Chyo MJ-6000 User manual

MJ-300

MJ-500

MJ-3000

MJ-6000

Oh\:jo.

YMC CO., LTD.

INTRODUCTION

Thank you for selecting a Chyo balance for your measurement needs. We have exercised the same

care in the construction and testing of your new balance as we do for the ultra high accuracy mass

measurement devices we supply to the Bureau International Des Poids &Measures, National Measument

Laboratory of Australia, United States National Bureau of Standard and Japan National Research

Laboratory of Metrology. Properly cared for this balance will give years of trouble free services.

Please read this instruction manual thoroughly. It contains care and operating instructions as well as

info~mation about function and use of several unique features of your new balance.

TABLE OF CONTENTS:

STRUCTURE OF THE BALANCE 2

PACKING L/ST 2

PANEL KEYBOARD 2

INST ALLA TlON 3

ABBREVIATED INSTRUCTlONS 3

PRECAUTIONS 4

DISPLAY MESSAGE 5

DESCRIPTlON OF FLNCTlON MENU -7

DESCRIPTlON OF FLNCTlONS 8

SAMPL/NG INTERVAL FUNCTlON (SAP) 9

STABIL/TY INDICATOR FUNCTlON (STb) 9

CA L/BR A TlON 11

LNIT SELECTlON 12

PIECE COUNTING······················································································ ·/4

PERCENT MODE ·16

APPL/CA TlONS ·/7

DATA OUTPUT INTERFACE RS-232C ··········/8

OUTPUT DA TAMODE················································································· 20

EXTERNAL CONTROL COMMANDS ·21

INSTALLATlON OF THE AIR SHIELD CASE ···················································22

TROUB LESHOOTlNG ·23

SPEClFICA TlONS ·24

STRUCTURE OF THE BALANCE

1. Weighing pan

2. Pan holder

3. Dust ring

4. Display

5. Keyboard

6. Feet

7. Spirit level

8. AC adapter

PACKING L1ST

1. Balance body

2. Pan holder

3. Weighing pan

4. AC adapter

5. Spare fuse IO.5A ¡

6. Dust cover

7. Instruction manual

8. Screwdriver

9. Warranty card

PANEL KEYBOARD

MJ-3000

*

CD

Max 3 1OO8 d=0.01 8

CD Stability control 1This indicator will be

disappeared when the balance is stable ¡

@ON/ST AND-BY Key

CID Tare key

@Unit selection key

CID Function key

®Print Key

-2-

INSTALLATION:

1.Check the shipping box fer the proper acces-

sories. See the packing list for correct items.

2. Select the proper location for the balance

according to the PRECAUTIONS Section of this

manual.

3. Remove the shipping cover utilizing a "Phillips"

type screw driver.

4.lnsert the weighing pan holder.

5.Carefully place the weighing pan into the holder.

6. Set the level of the balance by adiusting the

serew feet and aligning the bubble in the spirit

level into the center circule.

7. A ttach the AC adapter cord to the balance and

plug into power source. (Make certain the

power source is grounded l

8. The stand-by indicator on the display will

appear. Allow the balance to warm up for 30

minutes before calibrating.

ABBREVIATED INSTRUCTIONS:

1.Place the balance on a level surface free from vibration and drafts. Check the spirit level and adiust

the leveling feet if necessary.

2.Attach AC Adapter cord and then allow counting display "9999999 to CXXJOOOO". Press the Ü'J/STBY

key and wait 30 minutes to allow the balance to warm up.

3. Calibration .

.. ·Make certain 011air shield doors (if air shield case attached) are c10sed and the weighing pan

is empty .

.. ·Select the CAL program in furiction menu, and follow the pre-programmed steps .

... The display reads "PASS" when the calibration is complete.

4. Simple weighing

.. ·Press the TARE key .

.. ·Place a sample in center of the weighing pan .

.. ·C1ose air shield doors. (if air shield case attached)

... Allow reading to stabilize.

-3-

5. Taring

..·Place an empty container on center of the weighing pan.

..·C1ase aír shield doors (if air shield case attached)

..'Press the TARE key and allow zero to appeor on the display.

