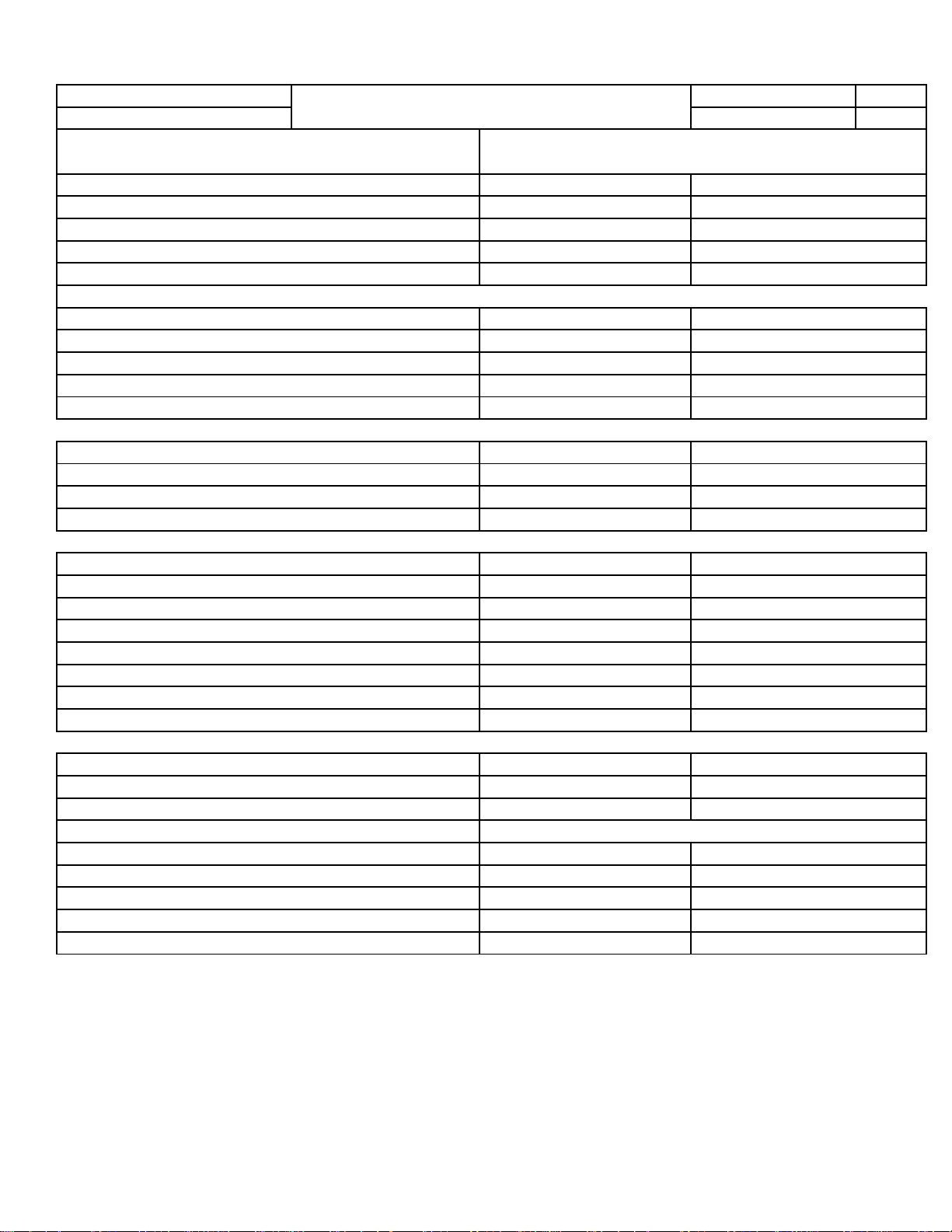

ConnectingRods

BearingClearance(WithCrush)

SideClearance

PistonPinBoreDiameter

BearingBoreOutofRound(Max.)

CrankshaftMainBearingJournals

Diameter

BearingClearance

OutofRound(Max.)

CrankshaftEndPlay

CrankshaftRodBearingJournals

Diameter

BearingClearance

OutofRound(Max.)

CamshaftJournalDia.&Clearance

BoreDia.CamTowerNo.1

BoreDia.CamTowersNo.2,3,4

JournalDia.No1

JournalDia.No.2,3,4

ClearanceNo.1

ClearanceNo.2,3,4

CamshaftEndPlay

CylinderHead

CompressedGasketThickness@FireRing

CylinderHeadDeckFlatness

ValveSeatAngle

IntakeValveSeatWidth

ExhaustValveSeatWidth

ValveGuideBoreDiameter

ValveStemtoGuideClearance(Intake)

ValveStemtoGuideClearance(Exhaust)

6.00‐6.02mm 0.236‐0.237in.

