CiDRA CYCLONEtrac PST User manual

1

Introduction

2

Equipment Safety Compliance

3

General Safety Guidelines

4

Preparation for Installation

5

Sensor Head Assembly Mounting

6

Electrical Connections to AC

Junction Box

7

Electrical Connections to Power

Entry Box

8

Sensor Head Assembly to Junction

Box Connection

9

Safety Issues of Improper

CYCLONEtrac PST Installation

10

System Operation

11

Maintenance & WEEE

12

13

14

Appendix A CYCLONEtrac PST

Specifications

Installation Manual

P/N 21464-01-EN Rev. 06

Table of Contents

P/N 21464-01-EN Rev. 06

21464-01-EN Rev 05

Page iii

Table of Contents

INTRODUCTION...................................................................................................1-1

Introduction ...........................................................................................................1-1

Junction Box, Power Entry Box and Sensor Head Assembly Description.............1-1

Intellectual Property Notices .................................................................................1-1

Warranty ...............................................................................................................1-2

CiDRA Contact Information...................................................................................1-2

CYCLONEtrac PST EU Declaration of Conformity................................................1-2

EQUIPMENT SAFETY COMPLIANCE .................................................................2-1

Safety....................................................................................................................2-1

North American Emissions....................................................................................2-1

2.2.1 European Emissions and Immunity ..........................................................2-1

GENERAL SAFETY GUIDELINES .......................................................................3-1

Introduction ...........................................................................................................3-1

Safety Precautions................................................................................................3-1

Definitions of Symbols...........................................................................................3-1

3.3.1 General Warning or Caution.....................................................................3-1

3.3.2 Grounding.................................................................................................3-2

3.3.3 Electric Shock Hazard ..............................................................................3-3

General Warnings and Cautions ...........................................................................3-3

PREPARATION FOR INSTALLATION .................................................................4-1

Introduction ...........................................................................................................4-1

Installation Considerations ....................................................................................4-1

4.2.1 Preparation...............................................................................................4-1

4.2.2 Power Requirements ................................................................................4-2

4.2.3 System Environmental Conditions............................................................4-3

4.2.4 Restriction of Access to Power Entry Box and Junction Box ....................4-3

Suggested Power Entry Box and Junction Box Installation...................................4-3

SENSOR HEAD ASSEMBLY MOUNTING ...........................................................5-1

Pipe Modification Procedure .................................................................................5-1

5.1.1 Sensor Head Assembly Installation ..........................................................5-5

ELECTRICAL CONNECTIONS TO AC JUNCTION BOX .....................................6-1

Junction Box Cable Entries ...................................................................................6-1

6.1.1 AC Junction Box Cable Connections........................................................6-2

AC Power for AC Junction Box .............................................................................6-2

6.2.1 Mains Power connection to AC Junction Box ...........................................6-3

Sensor Cables 1 thru 16 max Connection.............................................................6-4

Ethernet Connection .............................................................................................6-4

ELECTRICAL CONNECTIONS TO POWER ENTRY BOX ..................................7-1

Power Entry Box Cable Entries.............................................................................7-1

7.1.1 Power Entry Box Cable Connections........................................................7-2

7.1.2 DC Junction Box Cable Connections........................................................7-2

AC Power for Power Entry Box .............................................................................7-2

7.2.1 Mains Power connection to Power Entry Box...........................................7-3

24VDC Power Output from Power Entry Box........................................................7-5

DC Junction Box Power Connections ...................................................................7-7

Sensor Cables 1 thru 16 max Connection.............................................................7-9

Ethernet Connection .............................................................................................7-9

21464-01-EN Rev 05

Page iv

SENSOR HEAD ASSEMBLY TO JUNCTION BOX CONNECTION .....................8-1

Sensor Head Assembly Connector Attachment ....................................................8-2

8.1.1 Sensor Head to Junction Box Cable.........................................................8-2

8.1.2 Ethernet Sensor Head Assembly Connection...........................................8-3

8.1.3 Sensor Head Assembly Cable End Connection .......................................8-3

SAFETY ISSUES of IMPROPER CYCLONEtrac PST INSTALLATION ...............9-1

SYSTEM OPERATION....................................................................................10-1

Junction Box Operation....................................................................................... 10-1

10.1.1 Instruction for Use ...............................................................................10-1

10.1.2 Operating Controls ..............................................................................10-1

CYCLONEtrac PST Sensors............................................................................... 10-1