..·Place sample in the container and record a sample weight after " *"has disappeared.

PRECAUTIONS

1.Do not disconnect the AC adapter cord when in use.

2. Always place a sample in the center of the weighing pan when making measurement. Slight errors

may result if the sample is not near the center of the weighing pan.

3. Place the balance in a controlled environment.

a. Protect the balance from drafts (air currents).

b. Maintain the ambient temperature to ±3 degree C.

c. Maintain the ambient humidity to ± 10%.

d.If greater changes occur in temperature or humidity, recalibrate the balance.

e. The balance table should be level and free from excessíve vibration (Iess than O.3m sec2).

f. Do not expose to direct sunlightor radiated heat (keep away from windows, heaters, hot plates,

flames, etc. l. Allow hot or cold sample or containers to come to ambient temperature before

weighing.

h. Discharge any statically charged sample before weighing.

i. Do not expose the balance to corrosive gases.

4. Magnetized samples cannot be weighed accurately on an electronic balance.

5. Calibration and test weights should have a greater accuracy than the linearity specification of the

balance. For instance, the specification for M}-3000 is lOmg. The weights used to test or calibrate

should be accurate to a minimumof ± 3mg.

6. Make certain the power supply source is free from electrical disturbance.

7. Clean the balance with damp c10th only (no solventsl .

8. Always warm-up the balance before use.

9. Always handle the balance with care during use when moving or storing.

-4-

DISPLAY MESSAGE:

s

IAC-OFF

1+

COUNT - DOWN DISPLAY:

The balance will count down "9999999 to ?0ooooo" when

plugged into a power source before it is ready for

weighing.

STANDBY:

"S" sign indicates power is supplied to the balance.

POWER WARNING:

The power supply should not be off during STANDBY .

If power supply is off duringSTANDBY, then this message

will be appeared when replugged into the power source.

CAPAClTY ERROR:

"+" sample exceeds balance capacity.

"-" weighing pan or holder is out of place.

o

ISAP-2

ISTb-2

H

ZERO INDICA TOR:

".•••" sign indiates display is stable at 011zero reading.

SAMPLlNG INTERVAL:

Displays selected sampling interval (Integration Time).

See SAMPLlNG INTERVAL FUNCTION section, page 9.

5TABILlTY INDICA TOR COUNT:

Indicates selected stabilization requirements.

See STABILlTY INDICA TOR FUNCTION section,

page 9.

HOLD- DISPLAyMODE:

"H" sign indicates reading result is frozen.

See STABILlTY INDICA TOR FUNCTION section,

page 9.

-5-

ICAL

IPASS

ICAL Err

IUni-l

IoUt-l

IrS-8n 1

IrSS-1.2

IAST ON

CALIBRATION MODE:

Make certain the weighing pan is empty. The Calibration

sequence is started by pressing the TARE key. Donot

disturb the balance until calibration is complete.

See CALIBRATION section. page 11.

PASS:

Calibration rrode: Indicatescalibration sequenceis complete.

CALIBRATION ERROR:

Balance was unable to complete calibration sequence.

Check the CALIBRATION section. page 11.

UNIT SELECTION:

See UNIT SELECTION section. page 12.

OUTPUT DATA MODE:

See OUTPUT DATA MODE section. page 20.

RS-232C MODE:

See DATA OUTPUT INTERFACERS-232C section,

page 18.

BAUD RATE SPEED;

See DATA OUTPUT INTERFACERS-232C section.

page 18.

AUTo-ST ART MODE:

If auto-start mode is on, then balance will be weighing

position immediately without pressing the ON/STBY key.

-6-

DESCRIPTION OF FUNCTION MENU:

U.

Press the F key.

lo o

oo

91 ••Press the TARE key .

--+

Press the Ukey.

I

The display returns to the weighing mode if

no operation is made for 3 sec.

U. See the appropriate section for further

explanation of individual function .

SAP ..2l..~ ..A

••

ISTb :g-J} ~:~- ~-~

CAL

..~..

FULLPOINT VALUE

U.

<=:J

Uni :

~:~

u.

