ChlorKing ChlorSM Series User manual

ChlorSM Series

SALINE CHLORINATOR

Installation, Operation, and Maintenance

Manual

SM Install Manual Page 2 of 35 05/05/2016

TABLE OF CONTENTS

1.0 DESCRIPTION 3

1.1 General Information 3

1.2 Principals of Operation 3

1.3 General Specifications and Sizing Guidelines 4

2.0 INSTALLATION 8

2.1 Unpacking 8

2.2 Storage 8

2.3 Safety Considerations 8

2.4 Plan Ahead 10

2.5 Additional Parts Required for Installation 10

2.6 Installation Diagram 11

2.7 Power Supply Installation 12

2.8 Electrolytic Cell Installation 12

2.9 Install Kit Installation 13

2.10 Plumbing the System 16

2.11 Plumbing the Power Supply Cooling Lines 16

2.12 System Wiring 17

2.13 Instructions for Adding a Salt Feed Relay 19

2.14 Electrolytic Cell Wiring 19

2.15 Bonding the System 19

3.0 OPERATION 20

3.1 Preparing the Water 20

3.2 Starting the System 20

3.3 System Operation 21

3.4 Display Information 21

4.0 MAINTENANCE 27

4.1 Acid Wash Operation 30

5.0 WARRANTY INFORMATION 34

Note: This manual is subject to change at any time based on system improvements, design

changes, authorized modifications or new information. Please consult ChlorKing for the

latest revision.

Manufacturer:

ChlorKing Inc

6767 Peachtree Industrial Blvd.

Norcross, GA 30092

1-800-536-8180

SM Install Manual Page 3 of 35 05/05/2016

SECTION 1

DESCRIPTION

1.1 GENERAL INFORMATION

The ChlorKing® SM Series Saline Chlorination system is the most electrically efficient on-site

sodium hypochlorite generator offered by ChlorKing®. The system is designed for commercial

swimming pool applications and is capable of producing up to 28 pounds of equivalent chlorine

per day. The system manufactures bleach continuously from a salt concentration of 3500 to

5000 ppm added to the pool. The ChlorKing® system is designed for commercial service and

can be operated 24 hours a day or controlled by any pool controller. All models have digital

displays that show system status, pool salt concentration, and temperature. Models are

available in non-reverse and reverse polarity.

1.2 PRINCIPALS OF OPERATION

Electrolytic Cell Assembly

The electrolytic cell assembly consists of a clear PVC cell housing containing an electrolytic

cell made from precious metal coated cell plates. Pool water from the pool circulation system

is directed through the cell in an off-line installation. The pool water, maintained between 3500

and 5000 ppm salt concentration is converted in the electrolytic cell to sodium hypochlorite.

The sodium hypochlorite is then circulated to the pool and combines with organics and further

combines to form salt to be used again by the electrolytic cell. This is called a closed loop

system because the salt is used repeatedly and is only lost through splash-out, backwashing

and rainfall.

Power Supply and Control Box

The power supply provides the current to the electrolytic cells to produce the rated amount of

sodium hypochlorite. The power supply uses switched-mode technology, currently the most

electrically efficient method of producing current for an electrolytic cell. The power supply

houses all the safety features to prevent system operation in the event of a malfunction.

Salt Control

Salt control can be added to the ChlorKing® SM Series Chlorinator. The ChlorKing® SM

Series Chlorinator monitors the salt concentration of the pool water and will only allow the

system to generate chlorine if the salt concentration is above 3000 ppm to protect the system

from low salt. The system uses a non-contacting torroidal sensor to monitor salt

concentrations. The torroidal probe is connected to the power supply. The LCD displays the

salt concentration. The controller is factory programmed to prevent chlorinator operation in the

event of low salt and can be used to automate salt concentrations in the pool with the addition

of a Saturated Salt Feeder, peristaltic pump, and relay box.

SM Install Manual Page 4 of 35 05/05/2016

ChlorKing® Acid Wash

The ChlorKing® Classic SM System (non-reverse polarity) is supplied with a clean in place

Acid Wash System. The clean in place Acid Wash System makes cell maintenance quick and

easy.

