Chromalpx PF474-2 Installation and operating instructions

CCH-3x02xx0 ALL 2.0/1.0 6824/3412 105.0 NS

CCH-3x03xx0 ALL 3.0/2.0 10236/6824 105.0 NS

CCH-3x04xx0 ALL 4.0/2.0 13648/6824 105.0 NS

CCH-3x05xx0 ALL 5.0/3.0 17060/10236 105.0 NS

CCH-3x06xx0 ALL 6.0/3.0 20472/10236 105.0 NS

CCH-4x04xx0 ALL 4.0/2.0 13648/6824 145.0 NS

CCH-4x06xx0 ALL 6.0/4.0 20472/13648 145.0 NS

CCH-4x08xx0 ALL 8.0/4.0 27296/13648 145.0 NS

CCH-4x10xx0 ALL 10.0/6.0 34120/20472 145.0 NS

CCH-4x12xx0 ALL 12.0/6.0 40944/20472 145.0 NS

CCH-6x06xx0 ALL 6.0/3.0 20472/10236 240.0 NS

CCH-6x09xx0 ALL 9.0/6.0 30708/20472 240.0 NS

CCH-6x12xx0 ALL 12.0/6.0 40944/20472 240.0 NS

CCH-6x15xx0 ALL 15.0/9.0 51180/30708 240.0 NS

CCH-6x18xx0 ALL 18.0/9.0 61416/30708 240.0 NS

CCH-7x08xx0 ALL 8.0/4.0 27296/13648 275.0 NS

CCH-7x12xx0 ALL 12.0/8.0 40944/27296 275.0 NS

CCH-7x16xx0 ALL 16.0/8.0 54592/27296 275.0 NS

CCH-7x20xx0 ALL 20.0/12.0 68240/40944 275.0 NS

CCH-7x24xx0 ALL 24.0/12.0 81888/40944 275.0 NS

32” Cabinet with:

Fan Motor - 1050 RPM

HI/800 RPM LO

Air Flow - 250 CFM

HI/200 CFM LO

1 Blower Motor & 1

Wheel Throw Away Filter

45” Cabinet with:

Fan Motor - 1050 RPM

HI/800 RPM LO

Air Flow - 500 CFM

HI/400 CFM LO

1 Blower Motor & 2 Wheels

Throw Away Filter

65” Cabinet with:

Fan Motor - 1050 RPM

HI/800 RPM LO

Air Flow - 750 CFM

HI/600 CFM LO

2 Blower Motor & 3 Wheel

Throw Away Filter

78” Cabinet with:

Fan Motor - 1050 RPM

HI/800 RPM LO

Air Flow - 1000 CFM

HI/800 CFM LO

2 Blower Motors & 4

Wheels Throw Away Filter

DIVISION

4

SECTION

CCH

SALES

REFERENCE

DATE

SERVICE REFERENCE

Installation, Operation

and

MAINTENANCE

PF474-2

JULY, 2002

(Supersedes PF474-1)

161-506132-001

© 2010 Chromalox, Inc.