OUT I

:g-JJ-¡J-~-=p

u.

rS :

8@:JiJ

u.

rSS I

1¿J-~-~

u.

IO~:~

AST

-7-

DESCRIPTION OF FUNCTIONS:

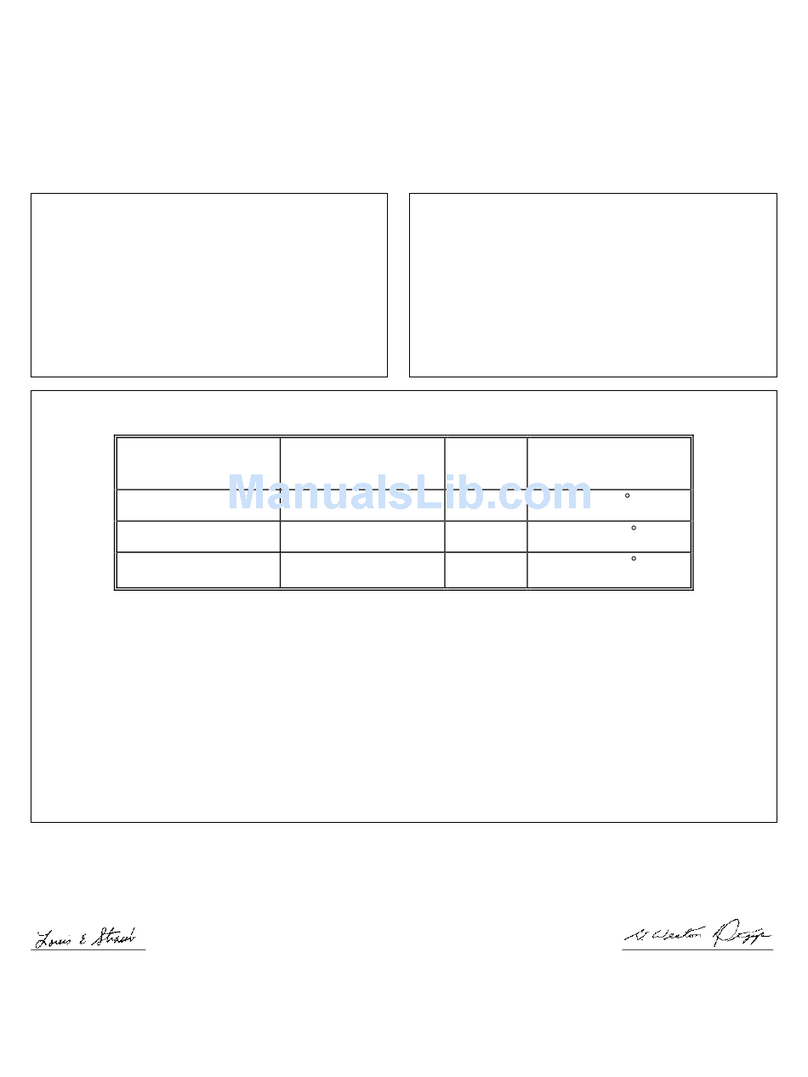

ITEMS SELECTABLE SETTING

FACTay SETTINGREMARKS

DISPLAY COMMAND

1

Very steady

RANGE OF 2

Normal

SAP VIBRATION 2Note 1

ADAPTER

3

Unstable

A

Extremely unstable

1

Limited

2

Standard

RANGE OF

3

Extensive

STb STABILlTY 2

Note1

Hl HOLD - limited

H2

HOLD - Standard

H3

HOLD - Extensive

CAL

CALlBRATIONSee the calibration section.

{page

111 Note 2

Uni

UNIT Locking the key.

2

Note 3

SELECTION Release the lock.

Output upon print command

1made only after the bolonce

has stabilized.

After print command made,

2output as soon as balance

DATA

has stabilized.

OUT TRANSMISSION 5Note 4

MODE 3

Output upon print command

regardless of stability.

4

Automatic output as soon as

balance has stabilized.

5

Automatic output regardless

of stability.

