LUBRICATION

ANDMAINTENANCE0-3

GROUP

0

LUBRICATIONANDMAINTENANCE

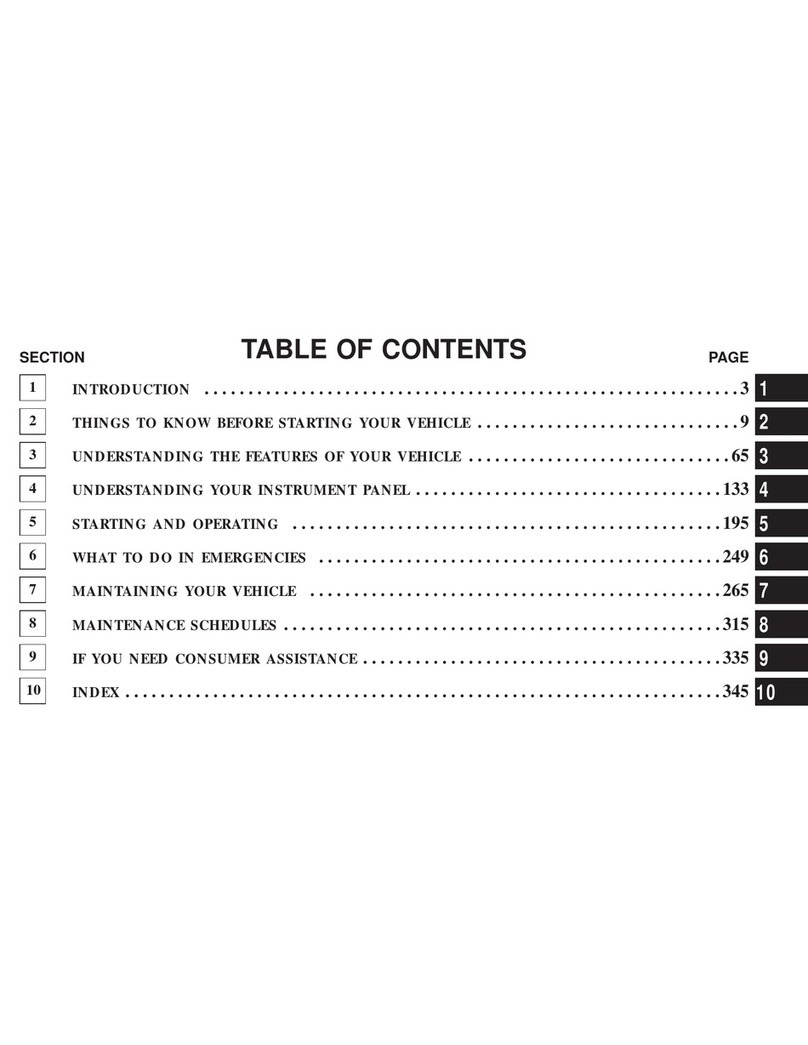

CONTENTS

Page

Air

Cleaner

6

Alternator7

Battery7

Body

Maintenance7

Brakes

8

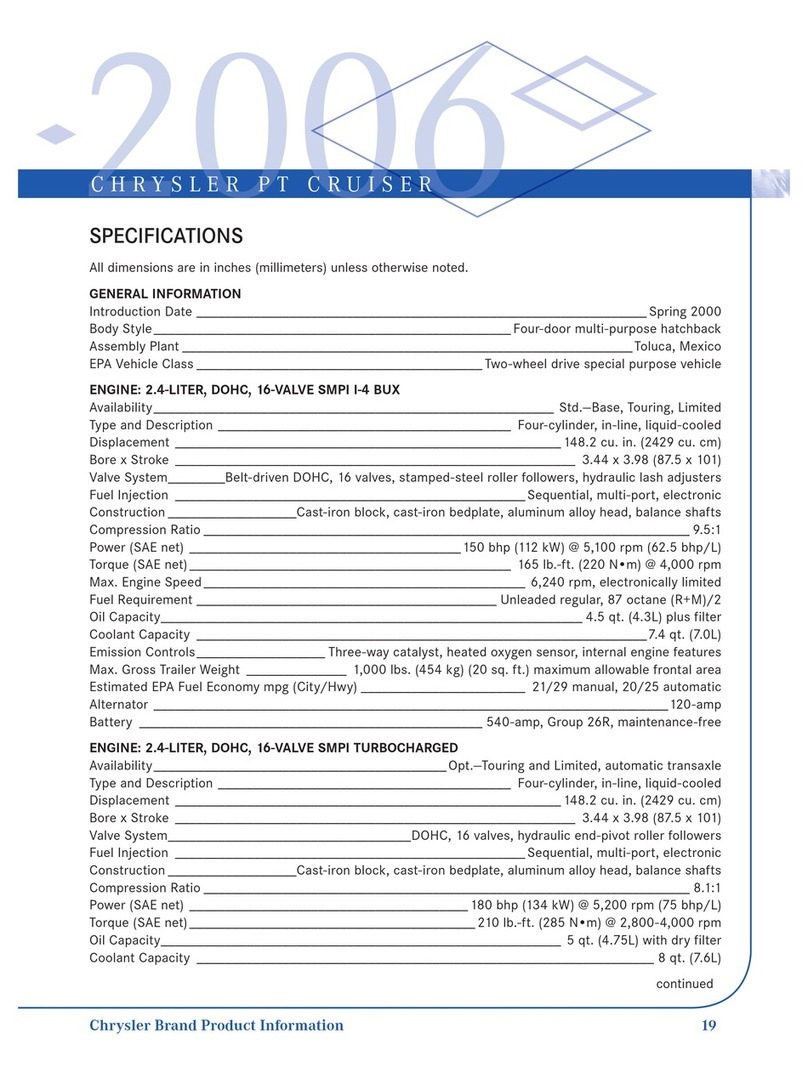

Capacities

Chart3

Carburetor

Choke

Piston6

CertifiedCar

Care—Brake

System

16

CertifiedCar

Care—Engine

Tune-up16

CertifiedCarCare—Front

Suspension

...............17

CertifiedCar

Care—Semi-Annua

I Maintenance16

CertifiedCarCare—Maintenance

Record

18

Chassis

Lubrication8

Clutch

TorqueShaft.10

Cooling

System

11

Crankcase

Ventilator

Valve6

Distributor11

Engine

Oil4

Frequency

ofOil

Change

5

Fuel

Filter7

Gearshift

Lever

12

Headlamps12

Manifold

Heat

ControlValve.7

OilFilter7

1,000

Mile

Inspection.15

Parts

RequiringNoLubrication12

Propeller

Shafts

andUniversal

Joints.

12

Rear

Axleand

Sure-Grip.

13

Selection

ofLubricant5

Speedometer

Cable

13

Steering

13

Tires

.....14

Transmission

14

Wheel

Bearings

11

WindshieldWipers15

SUMMARYOF

LUBRICATION

ANDMAINTENANCE

SERVICES

Maintenanceandlubricationservicesrecommenda-

tionsforthe1963ChryslerCorporationcarshave

beencompiled(designedetc.)toprovidemaximum

protectiontovehicleownersagainstalltypesofdriv-

ingconditions.These,aswellasdrivinghabits,are

sovariedthattoprescribethelubricationandmain-

tenanceservicesona mileagebasisonlydidnottake

careofthose whodrovefewermilesduringequal

