EN - 4

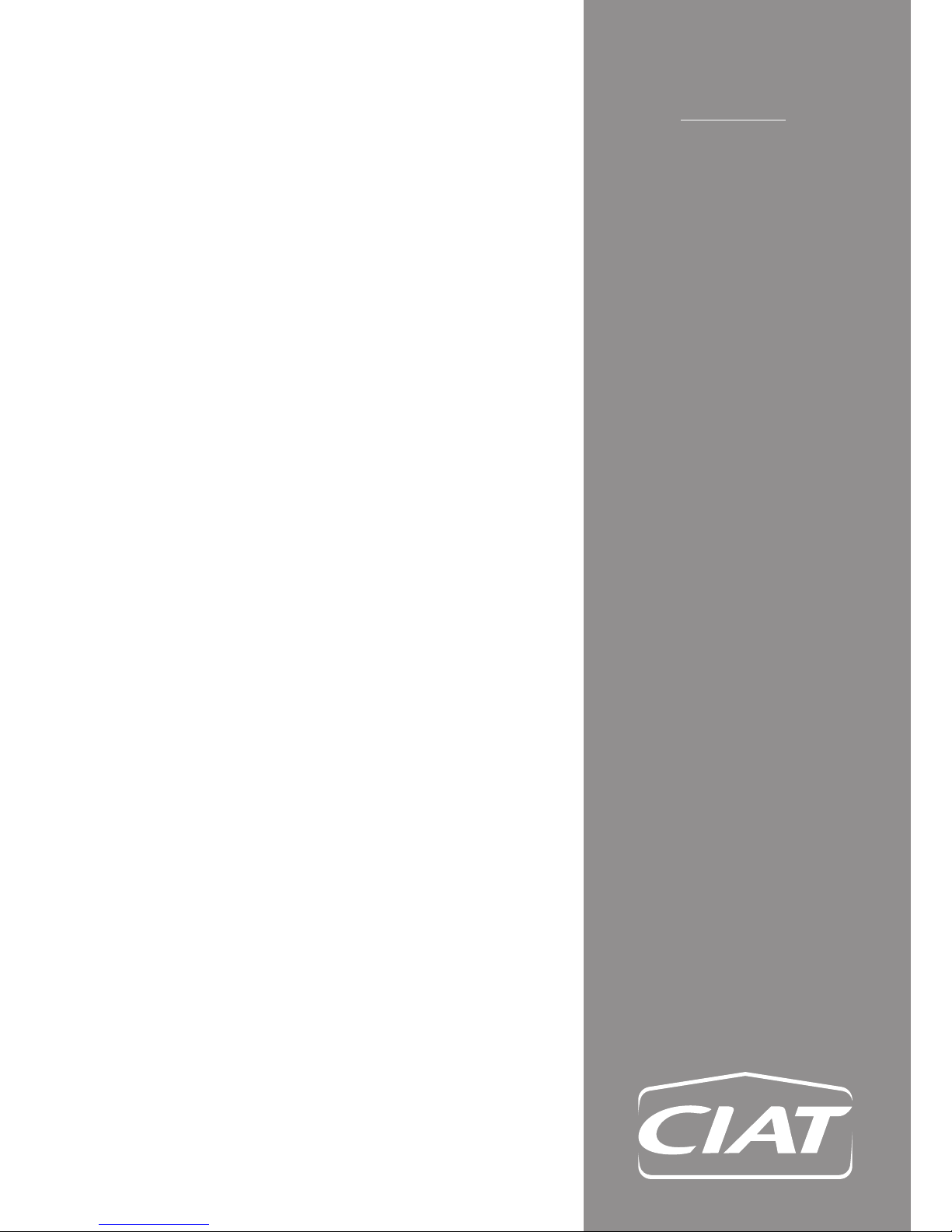

1.2.4 Identifying the equipment

A legible and indelible data plate listing the specifications of the

unit is affixed in a visible location on the unit.

This information (particularly the description and the serial

number) must be quoted in all correspondence.

The HP MAX value: PSM indicated on the name plate is the

maximum operating pressure (= 42 bar)

This value corresponds to the activation pressure for the safety

device: the HP pressure switch. A burst test on a representative

model is carried out periodically in accordance with standard

EN 378-2. The burst pressure must be at least 3 times the

operating pressure, i.e. 3 x 42 bar = 126 bar.

1.2.5 Handling

Units on pallets must be transported using a pallet truck.

Warning: the machine must be moved using a suitable means

of transport. The heat pump must not be dragged along the

ground directly on its rubber feet, as this may damage the

adjustment system.

Wear suitable gloves when handling the unit.