RS-232C

8nl

8 bit Non-parity

rS INTERFACE 8nlNote 5

MODE 7El

7 bit Non-parity

RS-232C

1.2

1200BPS

rSS

INTERFACE2.4

2400BPS 1.2

Note 5

SPEED MODE 4.8

4800BPS

AUTQ-START

ON

Auto-start is on.

AST MODE OFF

Note 6

OFF Auto-start is off.

RemarksI : Note 1 - This function is used to select the best operative condition in order to be free from excessive

vibration or draft.

Note 2 - Do not press the TARE key when calibrating.

Note 3 - Uni-l locks in one unit and does not allow switching between units when pressing the U key.

Note 4 - See the section for OUTPUT DATA MODE (page 20 I .

Note 5 - See the section for DATA OUTPUT INTERFACE RS-232C (page 181.

Note 6 - See the section for DISPLAY MESSAGE Ipage 5 I .

-8-

SAMPLlNG INTERVAL FUNCTION (SAP):

"VIBRATION ADAPTER"

"INTEGRA TION TIME"

The "SAP" function allows the balance to adapt to the surrounding environment conditions. (Please

.read the PRECAUTIONS section of this manual for optimum conditions 1.

The SAP should be adjusted to SAP-l for very stable conditions and to SAP-A for very unstable

conditions.

PROCEDURE fOR ADJUSTMENT Of SAP:

SAP-l

SAP-l

u.

SAP-2 u.

SAP-3 u.

SAP-A

.. ·Press the F key until "SAP" appears on the display.

.. ·Press the TARE key until the desired value is displayed.

STABILlTY INDICATOR FUNCTION(STb):

This feature adjusts the stability indicator (" *"will disappear from the display) fer different sample

types and weighing conditions. The weight reading should only be made when the stability indicator

is not displayed.

This allows similar weight determinations to be made from sample to sample and user to user. STb-l

reguires very stable conditions befere " *"will disappear. STb-3 may be required when unstable

conditions exist. MJ al so pro vides "HOLD-DISPLAY MODE" as SAP-Hl, -H2, -H3 fer conditions

of extreme vibration.

PROCEDURE fOR ADJUSTMENT Of SAP':

ISTb-l .. ·Press the F key until "SAP" appears on the display.

-9-

STb-l u

STb-2 u

STb-3 u

STb-Hl u

STb-H2 u

STb-H3

HOlD - DISPlAyMODE:

ISAP-H3

.. ·Press the TARE key until desired value is displayed.

···Seleet a desired value from "SAP-+ll through SAP-+l3".

.. ·Place a sample on the weighing pan .

Ho o

o

.. ·Reading result will be frozen when "H" sign is appears

on the display .

.. ·Remove the sample, and press the TARE key.

If the sample is large, the display will automatically

return to zero after the sample is removed without

pressing the TARE key. For smaller sample, press the

TARE key to reset the display to zero.

-10-

CALIBRATION:

Your balance should be calibrated on a regular basis for the best performance. The most accurate

calibration is made only after the balance has been connected to a power source for 30 minutes.

Under continuous use, calibrate the balance at least every 30 days, any time it is moved or bumped,

and whenever the ambient temperature changes by more than 3 degree Celcius.

MODEL CALIBRATION WEIGHT

MJ-300 3009 or 2009

MJ-500 5009 or 3009

MJ-3000 30009 or 20009

MJ-6000 60009 or 50009

CALIBRA TlON PROCEDURE:

···Check the spirit level of the balance and adjust if

necessary .

.. ·Make certain the weighing pan is empty .

ICAL

ICAL o

.. ·Press the F key until "CAL" appears on the display.

.. ·Press the TARE key to start calibration .

.. ·Press the TARE key.

... The balance automatically sets ZERO.

(In case of MJ-3000 1

CAL

OR

CAL

IPASS

3 O O O

2 O O O

... The balance will then request the appropriate size

calibration weight.

Carefully place the calibration weight on the weighing

pan.

.. ·Press the U key.

.. ·Press the TARE key.

... "PASS" appears on the display when calibration is

complete.

