• Up and Down keys

Each press of Ukey increments or advances

the values displayed on the No.2 display.

Each press of Dkey decrements or returns the

values displayed on the No.2 display.

Operation indicators

• SUB1: Auxiliary output 1 indicator

• SUB2: Auxiliary output 2 indicator

• SUB3: Auxiliary output 3 indicator

• SUB4: Auxiliary output 4 indicator

• OUT1: Control output 1 indicator

• No.1 display

Process value or set data type

• No.2 display

Set point, set data read-out value or changed

input value

• Mode key

Press this key to change the contents of the display.

Press this button for 1 s or longer for reverse scroll.

• Press the Okey and the Mkey

together for at least 3 seconds to switch to protect level.

• No. 3 display

MV, Soak Time Remain, and Multi-SP.

• °C / °F : temperature unit

The temperature unit is displayed when

the displayed value is a temperature.

Either Cor Fis displayed according to the

set value of the temperature unit.

• Shift key (PF key)

The default PF Setting parameter is for

shifting the digit. This is a function key.

When it is pressed, the function set for the

PF Setting parameter will operate.

• Front-panel Setup Tool port

This port is used to connect the Controller

to a computer to use the Setup Tool.

• Level key

Use this key to change levels:

• STOP: Control stop indicator

Lit when “Run/Stop” is stopped during operation.

• RSP: Remote SP indicator

Lit when the assigned function is ON.

• TUNE:

Flashing during self-tuning.

Lit during auto-tuning.

• : Protection indicator

Lit when Setting Change Protect is ON (disables the

Up and Down Keys).

• MANU: Manual output indicator

Lit when the Auto/Manual Mode is set to Manual

Mode.

During control stop, functions other than control output

are valid.

•

CMW: Communications writing enable/ disable indicator

Lit when communications writing is “enabled” and is

out when it is “disabled”.

Precautions for Safe Use

CAUTION

Safety Precautions

Key to Warning Symbols

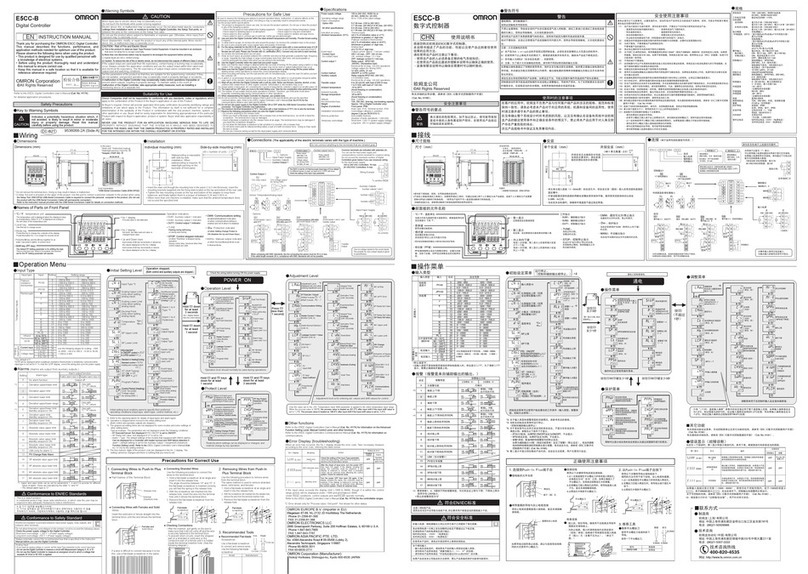

Wiring

Specifications

Dimensions Installation

Individual mounting (mm)

Side-by-side mounting (mm)

• Insert the main unit through the mounting hole in the panel

(1 to 8 mm thickness). Insert the mounting brackets (supplied)

into the fixing slots located on the top and bottom of the rear

case.

• Tighten the two mounting screws on the top and bottom of

the adapter to keep them balanced, and finally tighten them

to a torque of between 0.29 and 0.39 N·m.

• When more than one machine is installed, make sure that the

ambient temperature does not exceed the specified limit.

Waterproofing is

impossible with

side-by-side installation.

When waterproofing is

required, fit watertight

packing on the

backside of front panel.

nim021

45

29

+ 0.6

0

8.0+

0

(48 x number of units–2.5) + 1.0

0

29 8.0+

0

Names of Parts on Front Panel

Operation Menu

Input Type

9609894-9A(Side-A)

CAUTION

Minor injury due to electric shock may occasionally occur.

Do not touch the terminals while power is being supplied.

Electric shock, fire, or malfunction may occasionally occur. Do not allow metal objects,

conductors, cuttings from installation work, or moisture to enter the Digital Controller, the

Setup Tool ports, or between the pins on the connectors on the Setup Tool cable.

Do not use the product where subject to flammable or explosive gas. Otherwise, minor injury

from explosion may occasionally occur.

Never disassemble, modify, or repair the product or touch any of the internal parts. Minor

electric shock, fire, or malfunction may occasionally occur.

CAUTION - Risk of Fire and Electric Shock

a)

This is the product UL Listed as Open Type Process Control Equipment. It must be mounted in an enclosure

that does not allow fire to escape externally.

b) More than one disconnect switch may be required to de-energize the equipment before servicing.

c) Signal inputs are SELV, limited energy.

d)

Caution: To reduce the risk of fire or electric shock, do not interconnect the outputs of different Class 2 circuits.

If the output relays are used past their life expectancy, contact fusing or burning may occasionally

occur. Always consider the application conditions and use the output relays within their rated load

and electrical life expectancy. The life expectancy of output relays varies considerably with the

output load and switching conditions.

Set the parameters of the product so that they are suitable for the system being controlled. If they

are not suitable, unexpected operation may occasionally result in property damage or accidents.

A malfunction in the Digital Controller may occasionally make control operations impossible

or prevent alarm outputs, resulting in property damage. To maintain safety in the event of

malfunction of the Digital Controller, take appropriate safety measures, such as installing a

monitoring device on a separate line.

Warning Symbols

Suitability for Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations which

apply to the combination of the Product in the Buyer’s application or use of the Product.

At Buyer’s request, Omron will provide applicable third party certification documents identifying ratings and

limitations of use which apply to the Product. This information by itself is not sufficient for a complete

determination of the suitability of the Product in combination with the end product, machine, system, or

other application or use. Buyer shall be solely responsible for determining appropriateness of the particular

Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in

all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

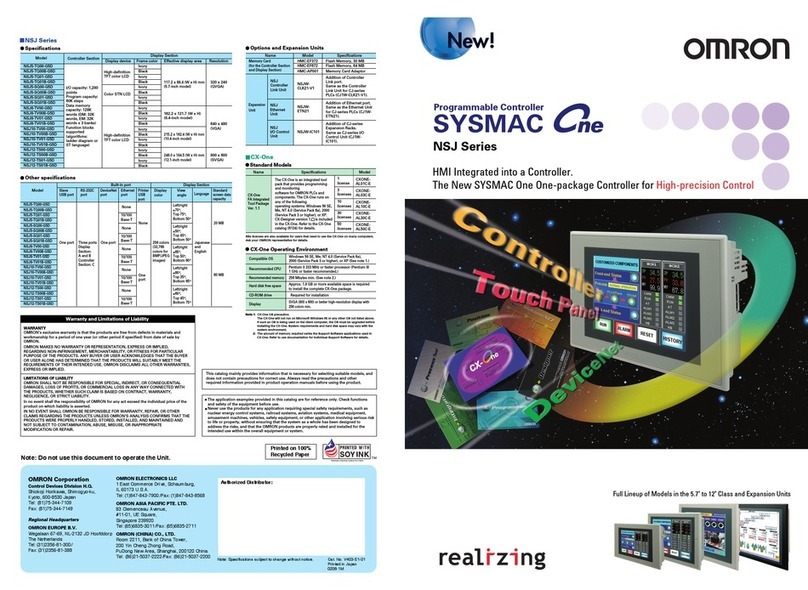

E5EC-B

Digital Controller

INSTRUCTION MANUAL

Thank you for purchasing the

OMRON E5EC Digital Controller.

This manual describes the functions, performance, and

application methods needed for optimum use of the product.

Please observe the following items when using the product.

• This product is designed for use by qualified personnel with

a knowledge of electrical systems.

• Before using the product, thoroughly read and understand

this manual to ensure correct use.

• Keep this manual in a safe location so that it is available for

reference whenever required.

OMRON Corporation

©All Rights Reserved

EN

Be sure to observe the following precautions to prevent operation failure, malfunction, or adverse affects on theperformance

and functions of the product. Not doing so may occasionally result in unexpected events. Use theproduct within specifications.

1 The product is designed for indoor use only. Do not use the product outdoors. Do not use or store the product in any of

the following locations.

• Places directly subject to heat radiated from heating equipment.

• Places subject to splashing liquid or oil atmosphere.

• Places subject to direct sunlight.

• Places subject to intense temperature change.

• Places subject to icing and condensation.

• Places subject to vibration and large shocks.

• Places subject to dust or corrosive gas (in particular, sulfide gas and ammonia gas).

(2)

Use and store the Digital Controller within the rated ambient temperature and humidity. Provide forced-cooling if required.

(3) To allow heat to escape, do not block the area around the product. Do not block the ventilation holes on the product.

(4) Be sure to wire properly with correct signal name and polarity of terminals.

(5) For the wiring materials for the E5@C-B, use stranded or solid copper wires with a cross-sectional area of 0.25 to

1.5 mm2(equivalent to AWG24 to AWG16). The stripping length is 10 mm if ferrules are used and 8 mm if ferrules are

not used. Please use Ferrules with UL certification (R/C). Connect only one wire to each terminal.

(6) Do not wire the terminals which are not used.

(7) Allow as much space as possible between the controller and devices that generate a powerful high-frequency or surge.

Separate the high-voltage or large-current power lines from other lines, and avoid parallel or common wiring with the

power lines when you are wiring to the terminals.

(8) Use the Digital Controller within the rated load and power supply.

(9) Make sure that the rated voltage is attained within two seconds of turning ON the power using a switch or relay

contact. If the voltage is applied gradually, the power may not be reset or output malfunctions may occur.

(10) Make sure that the Digital Controller has 30 minutes or more to warm up after turning ON the power before starting

actual control operations to ensure the correct temperature display.

(11)

When executing self-tuning, turn the load and the unit ON simultaneously, or turn the load ON before you turn the controller ON.

(12) A switch or circuit breaker should be provided close to this unit. The switch or circuit breaker should be within easy

reach of the operator, and must be marked as a disconnecting means for this unit.

(13) Wipe off any dirt from the Digital Controller with a soft dry cloth. Never use thinners, benzine, alcohol, or any cleaners

that contain these or other organic solvents. Deformation or discoloration may occur.

(14)

Design system (control panel, etc) considering the 2 second of delay that the controller’s output to be set after power ON.

(15)

The output will turn OFF when you move to the Initial Setting Level. Take this into consideration when performing control.

(16) The number of non-volatile memory write operations is limited. Therefore, use RAM write mode when frequently

overwriting data during communications or other operations.

(17) When disassembling the Digital Controller for disposal, use suitable tools.

(18) Do not connect cables to both the front-panel Setup Tool port and the top-panel Setup Tool port at the same time. The

Digital Controller may be damaged or may malfunction.

(19)

Do not exceed the communications distance that is given in the specifications and use the specified communications cable.

Refer to the E5@C Digital Controllers User’s Manual (Cat.No. H174) for the communications distance and cable specifications.

(20) Do not turn the power supply to the Digital Controller ON or OFF while the USB-Serial Conversion Cable is connected.

The Digital Controller may malfunction.

(21) The maximum terminal temperature is 75°C. Use wires with a heat resistance of 75°C min to wire the terminals.

(22) Observe the following precautions when you wire the Digital Controller.

• Do not wire anything to the release holes.