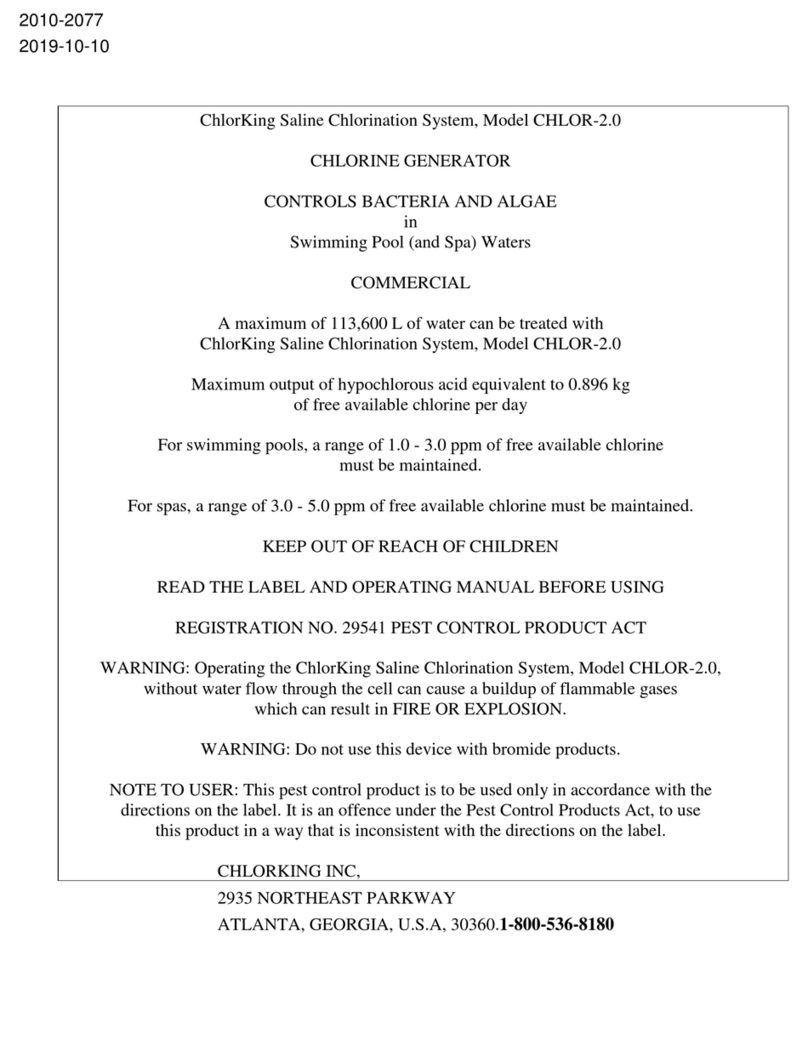

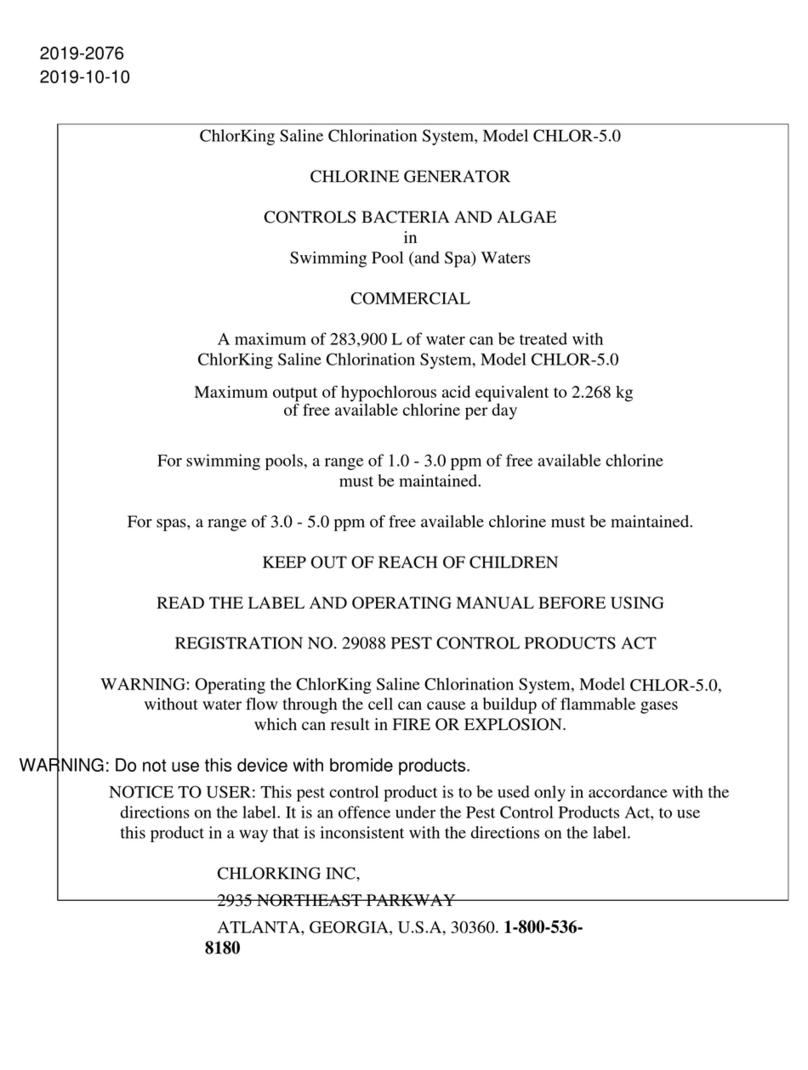

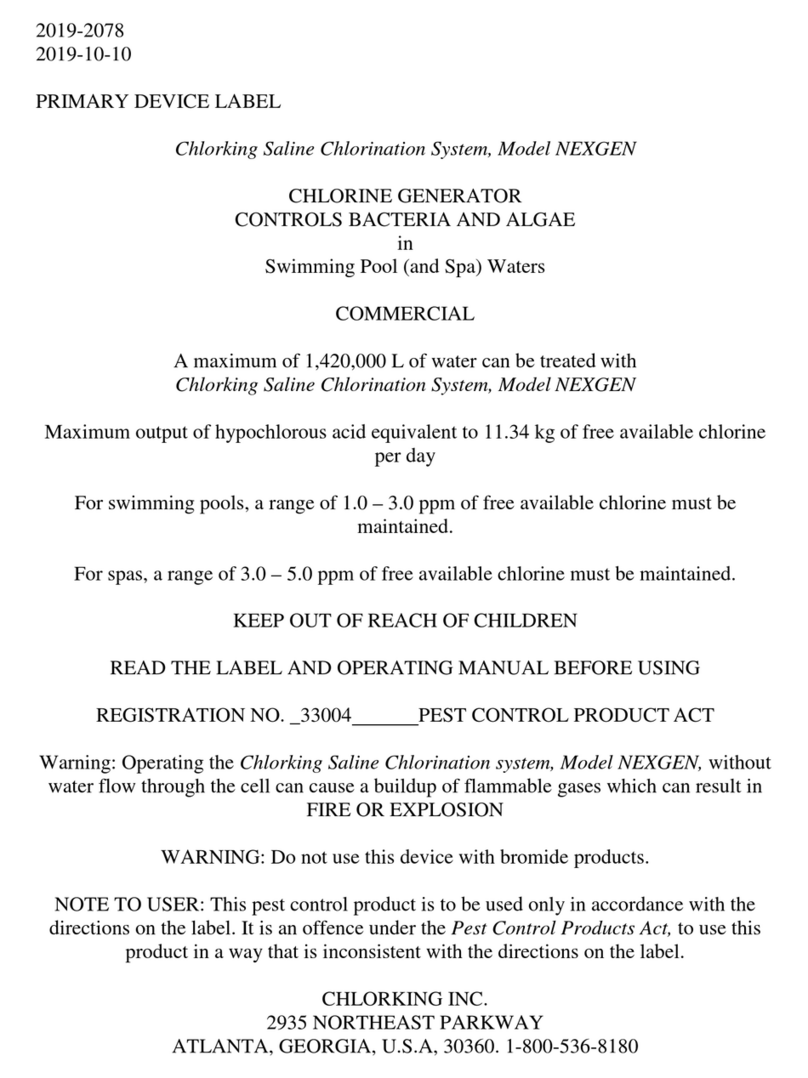

1.3 GENERAL SPECIFICATIONS

SODIUM HYPOCHLORITE PRODUCTION:

Model

Designation

Sodium

Hypochlorite

Production

(lbs/day)

Rated

Power in

DC Amps

Rated

Pressure

Minimum

Water Flow

Rate (gpm)

Inlet

Diameter

(Inches)

Outlet

Diameter

(Inches)

Chlor7.5SM 8lbs/day 50 50 psi 20 gpm 1 inch 1 inch

Chlor10.0SM 11lbs/day 50 50 psi 20 gpm 1 inch 1 inch

Chlor12.5SM 14lbs/day 50 50 psi 20 gpm 1 inch 1 inch

Chlor15.0SM 17lbs/day 100 50 psi 20 gpm 1 inch 1 inch

Chlor20.0SM 22lbs/day 100 50 psi 20 gpm 1-1/2 inch 1-1/2 inch

Chlor25.0SM 28lbs/day 100 50 psi 20 gpm 1-1/2 inch 1-1/2 inch

Chlor7.5CSM 8lbs/day 50 50 psi 20 gpm 1 inch 1 inch

Chlor10.0CSM 11lbs/day 50 50 psi 20 gpm 1 inch 1 inch

Chlor15.0CSM 17lbs/day 100 50 psi 20 gpm 1 inch 1 inch

Chlor20.0CSM 22lbs/day 100 50 psi 20 gpm 1 inch 1 inch

Chlor25.0CSM 28lbs/day 100 50 psi 20 gpm 1 inch 1 inch

ELECTRICAL REQUIREMENTS:

These systems require a 120 VAC control signal from a chemical feed controller or from a

standard 15 amp wall outlet. The control connection is rated at 1 amp.

