ChlorKing CHLOR-2.0 User manual

Table of contents

Other ChlorKing Water System manuals

Popular Water System manuals by other brands

AMI

AMI AAA-N50W Installation guide & owner's manual

SANZONATE

SANZONATE AQUAFLOW MAXI owner's manual

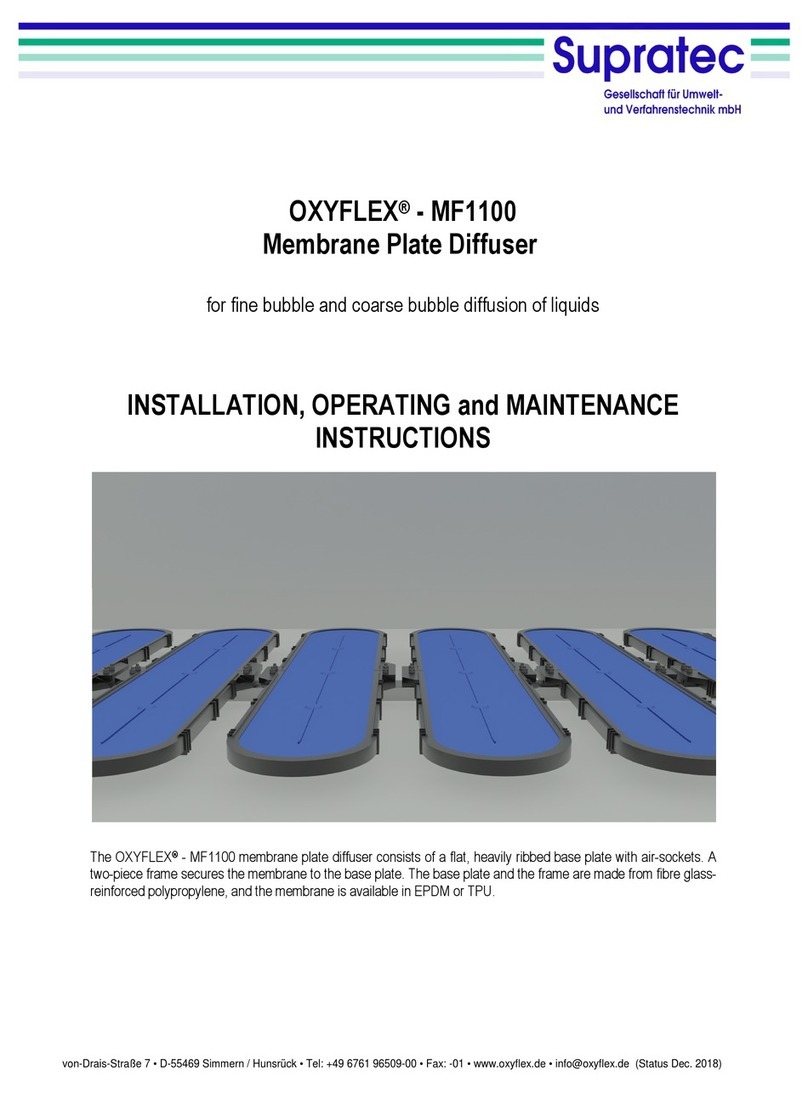

Supratec

Supratec OXYFLEX MF1100 Installation, operating and maintenance instructions

Elkay

Elkay EZH20 Series Installation, care & use manual

HotSpring

HotSpring ACE Quick reference guide

BWT

BWT Rondomat Duo Series Installation and operating manual

American Granby

American Granby Aquamatics Aquamate instruction manual

Everpure

Everpure Quad-MC EV9628-08 Specification sheet

Kohler

Kohler 10611A-NA installation instructions and home owner's guide

Everpure

Everpure QCP 10-L Specification sheet

EcoWater

EcoWater CHC Installation & service manual

Spectra Watermakers

Spectra Watermakers CABO 10,000 Installation and operating manual

MYPV

MYPV AC ELWA-E Operation manual

Ultra Max

Ultra Max 268 Co-Current Conditione Operation manual

Little Giant

Little Giant WRSC-6 owner's manual

Prochem

Prochem EVEREST 650 operating instructions

O-SO Pure

O-SO Pure Mineral Mizer Installation, operation & service manual

Waterco

Waterco OXISWIM Quick reference guide