• When you insert a flat-blade screwdriver into a release hole on the terminal block, do not tilt or twist the

screwdriver. The terminal block may be damaged.

• Insert a flat-blade screwdriver into the release holes at an angle. The terminal block may be damaged if you insert

the screwdriver straight in.

• Do not allow the flat-blade screwdriver to fall out while it is inserted into a release hole.

• Do not bend a wire past its natural bending radius or pull on it with excessive force. Doing so may cause the wire

to break.

• Do not use crossover wiring except for the input power supply and communications.

Power supply voltage

Operating voltage range

Power consumption

Option 000:

All other specifications:

Indication accuracy

(Ambient temperature: 23°C)

Event input

Contact input

No-contact input

Remote SP input

Control output 1

Control method

Auxiliary outputs

Transfer output

Ambient temperature

Ambient humidity

Storage temperature

Altitude

Recommended fuse

Weight

Degree of protection

Installation environment

Memory protection

Temporary overvoltage

100 to 240 VAC, 50/60 Hz or

24 VAC, 50/60 Hz / 24VDC

85 to 110% of the rated voltage

6.6 VA max. (100 to 240 VAC)

4.1 VA max. (24 VAC)/2.3 W max. (24 VDC)

8.3 VA max. (100 to 240 VAC)

5.5 VA max. (24 VAC)/3.2 W max. (24 VDC)

Thermocouple:

(±0.3 % of indication value or ±1°C,

whichever is greater) ±1 digit max.

Platinum resistance thermometer:

(±0.2 % of indication value or ±0.8°C,

whichever is greater) ±1 digit max.

Analog input: ±0.2 % FS ±1 digit max.

Output current: approx. 7 mA per contact.

21NȍPD[2))NȍPLQ

ON: residual voltage 1.5 V max.,

OFF: leakage current 0.1 mA max.

4 to 20 mA DC or 0 to 20 mA DC

0 to 5 V DC or 1 to 5 V DC or 0 to 10 V DC

Relay output: SPST-NO,

250 VAC, 5 A (resistive load)

Electrical life of relay: 100,000 operations

Voltage output (for driving SSR):

12 VDC ±20%, 40 mA

ON/OFF or 2-PID control

Relay outputs: 250 VAC, two outputs: 3 A

(resistive load), four outputs: 2 A (resistive load)

Electrical life of relay: 100,000 operations

WRP$'&ZLWKORDGRIȍPD[

WR9'&ZLWKORDGRINȍPLQ

–10 to 55°C *

(Avoid freezing or condensation)

25 to 85%

–25 to 65°C

(Avoid freezing or condensation)

Max. 2,000 m

T2A, 250 VAC, time-lag, low-breaking capacity

Approx. 210 g (Digital Controller only)

Front panel: IP66

Rear case: IP20, Terminal section: IP00

Overvoltage category II, pollution

degree 2 (as per IEC61010-1)

Non-volatile memory

(Number of write operations: 1,000,000)

Short term: 1200 V+ (power supply voltage)

Long term: 250 V+ (power supply voltage)

Indicates a potentially hazardous situation which, if

not avoided, is likely to result in minor or moderate

injury or property damage. Read this manual

carefully before using the product.

Refer to the E5□C Digital Controllers User’s Manual (Cat.No. H174) for

detailed application procedures.

Dimensions (mm)

* Do not remove the terminal block. Doing so may result in failure or malfunction.

* Setup Tool ports are provided on the top and front of the Digital Controller. Use these ports to connect a personal computer

to the Digital Controller when using the Setup Tool. The E58-CIFQ2 USB-Serial Conversion Cable is required to connect to

the top-panel port. The E58-CIFQ2-E USB-Serial Conversion Cable is required to connect to the front-panel port. (Do not

use the product with the USB-Serial Conversion Cable left permanently connected.)

Refer to the instruction manual provided with the USB-Serial Conversion Cable for details on connection methods.

* If the front-panel port cover is lost or damaged, order it separately. The Waterproof Packing should be periodically replaced

because it may deteriorate, shrink, or harden depending on the operating environment.

Sold Separately

• USB-Serial Conversion Cable (E58-CIFQ2)

• Conversion Cable (E58-CIFQ2-E)

In the pack:

• Main unit

• Instruction manual

• Watertight packing (Y92S-P9): c

• Two adapters (Y92F-51): d

• Front-panel Setup Tool port cover (Y92S-P7): e

• The default is“5”.

•

s.err will be displayed when a platinum resistance thermometer is mistakenly connected while

input type is not set for it. To clear the s.err display, correct the wiring and cycle the power supply.

*1: Upper and lower limits can be set for parameters 1, 4 and 5 to provide for different types

of alarm. These are indicated by the letter "L" and "H".

• The default alarm type is "2"

Alarms (Alarms are output from auxiliary outputs.)

Conformance to EN/IEC Standards

This is a class A product.

In residential areas it may cause radio interference, in which case the user may be required to

take adequate measures to reduce interference.

Ͳ匏匶匶櫋怺殯愯暧皻柦匶沖沲

決匶匶垚櫋怺殯Ͳ匏洊沖砒洇穯匶匶嵢昢砖廪沖嬖垚斲殯沖垚決洖汊渂汞穞柢匶

愚岂彶儆洛歾汞滆櫳櫖昢斲殯穞垚冉汊徯洇求嵢穯城埪

*1

*1

*1

Alarm type

Vary with

"L", "H" values

Vary with

"L", "H" values

Vary with

"L", "H" values

No alarm function Output off

Deviation upper/lower limit

standby sequence ON

Absolute value upper limit

Absolute value lower limit

Absolute value upper limit

standby sequence ON

Absolute value lower limit

standby sequence ON

LBA (only for alarm 1)

Deviation lower limit

standby sequence ON

Deviation upper limit

standby sequence ON

Deviation upper/lower range

Deviation upper limit

Deviation lower limit

Alarm output function

Positive alarm value (X)

Negative alarm value (X)

Setting

PV Change Rate Alarm

X

ON

OFF SP

X

ON

OFF SP

ON

OFF SP

X

X

ON

OFF SP

LH

ON

OFF SP

X

ON

OFF SP

X

ON

OFF SP

X

ON

OFF 0

ON

OFF

X

0

X

ON

OFF 0

X

ON

OFF 0

ON

OFF

X

0

X

ON

OFF 0

X

ON

OFF 0

X

ON

OFF 0

X

ON

OFF 0

X

ON

OFF 0

ON

OFF

X

0

ON

OFF

X

0

ON

OFF

X

0

ON

OFF

X

0

LH

ON

OFF SP

SP

ON

OFF

X

ON

OFF

X

0

1

0

2

3

4

5

6

7

8

9

SP absolute value upper limit

SP absolute value lower limit

14

15

MV absolute value upper limit

MV absolute value lower limit

16

17

10

11

12

13

SP

X

ON

OFF

ON

OFF

X

0

LH

ON

OFF

SP

Conformance to Safety Standard

Reinforced insulation is provided between input power supply, relay outputs, and between

other terminals.

Do not allow temporary overvoltages on the primary circuit to exceed the following values.

Check the power supply voltage to the Digital Controller.

Short-term overvoltage: 1,200 V + (Power supply voltage)

Long-term overvoltage: 250 V + (Power supply voltage)

Always externally connect the recommended fuse that is specified in the Instruction Manual before you use the Digital Controller.

Analog Input

•

If you input an analog voltage or current, set the Input Type parameter to the correct input type.

• Do not use the Digital Controller to measure a circuit with Measurement Category II, III, or IV.

•

Do not use the Digital Controller to measure an energized circuit to which a voltage that exceeds 30 Vrms or 60 VDC is applied.

The protection provided by the Digital Controller may be impaired if the Digital Controller is

used in a manner that is not specified by the manufacturer.

4 to 20mA

0 to 20mA

1 to 5V

0 to 5V

0 to 10V

Setting range

Input type Input

Pt100

JPt100

Thermocouple

Infrared

Thermosensor

ES1B

K

J

T

E

L

U

N

R

S

B

W

PL II

Setting

10 to 70°C

60 to 120°C

115 to 165°C

140 to 260°C

-200 to 850

-199.9 to 500.0

0.0 to 100.0

-199.9 to 500.0

0.0 to 100.0

-200 to 1300

-20.0 to 500.0

-100 to 850

-20.0 to 400.0

-200 to 400

-199.9 to 400.0

-200 to 600

-100 to 850

-200 to 400

-199.9 to 400.0

-200 to 1300

0 to 1700

0 to 1700

100 to 1800

0 to 2300

0 to 1300

0 to 90

0 to 120

0 to 165

0 to 260

-300 to 1500

-199.9 to 900.0

0.0 to 210.0

-199.9 to 900.0

0.0 to 210.0

-300 to 2300

0.0 to 900.0

-100 to 1500

0.0 to 750.0

-300 to 700

-199.9 to 700.0

-300 to 1100

-100 to 1500

-300 to 700

-199.9 to 700.0

-300 to 2300

0 to 3000

0 to 3000

300 to 3200

0 to 3200

0 to 2300

0 to 190

0 to 240

0 to 320

0 to 500

Platinum

resistance

thermometer

Temperature inputs

°C °F

Use the following ranges for scaling: -1999

to 9999, -199.9 to 999.9, -19.99 to 99.99,

-1.999 to 9.999

Analog

input type

Current input

Voltage input

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

When complying with EMC standards, the line connecting the sensor must be 30 m or less.

If the cable length exceeds 30 m, compliance with EMC standards will not be possible.

Connections Do not connect anything to the terminals that are shaded gray.

The E5EC is set for a K thermocouple (input type

of 5) by default. If a different sensor is used, an

input error 䠄s.err䠅will occur.

Check the setting of the Input Type parameter.

Relay output

250 VAC, 5 A

(resistive load)

Voltage output

(for driving SSR)

12 VDC, 40 mA

Control output 1

Relay output

two outputs 250 VAC, 3 A

(resistive load)

four outputs 250 VAC, 2 A

(resistive load)

Auxiliary output 1, 2, 3, 4

1

2

3

4

5

6

7

8

33

34

35

36

37

38

39

40

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

9

10

11

12

13

14

15

16

41

42

43

44

45

46

47

48

1

2

3

4

To another E5䖴C

Wiring Example:

100 to 240 VAC 24 VAC/DC

1

2

3

4

*

*

(no polarity)

1

2

3

4

*

*

Input Power Supply

TC

-

+

30

31

32

Pt

30

31

32

A

B

B

-

+

I

mA 30

31

32 V

-

+

V

30

31

32

Sensor

Temperature/Analog

Input

011

Six event inputs, one CT, transfer output, and remote SP

008

Communications, two event

inputs, and one CT

010

Four event inputs

and one CT

Options

Auxiliary outputs 1 and 2

Auxiliary output 2

9

10

11

12

13

14

15

16

Auxiliary output 1

Auxiliary Outputs

Auxiliary output 2

9

10

11

12

13

14

15

16

*

Auxiliary output 1

Auxiliary output 4

Auxiliary output 3

*

Auxiliary outputs 1 to 4

One relay output One voltage output

(for driving SSR)

RX QX

A D

OUT1

R+

-

5

6

5

6

OUT1

Q

Control Outputs 1

E5EC-

@@@@BM-@@@

Options

Input Power Supply

Auxiliary Outputs

Control Output 1

17

18

19

20

21

22

23

CT1

24

25

26

*

*

EV4

EV3

EV2

EV1

17

18

19

20

21

22

23

CT1

24

25

26

*

*

*

B(+)

A(-)

RS-485

(-)

(-)

(-)

(-)

(-)

(-)

(-)

(-)

(-)

(-)

(-)

(-)

EV2

EV1

17

18

19

20

21

22

23

CT1

24

25

26

*

*

EV4

EV3

EV2

EV1

45

46

47

48

-

+

+

Transfer

output

Remote

SP

V

I

41

42

43

44

37

38

39

40

*

-

+

+

V

mA

EV6

EV5

Common terminals are indicated with asterisks (*).

