Christ ALPHA 1-2 LDplus User manual

Translation of the original operating manual

sb-dc

Rev. 2.10 of 09/03/2020

Alpha 1-2 LDplus; ;

Version 11/2006

Alpha 1-2 LDplus

part no. 101521, 101470

Freeze-dryer

Operating Manual

Please retain for later use!

Freeze-dryer Alpha 1-2 LDplus

2 / 94

Version 11/2006, Rev. 2.10 of 09/03/2020 • sb-dc

Translation of the original operating manual

Freeze-dryer Alpha 1-2 LDplus

Version 11/2006, Rev. 2.10 of 09/03/2020 • sb-dc

3 / 94

Translation of the original operating manual

In case of inquiries, please state the following numbers:

Order number:

Serial number:

© Copyright by

Martin Christ Gefriertrocknungsanlagen GmbH

An der Unteren Söse 50

37520 Osterode am Harz

Germany

Tel.: +49 (0) 5522 / 5007-0

Fax: +49 (0) 5522 / 5007-12

Web: www.martinchrist.de

E-mail: info@martinchrist.de

Freeze-dryer Alpha 1-2 LDplus

4 / 94

Version 11/2006, Rev. 2.10 of 09/03/2020 • sb-dc

Translation of the original operating manual

Freeze-dryer Alpha 1-2 LDplus

Table of contents

Version 11/2006, Rev. 2.10 of 09/03/2020 • sb-dc

5 / 94

Translation of the original operating manual

1General information.............................................................................................................9

1.1 Importance of the operating manual..................................................................................9

1.2 Intended use.....................................................................................................................9

1.3 Warranty and liability.......................................................................................................11

1.4 Copyright........................................................................................................................12

1.5 Explanation of symbols...................................................................................................12

1.6 Standards and regulations..............................................................................................12

1.7 Scope of supply..............................................................................................................12

2Layout and mode of operation..........................................................................................13

2.1 Layout of the freeze-dryer...............................................................................................13

2.1.1 Functional and operating elements............................................................................13

2.1.2 Name plate................................................................................................................15

2.2 Mode of operation...........................................................................................................16

2.2.1 General information on freeze-drying.........................................................................16

2.2.2 Freeze-drying process...............................................................................................18

2.2.2.1 Preparation........................................................................................................18

2.2.2.2 Freezing.............................................................................................................19

2.2.2.3 Main drying........................................................................................................19

2.2.2.4 Final drying........................................................................................................19

2.2.2.5 End of drying and aeration.................................................................................20

2.2.2.6 Defrosting ..........................................................................................................20

3Safety..................................................................................................................................21

3.1 Marking of the unit..........................................................................................................21

3.2 Explanation of the symbols and notes.............................................................................22

3.3 Responsibility of the operator..........................................................................................23

3.4 Operating personnel .......................................................................................................24

3.5 Informal safety notes.......................................................................................................24

3.6 Safety notes concerning the transport, set-up and connection and initial start-up of the

freeze-dryer...............................................................................................................................24

3.6.1 General hazards........................................................................................................24

3.6.2 Hazards caused by improper transport......................................................................25

3.6.3 Hazards caused by improper set-up..........................................................................25

3.6.4 Hazards caused by improper connection...................................................................26

3.7 Safety notes concerning the operation............................................................................26

3.7.1 Hazards caused by electricity ....................................................................................26

3.7.2 Hazards caused by the refrigeration system (natural, flammable refrigerants)...........27

3.7.3 Hazards caused by the refrigeration system (non-flammable refrigerants).................27

3.7.4 Hazards caused by harmful products.........................................................................28

3.7.5 Hazards caused by solvents in the products..............................................................28

3.7.6 Hazards caused by acids in the products...................................................................28

3.7.7 Hazards caused by contaminated condensate (defrosting water)..............................29

3.7.8 Hazards caused by hot surfaces................................................................................29

3.7.9 Hazards caused by cold surfaces..............................................................................29

Freeze-dryer Alpha 1-2 LDplus

Table of contents

6 / 94

Version 11/2006, Rev. 2.10 of 09/03/2020 • sb-dc

Translation of the original operating manual

3.8 Safety devices ................................................................................................................29