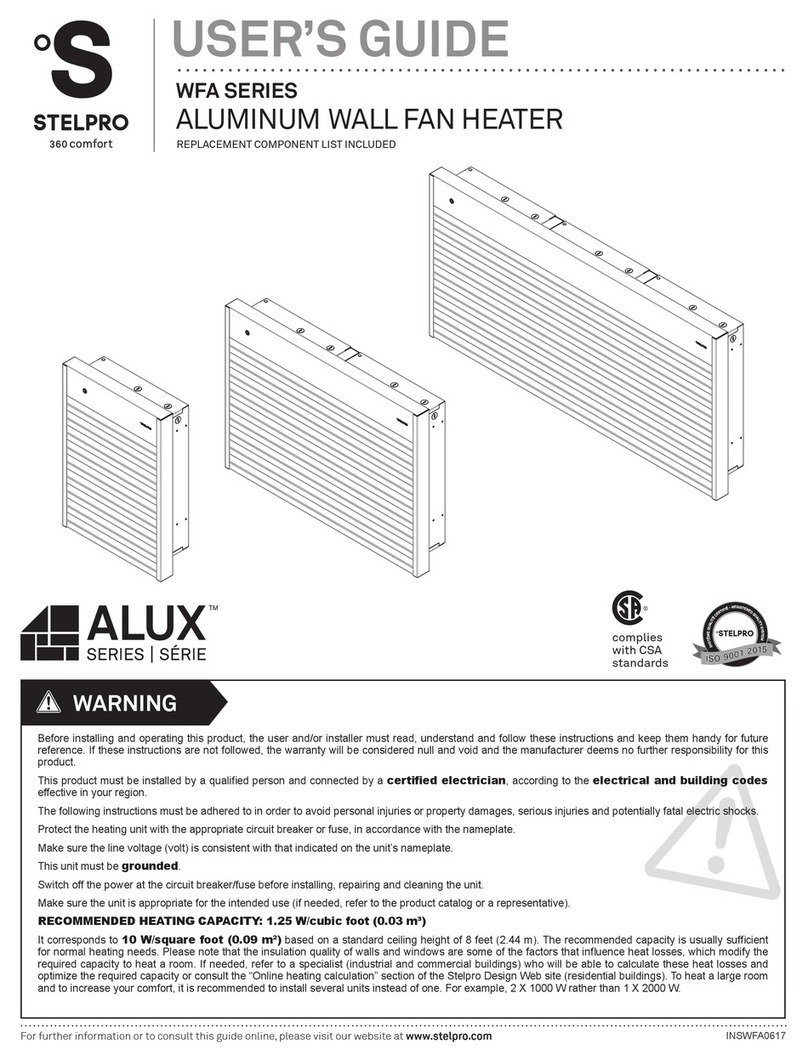

Type CCH — Cabinet Blower Heater

Specifications –

Model Description Volts Watts BTUH Weight Stock PCN

(kW) (Lbs.)

NOTES:

1. When ordering, specify volts, phase, wattage and any optional features required.

2. 208 to 600V units are available in both 1 and 3 phase, all others are single phase only.

3. All heaters rated over 48 amps require two circuits.

4. All heaters equipped with fusing where necessary to meet N.E.C. and UL requirements.

5. Fan Motor - Permanent split capacitor type - built-in overload projection - lifetime lubricated - resiliently mounted -

totally enclosed - 2 speed - direct drive - 1/20 HP.

6. Motor volts same as heater volts except 277/480V 3-phase, 4 wire heaters use 277V motor. 480V 3-phase, 3 wire

heaters have integral transformer to transform line voltage to 230V motor.

Model Description Weight Stock PCN

(Lbs.)

CCH-39004105 32” Trim Frame - Recess Mount 6.0 NS

CCH-39004106 45” Trim Frame - Recess Mount 7.0 NS

CCH-39004107 65” Trim Frame - Recess Mount 10.0 NS

CCH-39004108 78” Trim Frame - Recess Mount 11.0 NS

CCH-39004154 32” Permanent Washable Filter 12.0 NS

CCH-39004155 45” Permanent Washable Filter 15.0 NS

CCH-39004156 65” Permanent Washable Filter 17.0 NS

CCH-39004157 78” Permanent Washable Filter 18.0 NS

CCH-2-12kW 208V, 1-Phase

Built-in Circuit Breaker NS

CCH-2-12kW 208V, 3-Phase

Built-in Circuit Breaker NS

CCH-16-24kW 208V, 3-Phase

Built-in Circuit Breaker NS

CCH-2-12kW 240V, 1-Phase

Built-in Circuit Breaker NS

CCH-2-12kW 240V, 3-Phase

Built-in Circuit Breaker NS

CCH-16-24kW 240V, 3-Phase

Built-in Circuit Breaker NS

CCH-2-12kW 277V, 1-Phase

Built-in Circuit Breaker NS

CCH-2-24kW 480V, 3-Phase

Built-in Circuit Breaker NS

CCH-BG Architectural Cabinet Bar Grill NS

CCH-N Control Option for

Low Voltage Night Setback NS

CCH-R Control Option for

Line Voltage Wall Thermostat NS

CCH-3 Control Option for

Built-in Line Voltage Thermostat NS

CCH-X Ceiling Mount Kit NS

Optional Accessories –

NOTE: -3 and -n provided with a built-in snap action hydraulic action thermostat. The

sensing bulb is located in the air intake portion of the heater. Range 45-90˚F. The -

R option includes a thermostat for remote wall mounting with a temperature range

of 35-90˚F (shipped with heaters).

