Table of contents

1. How to use the manual .................................................................................... 1

1.1 Importance of the manual................................................................................................................. 1

1.2 How to keep the manual ................................................................................................................... 1

1.3 How to consult the manual ............................................................................................................... 1

1.4 Symbol ............................................................................................................................................... 2

2. General information......................................................................................... 3

2.1 General features................................................................................................................................ 3

2.2 Main components of ME550 ............................................................................................................. 4

2.3 Operating principle of ME550 ........................................................................................................... 6

2.4 Electrical specifications ..................................................................................................................... 7

2.5 Rating of the equipment and applicable standards ........................................................................... 7

2.6 Terms of use....................................................................................................................................... 7

2.7 Dimensions and weight...................................................................................................................... 7

2.8 Productioncapacities......................................................................................................................... 7

2.9 Operating precautions and safety regulations.................................................................................. 9

2.10 Safety requirements ........................................................................................................................ 10

2.11 Operation in technician mode......................................................................................................... 11

2.12 Symbols present on the machine..................................................................................................... 12

2.13 RAEE regulation ............................................................................................................................... 13

2.14 Declaration of compliance............................................................................................................... 15

3. Unpacking...................................................................................................... 17

3.1 Unpacking ........................................................................................................................................ 17

4. Installation..................................................................................................... 20

4.1 Accessories check list....................................................................................................................... 20

4.2 Positioning the machine .................................................................................................................. 21

4.3 Removing mechanical locks and installing accessories................................................................... 21

4.4 Electrical connection ....................................................................................................................... 24

4.5 Connection to a computer............................................................................................................... 25

4.6 Warnings and installation precautions............................................................................................ 25

4.7 Power on and checking.................................................................................................................... 27

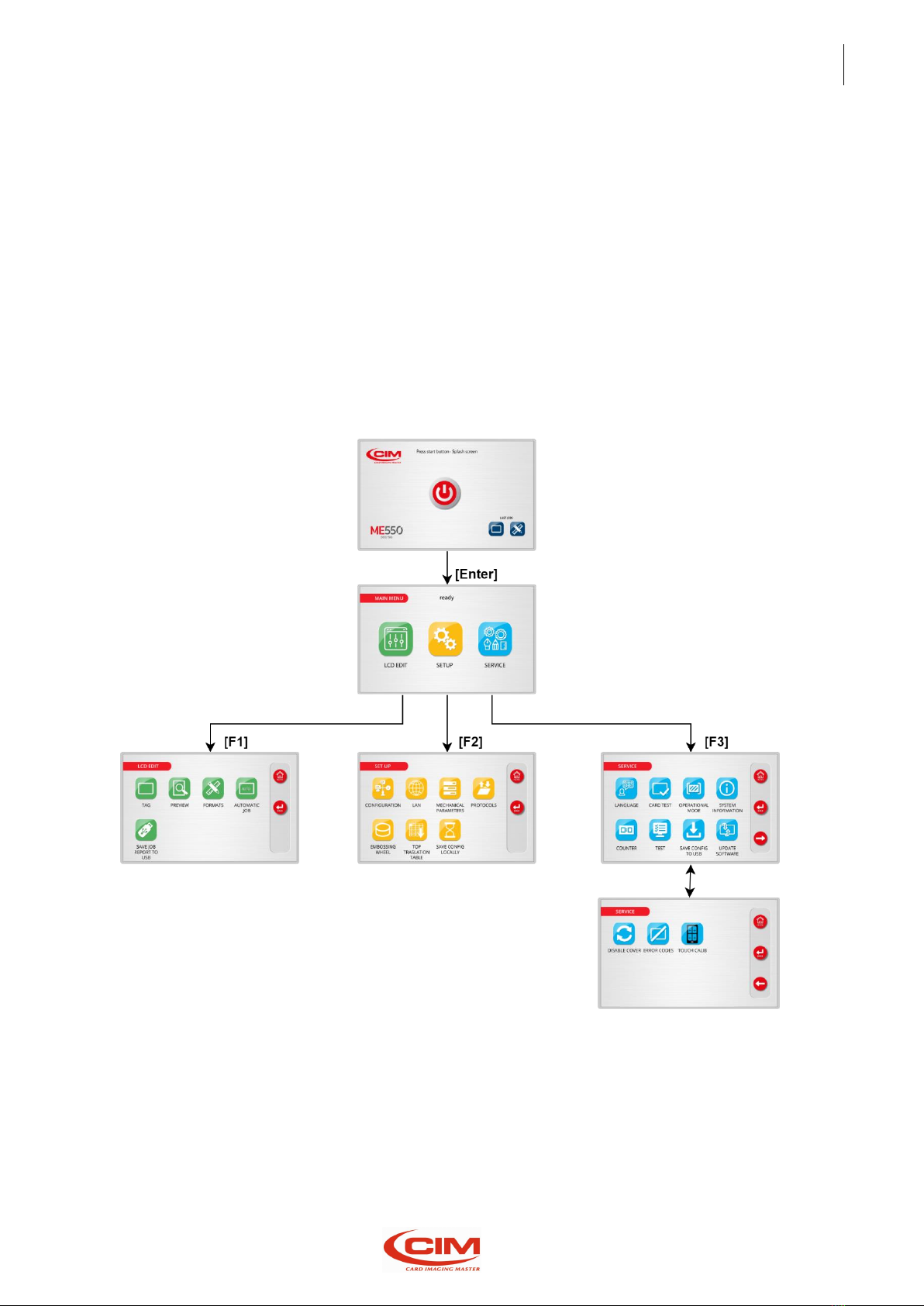

5. Human Machine Interface.............................................................................. 29

5.1 Introduction..................................................................................................................................... 29

5.2 Main screen ..................................................................................................................................... 29

5.3 LCD Edit............................................................................................................................................ 31

5.3.1 Tag [F1] .....................................................................................................................................32

5.3.2 Preview [F2]..............................................................................................................................33

5.3.3 Formats [F3]..............................................................................................................................34

5.3.4 Automatic job [F4]....................................................................................................................38

5.3.5 Save job report to USB [F5] ......................................................................................................40

5.4 Setup................................................................................................................................................ 41

5.4.1 Configuration [F1].....................................................................................................................42

5.4.2 Lan [F2] .....................................................................................................................................43

5.4.3 Mechanical parameters [F3].....................................................................................................44