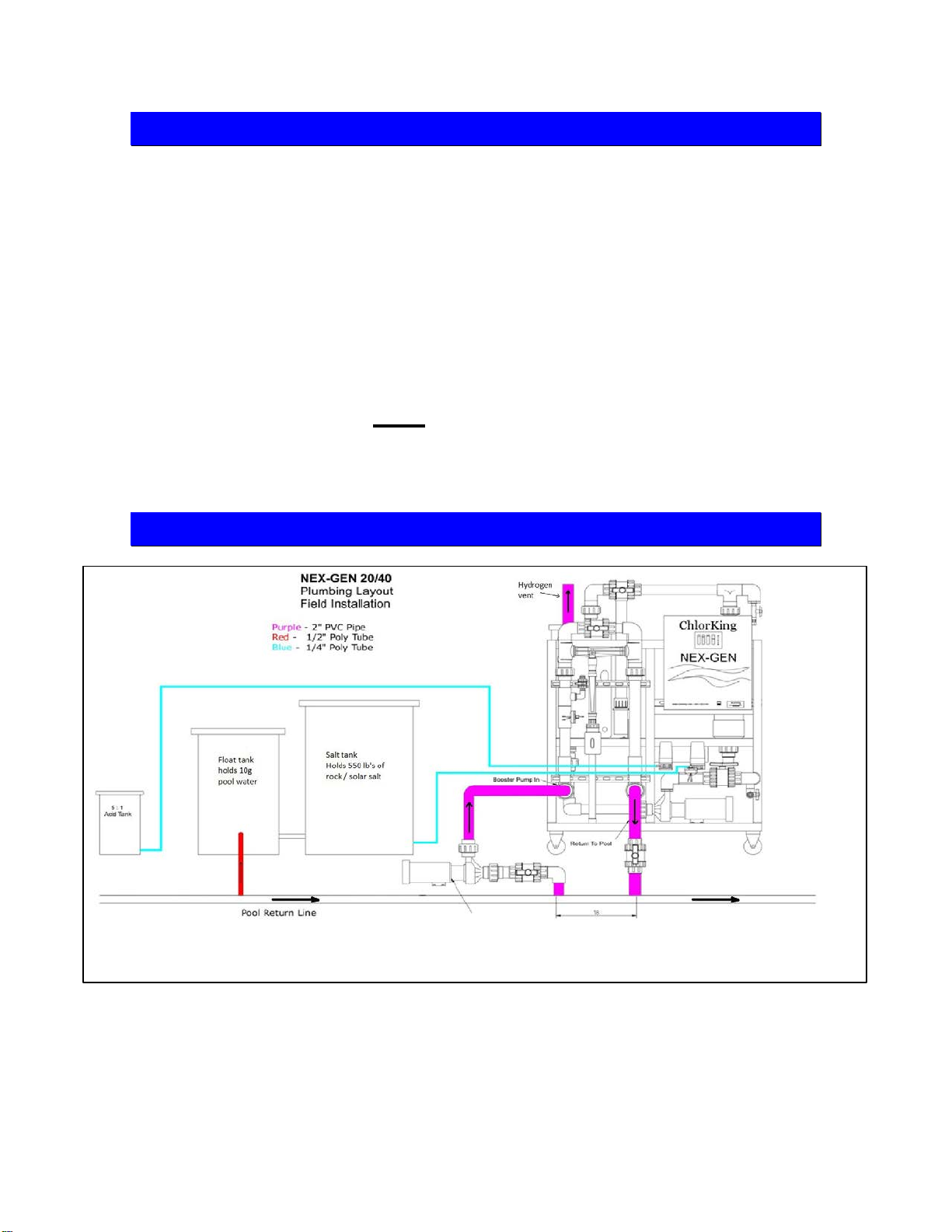

ChlorKing NEXGEN User manual

Table of contents

Other ChlorKing Water System manuals

Popular Water System manuals by other brands

HydraMaster

HydraMaster BoxxerXL owner's manual

BRENNTAG

BRENNTAG HEATSAVR instruction manual

Stern Engineering

Stern Engineering SWAN 1000 AB1953 Installation and maintenance guide

Sime

Sime Natural 160S manual

DIG

DIG G77AS installation instructions

DAB

DAB DIVERTEK Instruction for installation and maintenance

Kenmore

Kenmore 625.385560 UltraFilter 650 owner's manual

AmeriWater

AmeriWater 20-3021 Operation manual

Vaillant

Vaillant Solar hot water systems System manual

Stratco

Stratco Solarcore G21520N66VE installation guide

FlexiTank

FlexiTank AutoPot 100L Assembly instructions

Galletti

Galletti CSW T Installation, use and maintenance manual

Trane

Trane Axiom GEHB 006 Installation, operation and maintenance

Viega

Viega PureFlow installation manual

Rainfresh

Rainfresh UCS2 user manual

Lippert

Lippert Floe 868 Installation and owner's manual

Ecodyne Water Systems

Ecodyne Water Systems TB-RO Installation and operation manual

UNIPRODO

UNIPRODO UNI WATER 06 user manual