CIMCO GENiUS 2.0 User manual

1

Operating instructions for

CIMCO-Werkzeugfabrik - D-42855 Remscheid - www.cimco.de

3

3

2

Contents

1 General information

1.1 Components of these operating instructions

1.2 Before start-up

1.3 Reading these operating instructions

1.4 Illustrations and technical alterations

1.5 Translations

1.6 Storage

1.7 Safety information in complience with EN

1.8 Emphasis in these operating instructions

1.9 Intended use

1.10 Residual risk

2 Technical data

3 Description of appliance and functional

principle

3.1 Functional principle

3.2 Scope of delivery / performance features

3.3 Changing crimping inserts

3.4 Start-up

3.5 Crimping

3.6 Cutting

3.7 Hole punching

3.8 Permitted / not permitted

3.9 LED function

4 Scope of application

5 Rechargeable battery

5.1 Rechargeable battery technology

5.2 Type of battery

5.3 Charging the battery

5.4 Safety information for Li-Ion rechargeable

batteries

5.5 Disposal of Li-Ion rechargeable batteries

6 Packaging, storage and

disposal

6.1 Sensitivity

6.2 Packaging and temporary storage

6.3 Disposal

7 Cleaning, monitoring, repairs,

inspections

7.1 Regular cleaning after use

7.2 Regular monitoring

7.3 Faults / correction of faults

7.4 Inspection and maintenance of the GENiUS

2.0 hydraulic system

8 Customer service

9 EC Declaration of Conformity

1 General information

1 General information

WARNING Please read all safety informa-

tion and instructions. Failure to comply with the

safety information and instructions may cause

electric shock, fire and/or serious injury.

Please keep all safety information and instruc-

tions for future reference.

The term „electric tool“

used in the safety information refers to mains-ope-

rated electric tools (with mains cable) and to batte-

ry-operated electric tools (without mains cable)

1.1 Components of these operating

instructions

The following form part of these operating instruc-

tions:

• GENiUS 2.0 hydraulic system

• Crimpinghead,300mm2and 185 mm2

• Cuttingandpunchinghead

• Rechargeablebattery

, appropriate for the GENiUS

2.0 hydraulic system

Instructions for the battery charger and the battery

supplied are fully covered by the producer‘s opera-

ting instructions (see mention on the charger and

the battery). CIMCO Werkzeugfabrik does not pro-

vide a guarantee of completeness.

1.2 Before start-up

It is essential to keep the following in mind:

• Checkingthecompletenessofdeliveryandmo-

nitoring

the delivery with regard to any transport

damage

• Thesafetyregulations

• Theoperatinginstructions

1.3 Reading these

operating instructions

For use and charging of the battery, read the

producer‘s operating instructions for the charger

and the battery. If you have any questions after

reading these operating instructions, please get in

touch with the producers or your nearest customer

service point (see guarantee card for addresses).

We will not accept any liability for damage or faulty

operation resulting from disregard of the operating

instructions.

1.4 Illustrations and technical alterations

Illustrations may deviate from actual appliances

and are not binding on our part. In order to comply

with rapidly changing customer demands, we re-

serve the the right to make technical alterations to

the machines without prior notice.

1.5 Translations

The German language version of these operating

instructions is the sole legally valid version.

1.6 Storage

Store these operating instructions in

a safe place.

1.7 General safety information

1) Safety in the workplace

a) Keep your work space clean and well lit. Un-

tidy and poorly lit work spaces can lead to acci-

dents.

b) Do not work with the electric tool in an envi-

ronment where there is danger of explosion,

or which contains flammable liquids, gases

or various kinds of dust. Electric tools create

sparks that may ignite dust or vapour.

c) Keep children and other persons away while

using the electric tool.

If distracted, you may lose control of the appli-

ance.

2) Electrical safety

a) Avoid physical contact with earthed sur-

faces, such as those of pipes, heaters, sto-

ves and refrigerators. There is an increased

risk of electric shock if your body is earthed.

b) Keep electric tools away from rain or

moisture. If water penetrates the electric tool,

this will increase the risk of electric shock.