-ll-

ICAL Err

CALIBRA TION GUIDELlNE:

CHECKING THE CALIBRA TION :

UNIT SELECTION:

---If "CAL Err" appears, then check to make certain the

procedure was followed correctly Iincluding proper size

calibration weight) and follow the guidelines below to

find any possible errors_

---Check to see if the weighing pan is c1ear and properly

installed _

_.-Check the PRECAUTION section of the manual and

follow all guidelines_

-. -Check the SAP (Sampling Interval Function) and adjust

the setting to a large count if necessary_

See the SAP section of this manual.

_.-Check the STb (Stability Indicator Count) and adjust

to a higher setting if necessary_

See the STb section of this manual_

_.-Make certain the weighing pan is empty and press the

TARE key_

The balance display should read zero_

-_·Carefully place an accurate test weight in the center

of the weighing pan_

---The correct weight of the test weight should be

displayed.

If not, recalibrate the balance_

MJ provides different weighing units and one basic unit (grams) for any user' s demands.

Open the memory bank and modify your desired units by following the procedure below_

Important - Only two different units besides grams are availabele for selection.

oFF I

---Make certain that AST (Automatic start) is off.

---Disconnect the AC adapter cord from the balance_

.. -Reconnect the AC adapter cord into the balance.

9999999

COUNT DOWN --·Press and hold the TARE, U and F keys at the same

time when "1 111111" appears_

-12-

11I ~ lb ti momgr dwt ozt oz etCM

<4m¡8888888 ~~ ···Release the TARE, U and F keys when the "AII

Segment" message appears .

FE.. ·Parameter number will be appear after "AII Segment"

has stopped f1ashing.

.. ·Seleet desired parameter numbers by pressing the U &

TARE keys.

(See the below PARAMETER NUMBER CHART. )

F E

~~_tl'_

UNIT 2

Continuously press the U

key until the desired nurrrer

appears.

UNIT 1

Continuously press the TARE

key until the desired number

appears.

..·Press the F key to eonelude the UNIT SELECTION

proeedure.

PARAMATER NUMBER CHART

ogram 9

9

Carat C.M

1

CancelLast

Digit 9

A

Momme mom

2

kilogram kg

BTaiwan Tael ti

3

Pound lb

C

Singapore Tael ti

4

Ounee oz

D

Hongkong Tael ti

5

Toroyounee ozt

E

*Pereent %

6

Grain gr

F

*Pieee eounting pes

7

Pennyweight dwt

8

Carat et

*Faetory setting:

-13-

"g"

11'

I

DISPLAY CIRCULAR

(=> Press the U key)

=> UNIT 1 => UNIT 2 => "g"

U

I

PIECECOUNTING:

+

1+

5

u

20

u

100

u

1000

20

opcs

PCS

PCS

PCS

PCS

pcs

.. 'Continuously press the U key until "PCS" appears.

.. ·Press the F key until the desired number of pieces to

be used as a standard is displayed.

.. ·Place the same number of sample pieces as you seleeted

above on the weighing pan.

To get the mast precise counting, you should select the

largest number of pieces possible for your standard.

.. ·Press the TARE key to memarize the number of sample

pieces and their unit weight. The display will flash until

the balance has memorized this data .

.. ·Proceed with piece counting .

.. ·If the display shows a "Lo" message when pressing the

TARE key, the unit weight of the sample pieces is less

than the balance can detect.

MINIMUM WEIGHT OF EACH SAMPLE PIECE REQUIRED TO ESTABLlSH PIECE COUNTING:

MJ-300 -+

O.Olg

MJ-500

-+

O.Olg

MJ-3000

-+

0.1g

MJ-6000

-+

19

-14-

REVOlVING ESTABLISHMENT OF THE STANDARD UNIT WEIGHT FOR PIECE COUNTING:

This unique funetion of the MJ series is used to easily increase the number of pieces of sample used

as your piece counting standard without taking the time to count out each standard sample piece

separately. This is important because the greater the nurrberof samplepieces used to set your standard,

the more accurate and precise your piece counting will be.

+

5

20

20

res I

pes

res I

..·Establishthe standard numberof sample pieces and unit

weight at 5 pes, for example, by following the

procedure on the previous page .

..·Place 15 more sample pieces on the weighing pan. The

display will show that there are 20 pieces on the pan.

