11 10 987654321

521

511

512

522

523

513

010

PCB2 PROTECTION BOARD PCB1DETECTION BOARD

901

902

7.5V

STEP UP

STEP DOWN

MANUAL

MANUAL

AUTOMATIC

AUTOMATIC

Figure 11 Electrical Schematic Diagram of TNSZ-150320~

A101 102 T1 103

B

C

201

301

202

302

113

112

T1 203

213

212

T1 303

313

312

KM3 KM3KM3

111

211

311

KM2

KM1

104

204

304

TA1

810

820

TA2

830

TA3

a

b

c

T2 T2 T2

000

000

Nn

φ4

φ5

φ6

602

K1

421 KM3 422 K1

425

KM2 423 ST4 424 ST3

KM3

KM2 412411

FU1 4A

303

401

000 000

NSO2

0

010

020

34

3 4’’ PCB1-6

SB5

SB4

PCB1-11

511

521

T1-12

ST1 512

T1-10 T1-7

ST2 522

T1-9T1-8

513

523

514

524

KM5

KM4

KM4

KM5

FU2 4A

111

500

KM3

KM2

K3 501

K3

AF

501

603 K2

φ1

φ2

φ3

KM1

601 303

401

QF1

SO1

0

34

3’4’

811

821

831

SE

QF1

401030

000

000

401

401

401

MAINS

AUTOMATIC VOLTAGE STABILIZATION

TEMPERATURE PROTECTOR

EMERGENCY STOP

FAN THERMOSTAT

M

641 642 643

XT

633

632

631

621

KM4 KM5

623

622

QF2

111 211 311

(OVERVOLTAGE/UNDERVOLTAGE/TEMPERATURE PROTECTION)

SWITCH-ON DELAY

OVERVOLTAGE/UNDERVOLTAGE PROTECTION

PCB2-4 PCB2-6

451

K2

FAULT INDICATION

HR1 431

K2 441 PCB2-9 PCB2-7

K1

502 K1

13

TNDZ、TNSZ series pillar type AC automatic voltage regulators

COMPONENT NAME

COMPENSATION TRANSFORMER

THERMOSTAT AC CONTACTOR RELAY TRAVEL SWITCH FUSE INDICATOR

PROTECTION BOARD

COMPONENT NAME VOLTMETER MOTOR

CONTROL TRANSFORMER

CODE

CODE

CIRCUIT BREAKER

AMMETER

T1 φ1~φ6

K1~K3

ST1~ST4

PCB2

QF1

FU1 、

FU2

VOLTAGE REGULATOR

T2

PA1~PA3

CURRENT TRANSFORMER

TA1~TA3 PV1 PV2

、

MTC2

THE CORRESPONDENCE TABLE OF COMPONENT NAME AND CODE:

KM1~KM5

CHANGE-OVER SWITCH

PUSHBUTTON

SB1~SB5

CURRENT TRANSFORMER

TA1~TA3 SO1 SO2

、

FAN

AF

DETECTION BOARD

PCB1

CALL RESET SWITCH

SO3

HY1 HY2 G1

、 、H

HG2 HR1 HR2

、

、 、

(OVERVOLTAGE/UNDERVOLTAGE/TEMPERATURE PROTECTION)