3.8.1 System check............................................................................................................29

3.8.2 Earth conductor check...............................................................................................29

3.9 Procedures in the event of hazards and accidents..........................................................30

3.10 Maintenance and cleaning of the freeze-dryer................................................................30

3.11 Measures to be taken to ensure safe operation of the freeze-dryer.................................31

3.12 Remaining hazards.........................................................................................................32

4Storage and transport ....................................................................................................... 33

4.1 Dimensions and weight...................................................................................................33

4.2 Storage conditions..........................................................................................................33

4.3 Notes on transport..........................................................................................................34

4.4 Packaging.......................................................................................................................35

4.5 Transport safety device...................................................................................................35

5Set-up and connection ......................................................................................................36

5.1 Location of use ...............................................................................................................36

5.2 Power supply..................................................................................................................37

5.2.1 Type of connection ....................................................................................................37

5.2.2 Customer-provided fuses...........................................................................................37

5.3 Aeration and media drain valve.......................................................................................38

5.4 Vacuum sensor...............................................................................................................38

5.5 Vacuum pump.................................................................................................................40

5.6 Pressure control valve ....................................................................................................41

5.7 Rubber valves.................................................................................................................42

6Operation............................................................................................................................ 43

6.1 Initial start-up..................................................................................................................43

6.2 Installation of accessories...............................................................................................43

6.3 Preparation.....................................................................................................................43

6.4 Switching the freeze-dryer on .........................................................................................43

6.5 LDplus control system.....................................................................................................44

6.5.1 User interface............................................................................................................44

6.5.2 Mode .........................................................................................................................47

6.5.3 Main menu.................................................................................................................49

6.5.3.1 Changing set values ..........................................................................................49

6.5.3.2 Special functions................................................................................................51

6.5.3.3 Process and equipment information...................................................................52

6.5.3.4 Options..............................................................................................................53

6.5.3.5 Tutorial...............................................................................................................55

6.6 Switching the freeze-dryer OFF......................................................................................56

Freeze-dryer Alpha 1-2 LDplus

Table of contents

Version 11/2006, Rev. 2.10 of 09/03/2020 • sb-dc

7 / 94

Translation of the original operating manual

7Malfunctions and error correction....................................................................................57

7.1 General malfunctions......................................................................................................57

7.1.1 Power failure..............................................................................................................57

7.1.2 Insufficient vacuum....................................................................................................57

7.1.2.1 Small flange connections...................................................................................57

7.1.2.2 Aeration and media drain valve..........................................................................58

7.1.2.3 Pressure control valve........................................................................................58

7.1.2.4 Rubber valves....................................................................................................59

7.1.2.5 Vacuum sensor..................................................................................................59

7.1.3 Insufficient ice condenser temperature ......................................................................59

7.2 Process and equipment messages.................................................................................60

7.3 Service contact...............................................................................................................61

8Maintenance and service................................................................................................... 62

8.1 Maintenance...................................................................................................................62

8.1.1 General......................................................................................................................62

8.1.2 Ice condenser chamber .............................................................................................63

8.1.3 Aeration valve, media drain valve..............................................................................64

8.1.4 Heat exchanger (only for air-cooled freeze-dryers)....................................................65

8.1.5 Electrical system........................................................................................................65

8.1.6 Vacuum pump ...........................................................................................................65

8.1.7 Exhaust filter (oil mist separator)................................................................................66

8.1.8 Refrigeration system..................................................................................................67

8.1.9 Vacuum sensor..........................................................................................................67

8.1.10 Accessories...............................................................................................................68

8.2 Disinfection of the drying chamber and accessories .......................................................69

8.3 Service ...........................................................................................................................70

8.4 Return of defective parts.................................................................................................70