3) Safety of persons

a) Be observant, pay attention to what you are

doing and be sensible when working with an

electric tool. Do not use an electric tool if

you are tired or under the influence of drugs,

alcohol or medication. A moment‘s inattention

when using the electric tool can lead to serious

injury.

b) Wear personal protective equipment and al-

ways wear safety glasses. Wearing personal

safety equipment, such as a dust filter mask,

non-slip safety shoes, safety helmet or ear pro-

tectors, appropriate to the type of tool and its

use will reduce the risk of injury.

c) Avoid accidental start-up. Make sure that the

electric tool is switched off before you con-

nect it to the power supply and/or the batte-

ry, pick it up or carry it. If you have your finger

on the switch when carrying the electric tool or

connect the appliance to the power supply when

it is switched on, this may lead to accidents

d) Remove any adjustment tools or spanners

before switching on the electric tool. A tool or

spanner in a rotating part of the appliance can

lead to injuries.

e) Avoid any unusual posture or position. En-

sure that you are standing securely and keep

your balance at all times. If you do so, you will

be able to control the tool better in unexpected

situations.

3

3

f) Wear suitable clothing. Do not wear wide

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts. Loose clothing, jewellery or long hair

may be caught up in moving parts.

4) Use and handling of the electric tool

a) Do not overload the appliance. Use the elec-

tric tool appropriate for your task. If you use

the appropriate tool, you will work better and

more safely in the specified area of work.

b) Do not use any electric tool with a defective

switch. An electric tool that cannot be switched

on and off is dangerous and must be repaired.

c) Pull the plug out of the socket and/or remo-

ve the battery before adjusting the appli-

ance, exchanging accessories or putting

the appliance away. These safety precautions

will prevent accidental start-up of the tool.

d) Keep electric tools not in use out of the re-

ach of children. Do not allow any person to

use the appliance who is not familiar with it

or has not read these instructions. Electric

tools are dangerous if used by inexperienced

persons.

e) Take good care of electric tools. Check

whether the moving parts are functioning per-

fectly and without jamming, whether parts are

broken or damaged in such a way as to have

a detrimental effect on the function of the tool.

Have damaged parts repaired before using

the appliance. Many accidents are caused by

poorly maintained electric tools.

f) Keep the cutting tools sharp and clean.

Well-maintained cutting tools with sharp cutting

edges will jam less frequently and are easier to

guide.

g) Use the electric tool, accessories, inserted

tools etc. according to these instructions.

Take the operating conditions and the task

to be carried out into account. Using electric

tools for tasks other than those for which they

were intended can lead to dangerous situa-

tions.

5) Use and handling of the battery tool

a) Only charge the batteries in chargers re-

commended by the producer. There is a risk

of a charger intended for a particular type of

battery catching fire if it is used for other batte-

ries.

b) In electric tools, use only the batteries in-

tended for the tool. Using other batteries may

lead to injuries and the risk of fire.

c) Keep batteries not in use away from paper

clips, coins, keys, nails, screws or other

small metal objects that could cause a brid-

ging of the contacts. A short-circuit between

battery contacts can cause burns or fire.

d) If the battery is used wrongly, it may leak fluid.

Avoid skin contact with the battery. If the flu-

id accidentally comes in contact with skin,

rinse off with water. If the fluid comes in

contact with the eyes, also get medical at-

tention. Leaking battery fluid may cause skin

irritation or burns.

6) Service

a) Only allow CIMCO authorizied Customer

Service to repair your electric tool, using

only authentic replacement parts. This will

ensure that the safety of the tool is retained.

1.8 Special emphasis in these operating

instructions

Read the safety information in these operational

instructions and always keep it in mind! Special

emphasis in this safety information is shown as

follows:

Marks an instruction that may lead to

injury or death if not complied with..

Marks an instruction that may lead to

damage to the appliance or property if not complied

with.

Do not immerse in liquid!

Do not heat or burn!

For environmentally-friendly disposal,

send the hydraulic system to your nearest

customer service point (see guarantee card for

addresses) or pass it on to a recycling company.

Hydraulic systems must not be disposed of as scrap

or household waste.

Marks explanatory information or a special

instruction.

Listed points

Straightforward listed points are

marked with the symbol

•beforetheline:

• 1.Sampleline

• 2.Sampleline

Steps (where you do something!) are marked with

an arrow in front of the line:

1. Step

2. Step

Follow the sequence of stepsn.

1.9 Intended use

The GENiUS 2.0 are electro-hydraulic tools, which

when used with appropriate interchangeable heads

perform a variety of functions, such as crimping

electrical compression connections, cutting

electrical cables and hole punching operations.