Figure 12 Electrical Schematic Diagram of TNSZ-350500~

A101 102 T1 103

B

C

201

301

202

302

113

112

102

202

INPUT PV1

302

T1 203

213

212

T1 303

313

312

KM3 KM3KM3

111

211

311

KM2

KM1 104

204

304

PA1

TA1

810

820

PA2

TA2

830

PA3

TA3

800

a

b

c

T2 T2 T2

000

HR1HG1HY1

PHASE AINDICATOR PHASE B INDICATOR PHASE C INDICATOR

000

N

AB BC CA

SO1

204

304

104

902

901 PV2 OUTPUT

1

3

5

7

2

4

6

8

n

M

641 642 643

XT

633

632

631

621

KM4 KM5

623

622

QF2

111 211 311

111

211 380V

FU3 0.5A

TC2 701

702

711

710

712

721

722

17V

12V

11V

12 11 10 9 8 7 6

5

4 3 2

1

PCB2 PROTECTION BOARD

12V

441

000

000

451

102

202

302

521

511

512

522

523

513

010

PCB1DETECTION BOARD

TEMPERATURE PROTECTOR

φ4

φ5

φ6

SWITCH-ON DELAY

OVERVOLTAGE/UNDERVOLTAGE PROTECTION

PCB2-4 PCB2-6

451

602

K1

K2

FAULT INDICATION

KM2

HR2

SB2

KM3

VOLTAGE STABILIZATION

SELF-RESET

MAINS

421 KM3

431

K2 441 PCB2-9 PCB2-7

K1

422 K1

425

KM2 423 ST4 424 ST3

HG2

VOLTAGE STABILIZATION INDICATOR

KM3

HY2 MAINS INDICATOR

KM2

SO3

412411

MAINS

STOP

AUTOMATIC VOLTAGE STABILIZATION

SB1

FU14A

303

401

STOP

MANUAL

MANUAL

AUTOMATIC

030 SB3 000 000

NSO2

0

010

020

34

3 4’’ PCB1-6

SB5

AUTOMATIC

SB4

PCB1-11

511

521

T112-

ST1 512

T110- T17-

ST2 522

T19- T1-8

513

523

514

524

KM5

KM4

KM4

KM5

FU24A

111

500

KM3

KM2

000

K3

501

K3

AF FAN THERMOSTAT

502

603 K2

φ1

φ2

φ3

KM1

601 303

401

QF1

12 11 10 9 8 7 6

5

4 3 2

1

STEP UP

STEP DOWN

K1

14

TNDZ、TNSZ series pillar type AC automatic voltage regulators

PHASE AINDICATOR PHASE B INDICATOR PHASE C INDICATOR

(OVERVOLTAGE/UNDERVOLTAGE/TEMPERATURE PROTECTION)