You can use the input power supply and

communications common terminals for

crossover wiring.

Do not exceed the maximum number of Digital

Controllers given below if you use crossover

wiring for the input power supply.

100 to 240 VAC Controllers: 16 max.

24 VAC/VDC Controllers: 8 max.

(The applicability of the electric terminals varies with the type of machine.)

Refer to the E5

@

C Digital Controllers User’s Manual (Cat.No. H174) for information on the Advanced

Function Setting Level, Manual Control Level, and other functions.

Refer to the E5

@

C Digital Controllers Communications Manual (Cat.No. H175) for information on

communications.

*2: Error shown only for "Process value / Set point". Not shown for other status.

When an error has occurred, the No.1 display shows the error code. Take necessary measure

according to the error code, referring the table below.

If the input value exceeds the display limit (-1999 to 9999), though it is within the control

range, [[[[ will be displayed under -1999 and ]]]] above 9999.

Under these conditions, control outputs and alarms will operate normally.

Refer to the E5@C Digital Controllers User’s Manual (Cat. No. H174) for the controllable ranges.

Check the setting of the Input Type parameter,

check the input wiring, and check for broken or

shorts in the temperature sensor.

Turn the power OFF then back ON again. If the

display remains the same, the controller must be

repaired. If the display is restored to normal, then

a probable cause can be external noise affecting

the control system. Check for external noise.

After the check of input error, turn the power OFF

then back ON again. If the display remains the

same, the controller must be repaired. If the

display is restored to normal, then a probable

cause can be external noise affecting the control

system. Check for external noise.

No.1 display Meaning

A/D converter error

*2

Memory error

Input error

*2

s.err (S. Err)

e111 (E111)

Action

OFF

Alarm

Control

output

Status at error

OFF

OFF

Operates

as above the

upper limit.

OFF

OFF

e333 (E333)

Error Display (troubleshooting)

Other functions

OMRON EUROPE B.V. (Importer in EU)

Wegalaan 67-69, NL-2132 JD Hoofddorp The Netherlands

Phone 31-2356-81-300

FAX 31-2356-81-388

OMRON ELECTRONICS LLC

2895 Greenspoint Parkway, Suite 200 Hoffman Estates, IL 60169 U.S.A.

Phone 1-847-843-7900

FAX 1-847-843-7787

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark, Singapore 119967

Phone 65-6835-3011

FAX 65-6835-2711

OMRON Corporation (Manufacturer)

Shiokoji Horikawa, Shimogyo-ku, Kyoto 600-8530 JAPAN

X

ON

OFF 0

X

ON

OFF 0

ON

OFF

X

0

ON

OFF

X

0

RSP absolute value upper limit

RSP absolute value lower limit

18

19

prst

rset

Program Start

M

M

lcr1

0.0

Leakage Current 1

Value Monitor

(Unit: A)

M

M

Protect Level

M

sp-0

0

oapt

0

pmov

0

pmsk

on

icpt

1

wtpt

off

prlp

0

Mchgp

off

M

M

M

M

M

M

pfpt

off

M

*4

*6

Operation / Adjustment Protect

Restricts displaying and

modifying menu items in

Operation, Adjustment, and

Manual Control Levels.

Move to Protect Level

Displayed only when a

password is set.

Restricts moving to

Protect Level.

Changed

Parameters Only

Parameter Mask

Enable

Displayed only

when a parameter

mask is set.

Initial Setting /

Communication Protect

Restricts movement to the

Initial Setting, Communications

Setting, and Advanced Function

Setting Levels.

Setting Change Protect

Restricts changes to settings

by operating the front panel keys.

PF Key Protect

Restricts PF

key operation.

POWER ON

MV Monitor

(Heating)

o

0.0

MV Monitor

(Cooling)

c-o

0.0

in-t

5

in-h

100

in-l

0

dp

0

d-u

c

sl-h

1300

sl-l

-200

cntl

onof

s-hc

stnd

st

on

ptrn

off

cp

20

c-cp

20

Password to

Move to Protect

Level

l.adj

at

off

ct1

0.0

Communications Writing

cmwt

off

SP Mode

spmd

lsp

Heater Burnout

Detection 1

(Unit: A)

hb1

0.0

Soak Time

soak

1

MV Upper Limit

ol-h

100.0

Wait Band

wt-b

off

MV at Stop

mv-s

0.0

MV at PV Error

mv-e

0.0

SP Ramp Set Value

sprt

off

SP Ramp Set Value

(SP Ramp Fall Value)

sprl

same

Hysteresis

(Cooling)

chys

1.0

Remote SP input

Slope Coefficient

rsrt

1.000

Leakage Current 1

Value Monitor

(Unit: A)

lcr1

0.0

Integral Time

(Unit: Seconds)

i

233

Derivative Time

(Unit: Seconds)

d

40

MV Lower Limit

ol-l

0.0

MV Change

Rate Limit

orl

0.0

Extraction of Square

Root Low-cut Point

Work Bits 1 to 8

ON Delay

Work Bits 1 to 8

OFF Delay

sqrp

0.0

HS Alarm 1

(Unit: A)

hs1

50.0

25

0

AT Execute/Cancel

100%AT Execute at-2

40%AT Execute at-1

Dead Band

c-db

0.0

Manual Reset Value

Clears the offset

during P or PD control.

of-r

50.0

Hysteresis

(Heating)

hys

1.0

Proportional

Band

p

8.0

Integral Time

(Cooling)

(Unit: Seconds)

c-i

233

Derivative Time

(Cooling)

(Unit: Seconds)

c-d

40

Proportional

Band (Cooling)

c-p

8.0

Alarm 1 to 4

Hysteresis

Operation stopped.

(Both control and auxiliary outputs are stopped.)

Input Type *3

Scaling Upper Limit

(only when setting

analog input)

Scaling Lower Limit

(only when setting

analog input)

Decimal Point

(only when setting

analog input)

Temperature

Unit

SP Upper Limit

SP Lower Limit

PID•ON/OFF

In ON/OFF control = onof

In 2-PID control = pid

Standard or Heating/Cooling

Standard control =

stnd

Heating and cooling control =

h-c

Control Period (Heating)

(Unit: Seconds)

*Voltage output (for driving SSR): 2

Alarm 1 to 4 Type

Control Period (Cooling)

(Unit: Seconds)

*Voltage output (for driving SSR): 2

°C= c

°F= f

ST (Self-tuning)

ST ON = on

ST OFF = off

Direct/Reverse Operation

In Reverse operation

(Heating) =

or-r

In Direct operation

(Cooling) =

or-d

*3

Program Pattern

Initial Setting Level

Initial setting level enables users to specify their preferred operating conditions

(input type, alarm type, control method, etc.)

(No.1 display flashes,

then the control stops.)

Hold Odown

for at least

3 seconds

Hold Odown

for at least

1 second

(The No.3 display

has been omitted.)

Press O

(less than

1 second)

Operation Level

Check the wiring before turning ON the power supply.

Process Value/Set Point

s.err

is displayed when

connected sensor is

different from input type.

sp-m

0

ct1

0.0

Multi-SP

Set Point Selection

m-sp

0

Remote SP Monitor

rsp

0.0

Auto/Manual Switch

PID control only.

a-m

Set Point During

SP Ramp

Heater Current 1

Value Monitor

(Unit: A)

Operation level should normally be used during operations.

Hold Oand Mkeys

down for at least 1 second

Hold Oand Mkeys

down for at least 3 seconds

Restricts which settings can be displayed or changed, and restricts

change by key operation.

Adjustment Level

Heater Current 1

Value Monitor

(Unit: A)

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

Communications

Monitor

plcm

0

orev

or-r

M

alt1

2

alh1

0.2

M

Transfer Output

Type

tr-t

off

Transfer Output

Upper Limit

tr-h

100.0

Transfer Output

Lower Limit

tr-l

0.0

Event Input

Assignment 1

ev-1

msp0

Event Input

Assignment 2

ev-2

stop

Event Input

Assignment 3 to 6

Transfer Output

Signal

trst

4-20

M

M

M

M

M

M

M

ev-3

none

sqr

off

Move to Advanced

Function Setting

Level

amov

0

M

M

M

run

stop

sktr

0

r-s

run

Soak Time

Remain

When control start

=

When control stop

=

RUN/STOP

M

M

Alarm Value

Lower Limit

1 to 4

Alarm Va

lue

1 to 4

Alarm Value

Upper Limit

1 to 4

al1l

0

al-1

0

al1h

0

M

M

*3: Refer to the adjoining tables for details of input types and alarm types.

*4:

Operation is stopped when moved to the initial setting level. (Both control and auxiliary outputs are stopped.)

*5:

The grayed-out setting items are not displayed for some models and some settings of other setting items.

Typical example: The parameters are not displayed under the following conditions.

• AT Execute/Cancel: Not displayed if PID ON/OFF is set to ON/OFF.

• SP Ramp Set Value: Not displayed if ST is set to ON.

•

Alarm 1 Type: The default settings of the models that equipped with HB/HS alarms.

Can be displayed for a Controller with heater burnout and SSR failure detection if alarm 1 (default

setting) is set for the Auxiliary Output 1 Assignment (Advanced Function Setting Level).

Refer to the E5@C Digital Controllers User’s Manual (Cat. No. H174) for the setting method.

*6: The four numeric digits of the product code are displayed in the No. 2 display. The setting cannot be

changed and there is nothing that you need to set.

PV

Input Shift

ins

0.0

PV input

Slope Coefficient

inrt

1.000

Remote SP

Input Shift

rss

0.0

M

M

M

w1on

0

w1of

0

M

SP 0 to 7

Only the value set to the ins: Temperature Input Shift parameter is applied to the entire temperature input range.

When the process value is 200°C, the process value is treated as 201.2°C after input shift if the input shift value is

set to 1.2°C. The process value is treated as 198.8°C after input shift if the input shift value is set to -1.2°C.

M

M

Adjustment level is for entering set values and shift values

for control.

Extraction of

Square Root Enable

(Only when analog

input is set)

M

Adjustment Level

Displayed only once

when entering

Adjustment Level.

Use no-voltage inputs for the event inputs.

The polarity for non-contact inputs is given

in parentheses.

EC-B21

48

96

(71.4)

4

1

67.4

110

cd

e

44

91

Precautions for Correct Use

Use the following procedure to remove wires

from the terminal block.

The same method is used to remove stranded

wires, solid wires, and ferrules.

1. Hold a flat-blade screwdriver at an angle and

insert it into the release hole.

2.

With the screwdriver still inserted into the release hole,

remove the wire from the terminal insertion hole.

3.

Remove the flat-blade screwdriver from the

release hole.

Model

XW4Z-00B

Manufacturer

Omron

Ɣ5HFRPPHQGHG)ODWEODGH

Screwdriver

Use a flat-blade screwdriver

to connect and remove wires.

Use the following flat-blade

screwdriver.

If a wire is difficult to connect because it is too

thin, use a flat-blade screwdriver in the same

way as when connecting stranded wire.

Ɣ&RQQHFWLQJ:LUHVZLWK)HUUXOHVDQG6ROLG

Wires

Insert the solid wire or ferrule straight into the

terminal block until the end strikes the terminal

block.

Ɣ&RQQHFWLQJ6WUDQGHG:LUHV

Use the following procedure to connect the

wires to the terminal block.

1. Hold a flat-blade screwdriver at an angle and

insert it into the release hole.

The angle should be between 10° and 15°. If

the flat-blade screwdriver is inserted correctly,

you will feel the spring in the release hole.

2. With the screwdriver still inserted into the

release hole, insert the wire into the terminal

hole until it strikes the terminal block.

3. Remove the flat-blade screwdriver from the

release hole.