25 9-1/2

9-1/4

9/16" Dia K.O.

for Ceiling Mounts

(See Note)

Outlet Control Section

AB

C

Inlet

2-1/8

X

32, 45, 65

7-1/4

5-1/8

2-3/4

3

E

D

2-1/2

3

8-7/8

AB

C

1-1/2

WARNING: Hazard of Electric Shock. Disconnect all

power before installing heater.

WARNING: Hazard of Electric Shock. Any installation

involving electric heaters must be effectively ground-

ed in accordance with the National Electrical Code to

eliminate shock hazard.

WARNING: Do not store or use gasoline or other flam-

mable vapors and liquids in the vicinity of the heater.

Failure to comply can result in explosion or fire.

An exploded view of the major components of the Cabinet Blower

Heater is shown in Figure 1. The Cabinet Blower Heater is complete-

ly assembled when shipped and must be partially dismantled for instal-

lation.

Removing Front Panel —

To remove front panel, insert Allen wrench in each of two holes at

the upper right and left corners of the panel and turn counterclockwise.

After panel is swung open, pull the two spring-loaded hinges (located

at each end of the panel) towards the center of the panel and remove

panel. Units shipped with doors in position for upflow application. If

unit is to be installed as downflow, both doors can be removed and

installed in reverse position.

Fastening To Wall —

For floor-mounted units it is necessary to use only the holes

marked “A” in Figure 3 in order to secure unit to the wall. The motor

and blower assembly need not be removed. The filter may be removed

to assist in installation.

For wall-mounted units, in order to ensure adequate support, a

greater number of mounting holes may be used. To gain access to

them, the motor and blower assembly and filter must first be

removed. Remove the screws at each end of the assembly as shown

in Figure 2, then pull out assembly. Be sure to disconnect Molex plug

at the blower deck removing assembly. Slide out filter as shown. The

unit is now ready for securing to the wall.

With ceiling mounted units, use the same procedure as in the wall-

mounted units.

Semi and Full-Recessed Applications —

For either semi- or full-recessed applications, care must be taken to

provide the proper size of opening in the wall or ceiling. See Figure 4

for dimensions. On the length and width dimensions, 1/4 inch must be

allowed to insert trim frame.

In a semi-recessed application, the unit can be recessed to any

depth except when the inlet and/or discharge are on the top or bottom

of the cabinet as opposed to the front.

The trim frame is used in recessed applications. See Figure 5 for a

typical application. Refer to Table 1 for proper ordering information.

Accessory Trim Frame Assembly —

Refer to Figure 6 for assembly. Assemble heater frame on a flat

surface. Insert “L” shaped splices into each corner as shown. Use

carpenter’s square to be sure of exact 90˚ angle at corners. Square up

one corner at a time, then center punch one at a time to crimp down

inside flange onto “L” shaped splice. Trim frame can be secured to

wall with screws (not provided), cement or adhesive.

Table 1 Trim Frame —

For recessed mounting in wall or ceiling.

Servicing —

WARNING: Hazard of Severe Shock. Disconnect all

power to heater before servicing.

1. All motors are equipped with lifetime lubrication, consequently no

oiling is required.

2. If motors or blowers need servicing, they can easily be removed by

removing screws as illustrated in Figure 2. Complete assembly

then slides out, after Molex connector is unplugged.

3. If heat sections need servicing, they can easily be removed by

removing screws as illustrated in Figure 7. The complete heat sec-

tion assembly then slides out, after all wires into the terminal block

are removed. Care must be taken to assure that all wires are

replaced in the correct terminal block, per wire numbering or cod-

ing. The limit control and elements can be readily serviced when

the heat section is removed.