A101 102 T1 103

B

C

201

301

202

302

113

112

102

202

INPUT PV1

302

T1 203

213

212

T1 303

313

312

KM3 KM3KM3

111

211

311

KM2

QF1 104

204

304

PA1

TA1

810

820

PA2

TA2

830

PA3

TA3

800

a

b

c

T2 T2 T2

000

HR1HG1HY1

000

N

AB BC CA

SO1

204

304

104

902

901 PV2 OUTPUT

1

3

5

7

2

4

6

8

n

M

641 642 643

XT

633

632

631

621

KM4 KM5

623

622

QF2

111 211 311

111

211 380V

FU3 0.5A

TC2 701

702

711

710

712

721

722

17V

12V

11V

12 11 10 9 8 7 6

5

4 3 2

1

PCB2 PROTECTION BOARD

12V

441

000

000

451

102

202

302

521

511

512

522

523

513

010

PCB1DETECTION BOARD

TEMPERATURE PROTECTOR

φ4

φ5

φ6

SWITCH-ON DELAY

OVERVOLTAGE/UNDERVOLTAGE PROTECTION

PCB2-4 PCB2-6

451

602

K1

K2

FAULT INDICATION

KM2

HR2

SB2

KM3

VOLTAGE STABILIZATION

SELF-RESET

MAINS

421 KM3

431

K2 441 PCB2-9 PCB2-7

K1

422 K1

425

KM2 423 ST4 424 ST3

HG2

VOLTAGE STABILIZATION INDICATOR

KM3

HY2

MAINS INDICATOR

KM2

SO3

412411

MAINS

STOP

AUTOMATIC VOLTAGE STABILIZATION

SB1

FU14A

303

401

STOP

MANUAL

MANUAL

AUTOMATIC

030 SB3 000 000

NSO2

0

010

020

34

3 4’’ PCB1-6

SB5

AUTOMATIC

SB4

PCB1-11

511

521

T112-

ST1 512

T110- T17-

ST2 522

T19- T1-8

513

523

514

524

KM5

KM4

KM4

KM5

FU24A

111

500

KM3

KM2

000

K3

501

K3

AF

FAN THERMOSTAT

502

603 K2

φ1

φ2

φ3

QF1

601 303

401

QS1

COMPONENT NAME

COMPENSATION TRANSFORMER

THERMOSTAT AC CONTACTOR RELAY TRAVEL SWITCH

FUSE

INDICATOR

PROTECTION BOARD

COMPONENT NAME VOLTMETER MOTOR

CONTROL TRANSFORMER

CODE

CODE

CIRCUIT BREAKER

AMMETER

T1 φ1~φ6

K1~K3

ST1~ST4

PCB2

QF1

FU1 、

FU2

VOLTAGE REGULATOR

T2

PA1~PA3

CURRENT TRANSFORMER

TA1~TA3 PV1 PV2

、

MTC2

THE CORRESPONDENCE TABLE OF COMPONENT NAME AND CODE:

KM1~KM5

CHANGE-OVER SWITCH

PUSHBUTTON

SB1~SB5

CURRENT TRANSFORMER

TA1~TA3 SO1 SO2

、

FAN

AF

DETECTION BOARD

PCB1

CALL RESET SWITCH

SO3

HY1 HY2 G1

、 、H

HG2 HR1 HR2

、

、 、

12 11 10 9 8 7 6

5

4 3 2

1

Figure 13 Electrical Schematic Diagram of TNSZ-600

KNIFE SWITCH

QS1

STEP UP

STEP DOWN

K1

PHASE B INDICATOR

Figure 14 Electrical Schematic Diagram of TNSZ-8001000~

304

KM4-C

M

XT

KM5-C

501

502 500-C

000

KM4-B

M

XT

KM5-B

501

502 500-B

000

KM4-A

M

XT

KM5-A

501

502 500-A

000 NSO3-C

MANUAL AUTOMATIC

0

000

000

3 4

3 4’ ’

010

020 SB5-C

511

SB4-C

521

ST1-C KM5-C KM4-C

ST2-C KM4-C KM5-C

512 513

522 523

HR2C-

OVER / UNDER VOLTAGE INDICATION

OVERVOLTAGE/UNDERVOLTAGE PROTECTION

SWITCH-ON DELAY

K5-C 514

524 K5-C

AF

K2-C

FAN THERMOSTAT

φ1-C

φ2-C

451

441 K1-C

431 K1-C

311

500-C

FU2C-4A

000

TEMPERATURE PROTECTOR

φ3-C

φ4-C K6-C

605 402-C 303

FU1C4A-

N

KM3

KM2

422 421

KM3 KM2

411

SB1

103

FU1A-4A

MAINS

401

SB2

VOLTAGE STABILIZATION

K6-A K6-B K6-C

423 424 425 401

SB3

000 030

STOP

HY1

MAINS INDICATOR

KM3

KM3 ’ 412

HG1

VOLTAGE STABILIZATION INDICATOR

KM2

SO3-B

MANUAL AUTOMATIC

0

000

000

34

3 4’ ’