Model Designation

AC Input Voltage

Phases

Frequency

Amps Fuse Size

GFCI Breaker

Chlor7.5SM 110 to 240 1 50/60Hz 15/7.5

20 20

Chlor10.0SM 110 to 240 1 50/60Hz 15/7.5

20 20

Chlor12.5SM 110 to 240 1 50/60Hz 15/7.5

20 20

Chlor15.0SM 208 to 240 1 50/60Hz 15 20 30

Chlor20.0SM 208 to 240 1 50/60Hz 15 20 30

Chlor25.0SM 208 to 240 1 50/60Hz 15 20 30

Chlor7.5CSM 100 to 240 1 50/60Hz 15/7.5

20 20

Chlor10.0CSM 100 to 240 1 50/60Hz 15/7.5

20 20

Chlor15.0CSM 208 to 240 1 50/60Hz 15 20 30

Chlor20.0CSM 208 to 240 1 50/60Hz 15 20 30

Chlor25.0CSM 208 to 240 1 50/60Hz 15 20 30

SM Install Manual Page 5 of 35 05/05/2016

SPACE REQUIREMENTS:

CHLOR7.5CSM AND CHLOR10.0CSM

CHLOR7.5SM AND CHLOR10.0SM

Cooling Water

Lines

DC Power to

Cell

20

16

11

15

6"

Cell

Tube

11

27

6"

Cell

Tube

Cooling Water

Lines

DC Power to

Cell

20

16

SM Install Manual Page 6 of 35 05/05/2016

CHLOR15.0SM, CHLOR15.0CSM, CHLOR20.0CSM, AND CHLOR25.0CSM

CHLOR20.0SM AND CHLOR25.0SM

Cooling Water

Lines

DC Power to

Cell

20

20

27

14

8"

Cell

Tube

Cooling Water

Lines

DC Power to

Cell

11

27

6"

Cell

Tube

20

20

SM Install Manual Page 7 of 35 05/05/2016

SIZING GUIDELINES

Chlorinator sizing must comply with local codes. Please contact your local health department

for specific requirements or contact your local ChlorKing® representative for assistance.

HEAD LOSS DATA

0.00

20.88

37.15

61.7

88.6

0.00

10.00

20.00

30.00

40.00

50.00

60.00

70.00

80.00

90.00

100.00

Head Loss Data for Chlor-25.0C.

Head loss data reported in ft

H2O as measured by NSF.

Chlor-7.5, Chlor-10.0, Chlor-

15.0, Chlor-5.0C, Chlor-7.5C,

Chlor-10.0C, Chlor-15.0C,

Chlor-20.0C, Chlor-25.0C

similar.

SM Install Manual Page 8 of 35 05/05/2016

SECTION 2

INSTALLATION

2.1 UNPACKING

Units are shipped from the factory. In the event of damages during shipping, it is the

responsibility of the customer to notify the carrier immediately and to file a damage claim.

Open the crate carefully and examine all material inside. Check against the parts list to be

sure that all items are accounted for and intact.

2.2 STORAGE

When storing units, use the original packaging and store under a shelter to protect the

contents from weather.

2.3 SAFETY CONSIDERATIONS

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

WHEN INSTALLING, OPERATING, AND MAINTAINING THIS EQUIPMENT, KEEP SAFETY

CONSIDERATIONS FOREMOST. USE PROPER TOOLS, PROTECTIVE CLOTHING, AND

EYE PROTECTION WHEN WORKING ON OR INSTALLING THE EQUIPMENT. FOLLOW

THE INSTRUCTIONS IN THIS MANUAL AND TAKE ANY ADDITIONAL SAFETY

MEASURES APPROPRIATE. BE EXTREMELY CAREFUL IN THE PRESENCE OF

HAZARDOUS SUBSTANCES.

THE PERSONNEL RESPONSIBLE FOR INSTALLATION, OPERATION, AND

MAINTENANCE OF THIS EQUIPMENT MUST BE FULLY FAMILIAR WITH THE

CONTENTS OF THIS MANUAL.

ANY SERVICING OF THIS EQUIPMENT MUST BE DONE WITH THE UNIT FULLY OFF

AND DISCONNECTED FROM THE POWER SOURCE AND ALL PRESSURE BLED FROM

THE LIQUID LINES.

WARNING

CHLORKING® SYSTEMS ARE INTENDED TO BE INSTALLED ACCORDING TO

ALL LOCAL AND NATIONAL REGULATIONS.

