4

Product Features 2

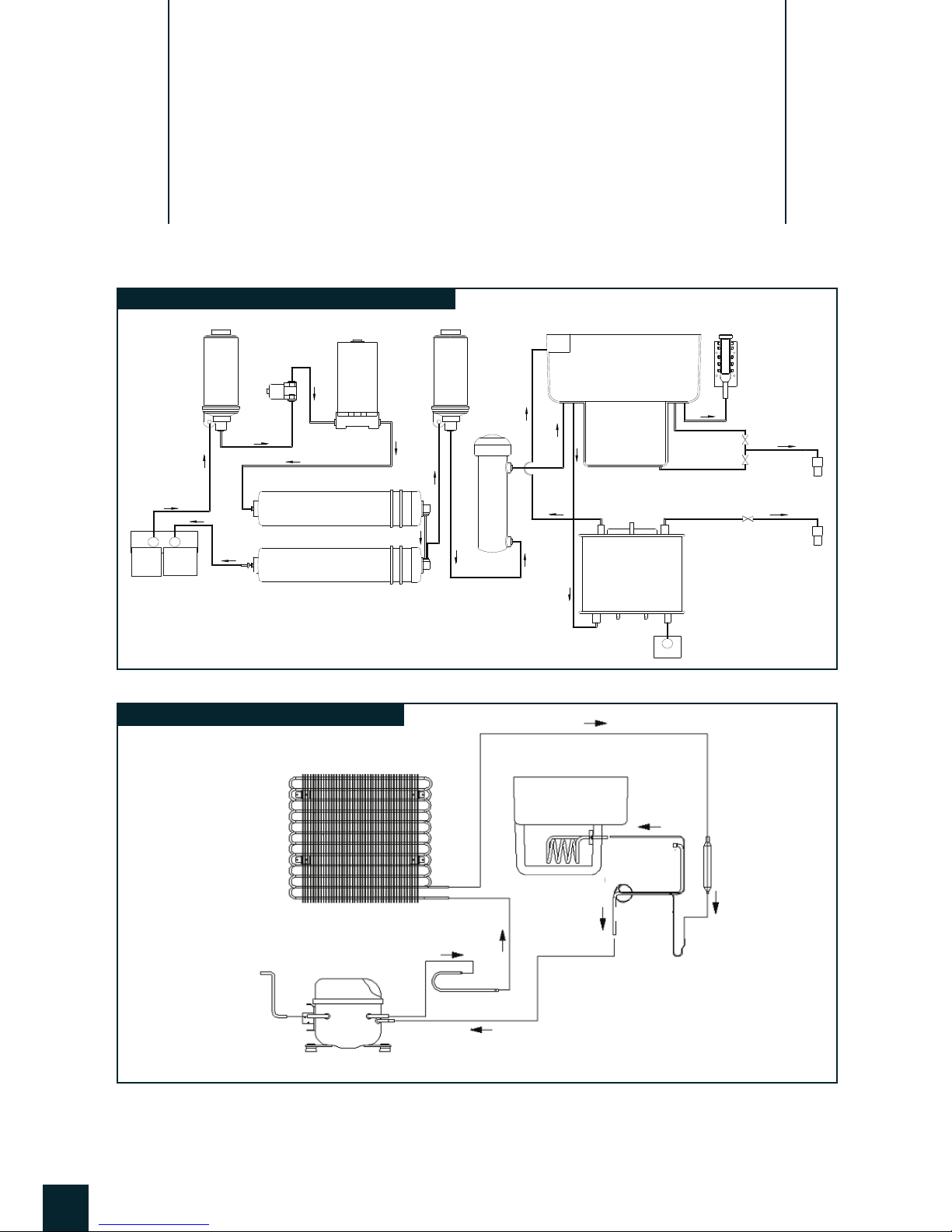

24 Hour natural water circulation system (N.W.P.W.)

This function of ChungHo purication systems is designed to allow water to continuously ow for 24

hours within the water purier by adopting a natural circulation method. This mode, entitle N.W.P.W.,

applies the natural weight of water pressure in order to always supply clean and fresh water.(Patent:

No.105585)

Energy saving function

The economically designed Iguassu Ice delivers puried water to the ice making unit in order to make

pure ice while simultaneously sending cooled water to cold water tank. This allows the system to

maintain a constant cold water temperature, thus inherently preventing water waste and helping to

conserve energy.