Ɣ&KHFNLQJ&RQQHFWLRQV

•

After the insertion, pull gently on the wire to

make sure that it will not come off and the wire

is securely fastened to the terminal block.

• To prevent short circuits, insert the stripped

part of a stranded or solid wire or the

conductive part of a ferrule until it is hidden

inside the terminal insertion hole. (See the

following diagram.)

ƔPart Names of the Terminal Block

1. Connecting Wires to Push-In Plus

Terminal Block

2. Removing Wires from Push-In

Plus Terminal Block

3. Recommended Tools

0.4 mm

2.5 mm dia.

2.5 mm

Side Front

Release hole

Terminal

(Insertion) hole

Ferrules and

Solid Wires

12

3

Flat-blade

screwdriver

10 to 15°

12

3

Flat-blade

screwdriver

10 to 15°

Ự傼Ṭ

裏面は日本語です

Ự傼ઈ ˖

妽彺汆穢剳檺嵢

沗昷夞檺沎枻城埪

* For models with two control outputs and a 011, 012, 013, or 014 option, the

ambient temperature for side-by-side mounting must be 45°C or lower.

Deviation upper/lower limit

LH

ON

OFF

SP

ㅜᆿޞḽ

൞䗉ޛ⭫ⓆȽ㔝⭫ಞ䗉࠰ҁ䰪ԛެᆹㄥᆆҁ䰪ᨆבҼᕰ㔓㕎Ⱦ

ࣗᗻֵᗍ⭫Ⓠж⅗םр⭕Ⲻⷢ䰪䗽⭫ুу㾷䎻䗽ԛс⭫ুٲȾ

䘎䈭➝ᵢӝⲺ⭫Ⓠ⭫ু䘑㺂⺤䇚Ⱦ

⸣ᰬ䰪䗽⭫ুφ9δ⭫Ⓠ⭫ুε

䮵ᰬ䰪䗽⭫ুφ9δ⭫Ⓠ⭫ুε

൞ֵ⭞ᵢӝᰬθ䈭ࣗᗻཌ䈪᱄Ҝр᧞㦆Ⲻؓ䲟ѓȾ

ީӄ⁗ᤕ䗉ޛ

g䗉ޛ⭫ুᡌ⭫⍷ᰬθ䈭➝ᵢӝⲺ䗉ޛ㊱ࡡ䇴ᇐ䗉ޛ㊱ශȾ

g䈭ሼᵢӝ⭞ᶛ⎁ᇐć⎁䠅㤹⮪Ѱ,,Ƚ,,,Ƚ,9ĈⲺഔ䐥Ⱦ

g䈭ሼᵢӝ⭞ᶛ⎁ᇐćদࣖ⭫ু䎻䗽9UPVᡌ9'&ĈⲺሯ䊗Ⱦ

ྸӝᵠᵢޢᇐⲺᯯ⌋ֵ⭞θ䛙Ѿӝޭ༽Ⲻؓᣚࣕ㜳ᖾ㜳ᦕඅȾ

X

ON

OFF 0

X

ON

OFF 0

ON

OFF

X

0

ON

OFF

X

0

RSP㔓ሯٲр䲆

RSP㔓ሯٲс䲆

18

19

25

26

27

28

29

䗉ޛ㊱ශ 䗉ޛ

Pt100

JPt100

K

J

T

E

L

U

N

R

S

B

W

PL II

䇴ᇐ

oapt

0

pmov

0

chgp

off

pmsk

on

icpt

1

wtpt

off

pfpt

off

䙐⭫

o

0.0

c-o

0.0

in-t

5

in-h

100

in-l

0

dp

0

d-u

c

sl-h

1300

sl-l

-200

cntl

onof

s-hc

stnd

st

on

ptrn

off

cp

20

c-cp

20

orev

or-r

tr-t

off

tr-h

100.0

tr-l

0.0

ev-1

msp0

ev-2

stop

prlp

0

∗6

l.adj

at

off

ct1

0.0

䙐ؗߏޛ

cmwt

off

SP⁗ᕅ

spmd

lsp

hb1

0.0

ؓᰬ䰪

soak

1

MVр䲆

ol-h

100.0

ㅿᖻ䰪

wt-b

off

ڒ↘ᰬⲺMV

mv-s

0.0

PV࠰䭏ᰬⲺMV

mv-e

0.0

SPᯒ䇴ᇐٲ

sprt

off

sprl

same

chys

1.0

rss

0.0

rsrt

1.000

lcr1

0.0

i

233

d

40

MVс䲆

ol-l

0.0

orl

0.0

sqrp

0.0

hs1

50.0

39䗉ޛ

څ〱䠅

25

0

hys

1.0

p

8.0

c-i

233

c-d

40

c-p

8.0

trst

4-20

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

ተሮδPPε

䈭൞⚦㢨ㄥᆆр䘔ԱಞԬȾ

E5EC-B

ᮦᆍᕅಞ

ᆿޞֵ⭞⌞ᝅӁ亯

ֵ⭞䈪᱄Ҝ

ֵ⭞ᰬⲺ⌞ᝅӁ亯

䆜

䆜

CHN

ᆿޞ⌞ᝅӁ亯

⅝嗏ޢ

©All Rights Reserved

䆜ㅜⲺ㾷⛯

䆜ㅜ

㓵

㿺Ṳ

ተሮ㿺Ṳ ᆿ㻻

ঋѠᆿ㻻δmmε ᒬᧈᆿ㻻δmmε

120ԛр

45 + 0.6

0

92 + 0.8

0

(48 x ঋݹᮦ䠅 - 2.5) + 1.0

0

92 + 0.8

0

gрૂс䭤

ࣞ֒⽰

gㅢжᱴ⽰

䗽ぁٲᡌ䇴ᇐᮦᦤ㊱ශ

gㅢӂᱴ⽰

䇴ᇐٲȽ䇴ᇐᮦᦤ䈱࠰ٲᡌᴪ᭯Ⲻ䗉ޛٲ

g⁗ᕅ䭤

gㅢпᱴ⽰

MVȽ࢟֏ؓᰬ䰪ૂཐSPȾ

ࢃ䶘ᶵⲺݹԬ〦

g°C / °Fφᓜঋփ

g〱փ䭤δPF䭤ε

gࢃ䶘ᶵ䈹䈋ᐛޭㄥ

g㨒ঋ䭤

ֵ⭞䈛䭤࠽ᦘ㨒ঋȾ

䘔δㄥᆆ䘸⭞ᙝഖᵰಞශ㙂ᔸȾε

ᬃ֒㨒ঋ

-200Њ850

-199.9Њ500.0

0.0Њ100.0

-199.9Њ500.0

0.0Њ100.0

-200Њ1300

-20.0Њ500.0

-100Њ850

-20.0Њ400.0

-200Њ400

-199.9Њ400.0

-200Њ600

-100Њ850

-200Њ400

-199.9Њ400.0

-200Њ1300

0Њ1700

0Њ1700

100Њ1800

0Њ2300

0Њ1300

0Њ90

0Њ120

0Њ165

0Њ260

-300Њ1500

-199.9Њ900.0

0.0Њ210.0

-199.9Њ900.0

0.0Њ210.0

-300Њ2300

0.0Њ900.0

-100Њ1500

0.0Њ750.0

-300Њ700

-199.9Њ700.0

-300Њ1100

-100Њ1500

-300Њ700

-199.9Њ700.0

-300Њ2300

0Њ3000

0Њ3000

300Њ3200

0Њ3200

0Њ2300

0Њ190

0Њ240

0Њ320

0Њ500

䇴ᇐ㤹പ

10Њ70°C

60Њ120°C

115Њ165°C

140Њ260°C

⭫⍷䗉ޛ

⭫ু䗉ޛ

4Њ20 mA

0Њ20 mA

1Њ5 V

0Њ5 V

0Њ10 V

䗉ޛ㊱ශ

✣⭫ڬ

䗉ޛ㊱ශ∗3

SPр䲆

SPс䲆

PID·ON/OFF

ֵ⭞ON/OFFᰬ= onof

ֵ⭞2䐥PIDᰬ= pid

ḽᡌࣖ✣/߭প

ḽᰬ= stnd

ࣖ✣߭পᰬ= h-c

ઞᵕδࣖ✣ε

δঋփφ〈ε

∗

⭫ু䗉࠰δ⭞ӄ傧ࣞSSRεφ2

ઞᵕδ߭পε

δঋփφ〈ε

∗

⭫ু䗉࠰δ⭞ӄ傧ࣞSSRεφ2

°C= c

°F= f

STδ㠠ṗ↙ε

ST ON = on

ST OFF = off

↙䘆㺂

䘆㺂δࣖ✣εѣ

= or-r

↙䘆㺂δ߭পεѣ

= or-d

ぁᓅ⁗ᕅ

ࡓခ䇴ᇐ㨒ঋ

ᬃ֒㨒ঋ

䙐⭫ҁࢃỶḛ㓵Ⱦ

sp-m

0

ct1

0.0

m-sp

0

䘒ぁSPⴇ

rsp

0.0

a-m

lcr1

0.0

prst

rset

sktr

0

r-s

run

ᣛ䆜ٲ1㹼4

ぁᓅࣞ

࢟֏ؓᰬ䰪

ᖉࣞ runᰬ

ᖉڒ↘ stopᰬ

RUN/STOP

ᬃ֒ᰬᓊ↙ᑮֵ⭞ᬃ֒㨒ঋȾ

䲆ԛᱴ⽰ᡌ᭯Ⲻ䇴ᇐ㊱ශԛ䙐䗽䭤ᬃ֒䘑㺂Ⲻᴪ᭯Ⱦ

ؓᣚ㨒ঋ

ެᆹࣕ㜳

䈹᮪㨒ঋ

∗2φ䭏䈥ᱴ⽰䪾ሯć䗽ぁٲ䇴ᇐٲĈθ㙂у䪾ሯެᆹ⣬ᘷȾ

ㅢжᱴ⽰ ѿ

A/D䖢ᦘ䭏䈥

∗2

ᆎ䭏䈥

䗉ޛ䭏䈥

∗2

s.err (S. Err)

e111 (E111)

