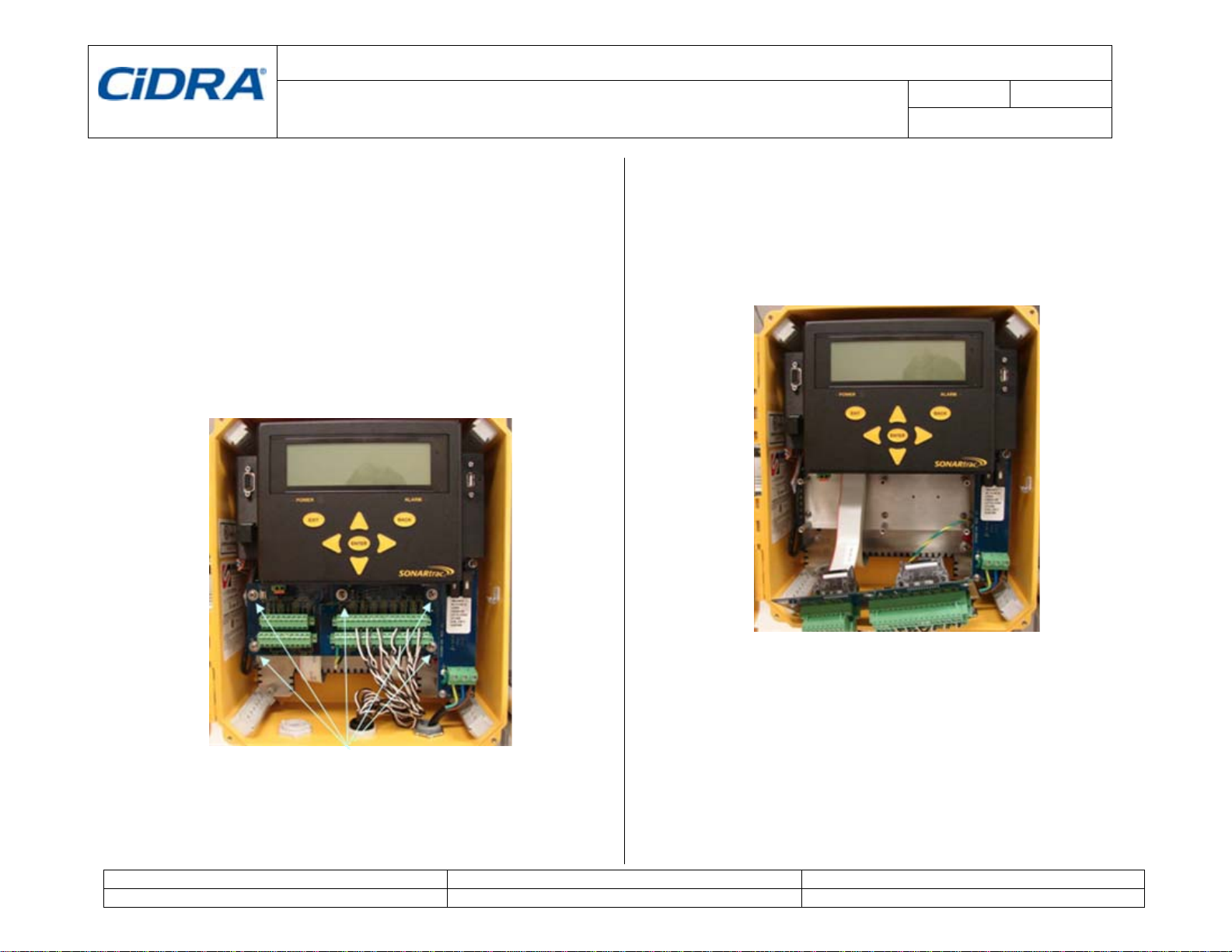

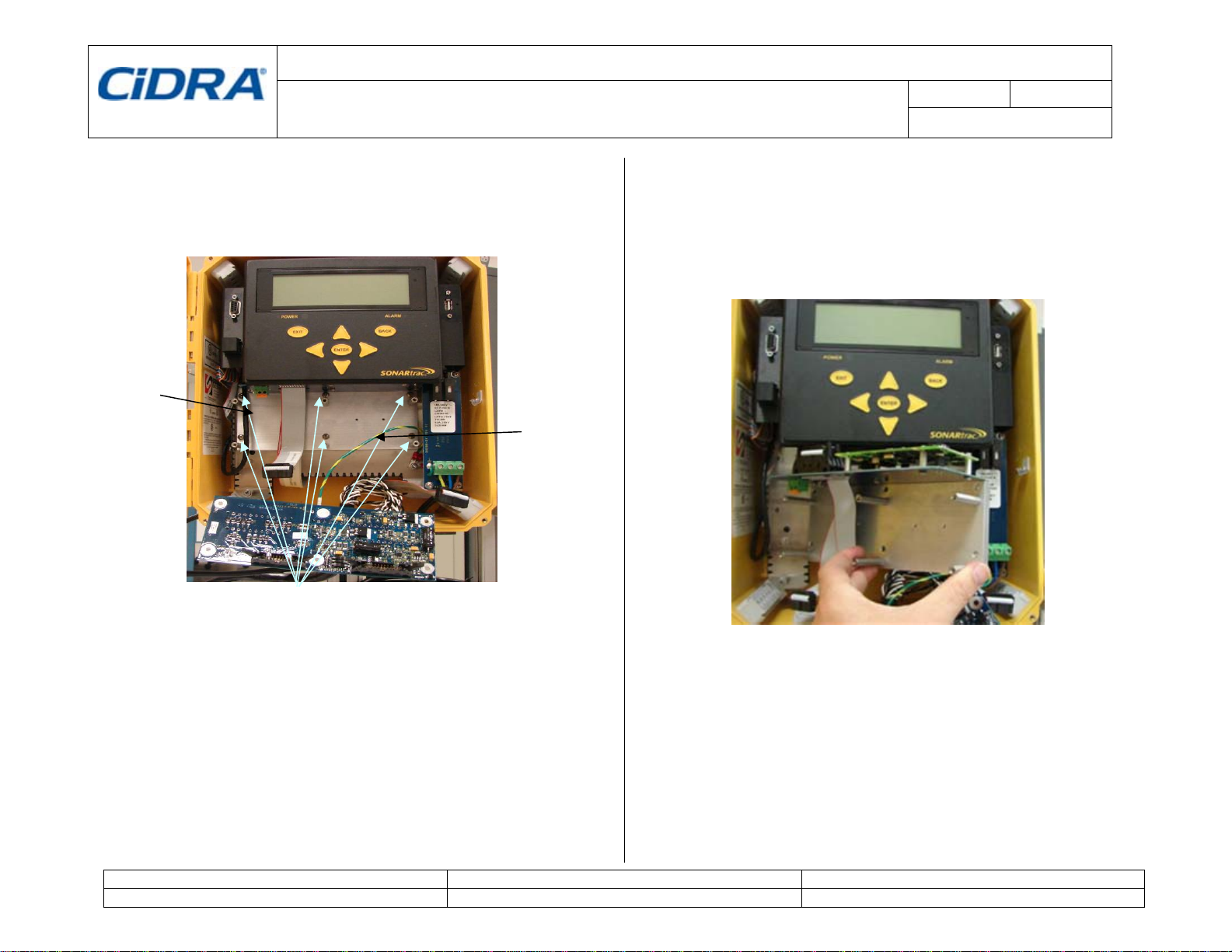

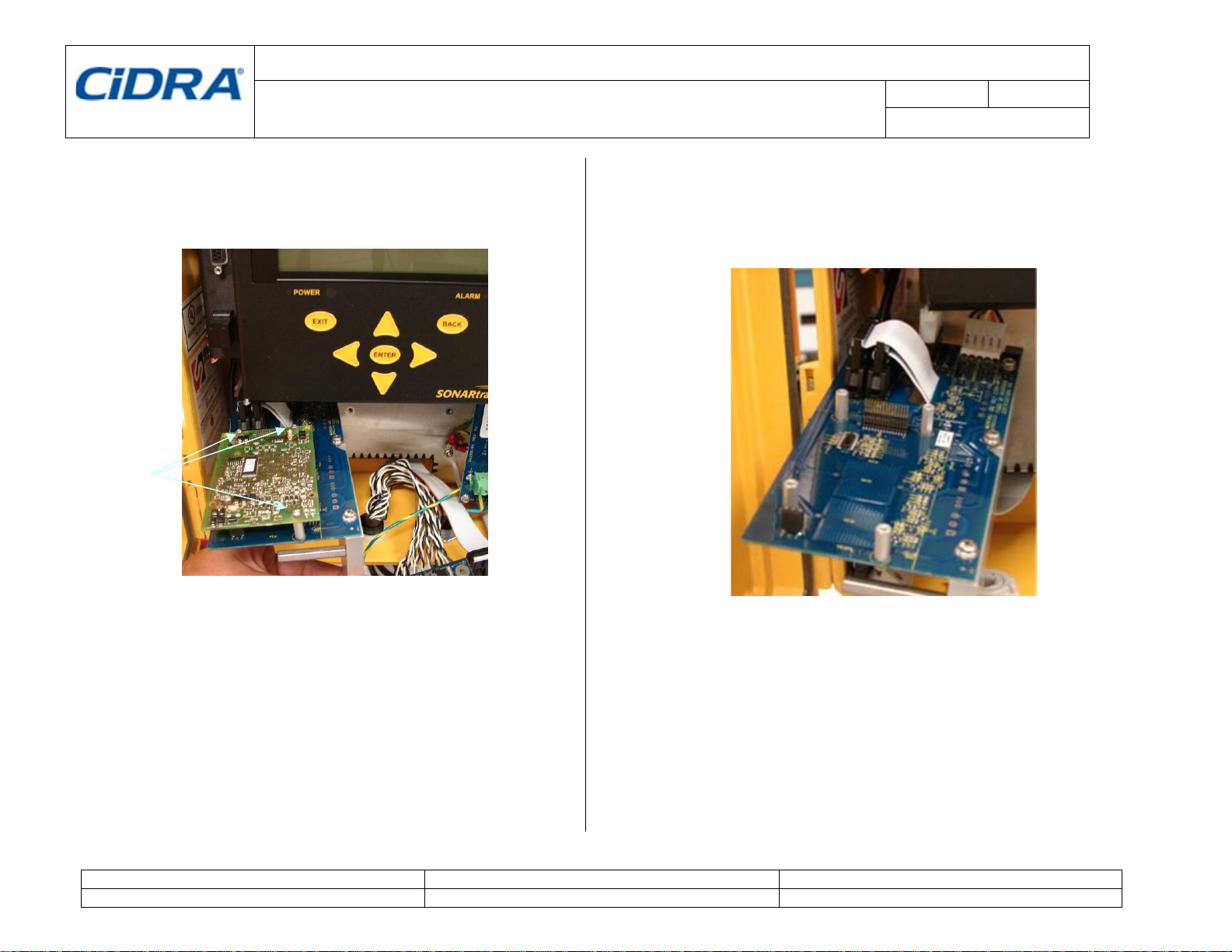

CiDRA SONARtrac 20924 User manual

Other CiDRA Measuring Instrument manuals

CiDRA

CiDRA SMARThatch Quick start guide

CiDRA

CiDRA CYCLONEtrac PST User manual

CiDRA

CiDRA Sonartrac GVF-100 Installation and operation manual

CiDRA

CiDRA SMARThatch Operating and maintenance manual

CiDRA