When operated, an internal electric motor powers a

hydraulicpumpwhichsuppliesuidtothecylinder

of the

tool, moving the ram forward and applying force to

specially designed interchangeable heads. The

tools are equipped with the QuickChange System

(QCS) for installing the various interchangeable

heads. This also allows interchangeable heads to

be rotated 360° for better access in tight spaces.

There are different QCS types. Make sure that the

tool and interchangeable head QCS types are

compatible. The tools come with two fabric loops

that can be used with appropriate attachments such

as shoulder straps or tie off lanyard. The tools are

equipped with a bright LED work light that lights up

when the run switch is pulled.This allows the user to

easily illuminate the work area. The tool LED display

indicates the tool’s status (tool ON/OFF, temperatu-

re out of range, service required.)

1.10 Residual risk

If the machine is used improperly, the operator may

crush his/her fingers.

2 Technical data

GENiUS 2.0 hydraulic system

Nominal capacity 320W

Voltage 18 V DC

Machine monitoring electronic

Sound pressure level 81 dB

Uncertainty 3 dB

Sound power level 92 dB

Uncertainty 3 dB

Vibration level 1.16m/s2

Uncertainty (K) 1.5m/s2

Power transmission hydraulic

Shear force min. 60 kN

Weight with battery 2.750 kg

Li-Ion rechargeable battery capacity 18V/2.0 Ah

(Guideline values, we reserve the right to make

changes)

The vibration emission value given was measured

in accordance with EN 60745-1 and can be used

for comparison with other electric tools.

During use of the hydraulic system, the

vibration emission value may diverge from the

given value. The vibration emission value is

independent of the manner in which the hy-

draulic system is used.

The term electromagnetic compatibility is

taken to mean the capability of the product to

function smoothly in an environment where

electromagnetic radiation and electrostatic

discharges are present and without causing

electromagnet interference to other equipment.

The GENiUS 2.0 conform to all applicable EMC

standards. However, the possibility of it cau-

sing interference in other devices cannot be

precluded.

5

4 5

Loops for

carrying strap Upper and lower

crimping inserts

Emergency stop

Start switch

Locking ring

Crimping head

LED

On / Off switch

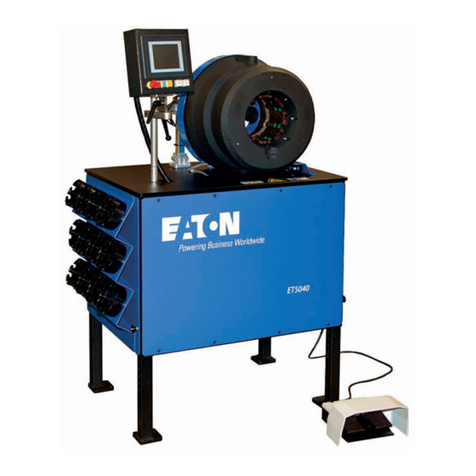

3 Description of appliance and

functional principle

3.1 Functional principle

GENiUS 2.0 hydraulic system

60 kN pressing strength

Max. 3

crimping,

punching and

cutting

processes

per minute

Machine‘s year

of construction

=

5

5

3 Description of appliance and

functional principle

3.2 Performance features

Rechargeable

battery

GENiUS 2.0 hydraulic system

Crimping head

Performance features:

- Heads can be rotated a full 360°!

- Automatic return after

maximum pressing strength of 60 kN is reached

- Quick change system for crimping, cutting and

hole punching head

- It is possible to interrupt the crimping, cutting

or punching process

(by releasing the start switch)

7

6 7

3 Description of appliance and

functional principle

3.3 Changing crimping inserts

1. Open the crimping

head

3. Place the crimping

insert in the lower

section of the

crimping head

4. Place the crimping

insert in the upper

section of the

crimping head

5. Close the crimping head

Additional safety instructions:

Before changing the crimping inserts, remove the battery or take the crimping head out

of the machine. Do not change the crimping inserts until this has been done.

2. To remove the crimping

insets, push them out

to the side

7

7

1. Pull back the locking

ring and insert the

appropriate head

2. Check that the head is correctly locked.

The edge of the locking device on the head

must be covered by the locking ring.