4. All controls are readily accessible through the inner control door.

All controls can be serviced through this control door.

5. Filter is accessible after the front panel is opened. Slide filter out

and through the use of a built-in filter track, clean or replace a min-

imum of twice per heating season. Optional permanent type filter

can be cleaned with water and detergent or any available filter

cleaning solution.

Wiring Information —

1. For service entrance refer to Figure 4 for knockout sizes available

and their locations.

IMPORTANT: For upflow application, control section and

knockouts are located on lower right hand side of unit and for

downflow application they will be on upper left hand side of unit.

2. Electric wiring to heater must be installed in accordance with the

National Electrical Code and with local codes by a qualified per-

son. WARNING: Use copper conductors only.

3. Refer to data plate and wiring diagram for correct voltage and

amperage ratings. These must be considered in the sizing of field

wiring.

4. When wiring “-N” and “-R” type heaters, control circuit field

wiring to be suitable for 600 volts.

Trim Frame Part No. Cabinet Length

CCH - 39004105 32”

CCH - 39004106 45”

CCH - 39004107 65”

CCH - 39004108 78”

INSTALLATION

INSTALLATION ILLUSTRATIONS

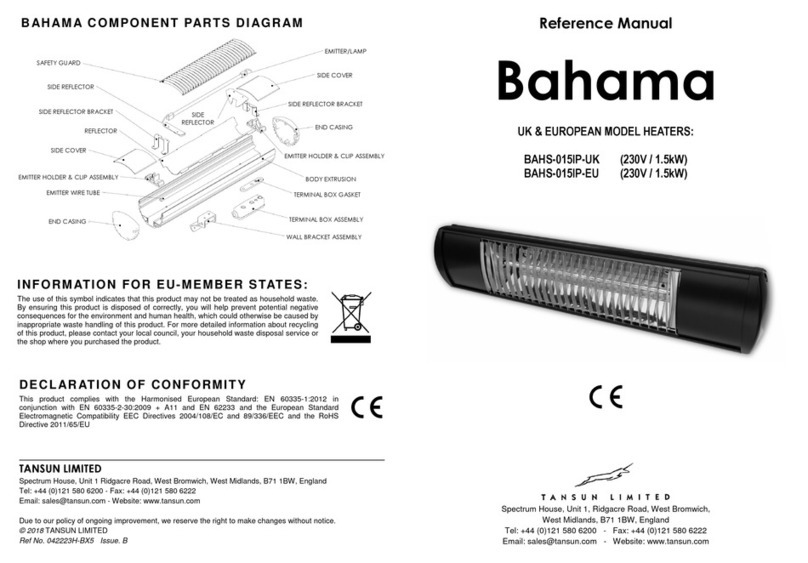

FIGURE 1 FIGURE 2 FIGURE 3

FIGURE 5

FIGURE 6 FIGURE 7

FIGURE 4

Cabinet

Heater Section

Blower

Assembly

Front Panel

Filter

Blower Assembly Cabinet

Permanent

Washable Filter

Screw “A”

Heater Section Terminal

Block

Control

Panel

Mounting Knockouts (4” Centers)

5-3/8”

Outlet

32, 45, 65 & 78

Inlet 4-7/8” 1/2-1-1-1/2

Knockouts 1-5/8”

3”

3”

1-1/2

Accessory

Adapter

Frame

25”

8-7/8”

5-1/2” 3-3/8”

Heater Section Cabinet Control

Panel

Lock

Front Panel

Blower

Assembly

AA

4

Typ.

8”

7-3/4”

Front Panel

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

MAINTENANCE

WARNING: Hazard of Severe Shock. Disconnect all

power to heater before servicing or replacing heaters.

Accumulated dust and lint inside the heater should be removed at

the beginning of each heating season.

REPLACEMENT PARTS

For replacement parts, please consult with the Product Service Center

listed below.

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Table of contents