lengthtimeperiods,especiallyduringadverse

weatherconditions.

Theserecommendations,therefore,havebeenre-

latedtothebestofourabilitytotimeintervals,yet

limitedbymileagewherenecessary.Ingeneral,semi-

annuallubricationandmaintenanceserviceshave

beenprescribedformostitems.Exceptionstothis

includetwomonthintervalsbetweenengineoil

changes,(nottoexceed4,000miles)opposedtothe

frontsuspensionlubricationevery32,000miles.

CERTIFIED

CAR

CARE

CertifiedCarCareis

a

thoroughservicingprogram

thathelpsmakesurethevehiclesyousellgetthe

regularattentionyouknowtheyneed.

CertifiedCarCarehelpsbuildbusinessforyouin

thesurestwayknown—throughcustomersatisfac-

tion,

nottomentiontheextraprofitsfromtheservice

department.Tellyourownerthatthebestapproach

totrouble-freedrivingisCertifiedCarCare. . .

Apracticalplantobuildsalesandserviceforyou,

providingforregularcustomerserviceatyourdealer-

ships.

1.

ENGINE

OIL

Lubricantsareclassifiedandgradedaccordingto

standardsrecommendedbytheSocietyofAutomotive

Engineers(SAE),theAmericanPetroleumInstitute

(API)andtheNationalLubricatingGreaseInstitute

(NLGI).

TheSAEgradenumberindicatestheviscosityof

thelubricant.(Example,SAE30).Engineoilsmay

havea dualnumber,oneofwhichisSAE10W-30.

Thismarkingindicatesthattheoiliscomparable

toSAE10W,SAE20WandSAE30grades.

TheAPIdesignationsrelatetothetypeofservice

forwhichtheengineoilisrecommended.Thethree

designationsare"MS""MM"and"ML".AHengines

MyMopar.com