9Disposal.............................................................................................................................. 72

9.1 Disposal of the freeze-dryer............................................................................................72

9.2 Disposal of the packaging...............................................................................................72

10 Technical data.................................................................................................................... 73

10.1 Ambient conditions .........................................................................................................74

10.2 Technical documentation................................................................................................74

11 Appendix............................................................................................................................ 75

11.1 Brief operating instructions .............................................................................................75

11.2 EC declaration of conformity in accordance with the EC Machinery Directive.................81

11.3 Declaration of conformity –China RoHS 2......................................................................83

11.4 EC declaration of conformity in accordance with the Pressure Equipment Directive .......85

11.5 Table of the sublimation pressure curve..........................................................................87

12 Glossary.............................................................................................................................89

13 Index................................................................................................................................... 91

Freeze-dryer Alpha 1-2 LDplus

Table of contents

8 / 94

Version 11/2006, Rev. 2.10 of 09/03/2020 • sb-dc

Translation of the original operating manual

Freeze-dryer Alpha 1-2 LDplus

1 General information

Version 11/2006, Rev. 2.10 of 09/03/2020 • sb-dc

9 / 94

Translation of the original operating manual

→

1 General information

→

1.1 Importance of the operating manual

A fundamental requirement for the safe and trouble-free operation of the

unit is to be familiar with the fundamental safety instructions and all

possible hazards.

The operating manual includes important information concerning the safe

operation of the freeze-dryer.

This operating manual, and in particular the notes on safety and hazards,

must be observed by all persons operating the unit.

In addition, the local rules and regulations for the prevention of accidents

must be complied with.

→

1.2 Intended use

The freeze-dryer has been exclusively designed for the freeze-drying of

solid or liquid products in ampoules, vials or dishes. It is, therefore, solely

intended for this application.

The freeze-dryer is suitable for freeze-drying solid substances and aqueous

solutions (e.g. bacteria and virus cultures, blood plasma, serum fractions,

antibodies, sera, vaccines and pharmaceutical products such as

chloramphenicol, streptomycin, vitamins, ferments and plant extracts for

biochemical tests).

Freeze-drying of solvent-containing products

(non-aqueous media)

With regards of corrosion resistance, the use of some organic solvents in

aqueous solutions with low concentrations is acceptable.

A freeze-dryer is designed to be chemically resistant to most compounds

that are commonly used in freeze-drying processes. However, by

necessity, the freeze-dryer is comprised of several different materials,

some of which may be attacked and degraded by certain chemicals.

The methods of fabrication and/or conditions of exposure of an acrylic door,

as well as the way the chemicals are applied, can influence the results.

Some of these factors are listed below:

•Fabrication: Stress generated while sawing, sanding, machining,

drilling, polishing, and/or forming.

•Exposure: Length of exposure, stresses induced during the life of the

product due to various loads, changes in temperature etc.

•Application of chemicals: by contact, rubbing, wiping, spraying etc.