System connection to computer with OPTIGrind application ..............................10-2

OPTIGrind application......................................................................................... 10-3

10.4.1 Main OPTIGrind GUI DIsplay ..............................................................10-3

Right-Click Pop-Up Window ............................................................10-4

Background Colors..........................................................................10-4

Hover Pop-Up Window.................................................................... 10-6

10.4.2 Checking Sensor Status in the logged Results Data...........................10-9

MAINTENANCE & WEEE................................................................................11-1

Instructions for Cleaning .....................................................................................11-1

Inspection and Maintenance ...............................................................................11-1

Fuse Replacement..............................................................................................11-5

Directive 2012/19/EU on Waste Electrical and Electronic Equipment (WEEE) recast

11-5

APPENDIX A................................................................................................................... 1

21464-01-EN Rev 05

Page v

List of Figures

Figure 1: General Warning or Caution Symbol.............................................................3-1

Figure 2: Grounding Symbol ........................................................................................3-2

Figure 3: Electric Shock Hazard...................................................................................3-3

Figure 4: Sensor Head Assembly Mounted to Pipe......................................................4-1

Figure 5: Junction Box Mounting..................................................................................4-4

Figure 6: Hydrocyclone Battery ....................................................................................5-1

Figure 7: Hole Placement.............................................................................................5-2

Figure 8: Mounted Sensor Head Assembly..................................................................5-3

Figure 9: Temporary Plug.............................................................................................5-3

Figure 10: Saddle Assembly ........................................................................................5-5

Figure 11: Junction Box Connections...........................................................................6-1

Figure 12: Mains Power Connection (NO POWER ENTRY BOX) ...............................6-4

Figure 13: Power Entry Box Connections.....................................................................7-1

Figure 14: Mains Power Connection ............................................................................7-4

Figure 15: 24VDC Power to Junction Box....................................................................7-5

Figure 16: DC Power Connection, Power Entry Box ....................................................7-6

Figure 17: Mains and DC Power Connections .............................................................7-7

Figure 18: Junction Box DC Power connection ............................................................7-8

Figure 19: Junction Box to Sensor Head Assembly Connector....................................8-1

Figure 20: Sensor Head Assembly Mounted to Pipe....................................................8-2

Figure 21: Sensor Head to Junction Box Cable ...........................................................8-3

Figure 22: Terminal Block Numbering 1-8, 9-16...........................................................8-4

Figure 23: Sensor Cable Connection to Junction Box Terminals .................................8-5

Figure 24: Typical CYCLONEtrac PST Array.............................................................10-2

Figure 25: Example OPTIGrind PST Display for version 5.01.06............................... 10-3

Figure 26: Right-click pop-up window.........................................................................10-4

Figure 27: Configuration Settings - Appearance tab...................................................10-5

Figure 28: Sensor Serial Number labels.....................................................................10-8

Figure 29: Configuration Settings – Settings tab ........................................................10-9

Figure 30: Sensor Status Info in logged Results Data..............................................10-10

21464-01-EN Rev 05

Page 1-1

INTRODUCTION

Introduction

CYCLONEtracTM PST (Particle Size Tracking system) is an individual

hydrocyclone performance monitoring system that provides on-line

particle size measurement of material in the overflow. This allows

optimization of the grind line and hydrocyclone battery.

This manual covers the basic installation and setup of the

CYCLONEtrac PST Junction Box, Power Entry Box, and Sensor Head

Assembly.

In all cases, local safety and operating practices take precedence over

the information contained within this document.

Junction Box, Power Entry Box and Sensor Head

Assembly Description

CYCLONEtrac PST has 2 possible configurations:

1. AC-powered Junction Box - Refer to section 6 for installation

instructions.

2. AC-powered Power Entry Box providing 24VDC to DC-powered

Junction Box - Refer to section 7 for installation.

The second configuration eliminates any hazardous voltages in the

Junction Box.

The Junction Box interfaces to a maximum of 16 Sensor Head

Assemblies. It provides RS485 communication to the Sensor Head

Assembly and converts the RS485 signals to Ethernet for Laptop

connection.

The Sensor Head Assembly (aka “Sensor”) attaches to the pipe and

varies in size according to pipe size. The Sensor Head Assembly

detects particles impinging or striking its probe which extends into the

pipe through a hole drilled in the pipe wall. The Sensor Head

assembly then converts the particles impinging to electric signals and

sends this information to the Junction Box.