010

020 SB5-B

511

SB4-B

521

ST1-B KM5-B KM4-B

ST2-B KM4-B KM5-B

512 513

522 523

HR2B-

OVER / UNDER VOLTAGE INDICATION

OVERVOLTAGE/UNDERVOLTAGE PROTECTION

SWITCH-ON DELAY

K5-B 514

524 K5-B

AF

K2-B

FAN THERMOSTAT

φ1-B

φ2-B

451

441 K1-B

431 K1-B

211

500-B

FU2B-4A

000

N

TEMPERATURE PROTECTOR

φ3-B

φ4-B

K6-B

605 402-B 203

FU1B4A-

QS1 102

202

302

INPUT

V1 V2

T1-A

000

104

103 V4 204

V3

T1-B 203

V6

T1-C 303

V5 QF1 104

204

304

PA1

PA2

TA1

800

810

800

820

TA2

PA3

800

830

204

304

104

AB BC CA

1 2

3 4

5 6

7 8

902

901

PV1

OUTPUT

SO1

a

b

c

行指示

C-PHASE

FUNCTION

INDICATION

HG2-B HG2C-

N

KM2

KM3 111

KM3

T2-A

HR1-B

HR1-C HR1-A

T3-A

701

702

711

710

712

721

722

17V

12V

11V

121110987654321

PCB2A-PROTECTION BOARD

12V

441

000

000

451

PCB1A-DETECTION BOARD

121110987654321

521

511

010

KM2

KM3 ‘

KM3

T2-B

211

701

702

711

710

712

721

722

17V

12V

11V

121110987654321

PCB2B-PROTECTION BOARD

12V

441

000

000

451

PCB1B-DETECTION BOARD

1211 10987654321

521

511

010

T3-B

KM2

KM3 ‘

T2-C

311

KM3 ‘

TA3

701

702

711

710

712

721

722

17V

12V

11V

121110987654321

PCB2C-PROTECTION BOARD

12V

441

000

000

451

PCB1C-DETECTION BOARD

1211 10987654321

521

511

010

T3-C

A101

B

C

201

301

N

FU3A-

PV2

FU3B- FU3C-

SB5-A

511

SB4-A

521

ST1-A KM5-A KM4-A

ST2-A KM4-A KM5-A

512 513

522 523

HR2A2-

OVER / UNDER VOLTAGE INDICATION

OVERVOLTAGE/UNDERVOLTAGE PROTECTION

SWITCH-ON DELAY

K5-A 514

524

K5-A

AF

K2-A

FAN THERMOSTAT

φ1-A

φ2-A

451

441 K1-A

431 K1-A

111

500-A

FU2A-4A

SO3-A

MANUAL AUTOMATIC

0

000

000

3 4

3 4’ ’

010

020

000

000

TEMPERATURE PROTECTOR

φ3-A

φ4-A K6-A

605 403 103

K6-A

604

K6-B

K6-C

HR2 - A1

FAULT INDICATION

FU1A4A-

000

631 K1-B 623 K2-B 630 K1-A 621 K2-A QF1

601 303

KM3

KM2 603 K1-C 632 K2-C

000

COMPONENT NAME

COMPENSATION TRANSFORMER

THERMOSTAT

AC CONTACTOR RELAY TRAVEL SWITCH

FUSE

INDICATOR

PROTECTION BOARD

COMPONENT NAME VOLTMETER MOTOR

CONTROL TRANSFORMER

CODE

CODE

CIRCUIT BREAKER

AMMETER

T1 φ1~φ6 K1~K6

ST1~ST4

PCB2

QF1

FU1~FU3

VOLTAGE REGULATOR

T2

PA1~PA3

CURRENT TRANSFORMER

TA1~TA3 PV1 PV2、

MTC2

THE CORRESPONDENCE TABLE OF COMPONENT NAME AND CODE:

KM1~KM5

CHANGE-OVER SWITCH

PUSHBUTTON

SB1~SB5

CURRENT TRANSFORMER

TA1~TA3

SO1 SO2

、

FAN

AF

DETECTION BOARD

PCB1

KNIFE SWITCH

QS1

VOLTMETER

V1~V6

HY1 HY2 G1、 、 H

HG2 HR1 HR2

、

、 、

C-PHASE

B-PHASE

A-PHASE

B-PHASE

FUNCTION

INDICATION

15

TNDZ、TNSZ series pillar type AC automatic voltage regulators

STEP UP

STEP DOWN

STEP UP

STEP DOWN

STEP UP

STEP DOWN

16

QC PASS

Test date:Please see the packing

ZHEJIANG CHINT ELECTRICS CO.,LTD.

TNDZ、TNSZ

series pillar type AC automatic

voltage regulators

Q/ZT 431

Check 18

TNDZ、TNSZ series pillar type AC automatic voltage regulators

TNDZ,TNSZ

AC automatic voltage regulators

series pillar type

User Instruction

This manual suits for next models

21

Table of contents

Other CHINT Controllers manuals