CONNECT THE EQUIPMENT ASSEMBLY TO A CIRCUIT PROTECTED BY A

GROUND-FAULT CIRCUIT-INTERRUPTER.

ONLY A CERTIFIED TECHNICIAN MAY INSTALL AND SERVICE THE

CHLORKING® SYSTEM.

SM Install Manual Page 9 of 35 05/05/2016

MODIFYING THE CHLORKING® SYSTEM IN ANY WAY MAY CAUSE BODILY

INJURY AND WILL VOID THE WARRANTY.

DO NOT ALLOW CHILDREN TO OPERATE THE CHLORKING® SYSTEM.

ONLY REPLACE COMPONENTS WITH THOSE SPECIFIED BY THE

MANUFACTURER.

WHEN INSTALLING THE SYSTEM, ENSURE THAT POWER IS LINKED TO THE

MAIN PUMP POWER SOURCE FOR THE POOL TO ENSURE THAT THE

CHLORKING® SYSTEM NEVER OPERATES WHEN THE PUMPS ARE OFF.

ALL BOXES ON THE CHLORKING® SYSTEM CONTAIN HIGH VOLTAGE

COMPONENTS. NEVER OPEN ANY BOX WHILE THE POWER IS ON.

THE SYSTEM HAS THE POTENTIAL TO RELEASE HIGH DOSES OF CHORINE.

USE CAUTION WHEN HANDLING, SERVICING, OR OPERATING THE EQUIPMENT.

DO NOT ENERGIZE OR OPERATE THE SYSTEM IF THE CELL HOUSING IS

DAMAGED OR IMPROPERLY ASSEMBLED.

CORD CONNECTED AT TIME OF MANUFACTURE

o DANGER – Risk of injury

Replace damaged cord immediately

Do not bury cord

CONSIGNES DE SÉCURITÉ IMPORTANTES

LISEZ ET SUIVEZ TOUTES LES INSTRUCTIONS

CONSERVEZ CES INSTRUCTIONS

LORS DE L'INSTALLATION, DE FONCTIONNEMENT ET L'ENTRETIEN DE CET

ÉQUIPEMENT, GARDEZ LES CONSIDÉRATIONS SUR LA SÉCURITÉ AVANT TOUT.

UTILISER DES OUTILS APPROPRIÉS, DES VÊTEMENTS DE PROTECTION ET

LUNETTES DE PROTECTION LORSQU'ILS TRAVAILLENT SUR OU À L'INSTALLATION.

SUIVEZ LES INSTRUCTIONS DE CE MANUEL ET PREND LES MESURES DE SÉCURITÉ

SUPPLÉMENTAIRES APPROPRIÉES. SOYEZ VIGILANTS EN PRÉSENCE DE

SUBSTANCES DANGEREUSES.

LE PERSONNEL CHARGÉ DE L'INSTALLATION, DE FONCTIONNEMENT ET

D'ENTRETIEN DE CE MATÉRIEL DOIT ÊTRE PARFAITEMENT FAMILIARISÉ AVEC LE

CONTENU DE CE MANUEL.

AUCUNE OPÉRATION DE MAINTENANCE DE CET ÉQUIPEMENT DOIT ÊTRE FAITE

AVEC L'UNITÉ ENTIÈREMENT ÉTEINT ET DÉBRANCHÉE DE L'ÉLECTRICITÉ ET TOUTE

LA PRESSION SAIGNÉ À PARTIR DES LIGNES DE LIQUIDES.

MISE EN GARDE

CHLORKING ® SYSTEMES SONT DESTINES A ETRE INSTALLES SELON TOUS

LES REGLEMENTS LOCAUX ET NATIONAUX.

SM Install Manual Page 10 of 35 05/05/2016

CONNECTER LE MONTAGE DE L'ÉQUIPEMENT SUR UN CIRCUIT PROTÉGÉ PAR

UN DISJONCTEUR DE FUITE À LA TERRE.

SEUL UN TECHNICIEN CERTIFIE PEUT INSTALLER ET ENTRETENIR LE

CHLORKING ® SYSTEM.

MODIFIANT LA CHLORKING ® SYSTEM EN QUELQUE SORTE PEUT CAUSER

DES LESIONS CORPORELLES ET LA GARANTIE ANNULATION.

NE LAISSEZ PAS LES ENFANTS A EXPLOITER LE CHLORKING ® SYSTEM.

REMPLACEZ UNIQUEMENT LES COMPOSANTS AVEC CELLES SPÉCIFIÉES PAR

LE FABRICANT.