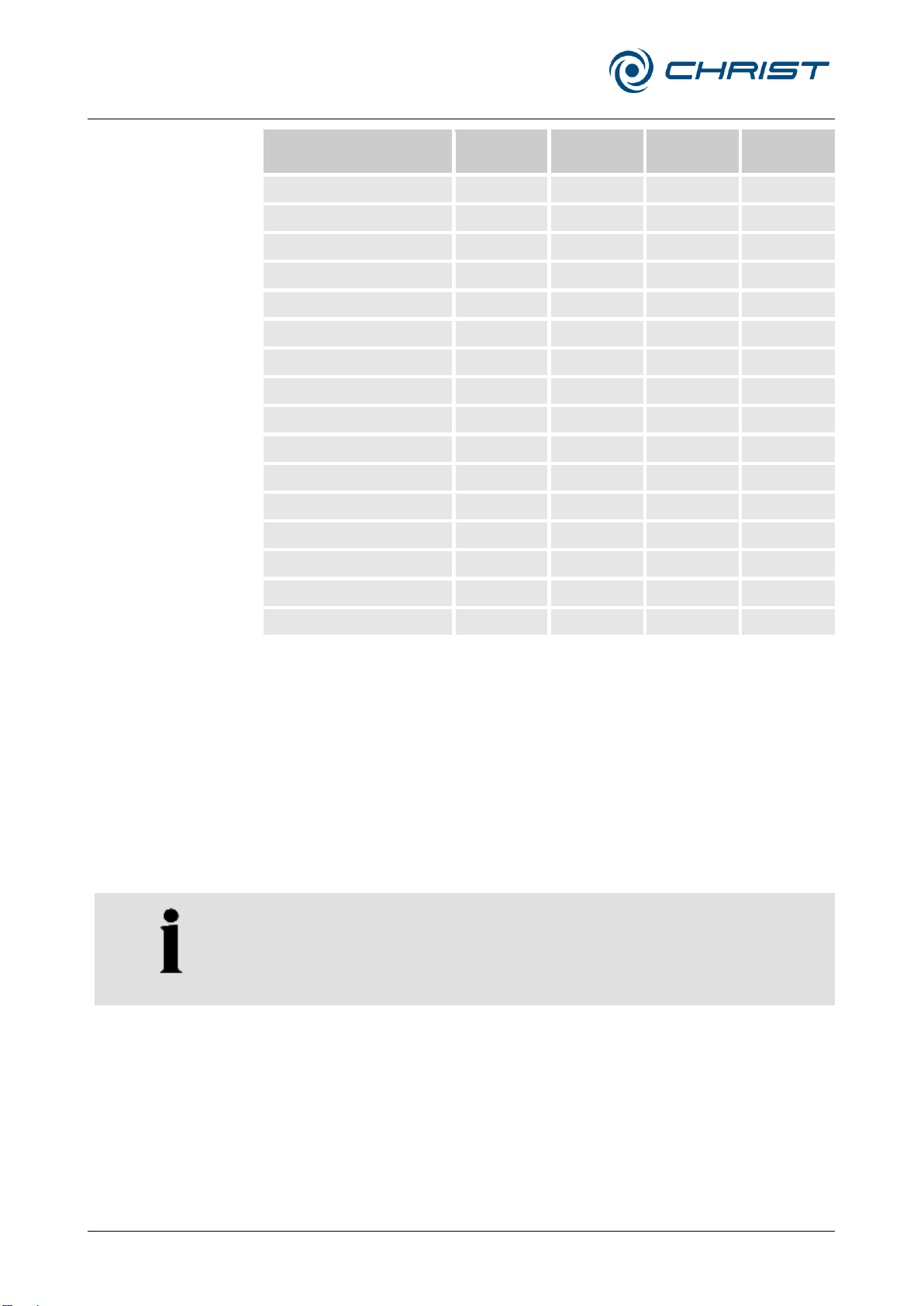

The following table can be used as a general guide for the expected

degradation during normal freeze-drying processes of organic solvents with

a total max. concentration of 10 vol-% in aqueous solutions.

Freeze-dryer Alpha 1-2 LDplus

1 General information

10 / 94

Version 11/2006, Rev. 2.10 of 09/03/2020 • sb-dc

Translation of the original operating manual

Solvent

Acrylic

glass

Stainless

steel

Silicon

rubber

EPDM

Acetic acid 20%

+

+

+

o

Formic acid

+

+

o

-

Trifluoracetic acid (TFA)

-

+

-

+

Calcium chloride

+

o

+

+

Sodium phosphate

+

+

-

+

Acetone

-

+

+

+

Acetonitrile

-

+

+

+

Carbon tetrachloride

-

+

-

-

Cyclohexane

+

+

-

-

Dioxane

+

+

-

o

Methyl-t-butyl ether

+

+

o

-

Pyridine

+

+

-

-

Methanol

-

+

+

+

Ethanol

o

+

+

+

tert-Butanol

-

+

o

o

DMSO

-

+

+

+

Legend:

+ No degradation to be expected

o Moderate degradation; limited use

- Severe degradation; infrequent use recommended;

immediate thorough cleaning required

The use of other solvents, e.g. ammonia, should be avoided.