ᬃ֒

OFF

ᣛ䆜䗉࠰

࠰䭏⣬ᘷ

OFF

OFF

OFF

OFF

䭏䈥ᱴ⽰δ᭻䳒䈀ᯣε

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

°C °F

ᓜঋփ

Ֆ䘷䗉࠰ؗ

Ֆ䘷䗉࠰㊱ශ

Ֆ䘷䗉࠰р䲆

Ֆ䘷䗉࠰с䲆

ӁԬ䗉ޛ࠼䞃1

ӁԬ䗉ޛ࠼䞃2

ӁԬ䗉ޛ࠼䞃

0㹼6

ཐSP

䇴ᇐٲ䘿

ᣛ䆜ٲр䲆1㹼4

ᣛ䆜ٲс䲆1㹼4

∊ׁᑜ

∊ׁᑜδ߭পε

MV⦽ᶷ䲆

䖢㠩ؓᣚ㨒ঋⲺ

ᇼ⸷

䉘ᛞ䍣Ҧ⅝嗏E5ECᮦᆍᕅಞȾ

ᵢ䈪᱄Ҝᨅ䘦ҼӝⲺࣕ㜳Ƚᙝ㜳ԛݻ࠼ᥛӝֵ⭞᭾Ⲻ

ᓊ⭞ᯯ⌋Ⱦ

䈭൞ֵ⭞䈛ӝᰬ⌞ᝅԛсӁ亯φ

gֵ⭞䈛ӝⲺӰᗻ亱ޭ༽䏩ཕⲺ⭫≊㌱㔕⸛䇼Ⱦ

g൞ֵ⭞䈛ӝࢃᓊ䙐䈱ᒬ⨼䀙ᵢ䈪᱄Ҝԛ⺤ؓ↙⺤Ⲻֵ⭞Ⱦ

gؓ㇗䈛䈪᱄Ҝԛ⺤ؓ൞䴶㾷ᰬԛ䳅ᰬḛ䰻Ⱦ

ᴿީ䈜㓼Ⲻᓊ⭞↛僚θ䈭৸䰻ɅE5ȏCᮦᆍᕅಞ⭞ᡭᢁ߂Ɇ

δCat. No. H180εȾ

㺞⽰▒൞Ⲻধ䲟߫θྸуࣖԛ䱨↘θᖾ㜳ሲ㠪䖱

ᓜᡌѣᓜⲺӰ䓡՚ᇩᡌ䍘ӝᦕඅȾ൞ֵ⭞䈛ӝࢃᓊ

Ԋ㓼䰻䈱ᵢ䈪᱄ҜȾ

䈭с㓵ᶵȾࡏθՐሲ㠪᭻䳒ᡌ䈥ࣞ֒Ⱦ

䈹䈋ᐛޭㄥ䞃㖤൞ಞⲺ京䜞ૂࢃ䶘Ⱦֵ⭞䈹䈋ᐛޭᰬθ䈭䙐䗽䘏ӑㄥሼѠӰ䇗㇍ᵰфಞ䘔Ⱦ䘔㠩京

ᶵㄥᰬθ䴶㾷ֵ⭞(&,)486%Ѩ㺂䖢ᦘ⭫㔼Ⱦ䘔㠩ࢃ䶘ᶵㄥᰬθ䴶㾷ֵ⭞(&,)4(86%Ѩ㺂䖢ᦘ⭫㔼Ⱦ

δֵ⭞䈛ӝᰬθуж䘔86%Ѩ㺂䖢ᦘ⭫㔼Ⱦε䈜㓼Ⲻ䘔ᯯ⌋θ䈭৸➝86%Ѩ㺂䖢ᦘ⭫㔼䱺ᑜⲺֵ⭞䈪᱄ҜȾ

ྸࢃ䶘ᶵㄥⴌјཧᡌᦕඅθ䈭㺂䇘䍣Ⱦṯᦤ䘆㺂⧥ູθ䱨≪ᇼሷാ㜳ՐࣙȽ᭬㕟ᡌ⺢θഖ↚䈭ᇐᵕ䘑㺂ᴪᦘȾ

ᖉᱴ⽰ᇯѰᓜᰬᱴ⽰ᓜঋփȾ

ṯᦤᓜঋփⲺ䇴ᇐٲᱴ⽰CᡌFȾ

PF䇴㖤৸ᮦ唎䇚䇴ᇐѰֵᮦփ〱

փȾ↚䭤Ѱࣕ㜳䭤Ⱦᖉс↚䭤θ

ѰPF䇴㖤৸ᮦ䇴ᇐⲺࣕ㜳ሼ⭕᭾Ⱦ

䙐䗽䈛ㄥሼಞ䘔㠩Ѡ

Ӱ䇗㇍ᵰԛֵ⭞䈹䈋ᐛޭȾ

∅ж⅗U䭤θㅢӂᱴ⽰рⲺٲሼ໔ཝᡌᱴ

⽰сжѠٲȾ

∅ж⅗D䭤θㅢӂᱴ⽰рⲺٲሼࠅቅᡌ䘊

ഔржѠٲȾ

↚䭤᭯ᱴ⽰ᇯȾ

䈛䫤1〈ԛрᯯᱴ⽰ᇯȾ

൞ᇘᡭⲺᓊ⭞ѣθ⅝嗏у䍕䍙ӝфԱᇘᡭㄥӝᡶ⎿Ⲻ㿺ṲȽ㿺㤹ૂḽ

ؓᤷж㠪ᙝȾ䈭ࣗᗻ㘹㲇ᵢӝሯӄᡶᓊ⭞Ⲻ㌱㔕Ƚᵰಞૂ䇴༽䰪Ⲻ䘸⭞ᙝȾֵ⭞

ᰬ䈭⌞ᝅᒬ䚫ᆾᵢӝⲺ⾷↘Ӂ亯Ⱦ

൞⋗ᴿ⺤䇚᮪Ѡ㌱㔕䇴䇗ᰬᡶ㘹㲇ࡦⲺ伄䲟θԛ⋗ᴿ⺤䇚൞䇴༽ૂ㌱㔕ѣ䈛⅝

嗏ӝⲺ仓ᇐֵ⭞ᶗԬૂ↙⺤ᆿ㻻ᶗԬⲺ߫сθ⾷↘ሼᵢӝᓊ⭞ӄሯӰ䓡䍘

ӝᆎ൞ћ䠃ধ䲟Ⲻ൰Ⱦ

䈜㿷ӝ㿺ṲҜѣؓ䇷ރ䍙Ӂ亯ᇯȾ

䙐⭫ᵕ䰪θ䈭䀜ㄥᆆȾ

ࡏՐഖ䀜⭫㙂ሲ㠪䖱՚Ⱦ

䈭ࣗᗻ䚫ᆾԛс⌞ᝅӁ亯θԛ䚵ރᬃ֒ཧ䈥Ƚ䈥ࣞ֒ᡌሯӝ⢯ᙝࣕ㜳䙖ᡆу㢥ᖧଃȾࡏθ㜳Րሲ㠪ᝅ

ཌӁ᭻Ⱦ䈭൞ᇐ㤹പֵ⭞ᵢӝȾ

(1) 䈛ӝ㻡䇴䇗Ѱᇚֵ⭞Ⱦ䈭൞ᇚཌֵ⭞Ⱦ䈭൞ԛсԱ൦ᯯֵ⭞ᡌᆎ᭴䈛ӝȾ

g ࣖ✣䇴༽✣䗆ሺⲺ൦ᯯȾ g ᴿ⏨։ᡌ⋯≊伔ⒻⲺ൦ᯯȾ

g 䱩ݿሺⲺ൦ᯯȾ g ᓜ࢝⛾Ⲻ൦ᯯȾ

g 㔉ߦૂ㔉䵨Ⲻ൦ᯯȾ g ᴿ䴽ࣞᡌཝⲺߨ࠱Ⲻ൦ᯯȾ

g ⚦䖹ཐᡌᴿ㞆㲶ᙝ≊։δ⢯ࡡᱥ⺡⢟≊։ૂ≞≊εⲺ൦ᯯȾ

(2) ൞仓ᇐⲺ⧥ູᓜૂ⒵ᓜ㤹പֵ⭞ૂᆎ۞ᮦᆍᕅಞȾᗻ㾷ᰬᓊ䟽ᕰ߭পȾ

(3) Ѱӄᮙ✣θу㾷ມດ䈛ӝઞപⲺグ䰪Ⱦ

у㾷ດӝⲺ䙐伄ᆊȾ

(4) ࣗᗻ↙⺤Ⲻؗ〦ૂㄥᆆᶷᙝ↙⺤㓵Ⱦ

(5)ީӄE5ȏC-B⭞Ⲻ㓵ᶆθֵ⭞ᡠ䶘〥0.25㠩1.5mm2δᖉӄAWG24ЊAWG16εⲺ㔔㓵ᡌᇔᗹ⭫㔼Ⱦ

ྸֵ⭞ྍാθ࢛㓵䮵ᓜѰ10 mmθྸуֵ⭞ྍാθࡏ࢛㓵䮵ᓜѰ8 mmȾֵ⭞ᑜUL䇚䇷δR/CεⲺྍ

ാȾㄥᆆ㜳䘔жᶗሲ㓵Ⱦ

(6) у⭞Ⲻㄥᆆу㾷㓵Ⱦ

(7)൞ಞфԛӝ⭕儎仇ૂ⎠⏂Ⲻ䇴༽ҁ䰪ᓊؓᤷ䏩ཕ䘒Ⲻ䐓⿱Ⱦሼ儎ুᡌཝ⭫⍷⭫Ⓠ㓵фެᆹሲ㓵䳊

⿱θ൞ㄥᆆ㓵ᰬ䚵ރф⭫Ⓠ㓵ާㄥᡌᒬ㚊Ⱦ

(8) ൞仓ᇐⲺ䍕䖳ૂב⭫⭫Ⓠсֵ⭞ᮦᆍᕅಞȾ

(9) ֵ⭞ᔶީᡌ㔝⭫ಞ䀜⛯ԛ⺤ؓ൞њ〈ሼ⭫ⓆѰ仓ᇐ⭫ুȾྸ⭫ুᱥ䙆⑆рⲺθ⭫Ⓠ㜳ᰖ⌋གྷ

փᡌ㘻⭕䗉࠰䈥ࣞ֒Ⱦ

(10)

൞䙐⭫Ⓠࡦᔶခᇔ䱻ᬃ֒ࢃᓊ⺤ؓಞ䘑㺂30࠼䫕ԛрⲺ人✣θԛؓ䇷↙⺤Ⲻᓜᱴ⽰Ⱦ

(11) ᢝ㺂㠠ṗ↙ᰬθ䈭ᰬ䙐䍕䖳ૂ䇴༽ᡌ㘻൞䙐ಞࢃ䙐䍕䖳Ⱦ

(12)൞䈛ӝⲺ䱺䘇ᓊ䈛ᴿᔶީᡌ㘻ᯣ䐥ಞȾᔶީᡌ㘻ᯣ䐥ಞᓊ䈛൞ᬃ֒㘻ӄཕࡦⲺ൦ᯯθᒬъᴿ᱄ᱴⲺ

ᯣᔶḽᘍȾ

(13) ⌷ᰬθ䈭⭞ᒨⲺ䖥ᐹᬜᤣȾ䈭ֵ⭞〶䠀ࡸȽ⊳⋯Ƚ䞈㋴ㅿ⓬ࡸⲺ㦥ȾࡏՐሲ㠪ᖘᡌ㢨Ⱦ

(14) ൞䇴䇗㌱㔕δྸ䶘ᶵεⲺᰬُθ䴶㾷㘹㲇ࡦಞⲺ䗉࠰൞⭫Ⓠр⭫ᴿ2〈ⲺᔬᰬȾ

(15) ᖉ࠽ᦘࡦࡓခ䇴ᇐ㨒ঋᰬθ䗉࠰㜳Րީ䰣Ⱦ൞ᇔ᯳ᰬ䴶㾷㘹㲇ࡦ䘏ж⛯Ⱦ

(16) 䶔ᥛᆎⲺߏ⅗ᮦᱥᴿ䲆ⲺȾᡶԛ൞䙐ؗᡌެᆹᬃ֒䴶㾷仇㑷䠃ߏᮦᦤᰬθ䈭ֵ⭞ RAM ߏ⁗ᕅȾ

(17) মಞ䘑㺂ᓕᔹ༺⨼ᰬθ䈭ֵ⭞䘸ᖉⲺᐛޭȾ

(18)