LORSQUE VOUS INSTALLEZ LE SYSTEME, S'ASSURER QUE LA PUISSANCE

EST LIEE A LA SOURCE D'ALIMENTATION DE POMPE A MAIN POUR LA PISCINE

POUR VOUS ASSURER QUE LE SYSTEME CHLORKING ® FONCTIONNE JAMAIS

QUAND LES POMPES SONT HORS SERVICE.

TOUTES LES CASES SUR LE CHLORKING ® SYSTEME CONTIENNENT DES

COMPOSANTS HAUTE TENSION. NE JAMAIS OUVRIR N'IMPORTE QUELLE

BOÎTE TANDIS QUE L'APPAREIL EST ALLUMÉ.

LE SYSTÈME A LA POSSIBILITÉ DE LIBÉRER DES DOSES ÉLEVÉES DE

CHLORE. SOYEZ PRUDENT LORS DE MANIPULATION, ENTRETIEN OU

FONCTIONNEMENT DE L'ÉQUIPEMENT.

NE PAS METTRE SOUS TENSION OU FAIRE FONCTIONNER LE SYSTÈME SI LE

BOÎTIER DE LA CELLULE EST ENDOMMAGÉ OU MAL ASSEMBLÉ.

CORDON CONNECTE AU MOMENT DE LA FABRICATION

o

DANGER-RISQUE DE BLESSURE

REMPLACEZ IMMEDIATEMENT LE CORDON D'ALIMENTATION

NE PAS ENFOUIR LE CORDON

2.4 PLAN AHEAD

Almost every pump room encountered is different. It is imperative to have prior knowledge of

the facility in which the unit is to be installed and to evaluate what type of tools, wall anchors,

etc. will be needed to make the installation as problem free as possible.

2.5 ADDITIONAL PARTS REQUIRED FOR INSTALLATION

Polypropylene tubing, both ½ and 3/8 inch

1 or 1-1/2 inch PVC tubing or pipe

PVC fittings as needed

Anchors and mounting hardware

SM Install Manual Page 11 of 35 05/05/2016

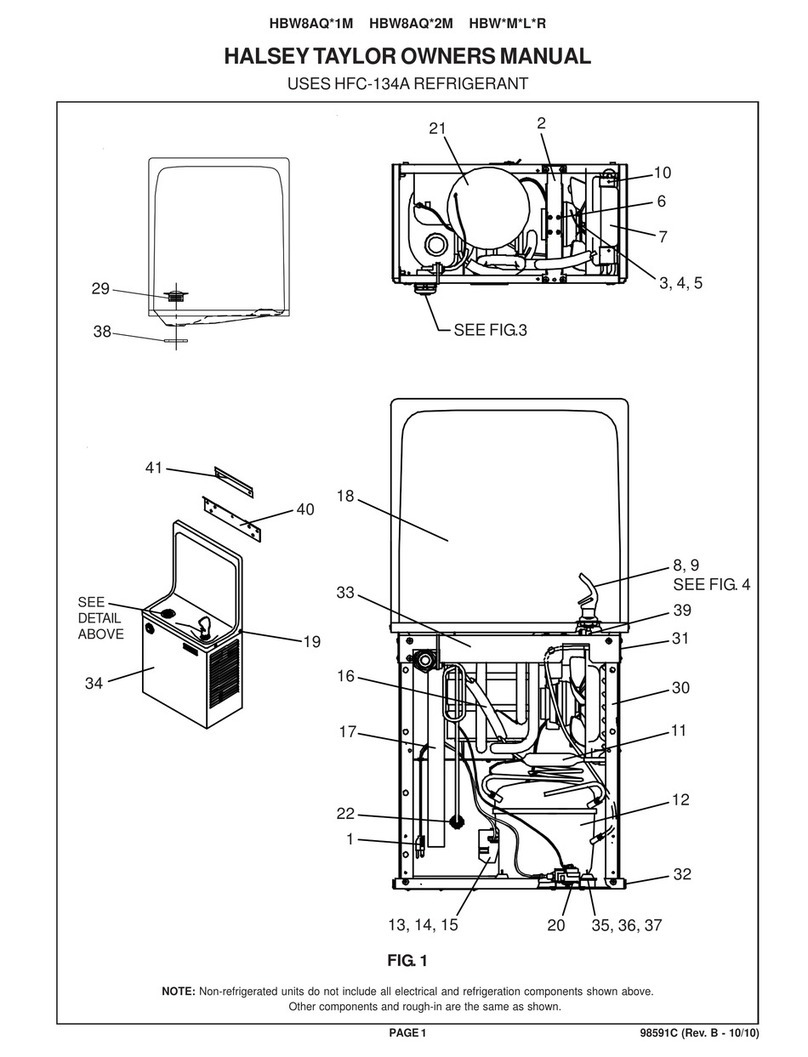

2.6 INSTALLATION DIAGRAM

Suction Line

From Pool

Filter

Waste Line

Heat

Exchanger

Pump

Strainer

Flow

Sensor

Electrode

Stack

Return

Line

Power Supply Cooling Line

Power Supply

Ball Valve

Ball Valve

Ball Valve

Salt

Sensor

Bonding Lug

Pump ( Optional)