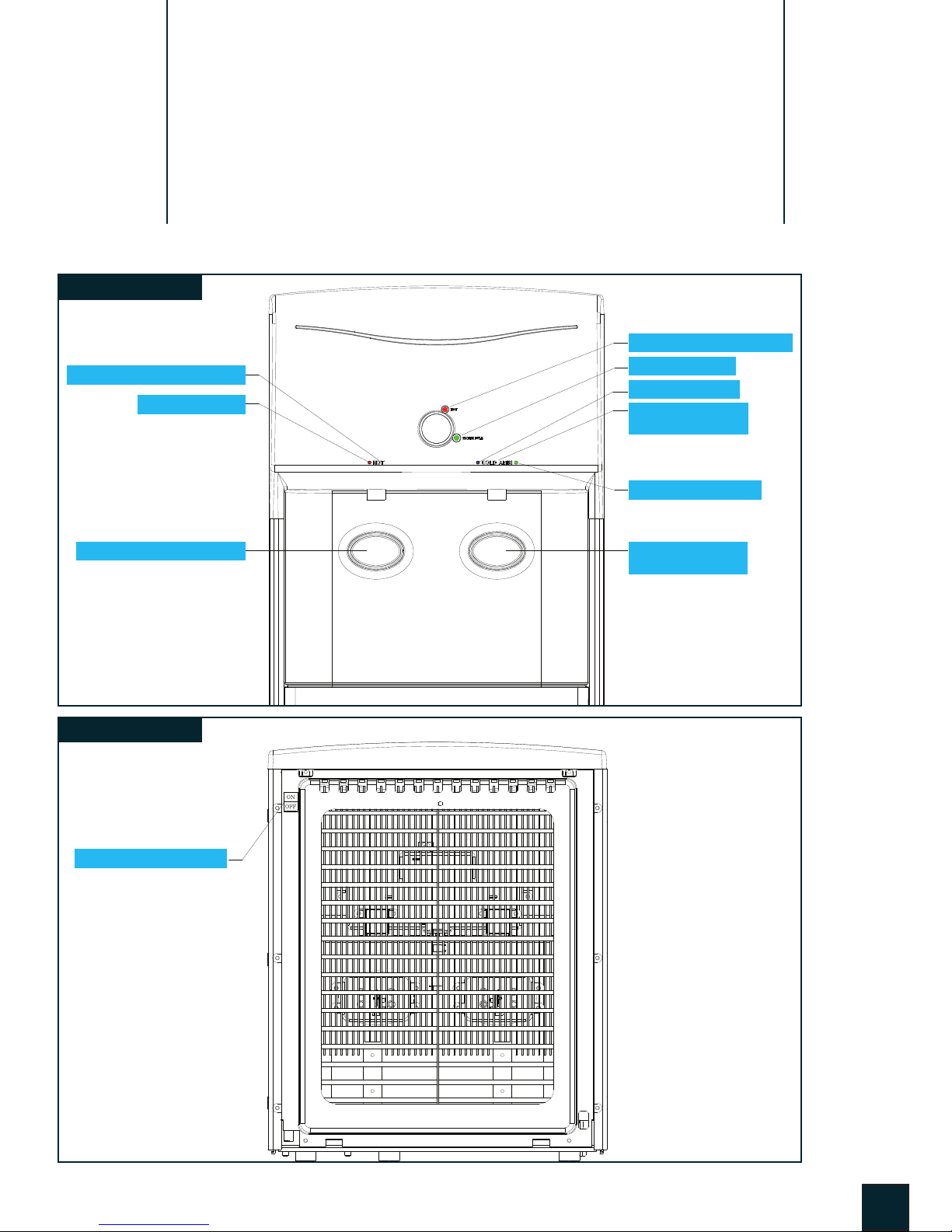

Touch sensor application

Breaking away from traditional button applications, the Iguassu CT II has a built- in touch sensor ap-

plication. This addition has been integrated into the already stellar system with customer convenience

in mind. The easy-to-use sensor application allows for eortless and enjoyable drinking water.

Infrared water level detection

With improved detection accuracy, as compared to existing mechanical detection types, the infrared

OLC sensor applies an electronic water level sensor that was developed for stable water level detec-

tion. The signal is connected to a controller in order to automatically adjust puried water levels.(Pat-

ent: No.426182)

Standard hot water safety function

(Hot water locking function + Hot water automatic selection / Release function)

Setting the hot water locking function using the Hot Lock touch sensor button prevents hot water

from being dispensed from the unit. This is in order to prevent burns and other unwanted injuries to

children, the elderly and any other vulnerable user. As a furthered safety procedure, you will nd that

upon the use of hot water and the releasing of the hot water lock, the system, after a certain period

of time, will automatically shut o the hot water even though the hot water release button has been

pressed.

System Display functions and safety reinforcement

The safety features of the product have been enhanced in order to prevent various problems from

occurring. The system will inform the user(s) of abnormal occurrences through a ashing display icon

and by automatically stopping the ice making function, cold water function, and water purication

function when an abnormality in the system is detected.