The chemical attack on devices and accessory components can be

significantly reduced by immediate cleaning after the end of operation. All

parts of the freeze-dryer that have come in contact with the product must

be checked regularly for damages and replaced if necessary.

The following features are not permissible or must be deactivated:

•omission of product temperature sensors of the PT100 or LyoRx type or

of specially connected PT100 sensors (with a cable connection),

NOTE

Solvents that are not listed in the table above, or the listed solvents in a

concentration higher than 10% by volume, must not be used!

Freeze-drying of acid-containing products

Freeze-drying of products containing acids is only permissible if special

protective measures and equipment-related precautions are taken. Other-

wise, there is a risk of damage to property and personal injury. Consultation

of Martin Christ Gefriertrocknungsanlagen GmbH is absolutely mandatory

in order to define the measures that need to be taken!

Freeze-dryer Alpha 1-2 LDplus

1 General information

Version 11/2006, Rev. 2.10 of 09/03/2020 • sb-dc

11 / 94

Translation of the original operating manual

Any other use beyond this area of application is regarded as improper use.

Martin Christ Gefriertrocknungsanlagen GmbH cannot be held liable for any

damage resulting from such improper use.

The intended use also includes:

•observation of all the notes and instructions included in the operating

manual;

•compliance with the inspection and maintenance instruction.

The following operations are regarded as NOT PERMISSIBLE:

•operation of the freeze-dryer if it is not properly installed

•use of the freeze-dryer if it is not in a perfect technical state;

•use of the freeze-dryer within hazardous locations where there is a risk

of explosions:

•use of the freeze-dryer with unauthorised additions or conversions

without the written approval by Martin Christ Gefriertrocknungsanlagen

GmbH;

•use of the freeze-dryer with accessories that have not been approved

by Martin Christ Gefriertrocknungsanlagen GmbH, with the exception of

commercially available freeze-drying vessels made of glass or plastic;

•use of the freeze-dryer with concentrated solvents;

•freeze-drying of products that may react during the freeze-drying

process following the supply of high amounts of energy, e.g. solvent-

containing products;

•freeze-drying of products containing azides;

•freeze-drying of products that may damage the material of the chamber

walls, shelves, pipes, or seals, or that may affect the mechanical

strength.

→

1.3 Warranty and liability

The warranty and liability are subject to our "General Terms and

Conditions" that were distributed to the operator upon the conclusion of the

contract.

Warranty and liability claims are excluded if they are due to one or several

of the following reasons:

•improper use

•non-compliance with the safety instructions and hazard warnings in the

operating manual

•improper installation, start-up, operation, and maintenance of the

freeze-dryer.

Freeze-dryer Alpha 1-2 LDplus

1 General information

12 / 94

Version 11/2006, Rev. 2.10 of 09/03/2020 • sb-dc

Translation of the original operating manual

→

1.4 Copyright The copyright concerning the operating manual remains with Martin Christ

Gefriertrocknungsanlagen GmbH.

The operating manual is solely intended for the operator and their

personnel. It includes instructions and information that may not be

•duplicated,

•distributed, or

•communicated in any other way neither in full nor in parts.

Non-compliance may be prosecuted under criminal law.

→

1.5 Explanation of symbols

In this operating manual, specialist terms that are explained in the glossary

(see chapter 12 - "Glossary") are marked by an arrow and printed in italics

(e.g. →sublimation).

→

1.6 Standards and regulations

EC declaration of conformity in accordance with the EC Machinery

Directive (see chapter 11.2 - "EC declaration of conformity in accordance

with the EC Machinery Directive")

→

1.7 Scope of supply

The scope of supply comprises:

•1 tube of high-vacuum grease

•1 drain hose 0.5 m (silicone 8 x 12 mm)

•1 open spanner (size 19)

•1 operating manual

In addition, if a vacuum pump is included:

•1 litre of vacuum pump oil

•1 hexagon socket key (size 6)

Accessories and commissioning

According to your order, our order confirmation, and our delivery note.