4. Switch on machine,

green LED lights up

3 Description of appliance and

functional principle

3.4 Start-up

3. Insert battery

9

8 9

3 Description of appliance and

functional principle

3.5 Crimping

1. Insert cable into

the crimping head

3. Carry out crimping while the start switch is pressed.

The crimping process has been correctly completed

when the lower cheek plate returns to the home

position by itself

2. Push terminal lug onto

the cabl

Emergency stop function

Pressing the release button

will automatically retract the

lower crimping insert.

9

9

3 Description of appliance and

functional principle

3.6 Cutting

1. Place the cable in the

cutting head

2. Carry out cutting procedure while pressing the start

switch. The cut has been correctly completed when

the cutting knife returns to home position by itself or

the cable has been completely cut through.

Emergency stop function

Pressing the release button

will retract the cutting

knives automatically

11

10 11

3 Description of appliance and

functional principle

3.7 Hole punching

1. The sheet metal hole

puncher to be used is to

be mounted in the

punching head..

4. Carry out punching while pressing the start switch.

The punching process has been correctly completed

once the sheet metal has been punched right through

without any residue.

Important:

The punching process

must then be stopped

immediately If it is

continued until automatic

switch-off, it can lead to

destruction of the hole

punchers.

2. After an appropriate hole has been pre-drilled, the

hole puncher plus the die and the tie bolt are

introduced into the hole and then locked finger-tight

with the punch

Emergency stop function

Pressing the release button

will retract the hole puncher

automatically..

11

11

3 Description of appliance and

functional principle

3.8 Permitted / not permited

X

X

Ready for crimping!

The crimping process must

not be started without

crimping inserts!

The appliance must not be

started without a head!

Piston rod in home position

If the machine has been started

without a head having been

inserted, the piston rod must be

returned to the home position by

pressing the emergency stop

If an almost discharged battery is

used during crimping, the machine

will automatically stop the crimping

procedure. This will protect the

battery from exhaustive discharge

Important: In this case the crimping head must be returned to the home position by

pressing the emergency stop. If this is not done, the machine‘s electronics may be

damaged. Now exchange the discharged battery for a charged one and the crimping

procedure can be started again.

13

12 13

3 Description of the

appliance and function

3.9 LED function

The hydraulic system is monitored electronically to

protect against operating errors and to ensure

fault-free pressing. The condition or the event is

displayed by light-emitting diodes (LEDs).

The following are monitored:

• Voltage/batterycapacity

• Serviceinterval

• Operatingtemperature

Condition displays after switching on the hy-

draulic system

Push battery into the hydraulic system.

Press the «ON-OFF» switch. To monitor the

function of the three LEDs, the LED display will

light up when the «ON-OFF» switch is pressed.

«ON-OFF» switch

• The«ON-OFF»switchcanbeusedatanytimeto

switch the machine on and off.

• IfthemachineisinONconditionandnotbeing

used, the electronics will switch to the OFF conditi-

on in 10 minutes.

4 Scope of application

The GENiUS 2.0 hydraulic system is used as a

crimping, cutting and punching tool. The original

tools, as described here, are to be used.

Crimping: GENiUS 2.0 crimping heads

for 300 mm2

and 185 mm2cable cross-sections

(CIMCO article no. 10 6301 and 10 6298)

Punching: GENiUS 2.0 punching head

(CIMCO article no. 10 6308)

Cutting: GENiUS 2.0 cutting head

(CIMCO article no. 10 6306)

Machines and parts are to be ordered through

CIMCO Werkzeugfabrik!

5 Rechargeable battery

5.1 Rechargeable battery technology

The GENiUS 2.0 hydraulic system is operated by

Li-Ion rechargeable battery technology.

5.2 Type of battery

Only the original-Li-Ion 18V/2.0Ah rechargeable

battery may be used.

5.3 Charging the battery

The battery may only be charged with the original

charger. See operating instructions for the

charger.

5.4 Safety information for

Li-Ion rechargeable batteries

Please note the following safety information for the

use of Li-Ion rechargeable batteries;

1. Do not crush!

2. Do not heat or burn!

3. Do not short-circuit!

4. Do not immerse in liquid!

5. Charging temperature from 5° C to 35° C

6. Only charge with the original charger!

7. Do not use Batteries with damaged housing

8. Do not disassemble Batteries

9. For EU-Countries defective or used batteries

must be recycled according standard 2006/66/EG

5.5 Disposal of Li-Ion

rechargeable batteries

The batteries must be disposed of in the same way

as the hydraulic system (

see Point 7.3).