..-Leave the 20 pieces on the pan and press the F key

until 20 pes appears on the screen.

..·Press the TARE key to memorize the new number of

sample pieces and the new unit weight .

..·Follow the same procedure to increase the standard

to 100 or 1000 pieces.

NOTE: The key is to let the balance do the counting for you when establishing the standard. For

example, count out 20 pieces yourself and set the standard at 20 pieces.

Use the piece counting mode to count up to 100 pieces and set the new standard at 100 pieces.

Then use the piece counting mode again to count up to 1000 pieces and set the new standard again

at 1000 pieces.

-15-

PERCENT MODE:

TARGET WEIGHT:

+o . o o %..'Continuously press the U key until "%" appears.

..·Place a sample of the ideal, 100% weight on the

weighing pan.

1 O O PCT

100.00%

..·Press the F key to memorize the 100%weight.

Make certain that "~" sign appears when entering a

sar11Jle.Press the TARE key if the "~" sign does not

appear .

..·Percent mode procedure is complete when "100.00%"

appears. Proceed with percent weighing by placing a

new sample on the pan.

Percentage display is 100.00% for MJ-300, MJ-SOO,

MJ-3000 and 100.0% for MJ-6000.

MINIMUM WEIGHT OF THE 100%SAMPLE REQUIRED TO ESTABLlSH PERCENTWEIGHING:

MJ-300

MJ-SOO

MJ-3000

MJ-6000

WEIGHING MIXTURE MODE:

~ 19

~ 19

~ lOg

~ lOg

This mode is used when you want to mix two

samples together. For instance when you add

sample B to sample A to make a 100%mixture

sample.

SompleB 40%

SompleA 60%

o O PCT ..·First, memorize sample A to be the 100%weight by

using the percent mode procedure above .

6O PCT

i i

c620

..·Reset sample A at 60% weight by pressing the U &P

keys.

... Add sample B to sample A until the 100%weight is

reached.

-16-

APPLlCATIONS:

SIMPLE WEIGHING:

TARING:

ANIMAL WEIGHING:

SUBTRACTIVE WEIGHING:

BELOW BALANCE WEIGHING:

Press the TARE key. Allow reading to stabilize and " *" to

disappear before reading value.

Place an empty container on the weighing pan.

Press the TARE key and allow zero and "*" to disappear from

the display. Place a sample in the container and record a sanple

weight when "*" disappears.

Set SAP and STb funcitons to high values (SAP-A plus STb+ll,

STb-H2 or STb-H3l described in appropriate sections before

weighing.

Place a sample container on the weighing pan. Press the TARE

key and allow zero and "*" to disappear from the display.

Remove a portion of the sample from the container. The weight

of the removed portion is displayed as a negative value.

For weight measurements below the balance, there is an optional

hanger (OMJ-l l .

=

.. ·Make certain the attachment wire is strong enough to

support the sample weight .

..·Check an alignment of a hanger to insure it hangs freely

at 011times.

.. ·Protect the hanger from drafts for best results.

This includs the lower portion of the balance between

the bottom of the balance and the table .

... When making normal measurements, the hanger should

be disconnected and the hole in the bottom of the

balance should be plugged.

-17-

DA TA OUTPUT INTERFACE RS- 232C :

... The interface is designed as a standared accessory on

the MJ series .

.. ·Please read this section and instruction manuals of

related equipment before using this device .

.. ·Disconnect the AC adapter cord when changing the

boud rate.

INTERFACE:

......... RS-232C

11 Type

2) Method

3) Speed

4) System

........ ·Half duplix transmission.

....... "Speed 1200, 2400, 4800 bps.

......... Asynchronous system Start bit: 1 bit

Stop bit: 1 bit

Character length 7 or 8 bits.

5) Error detection Non-parity, even parity.

6) Signal

(Inside the balance)

SG (Signal Ground)

[> 2SD(Send Data)

0<] 3RD(Receive Data)

[> 4RST(Request to Send)

5

v+ 6(Print Switch)

7

8DTR(Data Terminal Ready)

-18-

This manual suits for next models

3