Freeze-dryer Alpha 1-2 LDplus

2 Layout and mode of operation

Version 11/2006, Rev. 2.10 of 09/03/2020 • sb-dc

13 / 94

Translation of the original operating manual

→

2 Layout and mode of operation

→

2.1 Layout of the freeze-dryer

→

2.1.1 Functional and operating elements

1 Ice condenser

chamber with an

internal ice condenser

2 Aeration and media

drain valve

Fig. 1: Left side of the freeze-dryer

3 Pipe connection of the

vacuum pump (behind

the cover plate)

4 Ice condenser

Fig. 2: Ice condenser chamber

Freeze-dryer Alpha 1-2 LDplus

2 Layout and mode of operation

14 / 94

Version 11/2006, Rev. 2.10 of 09/03/2020 • sb-dc

Translation of the original operating manual

5 User interface (see

chapter 6.5.1 - "User

interface")

6 Mains power switch

Fig. 3: Front and right side of the freeze-dryer

7 Power supply of the

pressure control valve

8 Name plate (see

chapter 2.1.2 - "Name

plate")

9 Power supply of the

vacuum pump

10 Equipotential bonding

screw

11 Mains connection

12 Vacuum connection

13 Connection of the

vacuum sensor

14 Option: data interface

for further

accessories

15 Heat exchanger of the

refrigeration unit

Fig. 4: Rear view of the freeze-dryer

Freeze-dryer Alpha 1-2 LDplus

2 Layout and mode of operation

Version 11/2006, Rev. 2.10 of 09/03/2020 • sb-dc

15 / 94

Translation of the original operating manual

→

2.1.2 Name plate

1 Serial number

2 Type

3 Refrigerant data of

the 1st stage

4 Nominal voltage

5 Year of manufacture

(month/year)

6 Part number

7 Rated current /

apparent power

Fig. 5: Example of a name plate

Freeze-dryer Alpha 1-2 LDplus

2 Layout and mode of operation

16 / 94

Version 11/2006, Rev. 2.10 of 09/03/2020 • sb-dc

Translation of the original operating manual

→

2.2 Mode of operation

→

2.2.1 General information on freeze-drying

What is freeze-drying?

Freeze-drying or lyophilisation is a procedure for the gentle drying of high-

quality products. The product is dried by →sublimation without passing

through the liquid phase.

What are typical applications for freeze-drying?

An important area of application is the drying of biotechnological and

pharmaceutical products, e.g. tissues and tissue extracts, bacteria,

vaccines, and sera. Products that would not keep well when they are

dissolved in water can be preserved by freeze-drying. During this process,

the biological properties of these sensitive substances are preserved. The

compounds remain unchanged from a qualitative and quantitative point of

view. After the addition of water, the products will have the same

characteristics as the original products.

How does freeze-drying work?

Freeze-drying is a very gentle procedure for the extraction of water from a

product in the frozen state. The drying process takes place through →

sublimation, i.e. the direct transition of a product from the solid phase to the

gas phase. This happens under vacuum.

The following section describes the process of sublimation based on the

example of water, since most products that are processed by freeze-drying

are aqueous solutions. Their behaviour is based on identical fundamental

principles.

The vapour pressure curve for ice and water (sublimation pressure curve)

describes the phase transition as a function of the pressure and

temperature. The higher the temperature is, the higher the vapour

pressure.

•If the vapour pressure is higher than 6.11 mbar (A), water passes

through all three phases: solid, liquid, and gas (see the illustration).

•At 6.11 mbar and 0.0098°C, the melting pressure curve, vapor pressure

curve, and sublimation pressure curve meet in one point, the so-called

triple point. In this point, all three phases coexist (simultaneously).