6 Packaging, storage

and disposal

6.1 Sensitivity

The hydraulic system and the charger must be pro-

tected from hard impact, wet, damp, dirt, dust, ex-

treme cold, extreme heat (65° C), chemical solu-

tions and gases.

6.2 Packaging and temporary storage

The appliance is supplied in a plastic case.

If the hydraulic system is not in use, the battery must

be removed, and both are to be stored temporarily in

the case.

After a longer period of storage, the battery

will only reach its full theoretical capacity after

being fully charged 1-5 times.

If the hydraulic system is not put to use immediate-

ly after delivery, it should be stored in its original

packaging in a dry place (0° C - 40° C).

3.9 LED function

LED Condition Description

green Lit

Flashing

Machine ON

18V: charge battery

red

Lit Outside temperature range

-5 °C – +50 °C

yellow Flashing

Lit

Service display after 30,000 strokes

Machine is blocked – Service after

32,000 strokes or a defect

13

13

Store the hydraulic systems out of the

reach of unauthorised persons in dry

, lockable

storage places!

Hydraulic systems that have not been used

for a longer period of time (6 months or more) are

to be dry-wiped clean. You should also check their

functioning capacity on first use by carrying out the

checks as in Point 7.2.

6.3 Disposal

For environmentally-friendly disposal, send the

hydraulic system to your nearest customer service

point (see guarantee card for addresses) or pass it

on to a recycling company. Hydraulic systems must

not be disposed of as scrap or household waste.

7 Cleaning, monitoring,

repairs, inspections

Before cleaning operations, always dis-

connect the machine from the mains or remove

the battery from the hydraulic system!

7.1 Regular cleaning after use

Clean off dirt and metallic residues

from the heads using a cleaning oil.

Never use fluids (water or chemicals) or

damp cloths to clean the hydraulic system. The

outside of the housing can be cleaned by

wiping with a damp cloth (plastic parts).

7.2 Regular monitoring

Ensure that when crimping the cheek plates

close completely.

After every use, monitor the geometry of the

crimping inserts for damage or visible wear.

In the case of faults, contact an

authorised customer service point (see guarantee

card for addresses).

7.3 Faults / Fault correction

Faults: it may become difficult to insert the ap-

propriate head into the machine due to conta-

mination of the crimping, cutting or punching

head or respectively the holder for the head.

Fault correction: clean dust and dirt off the crim-

ping, cutting or punching head with a dry cloth and

do the same for the head holder.

Do not carry out any repair

works yourself, but pass repairs on to an

authorised customer service point (for addres-

ses, see guarantee card)

7.4 Inspection and maintenance

Perfect crimped connections require a well-functio-

ning and regularly maintained hydraulic system.

The hydraulic system should therefore be sent to

the CIMCO Werkzeugfabrik or authorizied custo-

mer services for inspection and maintenance when

the service display lights up.

The service display (green LED and yellow LED

flash) automatically draws your attention to the

need for maintenance after 30,000 pressings.

After 32,000 pressings, the GENiUS 2.0 hydraulic

tool will be locked by the electronic monitoring

system (yellow LED is lit).

If the machine is defective, the GENiUS 2.0-

hydraulic tool will be blocked immediately by the

electronic monitoring system and should be sent to

a customer service point for inspection

(it is essential to refer to Chapter 4.4).

8 Customer service

For CIMCO customer services, see

the guarantee card.

9 EC Declaration of

Conformity

We as producers of the machine declare that the

machine named below conforms to the following

listed directives and standards.