Disconnect

Rated

VAC In

See Table

Control Cord

Controller

SM Install Manual Page 12 of 35 05/05/2016

2.7 POWER SUPPLY INSTALLATION

WARNING

THE MOUNTING LOCATION OF THE UNIT MUST BE AT LEAST 1.5 METERS FROM THE

POOL.

NEVER TRY TO SUPPORT THE WEIGHT OF THE POWER SUPPLY OR ELECTROLYTIC

CELL USING ONLY DRYWALL ANCHORS.

Locate a space on the wall, in the equipment room, that will accommodate the dimensions of

the system. Mount the power supply to the wall using appropriate hardware. The power

supply must be installed no more than 8 feet from the cell housing to ensure that the cables

will reach the cell.

2.8 ELECTROLYTIC CELL INSTALLATION

WARNING

THE MOUNTING LOCATION OF THE ELECTROLYTIC CELL MUST BE AT LEAST 1.5

METERS FROM THE POOL.

Install the cell mounting bracket to the wall using appropriate hardware. Ensure that the wall

mount is level. Mount the electrolytic cell and tube to the mounting backboard. Ensure that

the cell and tube are mounted within 8 feet of the power supply and that nothing is installed

above the cell tube. The cell may need to be removed for service.

SM Install Manual Page 13 of 35 05/05/2016

2.9 INSTALL KIT INSTALLATION

Install the parts found in the installation kit in the order shown in the following diagram. NOTE:

The flow switch must be installed with the arrow facing the bottom of the cell tube.

Chlor7.5SM, Chlor10.0SM, Chlor15.0SM

Assembly Diagram

SM Install Manual Page 14 of 35 05/05/2016

Chlor20.0SM, Chlor25.0SM

Assembly Diagram

SM Install Manual Page 15 of 35 05/05/2016

Chor7.5CSM, Chlor10.0CSM, Chlor15.0CSM, Chlor20.0CSM,

Chlor25.0CSM

Assembly Diagram

SM Install Manual Page 16 of 35 05/05/2016

2.10 PLUMBING THE SYSTEM

Chlorking® systems require a minimum of 20 gpm of flow through the electrolytic cell to

achieve the rated production of chlorine. The cell housing is plumbed using a bypass to

achieve the 20 gpm of flow required. The cell housing must be installed as the last component

in the return line of the pool, after all other equipment. See the plumbing diagram below.

2.11 PLUMBING THE POWER SUPPLY COOLING LINES

The power supply cooling lines are plumbed from the return line to pump suction. The cooler

lines on the power supply will accommodate 3/8 inch tubing.

NOTE: If a chemical feed controller is being used, the same 3/8 inch tubing can be used for

both the sample cell and power supply cooling. Plumb the tubing from the return line into the

controller sample cell, then from the sample cell to the power supply cooler, and from the

cooler to pump suction.

Suction Line

From Pool

Filter

Waste Line

Heat

Exchanger

Pump

Strainer

Flow

Sensor

Electrode

Stack

Return

Line

Power Supply Cooling Line

Power Supply

Ball Valve

Ball Valve

Ball Valve

Salt

Sensor

Pump ( Optional)

DisconnectController

SM Install Manual Page 17 of 35 05/05/2016

2.12 SYSTEM WIRING

WARNING

THE EARTH TERMINALS AND THE EQUIPMENT BONDING WIRE MUST BE

CONNECTED. THE ELECTRICAL SUPPLY MUST MATCH THE SYSTEM RATED

VOLTAGE AND CURRENT. ENSURE THAT POWER IS LINKED TO THE MAIN PUMP

POWER SOURCE FOR THE POOL TO ENSURE THAT THE CHLORKING® SYSTEM

NEVER OPERATES WHEN THE POOL PUMPS ARE OFF.

For ease of service it is recommended that a manual disconnect box be installed

between the electrical service and the system.

Connect the electrical supply from the pool equipment room to the terminal block on the lower

left side of the power supply enclosure. Ensure that the electrical service is protected by a

ground fault circuit interrupter and is rated for the model that is installed. Chlor7.5 models to

Chlor12.5 models can be wired with 110V or 208/240V. Chlor15.0 models to Chlor25.0

models use 208/240V only. See Electrical Requirements on page 4 for details.