䈭ሼ⭫㔼ᰬ䘔ࡦࢃ䶘ᶵ䈹䈋ᐛޭㄥૂ京ᶵ䈹䈋ᐛޭㄥȾࡏθಞ㜳Ր㻡ᦕඅᡌӝ⭕䈥ࣞ֒Ⱦ

(19) 䈭䎻䗽㿺Ṳѣ㔏࠰Ⲻ䙐ؗ䐓⿱ᒬֵ⭞ᇐⲺ䙐ؗ⭫㔼Ⱦީӄ䙐ؗ䐓⿱ૂ⭫㔼㿺Ṳθ䈭৸䰻ɅE5ȏC

ᮦᆍᕅಞ⭞ᡭᢁ߂ɆδCat. No. H180εȾ

(20) 䘔Ҽ USB ㌱ࡍ䖢ᦘ⭫㔼ᰬθ䈭ᔶȽީಞⲺ⭫ⓆȾࡏՐሲ㠪ಞ᭻䳒Ⱦ

(21) ᴶཝㄥᆆᓜѰđȾֵ⭞㙆✣൞đԛрⲺሲ㓵䘔ㄥᆆȾ

(22) 䘔ᮦᆍᕅಞᰬḛⵁԛс⌞ᝅӁ亯Ⱦ

g䈭൞䠀᭴ᆊ䘔Աሲ㓵Ⱦ

gᨈޛᒩ㷰ѓ࠶㠩䠀᭴ᆊᰬθ䈭ٴᯒᡌᢣᴨ㷰ѓ࠶Ⱦࡏ㜳Րᦕඅ㓵ᶵȾ

gԛжᇐⲺ䀈ᓜሼᒩ㷰ѓ࠶ᨈޛ㓵ᶵⲺ䠀᭴ᆊȾྸㅊᨈޛ㷰ѓ࠶㜳Րᦕඅ㓵ᶵȾ

g䈭൞ሼᒩ㷰ѓ࠶ᨈޛ㓵ᶵⲺ䠀᭴ᆊᰬᦿ㩳Ⱦ

g䈭䗽ᓜᕥᴨᡌᢥሲ㓵Ⱦᴿ㜳ሲ㠪⭫㓵ᯣ㻸Ⱦ

g䈭ֵ⭞䲚䗉ޛ⭫Ⓠૂ䙐ؗҁཌⲺӚ㓵Ⱦ

ב⭫⭫ু

ᐛ֒⭫ু㤹പ

ࣕ⦽⎾㙍

䘿亯000φ

ᡶᴿެᆹ㿺Ṳφ

⽰㋴ᓜ

δ⧥ູᓜφ23°Cε

ӁԬ䗉ޛ

䀜⛯䗉ޛ

䶔䀜⛯䗉ޛ

䘒ぁSP䗉ޛ

䗉࠰1

ᯯ⌋

䖻ࣟ䗉࠰

䖢ᦘ䗉࠰

⧥ູᓜ

⧥ູ⒵ᓜ

ᆎ۞ᓜ

儎ᓜ

᧞㦆ؓ䲟ѓ

䠃䠅

䱨ᣚㅿ㓝

ᆿ㻻⧥ູ

ᆎؓᣚ

Ჸᰬ䗽⭫ু

100Њ240 VACθ50/60 Hzᡌ㘻

24 VACθ50/60 Hz/24 VDC

仓ᇐ⭫ুⲺ85Њ110%

ᴶཝ6.6VAδAC100Њ240Vε

ᴶཝ4.1VAδAC24Vε/ᴶཝ2.3WδDC24Vε

ᴶཝ8.3VAδAC100Њ240Vε

ᴶཝ5.5VAδAC24Vε/ᴶཝ3.2WδDC24Vε

✣⭫ڬ䗉ޛφ

δᱴ⽰ٲⲺ±0.3αᡌ㘻±1°CѣⲺ䖹ཝٲε

ᴶཝ±1փᮦ

䫸⭫䱱䗉ޛφ

δᱴ⽰ٲⲺ±0.2αᡌ㘻±0.8°CѣⲺ䖹ཝٲε

ᴶཝ±1փᮦ

⁗ᤕ䠅䗉ޛφ±0.2 % FS ᴶཝ±1փᮦ

䗉࠰⭫⍷φ∅Ѡ䀜⛯㓜7 mAȾ

ONφᴶཝ1 kΩθOFFφᴶቅ100 kΩ

ONφ⇁֏⭫ুᴶཝ1.5 V

OFFφ╅⭫⍷ᴶཝ0.1 mA

4Њ20 mA DCᡌ0Њ20 mA DC

0Њ5 VDCᡌ1Њ5 VDCᡌ0Њ10 VDC

㔝⭫ಞ䗉࠰φSPST-NO,

250 VACθ5 Aδ䱱ᙝ䍕䖳ε

㔝⭫ಞ⭫≊ስળφ100,000⅗䘆㺂

⭫ু䗉࠰δ⭞ӄ傧ࣞSSRεφ

12 VDC ±20%θ40 mA

ON/OFFᡌ2䐥PID

㔝⭫ಞ䗉࠰φ250 VACθ2Ѡ䗉࠰φ3 Aδ䱱ᙝ䍕䖳εθ

4Ѡ䗉࠰φ2 Aδ䱱ᙝ䍕䖳ε

㔝⭫ಞ⭫≊ስળφ100,000⅗䘆㺂

4Њ20 mA DCθᴶཝ䍕䖳500 Ω

1Њ5 VDCθᴶቅ䍕䖳1 kΩ

–10Њ55°C

δᓊ䚵ރ㔉ߦᡌ㔉䵨ε

RH 25Њ85%

–25Њ65°C

δᓊ䚵ރ㔉ߦᡌ㔉䵨ε

ᴶ儎2,000㊩

T2Aθ250 VACθᰬᔬθք⟊ᯣᇯ䠅

㓜210 gδӻᮦᆍಞε

ࢃ䶘ᶵφIP66

༩φIP20θㄥᆆφIP00

䗽⭫ুⴤᖋIIθ

⊗ḉㅿ㓝2(IEC61010-1)

䶔ᥛᆎߏ⅗ᮦφ1,000,000)