•If the vapour pressure is below 6.11 mbar (B) and energy is added, the

ice will be directly converted into water vapour once the sublimation

curve is reached. This transition is called “sublimation”. If thermal

energy is added to pure ice with a temperature of less than –30°C at a

pressure of 0.37 mbar, it will be converted into water vapour once it

reaches –30°C (see figure).

The vacuum prevents the melting of ice when energy is added. If thermal

energy is added to a frozen product under vacuum, thawing of the product

will be prevented and the water that is contained within the product will be

released in the form of water vapour.

Freeze-dryer Alpha 1-2 LDplus

2 Layout and mode of operation

Version 11/2006, Rev. 2.10 of 09/03/2020 • sb-dc

17 / 94

Translation of the original operating manual

Fig. 6: Vapour pressure curve for ice and water

From a physical point of view, the freeze-drying process covers three

phases (see figure below):

(1) Freezing: The product to be dried is frozen under atmospheric pressure.

This can be done either directly in the freeze-dryer or in a separate deep-

freeze. The freezing temperature should be approximately 10°C below the

solidification point of the product.

(2) Evacuation: When the product is sufficiently frozen, the vacuum pump is

activated. The pressure inside the drying chamber will be lowered to the

value that corresponds to the freezing temperature in accordance with the

vapour pressure curve for ice and water.

(3) Sublimation: Thermal energy is added to the product, thus starting the

sublimation process. Due to the added energy, the water in the product is

converted into water vapour. Since the ice condenser is much colder than

the product that is to be dried, the vapour pressure in the ice condenser is

considerably lower than above the product. As a result, the water vapour

that is released by the product streams to the ice condenser, where it

condenses on the condenser coils.

Once the free water has been extracted from the product during the main

drying phase, the last traces of bound water will also be removed at a final

pressure that is as low as possible and at higher temperatures. This takes

place by way of →desorption. This drying phase is also called final drying.

Freeze-dryer Alpha 1-2 LDplus

2 Layout and mode of operation

18 / 94

Version 11/2006, Rev. 2.10 of 09/03/2020 • sb-dc

Translation of the original operating manual

Fig. 7: Freeze-drying phases

NOTE

Please find further information about basic principles, optimum

procedures and applications in the brochure "Smart freeze-drying", which

can be downloaded at www.martinchrist.de →[Applications] →

[Lyophilisation].

→

2.2.2 Freeze-drying process

The main components of a freeze-dryer are:

•vacuum drying chamber or drying manifold,

•vacuum pump for generating a vacuum inside the drying chamber,

•ice condenser for binding the water vapour that is released by the

product.

→

2.2.2.1 PreparationThe ice condenser chamber must be clean and dry. Any water residues

from a preceding drying run must be removed.

The media drain valve and the aeration valve must be closed.

In the case of units that are equipped with a pressure control valve

(standard on LSCplus and LSCbasic units), the vacuum pump should be

warmed up (“warm-up”) for at least 15 minutes prior to the start of the main

drying phase. Do not subject the vacuum pump to condensable gases until

the operating temperature is reached. In this way, the service life of the

vacuum pump can be extended.

At the same time, the ice condenser is pre-cooled ("cool-down"). The ice

condenser temperature does not have any influence on the product

temperature. The sole purpose of the ice condenser is to bind the released

water vapour.

Freeze-dryer Alpha 1-2 LDplus

2 Layout and mode of operation

Version 11/2006, Rev. 2.10 of 09/03/2020 • sb-dc

19 / 94

Translation of the original operating manual

→

2.2.2.2 Freezing First, the product that is to be dried is frozen. Especially in the case of small

filling quantities, we recommend pre-cooling the shelves as well in order to

prevent the product from thawing during the evacuation.

Two very different structures of the frozen material can be distinguished:

•crystalline structures with clearly distinguishable crystals

•amorphous structures with no crystal junctions at all (e.g. glass)

The majority of the freeze-drying products have a crystalline form.