Intellectual Property Notices

Hydrocyclone Performance Monitoring Products may be covered by

one or more of the following granted U.S. Patent(s): 7,032,432;

7,058,549; 7,062,976; 7,086,278; 7,110,893; 7,121,152; 7,127,360;

7,134,320; 7,139,667; 7,146,864; 7,150,202; 7,152,003; 7,152,460;

7,275,421; 7,359,803; 7,363,800; 7,437,946; 7,529,966;

7,657,3927,810,400; 8,739,637; 9,057,635; 9,645,001; 9,921,092;

21464-01-EN Rev 05

Page 1-2

10,309,887; 10,394,207; 10,814,339; 10,830,623; 10,989,635;

11,125,593; 11,260,399.

Other patents are pending; see www.cidra.com for the latest listing of

patents.

This manual is covered by U.S. and international copyright laws. No

part of this manual may be reproduced, modified or transmitted in

whole or in part in any form or by any means, electronic or

mechanical, including photocopy, recording, or any information

storage and retrieval system, without permission in writing from

CiDRA Minerals Processing Inc.Copyright © 2022 by CiDRA

Minerals Processing Inc., all rights reserved.

CYCLONEtracTMPST,and logo are trademarks of CiDRA Minerals

Processing Inc.

Warranty

The terms and conditions, including warranty, of the purchase of

CYCLONEtrac PST Hydrocyclone Monitoring System are given in the

document titled “CiDRA’s Terms and Conditions of Sale”.

CiDRA Contact Information

CiDRA Minerals Processing Inc.

50 Barnes Park North

Wallingford, CT, USA 06492

Telephone: 1-203-265-0035

1-877-243-7277 (US and Canada)

Email: www.cidra.com

Sales Support: sales@cidra.com

Customer and Technical Support: customersupport@cidra.com

CYCLONEtrac PST EU Declaration of Conformity

The EU Declaration of Conformity provides the justification for the CE

marking of a product. It identifies all the EU Directives that apply to the

product along with the Standards that the product was designed to or

tested against to demonstrate compliance with those directives. CE

marking is a requirement only for products sold in the European

community. The EU Declaration of Conformity is for CYCLONEtrac

PST product in Ordinary Location.

The Declaration of Conformity is shipped with the CYCLONEtrac PST

and can also be found on www.cidra.com in Resource

Center/Certification.

21464-01-EN Rev 05

Page 2-1

EQUIPMENT SAFETY COMPLIANCE

Safety

This equipment is listed with TÜV Rheinland of North America, Inc., a

nationally recognized testing laboratory, and certified for ordinary

location use per the following US, and Canadian standards: IEC / EN

61010-1, UL 61010-1 and CSA C22.2 No 61010-1.

North American Emissions

This equipment is compliant with Class A limits for radiated and

conducted radio noise emissions, as defined in Subpart A of Part 15 of

the FCC rules, as well as the requirements defined in ICES-003 for

Canada.

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-

003 du Canada.

For Electromagnetic Compatibility (EMC) requirements, this product is

categorized as Group 1, Class A ISM equipment. This categorization

applies to Industrial, Scientific or Medical equipment that intentionally

generates or uses conductively coupled (but not intentionally radiated)

radio-frequency energy that is necessary for the internal functioning of

the equipment. The level of EMC compliance is consistent with

industrial use but not for domestic purposes.

2.2.1 European Emissions and Immunity

This equipment is compliant with the requirements set forth in EN

61326-1, Laboratory Use - EMC requirements as well as EN 55011

Industrial, Scientific, and Medical (ISM) Radio Frequency Equipment -

Radio Disturbance Characteristics - Limits and Methods of

Measurement.

CAUTION

Class A equipment is intended for use in an industrial

environment. There may be potential difficulties in ensuring

electromagnetic compatibility in other environments, due to

conducted as well as radiated disturbances.

21464-01-EN Rev 05

Page 2-2

*** This Page is Blank***

21464-01-EN Rev 05

Page 3-1

GENERAL SAFETY GUIDELINES

Introduction

This manual is intended to be a general installation guide for the

CYCLONEtrac PST process monitoring systems. It is not intended to

cover the installation details for every process due to the wide variety

of applications and processes on which the system can be used. In all

cases, local safety and operating practices should take precedence

over instructions contained within this manual.

The installer must fully read this manual prior to installing and

operating the CYCLONEtrac PST process monitoring system.