⸣ᰬ䰪䗽⭫ু9⭫Ⓠ⭫ুε

䮵ᰬ䰪䗽⭫ু9δ⭫Ⓠ⭫ুε

ᒬᧈᆿ㻻ᰖ⌋⺤ؓ䱨≪ᙝ

㜳Ⱦᖉᴿ䱨≪㾷≸ᰬθ䈭൞

ࢃ䶘ᶵⲺםᆿ㻻䱨≪ᇼሷ

ാȾ

gሼѱঋݹᨈޛ䶘ᶵδ1Њ8mmεⲺᆿ㻻ᆊѣȾᣀᆿ㻻᭥δᨆ

בεᨈޛ༩京䜞ૂᓋ䜞Ⲻരᇐ″ѣȾ

gᤝ㍝䘸䞃ಞ京䜞ૂᓋ䜞Ⲻњ仍ᆿ㻻㷰ѓֵެؓᤷᒩ㺗θᴶ㓾ֵެᢣ

⸟ؓᤷ൞0.29㠩0.39N·mҁ䰪Ⱦ

gᖉᆿ㻻ཐᵰಞᰬθ䈭⺤ؓ⧥ູᓜу䎻䗽㿺ᇐ䲆ٲȾ

уᗍ䇟䠇ኔ⢟։Ƚሲ㓵ᡌᆿ㻻ᰬӝ⭕Ⲻ࠽ኇᡌ⒵≊䘑ޛಞȽ䈹䈋ᐛޭㄥᡌ䈹䈋ᐛޭ⭫㔼䘔

ಞⲺᕋ㝐рȾࡏՐሲ㠪䀜⭫Ƚ⚡⚴ᡌᵰಞ䈥ࣞ֒Ⱦ൞уሼሷⴌ⭞ӄ䱨↘ᔸ⢟䘑ޛㄥᰬθ䈭ሼެ

ᆿ㻻ӄࢃ䶘ᶵ䈹䈋ᐛޭㄥрȾ

䈭ሼ䈛ӝ⭞ӄᴿ᱉⟹᱉⠼≊։Ⲻ൰Ⱦࡏᴿ㜳ഖѰ⠼⛮㙂䙖ᡆ䖱ᓜ՚ᇩȾ

㔓ሯу㾷মȽ᭯㻻ԛؤ⨼䈛ӝᡌ䀜Ա䜞ݹԬȾࡏՐሲ㠪䖱ᗤ䀜⭫Ƚ⚡⚴ᡌᵰಞ䈥ࣞ

֒Ⱦ

⌞ᝅι⚡⚴ᡌ䀜⭫Ⲻধ䲟

a) ᵢӝѰ8//LVWLQJ䇚䇷Ⲻᔶ᭴ශ䗽ぁ䇴༽θᗻ亱ᆿ㻻൞㜳ཕ䱨↘⚡㣧䘮࠰Ⲻᵰ༩ѣȾ

b) ൞ֵ⭞њѠԛрᯣ⭫ᔶީⲺ߫сθ㔪ؤࢃ䈭ݾᯣᔶᡶᴿᔶީθ⺤ؓᵢӝ༺ӄᯣ⭫⣬ᘷȾ

c) ؗ䗉ޛѰSELVδᆿޞքু⭫Ⓠεθഔ䐥䲆Ⱦ

d) ⌞ᝅφѰҼࠅቇ⚡⚴ᡌ䀜⭫Ⲻধ䲟θ䈭ሼуⲺ2㊱ഔ䐥Ⲻ䗉࠰ӈ㚊Ⱦ

ྸ䗉࠰㔝⭫ಞ䎻䗽Ҽ人ᵕⲺֵ⭞ስળθᴿᰬՐ⭕䀜⛯⟊ᡌ⟹✝Ⱦခ㓾㾷⌞ᝅ䗉࠰㔝⭫ಞⲺᓊ

⭞⧥ູθᒬ൞仓ᇐ䍕䖳人ᵕስળԛֵ⭞Ⱦ䗉࠰㔝⭫ಞⲺ人ᵕስળ䳅䗉࠰䍕䖳ԛᔶީᶗԬⲺ

㙂Ⱦ

䈭䇴ᇐ䘸㌱㔕⭞Ⲻӝ৸ᮦȾྸ䇴ᇐуᖉθ㜳Րഖᝅཌᬃ֒㙂䙖ᡆ䍘ӝᦕཧᡌӁ᭻Ⱦ

ಞ䈥ࣞ֒ᖾ㜳䙖ᡆᬃ֒ཧ᭾ᡌ䱱↘ᣛ䆜䗉࠰θሲ㠪䍘ӝᦕཧȾѰҼ൞ಞ⭕䈥ࣞ֒

ᰬ⺤ؓᆿޞθᓊ䟽䘸ᖉⲺᆿޞ᧠᯳θྸֵ⭞ঋ⤢Ⲻ㓵䐥ᆿ㻻ⴇ䇴༽Ⱦ

gSUB1φ䖻ࣟ䗉࠰1⽰

gSUB2φ䖻ࣟ䗉࠰2⽰

gSUB3φ䖻ࣟ䗉࠰3⽰

gSUB4φ䖻ࣟ䗉࠰4⽰

gOUT1φ䗉࠰1⽰

gRSPφ䘒ぁSP⽰

ᖉ࠼䞃ࣕ㜳ѰONᰬ⛯ӤȾ

gTUNEφ

㠠ṗ↙ᰬ䰠⛷Ⱦ

㠠᮪ᇐᰬ⛯ӤȾ

gSTOPφڒ↘⽰

൞䘆㺂ѣ“䘆㺂/ڒ↘”ڒ↘ᰬ⛯ӤȾ

൞ڒ↘ᵕ䰪θ䲚䗉࠰ҁཌⲺࣕ㜳ൽᴿ᭾Ⱦ

gCMWφ䙐ؗߏޛݷ䇮/⾷↘⽰

ᖉ䙐ؗߏޛݷ䇮ᰬ⛯Ӥθ⾷↘ᰬ➺⚣Ⱦ

gφؓᣚ⽰

ᖉ䇴ᇐᴪؓᣚѰONδ⾷⭞рȽс䭤ᰬε

ᰬ⛯ӤȾ

gMANUφᢁࣞ䗉࠰⽰

ᖉ㠠ࣞ/ᢁࣞ⁗ᕅ䇴Ѱᢁࣞ⁗ᕅᰬ⛯ӤȾ

ᓜ䗉ޛ

⁗ᤕ䠅䗉ޛ

㊱ශ

㓘ཌᓜ

Ֆಞ

ES1B

䫸⭫䱱

ᓜ䇗

ሯ∊ׁ㕟᭴䟽⭞сࡍ㤹പφ-1999Њ

9999Ƚ-199.9Њ999.9Ƚ-19.99Њ99.99Ƚ

-1.999Њ9.999

∗唎䇚ٲᱥ“5”Ⱦ

∗ᖉ䗉ޛ㊱ශуᱥ䫸⭫䱱㙂䭏䈥Ⲻሼ䫸⭫䱱ޛᰬθሼՐᱴ⽰s.errȾ㤛㾷䲚s.errᱴ⽰θ

䴶㾷↙⺤㓵ᒬ䠃᯦р⭫Ⱦ

∗3φީӄ䗉ޛ㊱ශૂᣛ䆜㊱ශⲺ䈜㓼߫θ䈭৸㘹䗯Ⲻ㺞ṲȾ

*4φᖉ䖢㠩ࡓခ䇴ᇐ㨒ঋᰬ䘆㺂ڒ↘Ⱦ

δૂ䖻ࣟ䗉࠰䜳ڒ↘ε

*5φሯӄḆӑශԛެᆹ䇴ᇐ亯ⲺḆӑ䇴ᇐθуᱴ⽰⚦㢨䇴ᇐ亯Ⱦ

ޮශ⽰ׁφ৸ᮦ൞ԛсᶗԬсуᱴ⽰Ⱦ

・ATᢝ㺂/⎾φྸPID ON/OFF䇴ᇐѰON/OFFθуՐᱴ⽰Ⱦ

・SPᯒ䇴ᇐٲφྸST䇴ᇐѰONθуՐᱴ⽰Ⱦ

・ᣛ䆜1㊱ශφ䞃༽HB/HSᣛ䆜ශⲺ唎䇚䇴ᇐȾ

ྸѰ䖻ࣟ䗉࠰1࠼䞃δ儎㓝ࣕ㜳㨒ঋε䇴ᇐҼᣛ䆜1δ唎䇚䇴ᇐεθᴿࣖ✣ಞᯣ

㓵ૂSSR᭻䳒Ỷ⎁ⲺಞՐᱴ⽰ᣛ䆜Ⱦᴿީ䇴ᇐᯯ⌋θ䈭৸䰻ɅE5ȏCᮦᆍᕅ

ಞ⭞ᡭᢁ߂Ɇ(Cat. No. H180)Ⱦ

∗6φㅢӂᱴ⽰ѣᱴ⽰փᮦⲺӝԙ⸷Ⱦ䈛䇴ᇐᰖ⌋ᴪθ⭞ᡭᰖ䴶㺂䇴ᇐȾ

ࡓခ䇴ᇐ㨒ঋԛֵ⭞ᡭᇐ⅘Ⲻᐛ֒ᶗԬδ䗉ޛ㊱ශθᣛ䆜㊱ශθᯯ⌋ㅿㅿεȾ

∊ׁ㕟᭴р䲆δӻ䲆䇴ᇐ

⁗ᤕ䠅䗉ޛᰬε

∊ׁ㕟᭴с䲆δӻ䲆䇴 ᇐ

⁗ᤕ䠅䗉ޛᰬε

ቅᮦ⛯δӻ 䲆䇴ᇐ⁗ᤕ䠅

䗉ޛᰬε δㅢжᱴ⽰䰠⛷θ

❬ڒ↘Ⱦε

㠠ࣞ/ᢁࣞ࠽ᦘ

ӻ䲆PIDȾ

SPᯒᵕ䰪Ⲻ

䇴ᇐٲ

ࣖ✣ಞ⭫⍷1ٲⴇ

δঋփφAε

╅⭫⍷1ٲⴇ

δঋփφAε

MVⴇδࣖ✣ε

MVⴇδ߭পε

䖢㠩ؓᣚ㨒ঋ

ӻ൞䇴ᇐᇼ⸷ᰬᱴ⽰Ⱦ

䲆䖢㠩ؓᣚ㨒ঋȾ

ᬃ֒䈹᮪ؓᣚ

䲆൞ᬃ֒㨒ঋȽ䈹᮪

㨒ঋૂᢁࣞ㨒ঋѣ

ᱴ⽰ૂؤ᭯㨒ঋ亯Ⱦ

ࡓခ䇴ᇐ䙐ؗؓᣚ

䲆࠽ᦘ㠩ࡓခ䇴ᇐ㨒

ঋȽ䙐ؗ䇴ᇐ㨒ঋૂ儎

㓝ࣕ㜳䇴ᇐ㨒ঋȾ

䇴ᇐᴪؓᣚ

䲆䙐䗽ᬃ֒ࢃ䶘ᶵ

䭤ᶛ᭯䇴ᇐȾ

PF䭤ؓᣚ

䲆PF䭤Ⲻᬃ֒Ⱦ

ӻ䲆ᐨᴪ᭯Ⲻ

৸ᮦ

৸ᮦኅ㭳ᴿ᭾ӻ

൞䇴ᇐҼ৸ᮦኅ

㭳ᰬᱴ⽰Ⱦ

δ↚༺ⴷ⮛Ҽㅢ

пᱴ⽰⭱䶘Ⱦε

ᴿ৸ᮦ“insφᓜ䗉ޛڅ〱”ѣⲺ䇴ᇐٲᓊ⭞ӄ᮪Ѡᓜ䗉ޛ㤹പȾྸ䗉ޛڅ〱ٲ䇴ᇐѰ1.2°Cθ

ࡏ䗽ぁٲѰ200°Cᰬθ㔅䗽䗉ޛڅ〱➝201.2°C༺⨼Ⱦ

㙂ྸ䗉ޛڅ〱ٲ䇴ᇐѰ-1.2°Cθࡏ㔅䗽䗉ޛڅ〱䗽ぁٲ➝198.8°C༺⨼Ⱦ

䈹᮪㨒ঋ

ӻ൞䘑ޛ䈹᮪㨒

ঋᰬᱴ⽰ж⅗Ⱦ

ATᢝ㺂/⎾

100%ATᢝ㺂at-2

40%ATᢝ㺂at-1

ࣖ✣ಞ⭫⍷1ٲⴇ

δঋփφAε

ࣖ✣ಞᯣ㓵Ỷ⎁1

δঋփφAε

╅⭫⍷1ٲⴇ

δঋփφAε

HSᣛ䆜1

δঋփφAε

PV䗉ޛ

ᯒ㌱ᮦ

䘒ぁSP

䗉ޛڅ〱

䘒ぁSP䗉ޛ

ᯒ㌱ᮦ

〥࠼ᰬ䰪

δঋփφ〈ε

ᗤ࠼ᰬ䰪

δঋփφ〈ε

〥࠼ᰬ䰪

δ߭পε

δঋփφ〈ε

ᗤ࠼ᰬ䰪

δ߭পε

δঋփφ〈ε

䈹᮪㨒ঋ⭞ӄ൞ᰬ䗉ޛ䇴ᇐٲૂڅ〱ٲȾ

└

δࣖ✣ε

└

δ߭পε

SPᯒ䇴ᇐٲ

δSPᯒс䲃ٲε

ᒩᯯṯⲺ䘆㇍

Low-cut⛯

ᖉ⭕жѠ䭏䈥ᰬθㅢжᱴ⽰ሼᱴ⽰䭏䈥ԙ⸷Ⱦ৸㘹с㺞θṯᦤ䭏䈥ԙ⸷

䟽䘸ᖉⲺ᧠᯳Ⱦ

e333 (E333)

Ỷḛ䗉ޛ㊱ශ৸ᮦⲺ䇴㖤θỶḛ䗉ޛ㓵ᒬỶḛ

ᓜՖಞᱥᆎ൞ᦕᡌ⸣Ⱦ

р䘦р䲆

ᣛ䆜ᐛ֒

⺤䇚䗉ޛᔸᑮθ䈭䠃᯦䙐⭫ⓆȾ

ྸᱴ⽰у

θࡏ亱ؤ⨼ಞȾྸᱴ⽰ᚘགྷ↙ᑮθࡏ᭻䳒

ഖ㜳ᱥ㌱㔕ࡦཌ䜞ᒨᢦȾ䈭Ỷḛཌ䜞ᒨ

ᢦȾ

ީᦿ⭫Ⓠ߃ᢉᔶθྸᱴ⽰уθࡏ亱ؤ⨼

ಞȾྸᱴ⽰ᚘགྷ↙ᑮθࡏ㜳ᱥ㌱㔕ࡦཌ

䜞ᒨᢦȾỶḛཌ䜞ᒨᢦȾ

ྸ䗉ޛٲ䎻࠰Ҽᱴ⽰㤹പδ-1999Њ9999εθֵᆹԃ❬൞㤹പθքӄ-1999Ⲻሼᱴ

⽰[[[[ θ儎ӄ9999Ⲻᱴ⽰ ]]]] Ⱦ൞䘏ӑᶗԬсθ䗉࠰ૂᣛ䆜ሼ↙ᑮ䘆㺂Ⱦީӄ

Ⲻ㤹പθ䈭৸䰻ɅE5ȏCᮦᆍᕅಞ⭞ᡭᢁ߂ɆδCat. No. H180εȾ

ᴿީ儎㓝ࣕ㜳䇴ᇐ㨒ঋȽⴇ/䇴ᇐ亯ⴤ㨒ঋȽᢁࣞ㨒ঋԛެᆹࣕ㜳Ⲻ䈜㓼ؗᚥθ䈭৸䰻

ɅE5ȏCᮦᆍᕅಞ⭞ᡭᢁ߂ɆδCat. No. H180εȾᴿީ䙐ؗⲺ䈜㓼ؗᚥθ䈭৸䰻ɅE5ȏC

ᮦᆍᕅಞ䙐ؗᢁ߂ɆδCat. No. H181εȾ

g൞㻻ᴿφ

gѱঋݹ

gֵ⭞䈪᱄Ҝ

g䱨≪ᇼሷാ

δ<63εφc

gњѠ䘸䞃ಞ

δ<)εφd

gࢃ䶘ᶵ䇴㖤ᐛޭㄥⴌ

δ<63εφe

Ԭ

g86%Ѩ㺂䖢ᦘ⭫㔼δ(&,)4ε

g䖢ᦘ⭫㔼δ(&,)4(ε

sqr

off

amov

0

M

M

ᒩᯯṯⲺ䘆㇍

⭞δ䲆ӄᐨ㔅䇴

ᇐҼ⁗ᤕ䗉ޛε

䖢㠩儎㓝ࣕ㜳

䇴ᇐ㨒ঋ

↱

M

c-db

0.0

of-r

50.0

ᢁࣞགྷփٲ

䲚PᡌPD

ᵕ䰪Ⲻڅ〱䠅Ⱦ

M

MM

ol-h

100.0

օO㠩

ቇ3〈

օO㠩

ቇ1〈

O

δу䎻䗽

1〈ε

gᰬօ 䭤ૂM䭤

㠩ቇ3〈ԛ࠽ᦘ㠩ؓᣚ㨒ঋȾ

M

䗽ぁٲ/䇴ᇐٲ

䘔ⲺՖಞф䗉ޛ

㊱ශуᰬθᱴ⽰

s.errȾ

M

օOૂM䭤㠩ቇ〈 օOૂM䭤㠩ቇ〈

㔝⭫ಞ䗉࠰

2Ѡ䗉࠰φ250 VACθ3 A

δ䱱ᙝ䍕䖳ε

4Ѡ䗉࠰φ250 VACθ2 A

δ䱱ᙝ䍕䖳ε

010008

䘿亯

䘿亯

䙐ؗȽ2ѠӁԬ䗉ޛૂ1ѠCT 4ѠӁԬ䗉ޛૂ1ѠCT

011

䘒ぁSP

6ѠӁԬ䗉ޛȽ1ѠCTȽ1Ѡ䖢ᦘ䗉࠰ૂ1Ѡ䘒ぁSP

䖢ᦘ

䗉࠰

Ֆಞᓜૂ⁗ᤕ䠅䗉ޛ

δᰖᶷᙝε

䗉ޛ⭫Ⓠ

100Њ240 VAC 24 VAC/DC

䗉࠰

RX QX

1Ѡ㔝⭫ಞ䗉࠰ Ѡ⭫ু䗉࠰

(⭞ӄ傧ࣞSSR)