CiDRA CYCLONEtrac PST User manual

CiDRA

CiDRA AIRtrac Installation instructions

CiDRA

CiDRA SMART HATCH User manual

Popular Measuring Instrument manuals by other brands

Schaller Messtechnik

Schaller Messtechnik humimeter GE1 user manual

Hydreon

Hydreon RG-11 Application notes

Kobold

Kobold Heinrichs TMU-W Series Installation and operation manual

Spectral Evolution

Spectral Evolution PSR-1100f Operator's manual

YOKOGAWA

YOKOGAWA LoRaWAN Sushi Sensor technical information

Transcom

Transcom VT5502 manual

Agilent Technologies

Agilent Technologies E444xAU Option H37 installation guide

Omni Instruments

Omni Instruments Fastrack Supreme user guide

Bosch

Bosch BEA 150 Repair instructions

SATO KEIRYOKI

SATO KEIRYOKI 7790-00 instruction manual

Sierra

Sierra 780S Series Flat-Trak Quick install guide

Sealey

Sealey VSE5863 instructions

GTE

GTE COBOSAFE CBSF operating manual

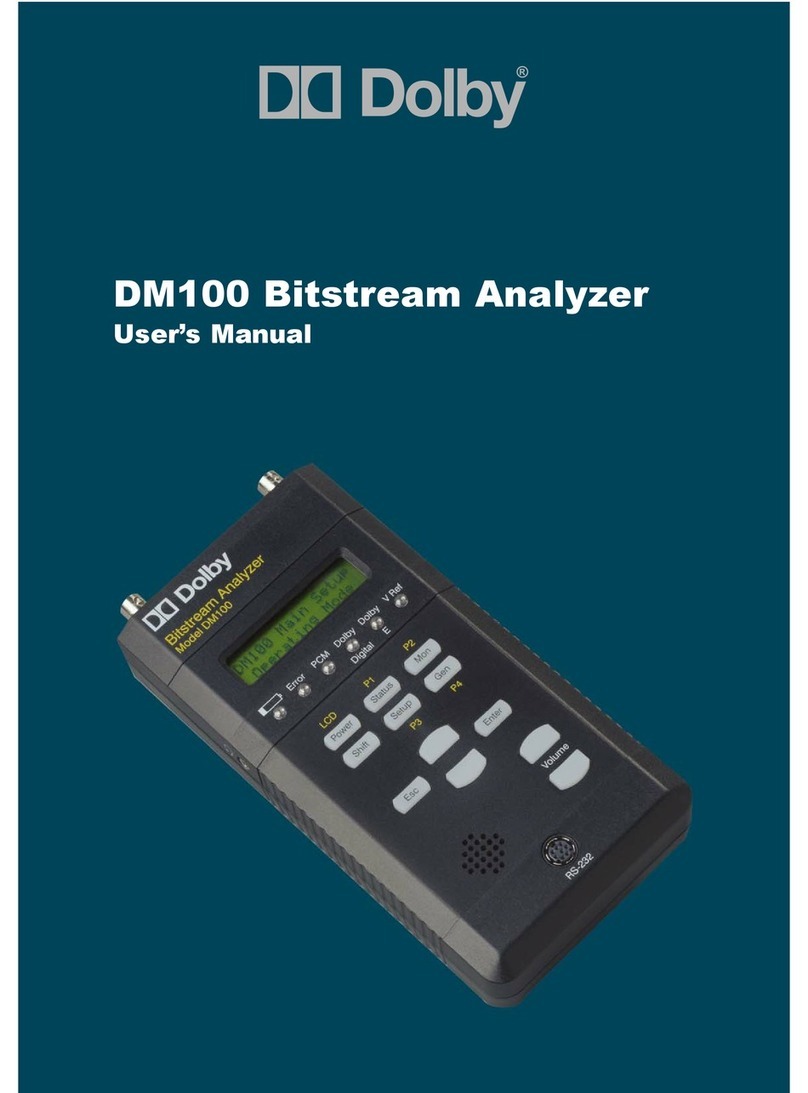

Dolby Laboratories

Dolby Laboratories DM100 user manual

Dräger

Dräger Interlock 5000 installation instructions

BELITE ELECTRONICS

BELITE ELECTRONICS RADIANT RFGA-022C Specifications - installation and operation instructions

Meco

Meco Power Guard PG07 instruction manual

Brandson

Brandson 306118 user manual