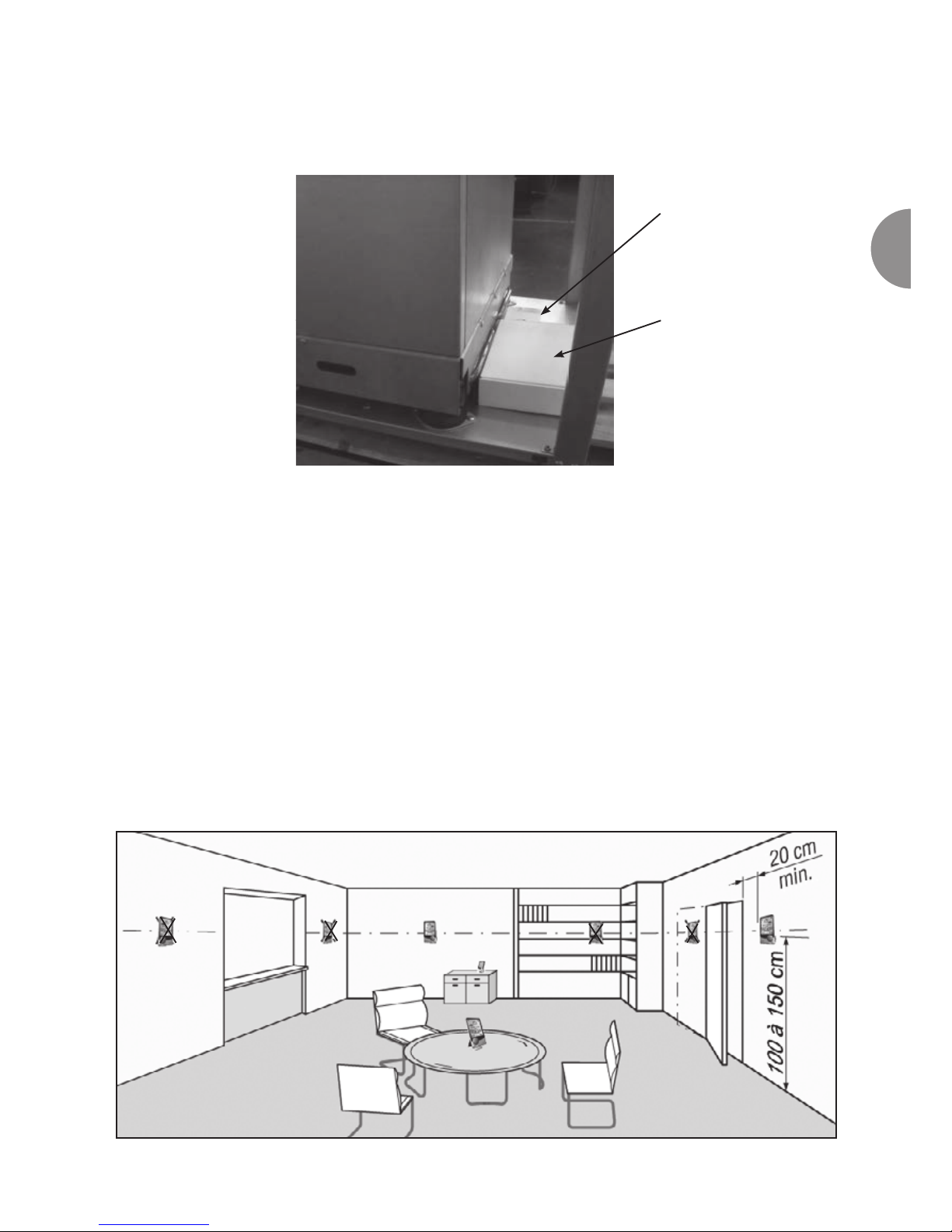

1.2.6 Installation

CIAT units must only be installed by experienced, qualified

personnel with the necessary electrical and hydraulic

accreditation. The installing company must provide the

equipment manager with a declaration of conformity in

accordance with current standards and the indications supplied

by CIAT in this manual. The recommendations and instructions

given in the maintenance brochures and the special instructions

on the labels must be followed.

Always comply with applicable standards and regulations.

CIAT accepts no contractual or non-contractual liability for

damage caused to persons, animals or property due to

installation, maintenance or servicing errors or misuse.

This instruction manual and the user manual form an integral

part of the unit, and must therefore be kept safe and ALWAYS

handed over if the unit is transferred to a new owner or another

system. If a manual is damaged or lost, you can order a new

1.3 Basic safety rules

To prevent the risk of accidents during installation,

system start-up and adjustment, it is essential to

remember that a heat pump contains a pressurised

refrigeration circuit and refrigerant, as well as electrical

voltage and fluid at a temperature up to 150°C (risk of burns

from touching the pipes)

Note that certain basic safety rules apply to the use of this type

of unit:

• Before carrying out any work on the equipment, ensure

that the supply voltage is switched off (and the capacitors

discharged). Any electrical discharge carries a risk of injury.

• The unit must not be used by unsupervised people with

disabilities or children.

• It is forbidden to touch the unit in bare feet or if any part of the

body is wet or damp.

• It is forbidden to modify the safety or adjustment devices

without authorisation and instructions from the device

manufacturer.

• For work on the machine during or shortly after operation,

wear gloves suitable for high temperatures and electrically

insulated tools.

1.4 Waste disposal by users in private waste

facilities within the European Union

This symbol indicates that the product and its packaging

must not be disposed of in ordinary household

waste or in the natural environment. It is your

responsibility to ensure your waste is taken

to a designated recycling point for electrical

and electronic devices. Separating your waste

for recycling during disposal helps protect the

environment and safeguard health.

To find your nearest recycling centre, contact your local council

or waste disposal service.

The units are not stackable.