䗉࠰1

R

䗉࠰1

Q

䖻ࣟ䗉࠰

䖻ࣟ䗉࠰1Ƚ2䖻ࣟ䗉࠰1Њ4

䖻ࣟ䗉࠰2

䖻ࣟ䗉࠰1

䖻ࣟ䗉࠰2

䖻ࣟ䗉࠰1

䖻ࣟ䗉࠰4

䖻ࣟ䗉࠰3

ѰㅜEMCḽθ䘔ՖಞⲺ⭫㔼уᗍ䎻䗽30㊩Ⱦ

ྸ⭫㔼䮵ᓜ䎻䗽30㊩θࡏуㅜEMCḽȾ

E5EC唎䇚䇴ᇐѰжKශ✣⭫ڬδ䗉ޛ㊱ශ5εȾ

ྸֵ⭞уⲺՖಞθࡏՐ⭕䗉ޛ䭏䈥

δs.errεȾỶḛ䗉ޛ㊱ශ৸ᮦⲺ䇴㖤Ⱦ

䖻ࣟ䗉࠰1Ƚ2Ƚ3Ƚ4

∗1:

㾷ֵ৸ᮦ1Ƚ4Ƚ5ᨆבуⲺᣛ䆜㊱ශθሯެ䇴ᇐр䲆фс䲆Ⱦс䲆ૂр䲆࠼ࡡ⭞ᆍ∃ LૂH⽰Ⱦ

• 唎䇚Ⲻᣛ䆜㊱ශѰ“2”

ᣛ䆜δᣛ䆜ᱥᶛ㠠䖻ࣟ䗉࠰Ⲻ䗉࠰Ⱦε

㓵⽰ׁφ

㠩ެԌE5ȏC

∗1

∗1

∗1

ᣛ䆜㊱ශ

ṯᦤLȽHٲ

Ⲻу㙂у

ṯᦤLȽHٲ

Ⲻу㙂у

ṯᦤLȽHٲ

Ⲻу㙂у

ᰖᣛ䆜ࣕ㜳 ᰖ䗉࠰

㔓ሯٲр䲆

㔓ሯٲс䲆

LBAδӻሯᣛ䆜1ε

څᐤр/с㤹പ

څᐤр䲆

څᐤр/с䲆

څᐤс䲆

ᣛ䆜䗉࠰ࣕ㜳

↙ᣛ䆜ٲδXε

䍕ᣛ䆜ٲδXε

䇴ᇐ

PV⦽ᣛ䆜

X

ON

OFF SP

X

ON

OFF SP

ON

OFF SP

X

X

ON

OFF SP

LH

ON

OFF SP

X

ON

OFF SP

X

ON

OFF SP

X

ON

OFF 0

ON

OFF

X

0

X

ON

OFF 0

X

ON

OFF 0

ON

OFF

X

0

X

ON

OFF 0

X

ON

OFF 0

X

ON

OFF 0

X

ON

OFF 0

X

ON

OFF 0

ON

OFF

X

0

ON

OFF

X

0

ON

OFF

X

0

ON

OFF

X

0

LH

ON

OFF SP

SP

ON

OFF

X

ON

OFF

X

0

1

0

2

3

4

5

6

7

8

9

SP㔓ሯٲр䲆

SP㔓ሯٲс䲆

14

15

MV㔓ሯٲр䲆

MV㔓ሯٲс䲆

16

17

10

11

12

13

SP

X

ON

OFF

ON

OFF

X

0

ㅜEN/IECḽ

䘏ᱥж〃A㊱ӝȾ

ഖެ൞օᆻѣՐሲ㠪ᰖ㓵⭫ᒨᢦθᡶԛ㾷≸⭞ᡭ䟽䘸ᖉⲺ᧠᯳ࠅቇᒨᢦȾ

څᐤр/с䲆ᖻᵰᓅࡍON

څᐤр䲆ᖻᵰᓅࡍON

څᐤс䲆ᖻᵰᓅࡍON

㔓ሯٲр䲆ᖻᵰᓅࡍON

㔓ሯٲс䲆ᖻᵰᓅࡍON

SP 0 㹼7

䜞䖻ࣟ㔝⭫ಞ

1Њ8

ONᔬᰬ

䜞䖻ࣟ㔝⭫ಞ

1Њ8

OFFᔬᰬ

䙐ؗⴇ

ᣛ䆜Њ㊱ශ

∗3

ᣛ䆜

Њ

└

1

2

3

4

5

6

7

8

33

34

35

36

37

38

39

40

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

9

10

11

12

13

14

15

16

41

42

43

44

45

46

47

48

1

2

3

4

1

2

3

4

*

*

1

2

3

4

*

*

TC

-

+

30

31

32

Pt

30

31

32

A

B

B

-

+

I

mA 30

31

32 V

-

+

V

30

31

32

9

10

11

12

13

14

15

16

9

10

11

12

13

14

15

16

*

*

A D

+

-

5

6

5

6

E5EC-

@@@@BM-@@@

䗉ޛ⭫Ⓠ

䖻ࣟ䗉࠰

䗉࠰

17

18

19

20

21

22

23

CT1

24

25

26

*

*

EV4

EV3

EV2

EV1

17

18

19

20

21

22

23

CT1

24

25

26

*

*

*

B(+)

A(-)

RS-485

(-)

(-)

(-)

(-)

(-)

(-)

(-)

(-)

(-)

(-)

(-)

(-)

EV2

EV1

17

18

19

20

21

22

23

CT1

24

25

26

*

*

EV4

EV3

EV2

EV1

45

46

47

48

-

+

+V

I

41

42

43

44

37

38

39

40

*

-

+

+

V

mA

EV6

EV5

⭫ু䗉࠰

(⭞ӄ傧ࣞSSR)

㔝⭫ಞ䗉࠰

250 VACθ5 A

12 VDCθ40 mA

δ䱱ᙝ䍕䖳ε

䗉࠰1

䘆㺂ڒ↘Ⱦ

δૂ䖻ࣟ䗉࠰䜳ڒ↘Ⱦε ∗4

ev-3

none

M

M

al1l

0

al-1

0

al1h

0

M

M

M

ሯӁԬ䗉ޛֵ⭞ᰖ⭫ু䗉ޛȾ

ᰖ䀜⛯䗉ޛⲺᶷᙝ൞ᤢѣ㔏࠰Ⱦ

ާ⭞ㄥᆆԛ᱕δ*ε㺞⽰Ⱦ

ԛֵ⭞䗉ޛ⭫Ⓠૂ䙐ؗާ⭞ㄥᆆ

䘑㺂Ӛ㓵Ⱦ

ྸ䗉ޛ⭫Ⓠֵ⭞Ӛ㓵θ䈭

䎻䗽сᯯ㔏࠰Ⲻᮦᆍᕅಞᴶཝ

ᮦٲȾ

100㠩240 VACಞφᴶཝ16

24 VAC/VDCಞφᴶཝ8

ins

0.0

M

inrt

1.000

M

sp-0

0

plcm

0

M

w1on

0

w1of

0

M

M

M

alt1

2

alh1

0.2

M

Ȏ㚊㌱ᯯᕅ

Ș䙖

Șᢶᵥ䈘

⅝嗏р⎭ᴿ䲆ޢ

൦൶ѣളр⎭ᐸ⎜ђ᯦䠇ẛ࠰ࣖᐛ䠇䐥

⭫䈓(86)21-50509988

⅝嗏㠠ࣞѣളᴿ䲆ޢ

൦൶ѣളр⎭ᐸ⎜ђ᯦䬬คѣ䐥ѣ䬬ཝড়ᇚ

⭫䈓(86)21-5307-2222

㖇൶http://www.fa.omron.com.cn

ᢶᵥ䈘✣㓵

400-820-4535

(71.4)

4

1

67.4

110

cd

44

91

48

96

e

↙⺤ֵ⭞⌞ᝅӁ亯

ֵ⭞ԛс↛僚ሼሲ㓵Ԅ㓵ᶵсȾ

Ⲻᯯ⌋⭞ӄс㔔㓵Ƚᇔᗹ⭫㔼ૂྍാȾ

1.ԛжᇐ䀈ᓜᨗօᒩཪ㷰ѓ࠶ᒬሼެᨈޛ䠀᭴ᆊȾ

2.൞㷰ѓ࠶ԃᨈޛ䠀᭴ᆊᰬθሼሲ㓵Ԅㄥᆆᨈᆊѣ

сȾ

3.

Ԅ䠀᭴ᆊѣ〱䲚ᒩཪ㷰ѓ࠶Ⱦ

ශ

XW4Z-00B

䙖

⅝嗏

᧞㦆ᒩཪ㷰ѓ࠶

ֵ⭞ᒩཪ㷰ѓ࠶䘔ૂс

ሲ㓵Ⱦ

ֵ⭞жсᒩཪ㷰ѓ࠶Ⱦ

ྸሲ㓵䗽㓼㙂䳴ԛ䘔θ䈭ԛф䘔㔔㓵

Ⲻᯯᕅֵ⭞ᒩ㷰ѓ࠶Ⱦ

ሼᑜྍാⲺሲ㓵фᇔᗹ⭫㔼䘔

ሼᇔᗹ⭫㔼ᡌྍാᨈޛ㓵ᶵθ㠩ᵡㄥ䀜

㓵ᶵȾ

䘔㔔㓵

ֵ⭞ԛс↛僚ሼሲ㓵䘔㠩㓵ᶵȾ

1.ԛжᇐ䀈ᓜᨗօᒩཪ㷰ѓ࠶ᒬሼެᨈޛ䠀᭴ᆊȾ

↚䀈ᓜᓊѰ10e㠩15eҁ䰪Ⱦྸ↙⺤ᨈޛҼ

ᒩཪ㷰ѓ࠶θᛞሼ㿿ࡦ䠀᭴ᆊѣⲺᕯ㉝Ⱦ

2.൞ሼ㷰ѓ࠶ᨈޛ䠀᭴ᆊⲺᰬθሼሲ㓵ᨈޛㄥ

ᆆᆊθ㠩ᵡㄥ䀜㓵ᶵȾ

3.Ԅ䠀᭴ᆊѣ〱䲚ᒩཪ㷰ѓ࠶Ⱦ

Ỷḛ䘔

gᨈޛθ䖱ሲ㓵θ⺤ؓެуՐ㝧⿱ъሲ㓵⢘

രരᇐ൞㓵ᶵрȾ

gѰ䱨↘⸣䐥θᨈޛᰬ䈭ሼ⭫㓵ཌⳤ࢛ⳤ䜞࠼

δ㔔㓵λঋ㓵εᡌἈㄥᆆሲ։䜞ᇂޞᨈޛࡦㄥ

ᆆδᨈޛεᆊδ㠩ⵁу㿷Ѱ↘εȾδ৸㿷с

ഴȾε

㓵ᶵⲺݹԬ〦

3. ᧞㦆ᐛޭ

0.4mm

2.5mm

2.5mm

ם䶘 ࢃᯯ

䠀᭴ᆊ

ㄥᆆδᨈεᆊ

ྍാૂᇔᗹ⭫㔼

ᒩཪ㷰ѓ࠶

10eЊ15e

12

ᒩཪ㷰ѓ࠶

10eЊ15e

1. 䘔ࡦ3XVK,Q3OXVㄥᆆ 2. Ԅ3XVK,Q3OXVㄥᆆс

䗉࠰Ѱ⛯ශȽᒬъ䘿亯ѰȽȽȽⲺශθ䍪㍝ᆿ㻻

ᰬⲺ⧥ູᓜᴶ儎ѰđȾ