Safety Precautions

The following style of Warnings and Cautions are used throughout the

manual to draw attention to information regarding personnel safety

and equipment care. They are intended to supplement but not replace

local or plant safety procedures.

WARNING

Situation has the potential to cause bodily harm or death.

CAUTION

Situation has the potential to cause damage to property or

equipment.

Definitions of Symbols

The following terms and symbols are used in this document and on

the process monitoring system where safety related issues occur.

3.3.1 General Warning or Caution

Figure 1: General Warning or Caution Symbol

The Caution Symbol in Figure 1 appears in Warning and Caution

tables throughout this document. This symbol designates an area

where personal injury or damage to the equipment is possible.

This symbol is also used on the equipment. Documentation needs to

be consulted in all cases where this symbol is used.

21464-01-EN Rev 05

Page 3-2

On the AC Junction box, this symbol is found on the certification label

(on the box exterior) next to the AC electrical ratings, and on labels

inside the box drawing attention to the AC power cable (one on the

inside of the door and another near the power entry board where the

AC power terminals are). In addition to the information on those

interior labels about the minimum temperature rating for the AC

power cable, other important information is to be found in section 6,

and especially 6.2 and 6.2.1.

On the Power Entry box, this symbol is found on the certification label

(on the box exterior) next to the AC electrical ratings, and on a label

inside the box drawing attention to the AC power cable (below the

DIN-rail-mounted AC power terminals). In addition to the information

on that interior label about the minimum temperature rating for the AC

power cable, other important information is to be found in section 7,

and especially 7.2 and 7.2.1.

On the Power Entry box, this symbol is also found on a label or labels

inside the box below the DIN-rail-mounted 24VDC output power

terminals. In addition to the information on that interior label about

the minimum temperature rating, minimum wire gauge, and maximum

cable length for the DC output power cable, other important

information is to be found in section 7, and especially 7.3.

3.3.2 Grounding

Figure 2: Grounding Symbol

The Grounding Symbol in Figure 2 appears on labels affixed to the

CYCLONEtrac PST system. This symbol identifies components that

are part of the protective earth circuit. See sections 6 or 7 for

instructions for wiring this protective earth circuit to a local earth

ground.

21464-01-EN Rev 05

Page 3-3

3.3.3 Electric Shock Hazard

The Electric Shock Hazard warning symbol in Figure 3 appears on

labels near the mains power connections inside the Power Entry Box

and the AC Junction Box and also in this manual in conjunction with

warnings about the hazard of electric shock. Those mains power

terminals and the associated wires and fuses are the primary risks of

electric shock in the CYCLONEtracTM PST system. The electronic

circuitry, itself, does not generate voltages higher than nominal

24VDC. This symbol is used where AC wiring is exposed at terminals

on circuit boards, DIN rails, or Power Supply modules and at fuses. In

systems that include a Power Entry box, the DC Junction box is

powered by non-hazardous 24VDC and so no electric shock warning

symbols are used inside the DC Junction box. Similarly, the Sensors

in both types of systems are powered by non-hazardous 24VDC and

so there are no electric shock warnings associated with the Sensors.

For the boxes that are powered by AC mains voltages, electric shock

safety is ensured by depowering the box prior to opening it.

Whenever the box is open with AC power applied, to avoid electric

shock keep hands and tools away from those areas where AC wiring

exists (identified with the electric shock warning symbol).

General Warnings and Cautions

Observe these rules when operating or servicing this equipment:

•The safety of any system incorporating this CYCLONEtracTM PST

system as an element is the responsibility of the assembler of that

system.

•If the equipment is used in a manner not specified by

manufacturer, the protection provided by the equipment may be

impaired.

•Prior to operation of this equipment, personnel should read the

instruction manual thoroughly.

•Trained personnel must carry out service on this equipment.

•Follow all warnings on the unit and in the operating instructions.

•Follow static sensitive device precautions when servicing.

Figure 3: Electric Shock Hazard

21464-01-EN Rev 05

Page 3-4

•Do not wear rings or wristwatches when servicing this equipment.

•To preserve the safety of this product, use only manufacturer

specified replacement parts and do not perform unauthorized

substitutions or modifications.

•Prior to servicing, lockout all electrical power sources.

•This product should only be powered as described in the manual.

Read the instructions for proper input voltage range selection.

•This equipment is grounded through the grounding conductor of

the power cord.

