ENGINE SPECIFICATIONS

EAS20290

ENGINE SPECIFICATIONS

Engine

Engine type Liquid cooled 4-stroke, SOHC

Displacement 124.7 cm³

Cylinder arrangement Forward-inclined single cylinder

Bore ×stroke 52.0 ×58.6 mm (2.05 ×2.31 in)

Compression ratio 11.20 :1

Standard compression pressure (at sea level) 550 kPa/600 r/min (5.5 kgf/cm²/600 r/min, 78.2

psi/600 r/min)

Minimum–maximum 480–620 kPa (4.8–6.2 kgf/cm², 68.3–88.2 psi)

Starting system Electric starter

Fuel

Recommended fuel Premium unleaded gasoline only

Fuel tank capacity 8.5 L (2.25 US gal, 1.87 Imp.gal)

Fuel reserve amount 1.6 L (0.42 US gal, 0.35 Imp.gal)

Engine oil

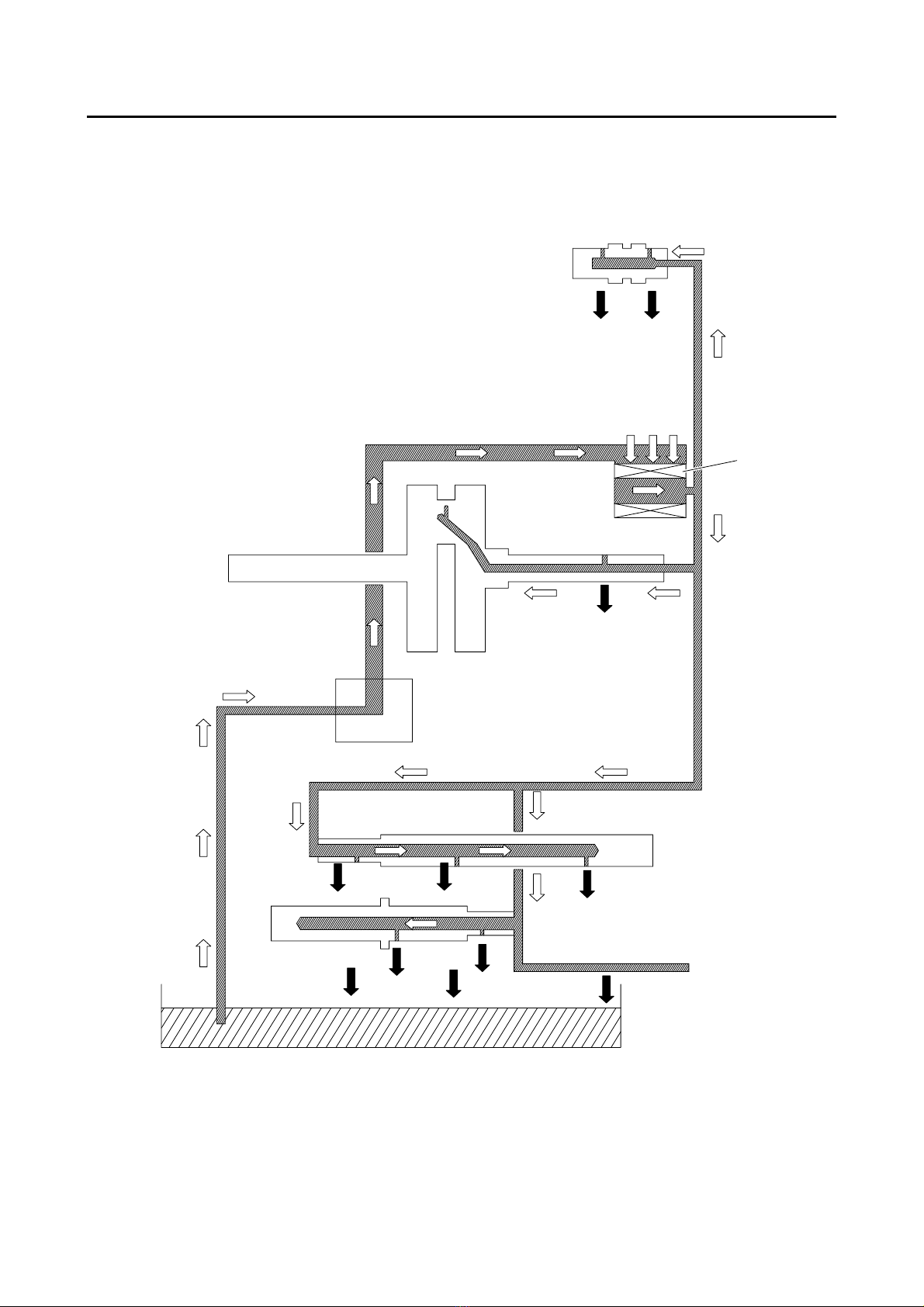

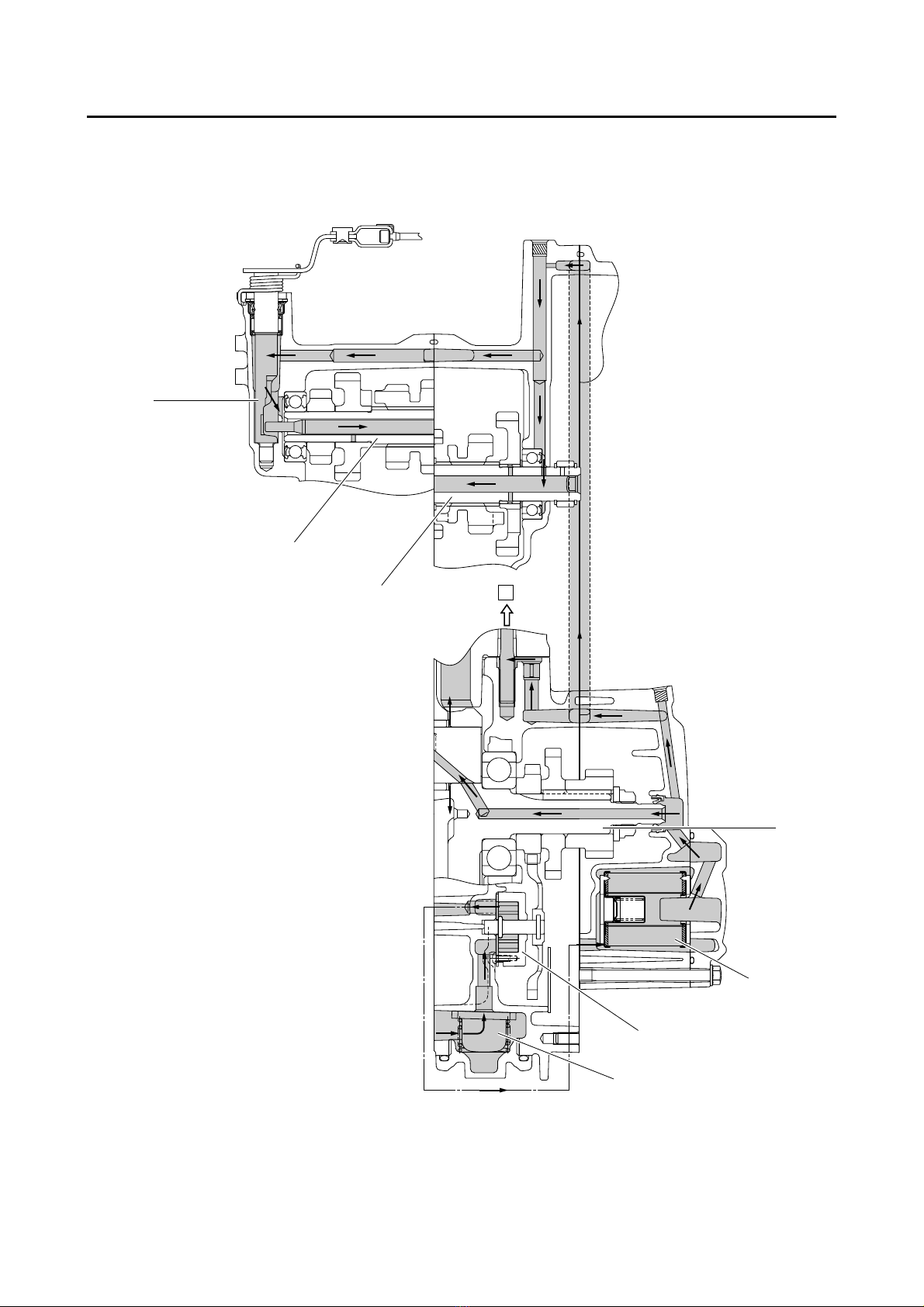

Lubrication system Wet sump

Type SAE 10W-30, SAE 10W-40, SAE 15W-40, SAE

20W-40 or SAE 20W-50

Recommended engine oil grade API service SG type or higher, JASO standard

MA

Engine oil quantity

Total amount 1.15 L (1.22 US qt, 1.01 Imp.qt)

Without oil filter element replacement 0.95 L (1.00 US qt, 0.84 Imp.qt)

With oil filter element replacement 1.00 L (1.06 US qt, 0.88 Imp.qt)

Oil filter

Oil filter type Paper

Oil pump

Oil pump type Trochoid

Inner-rotor-to-outer-rotor-tip clearance Less than 0.150 mm (0.0059 in)

Limit 0.23 mm (0.0091 in)

Outer-rotor-to-oil-pump-housing clearance 0.130–0.180 mm (0.0051–0.0071 in)

Limit 0.25 mm (0.0098 in)

Oil-pump-housing-to-inner-and-outer-rotor

clearance 0.06–0.11 mm (0.0024–0.0043 in)

Limit 0.18 mm (0.0071 in)

Relief valve operating pressure 39.2–78.4 kPa (0.39–0.78kgf/cm², 5.7–11.4 psi)

Pressure check location Check bolt on cylinder head body