0.023‐0.061mm 0.0009‐0.0024in.

44.75°±0.25°fromthevalveguideaxis

0.030‐0.068mm 0.0012‐0.0027in.

1.0‐1.2mm 0.04‐0.05in.

1.41‐1.61mm 0.055‐0.063in.

Metric Standard

0.48‐0.60mm 0.019‐0.024in.

0.09mm 0.0035in.

0.024‐0.064mm 0.0009‐0.0025in.

0.008mm 0.0003in.

0.075‐0.251mm 0.003‐0.010in.

23.977‐23.996mm 0.9440‐0.9447in.

0.025‐0.065mm 0.001‐0.0026in.

32.020‐32.041mm 1.2606‐1.2615in.

24.020‐24.041mm 0.9457‐0.9465in.

31.976‐31.995mm 1.2589‐1.2596in.

0.023‐0.064mm 0.0009‐0.0025in.

0.005mm 0.0002in.

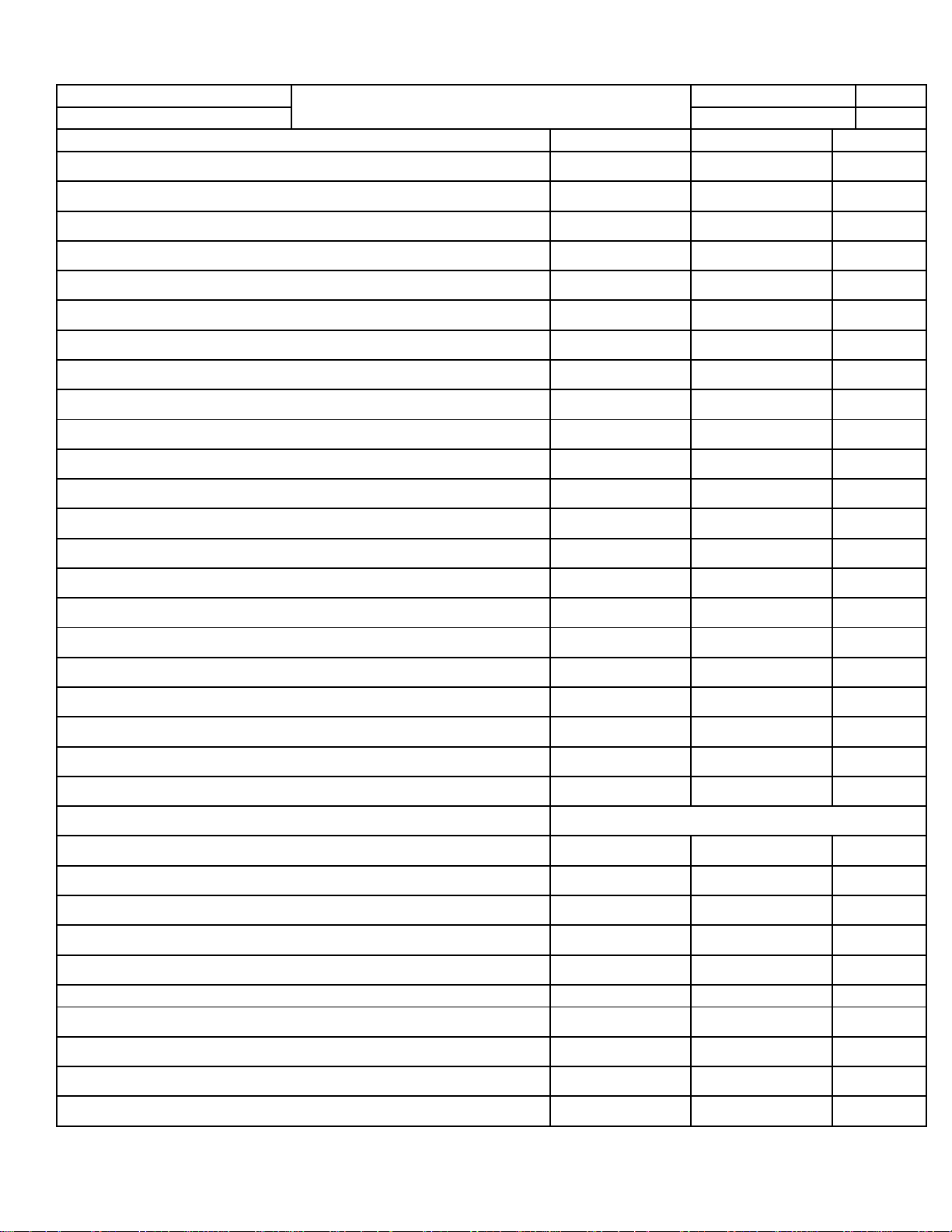

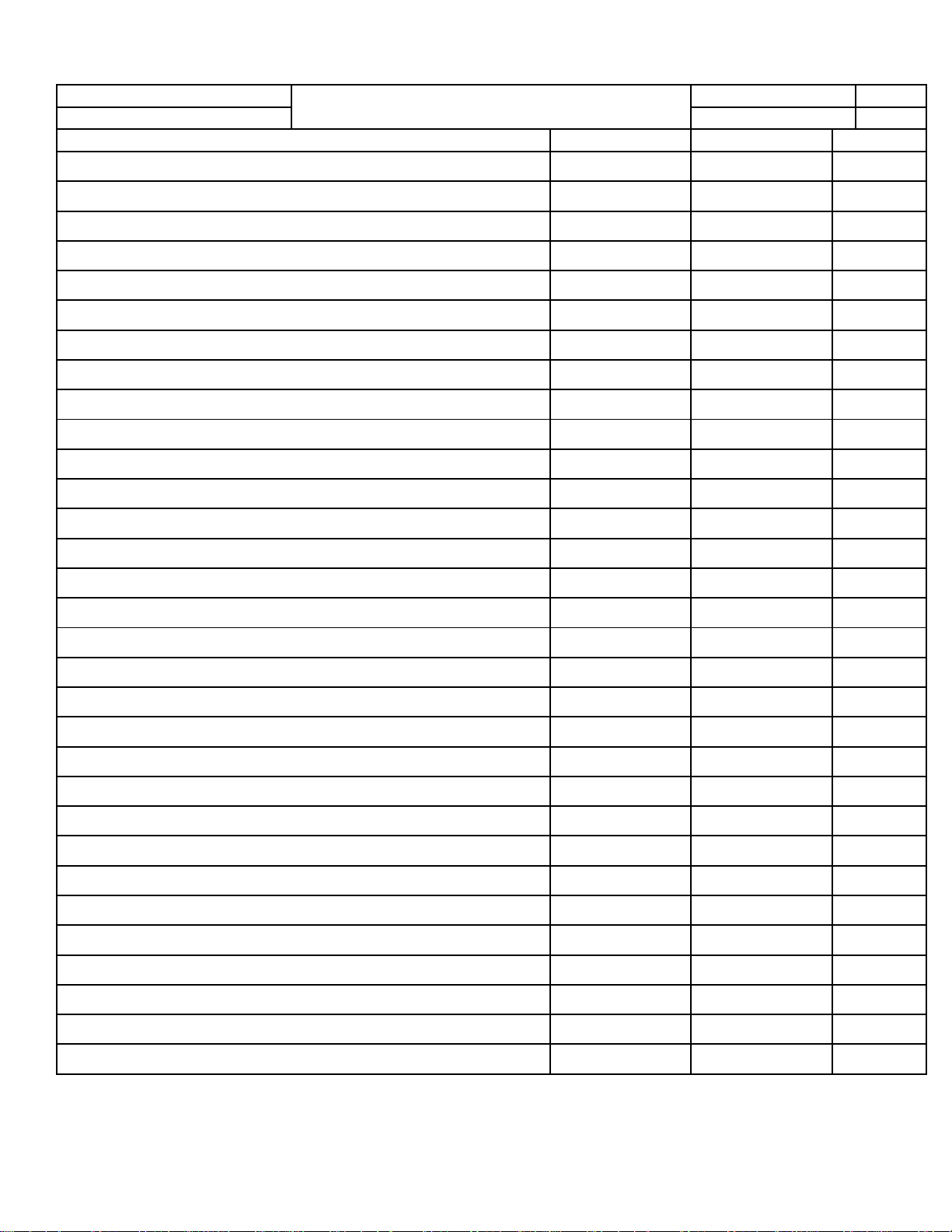

Metric Standard

Metric Standard

59.0±0.009mm 2.3228±0.0035in.

0.050‐0.290mm 0.002‐0.0114in.

71.996±0.009mm 2.8345±0.0035in.

0.024‐0.050mm 0.0009‐0.0020in.

0.005mm 0.0002in.

0.070‐0.370mm 0.0028‐0.0146in.

22.016±0.005mm 0.8668±0.0002in.

Metric Standard

Description Specification

Metric Standard

0.023‐0.064mm 0.0009‐0.0025in.

ChryslerIIIHEngineSpecifications

RevisionDRAFT Section 1

Mar‐16 Sheet 2