OPERATOR MANUAL

Table of ontents

1.

How to use the manual .................................................................................... 1

1.1 Importance o the manual ................................................................................................................. 1

1.2 How to keep the manual ................................................................................................................... 1

1.3 How to consult the manual ............................................................................................................... 1

1.4 Symbol ............................................................................................................................................... 2

2.

General information......................................................................................... 3

2.1 General eatures ................................................................................................................................ 3

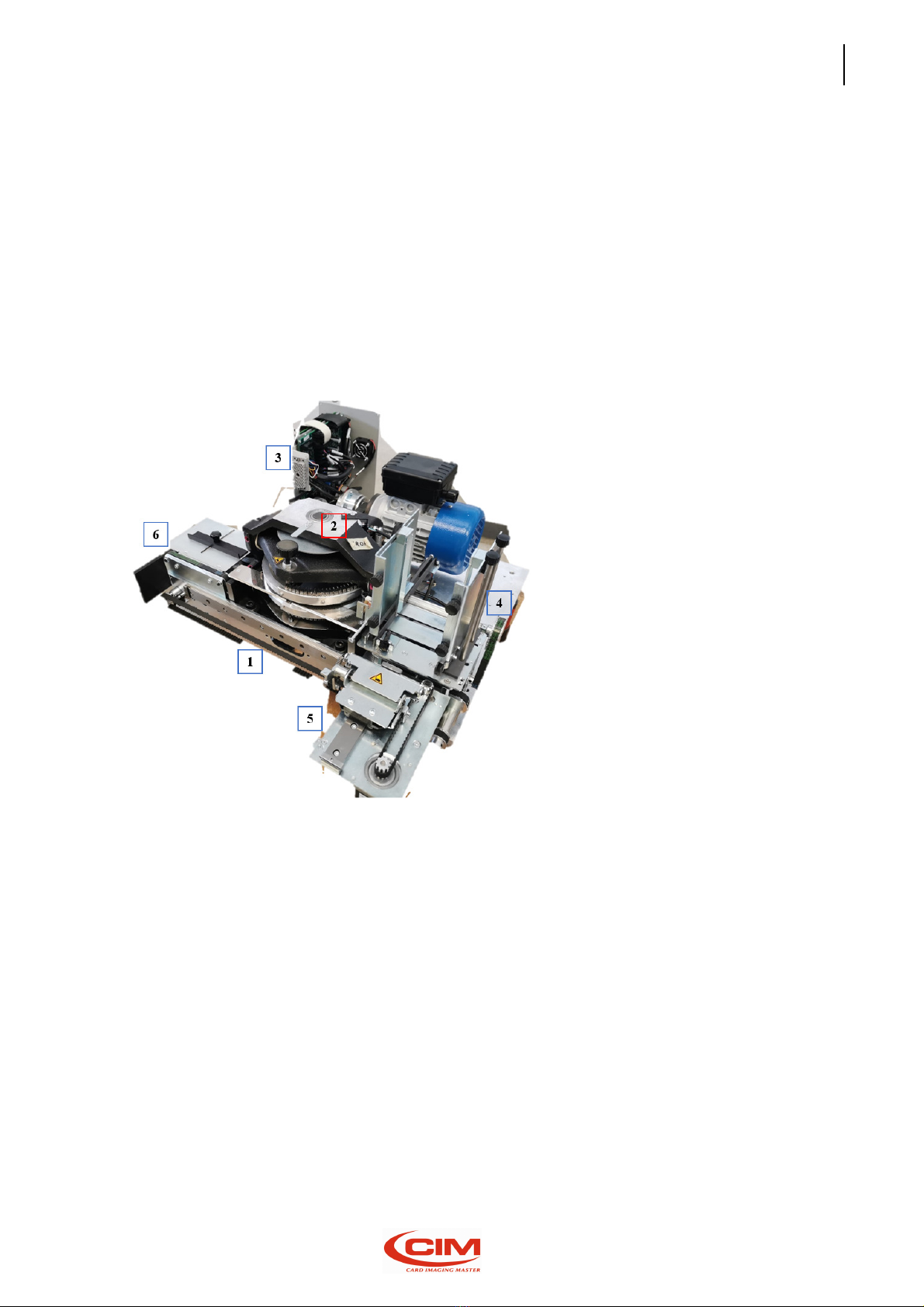

2.2 Main components o ME2000S ......................................................................................................... 4

2.3 Operating principle o ME2000S ....................................................................................................... 6

2.4 Electrical speci ications .............................................................. Errore. Il segnalibro non è definito.

2.5 Rating o the equipment and applicable standards .................... Errore. Il segnalibro non è definito.

2.6 Physical environment and operating conditions ........................ Errore. Il segnalibro non è definito.

2.7 Communication and so tware ........................................................................................................... 7

2.8 Plate; eeder and marking ................................................................................................................. 8

2.9 Intended use and limits ..................................................................................................................... 8

2.10 Residual risks ..................................................................................................................................... 9

2.11 Operating precautions and sa ety regulations ................................................................................ 10

2.12 Sa ety requirements ........................................................................................................................ 11

2.13 Operation in technician mode ......................................................................................................... 12

2.14 Symbols present on the machine ..................................................................................................... 13

2.15 RAEE regulation ............................................................................................................................... 14

2.16 Declaration o “CE” Con ormity ....................................................................................................... 15

2.17 Declaration o compliance ............................................................................................................... 16

3.

Unpa king ...................................................................................................... 17

3.1 Unpacking ........................................................................................................................................ 17

4.

Installation ..................................................................................................... 19

4.1 Accessories check list....................................................................................................................... 19

4.2 Positioning the machine .................................................................................................................. 20

4.3 Electrical connection ....................................................................................................................... 21

4.4 Connection to a computer ............................................................................................................... 21

4.5 Warnings and installation precautions ............................................................................................ 22

4.6 Power on and checking.................................................................................................................... 23

5.

Human Ma hine Interfa e .............................................................................. 25

5.1 Introduction ..................................................................................................................................... 25

5.2 Main screen ..................................................................................................................................... 25

5.3 LCD Edit ............................................................................................................................................ 27

5.3.1 Tag [F1] ..................................................................................................................................... 28

5.3.2 Preview [F2] .............................................................................................................................. 29

5.3.3 Formats [F3] .............................................................................................................................. 30

5.3.4 Automatic job [F4] .................................................................................................................... 34

5.3.5 Save job report to USB [F5] ...................................................................................................... 36

5.4 Setup ................................................................................................................................................ 37

5.4.1 Con iguration [F1] ..................................................................................................................... 38

5.4.2 Lan [F2] ..................................................................................................................................... 39