•Ensure all power cords, Junction Box cables, Power Entry Box

cables, and Sensor Head Assembly signal cables are properly

routed to eliminate damage to them. Cable conduit may be

desirable to minimize potential damage.

•Do not run power and signal wires in a common conduit.

•Fuse replacement must be performed by trained service

personnel.

•Disconnect power to Junction Box or Power Entry Box prior to

replacing fuse(s).

WARNING

Electrical shock hazard. Always disconnect power source prior

to removing fuses. Failure to remove power source may result

in injury or death.

•Use only the specified fuse(s) with the correct type number,

voltage and current ratings as referenced in Appendix A and on the

labels on the equipment.

•CiDRA performs a leak test (pipe to Saddle/Sensor Head

Assembly) at maximum pressure of 30 PSI prior to shipment of the

assembly. This verifies non-leakage of Sensor and improves

safety risk factor.

•The only moving parts in the CYCLONEtracTM PST system are the

hinged covers of the Power Entry and Junction boxes. Use

caution to avoid pinching wiring or fingers when closing the covers.

21464-01-EN Rev 05

Page 4-1

PREPARATION FOR INSTALLATION

Introduction

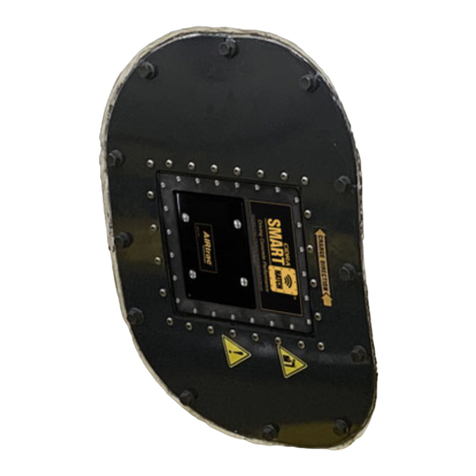

The Sensor Head Assemblies (Figure 4: Sensor Head Assembly

Mounted to Pipe) process the Sensor data for output to the

CYCLONEtrac PST data acquisition and reporting system.

Figure 4: Sensor Head Assembly Mounted to Pipe

Installation Considerations

4.2.1 Preparation

Prior to installing the CYCLONEtrac PST system, verify that the

system is rated for the area where it will be installed. Consider the

available power, the ambient temperature, and the installation area

classification. If the markings on the Junction Box, Power Entry Box

and Sensor Head Assembly received are not consistent with the

conditions of the area in which it is be installed, contact Customer

Support.

Note: The CYCLONEtrac PST system is rated for use only in non-

hazardous locations.

Warning

Explosion hazard – Install only in Non-Hazardous locations.

21464-01-EN Rev 05

Page 4-2

In addition to the warnings and cautions in this section, refer also to

the General Safety Guidelines in section 3.

4.2.2 Power Requirements

The CYCLONEtrac PST system requires an input voltage of 100 –

240 volts AC, 50/60 Hz applied to the Power Entry box (for systems

which include a Power Entry box) or to an AC Junction Box. The

power rating is 200W per Junction box, or 400W for systems wherein

a Power Entry box powers 2 Junction boxes.

.

WARNING

Electrical shock hazard. Always disconnect power source prior

to removing fuses. Failure to remove power source may result

in injury or death.

Each Sensor Head Assembly requires 24VDC and 6 watts of power,

which is provided by the Junction Box.

21464-01-EN Rev 05

Page 4-3

4.2.3 System Environmental Conditions

See Appendix A for the System Environmental Conditions.

4.2.4 Restriction of Access to Power Entry Box and Junction Box

Access to opening the cover to the Junction Box and Power Entry Box

must be restricted to properly trained service personnel only. The

Power Entry and Junction Box enclosures have their hinged cover

held closed with 4 screw-down door clamps and there is also a hasp

and staple for padlocking to further prevent unauthorized access if

necessary. Note: It should never be necessary to open the Sensor

Head Assembly anywhere other than at the factory.

Suggested Power Entry Box and Junction Box

Installation

The envelope drawings of the Power Entry box and Junction box are

shown in Appendix A in sections A10 and A11, respectively, along

with their mounting hole locations. The tabs on the top have two holes

that are 0.44” (11mm) in diameter, and the tabs on the bottom have

two slots of the same width. It is suggested to mount each box to 2

vertical strut channels. and to use two adjustable pipe strut mount

clamps inserted into each strut channel which can be then be used to

mount the box to a railing. These drawings and others include those

suggested struts and clamps even though they are not provided as

part of the CYCLONEtrac PST kit. Allow at least 6-inch [15.3cm]

clearance on all sides of boxes.