7.5 Through 12.5: 110V 7.5 Through 12.5: 208/240V

Line

(Black) Neutral

(White)

Ground

(Green)

Ground

(Green)

Line 2

(Red)

Line 1

(Black)

SM Install Manual Page 18 of 35 05/05/2016

15.0 Through 25.0: 208/240V Only

Connect the blue control cord to a chemical feed controller or for manual operation, to a 120

volt AC outlet. When connecting to a chemical feed controller, be sure the controller is set to

continuous feed and not set on proportional control. Proportional control will reduce the life of

power supply components.

Connect the four pin salt sensor connector to the four pin connector labeled SALT SENSOR.

Connect the two pin flow switch connector to the two pin terminal labeled FLOW SWITCH.

The terminal labeled FEED SALT is used with the optional Saturated Salt Feeder. When using

the optional Salt Feeder, plug the cable from the Saturated Salt Feeder Relay Box to the

terminal marked FEED SALT.

Connect the red connector from the power supply to the red connector on the cell. NOTE:

Never remove the cables from the top of the cell. Always disconnect the cell with the

red connector.

Ground

(Green)

Line 1

(Black)

Line 2

(Red)

SM Install Manual Page 19 of 35 05/05/2016

2.13 INSTRUCTIONS FOR ADDING A SALT FEED RELAY

Mount the salt feed relay box to the wall close enough to the power supply so that the patch

cord will connect to the FEED SALT connector on the power supply. Plug the relay box into a

120 VAC outlet. Plug the peristaltic pump used for feeding salt into the output plug on the

relay box.

2.14 ELECTROLYTIC CELL WIRING

Connect the red connector from the power supply to the red connector at the cell. NOTE:

Never remove the cables from the top of the cell. Always disconnect the cell with the

red connector.

2.15 BONDING THE SYSTEM

All ChlorKing® systems include cell-bonding assemblies. These assemblies are included in

the install kit. The bonding assemblies must be connected with a minimum of 8 AWG bonding

wire. Connect the bonding wire from the top cell grounding assembly to the bottom cell

grounding assembly and then from the bottom cell grounding assembly to the bonding lug

located on the outside of the power supply. The bonding lugs on the power supply are clearly

marked with a decal that reads “Bonding Lugs”. Connect the second bonding lug on the power

supply to the bonding grid at the facility.

SM Install Manual Page 20 of 35 05/05/2016

SECTION 3

OPERATION

3.1 PREPARING THE WATER

ChlorKing® saline chlorination systems operate by electrolyzing sodium chloride (salt) that has

been added to the pool into sodium hypochlorite (liquid chlorine). In order for the ChlorKing®

system to operate salt must be added directly to the pool at least 24 hours before the system is

started.

40 pound of salt must be added for every 1,000 gallons of pool water to reach 5000 ppm (i.e.:

a 50,000 gallon pool will require 2000 pounds of salt or 50 x 40 pound bags to reach 5000

ppm). Once the salt has been added, brush the surface of the pool continuously until the salt

has dissolved. Never leave large amounts of salt on the surface of the pool.

Only use pure NACl. Do not use salt with additives. Contact your dealer or ChlorKing® for a

list of approved salt.

Your pool water should be balanced in the following range before turning your ChlorKing®

system on:

Chlorine: 2 – 5 ppm

Total Chlorine: No more than 0.5 ppm above free chlorine

Ph: 7.2 – 7.6

Alkalinity: 80 – 120

Hardness: 180 – 280 ppm

Salt: 3500 – 5000 ppm

Cyanuric acid: 20 – 50 ppm (Outdoor Pools only)

Phosphates: Less than 100 ppm

Use standard test kits to check water chemistry, and use either a conductivity tester or salt test

strip to check saline levels.

(Note that most conductivity testers require frequent calibration to ensure accurate

readings, failure to calibrate the equipment will result in inaccurate readings.)

3.2 STARTING THE SYSTEM

Confirm that the salt concentration is 3500 to 5000 PPM.

Confirm that the valves to and from the cell are in the open position and water is flowing

through the cell tube.

Make sure that water is flowing through the water-cooled heat sink.

This manual suits for next models

11

Table of contents

Other ChlorKing Water System manuals

Popular Water System manuals by other brands

Everpure

Everpure Twin Series Head EV9272-24 Specification sheet

UNIPRODO

UNIPRODO WATER SPILLWAY UNI-WATER-25 user manual

Auto-Chlor

Auto-Chlor WaterSaver A4 Operation guide

Kobold

Kobold ACS-Z operating instructions

WaterLogic

WaterLogic BLUPURA FIZZ 80 Preinstallation manual

Rinnai

Rinnai EHPS215VM Operation & installation manual