When freezing these kinds of products, one must take into consideration

that too deep and too quick freezing leads to smaller ice crystals, which has

a negative effect on the duration of the drying process.

For every product to be dried, the solidification point must be determined as

a first step. This is the point at which the water that is contained in the

product has completely crystallised. In order to ensure an optimum freeze-

drying process, the product temperature should be approximately 10°C

below the solidification point.

→

2.2.2.3 Main drying

When the product is frozen, the main drying phase commences. The

vacuum pump is switched on. The pressure inside the drying chamber will

be lowered to the value that corresponds to the freezing temperature in

accordance with the vapour pressure curve for ice and water (sublimation

pressure curve). At the same time, thermal energy will be added to the

product. In the case of products in round-bottom flasks, wide-neck bottles,

etc., this is realised through the environment that is considerably warmer

(direct contact heat), in the case of unheated shelves by way of thermal

radiation from the environment, and in the case of temperature-controlled

shelves directly via the shelves. As a result, the sublimation process starts.

At the beginning of the drying process, the maximum drying rate will be

reached. The more the sublimation area recedes into the product, the

further the produced water vapour must pass through the layers that have

already been dried.

Under certain conditions, it is possible that the vacuum inside the ice

condenser chamber increases during the main drying phase (e.g. from 0.63

mbar to 0.47 mbar) although the valve towards the vacuum pump is closed.

From a physical point of view, this is due to the pumping effect of the ice

condenser ("cryo-pumping effect").

The required drying time depends strongly on the drying vacuum. At 1.0

mbar, one gram of ice takes up a volume of 1 m3of vapour, at 0.1 mbar a

volume of 10 m3of vapour, and at 0.001 mbar a volume of 100 m3. The

closer the vacuum is to the solidification point, the smaller is the resulting

vapour volume. The drying rate increases and the drying time decreases.

→

2.2.2.4 Final drying

Final drying is an option whenever one requires a product with minimal

residual moisture. In the physical sense, this process is a desorption

process, i.e. the removal of adsorptively bound water. Final drying is

performed under the lowest possible final pressure that depends on the ice

Freeze-dryer Alpha 1-2 LDplus

2 Layout and mode of operation

20 / 94

Version 11/2006, Rev. 2.10 of 09/03/2020 • sb-dc

Translation of the original operating manual

condenser temperature in accordance with the vapour pressure curve for

ice and water as well as on the final vacuum of the vacuum pump that is

used. The process is supported by a higher shelf temperature.

→

2.2.2.5 End of drying and aeration

The end of the drying process is reached when both the product and shelf

temperature are clearly in the positive range (+15 to +20°C) and if their

difference is not greater than 5 K.

Another indication of the end of the drying process is the behaviour of the

vacuum and of the ice condenser temperature. The ice condenser is no

longer subject to load and reaches the final temperature of approximately -

55°C or -85°C. The pressure in the drying chamber decreases in

accordance with the ice condenser temperature.

The vacuum pump will be switched off and the drying chamber will be

aerated via a rubber valve or via the aeration valve. The aeration valve can

also be used to flood the unit with nitrogen or another inert gas instead of

ambient air.

Then, the product can be removed from the unit.

→

2.2.2.6 Defrosting Defrosting of the ice condenser is carried out at room temperature or with

warm water.

•At a maximum, the ice condenser chamber may be half filled with water.

•Ensure that no water gets into the pipe connection of the vacuum pump

and the vacuum sensor (behind the cover plate, see figure)

1 Cover plate

Fig. 8: Eis condenser chamber

•Drain the condensate through the media drain valve at the left side of

the freeze-dryer by attaching a hose on the nozzle (included in the

scope of supply) and placing a vessel underneath.

In order to avoid damage, the condensate must be removed directly after

the completion of the defrosting process. Then, any residual water must be

removed from the ice condenser chamber by way of a cloth.

Other manuals for ALPHA 1-2 LDplus

2

This manual suits for next models

2

Table of contents