21464-01-EN Rev 05

Page 4-4

Figure 5: Junction Box Mounting

21464-01-EN Rev 05

Page 5-1

SENSOR HEAD ASSEMBLY MOUNTING

Pipe Modification Procedure

The following figure illustrates a typical hydrocyclone battery

Figure 6: Hydrocyclone Battery

21464-01-EN Rev 05

Page 5-2

To install the PST system, the hydrocyclone overflow pipes must have

a through-hole on the pipe to admit the Sensor’s probe. The exact

size of the hole will be specified by CiDRA. The following example

shows a 2” (5.1cm) hole installed in a hydrocyclone overflow pipe.

Figure 7: Hole Placement

Other manuals for CYCLONEtrac PST

1

Table of contents

Other CiDRA Measuring Instrument manuals

CiDRA

CiDRA AIRtrac Installation instructions

CiDRA

CiDRA CYCLONEtrac PST User manual

CiDRA

CiDRA SMARThatch Quick start guide

CiDRA

CiDRA SMART HATCH User manual

CiDRA

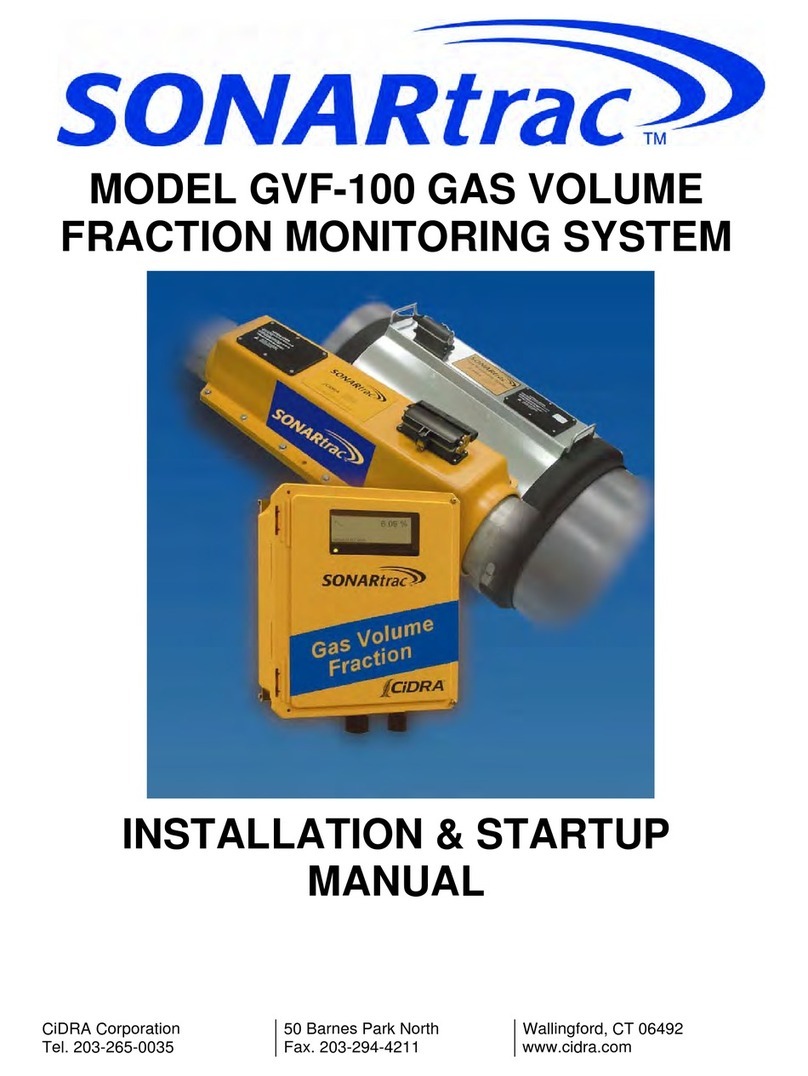

CiDRA Sonartrac GVF-100 Installation and operation manual

CiDRA

CiDRA SONARtrac 20924 User manual

CiDRA

CiDRA SMARThatch Operating and maintenance manual