Name of appliance

GENiUS 2.0 hydraulic system

Type of appliance

CIMCO article no. 10 6300

Directives

2006/42/EC, 2004/108/EC

Applicable standards

EN 60745-1:09 / EN 55014-1:06 + A1:09 + A2:11 /

EN 62233:08 / EN 61000-6-2:05

Responsible for documentation

Arnd Diedrichs

Remscheid, 28.02.2014

CIMCO-Werkzeugfabrik - 42855 REMSCHEID

Joachim Quirl

Geschäftsführer

Producer

CIMCO-Werkzeugfabrik

Carl Jul. Müller GmbH & Co.KG

D - 42855 Remscheid

15

14 15

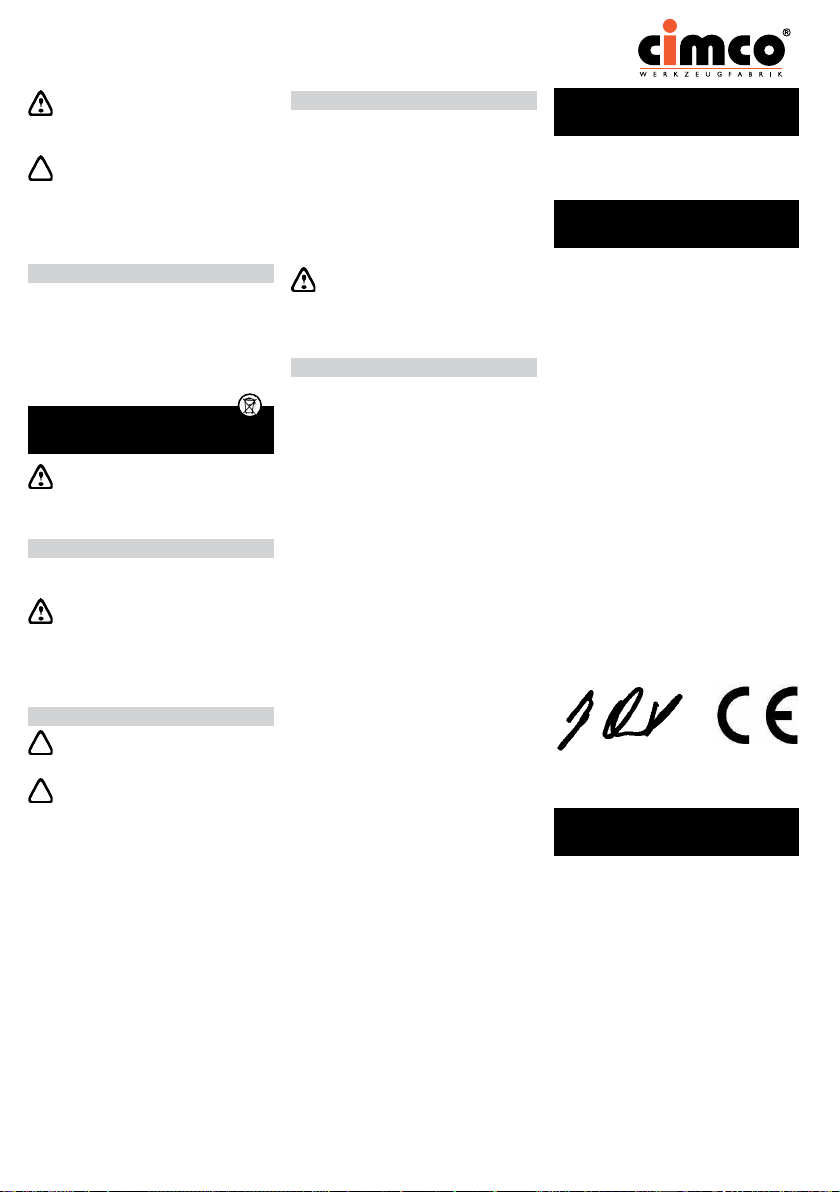

Crimping head 10 6301

Operating instructions

Original operating instructions

9 EC Declaration of

Conformity

We as producers of the product

declare that the exchangeable item of

of equipment named below conforms to

the following directives listed.

Name of product

Crimping head

Type of appliance

CIMCO article no. 10 6301

Directive

2006/42 EC

Responsible for documentation

Arnd Diedrichs

Remscheid, 28.02.2014

CIMCO-Werkzeugfabrik - 42855 REMSCHEID

Joachim Quirl

Geschäftsführer

Producer

CIMCO-Werkzeugfabrik

Carl Jul. Müller GmbH & Co.KG

D - 42855 Remscheid

1 Technical product data

Name: Crimping head

Type: 10 6301

Max. pressing strength: 60 kN

Max. cable cross-section: 300 mm2

Dead weight: 1.5 kg.

Use: exclusively in

CIMCO GENiUS 2.0 pressing tool

2 Description of crimping head

The 10 6301 crimping head forms part of the CIMCO pressing tool GENiUS 2.0.

3 Intended use

The 10 6301 crimping head is used for crimping connecting materials.

4 Residual risk

If the tool is used improperly, the operator may

crush his/her fingers.

5 Functional principle

See from page 4 on

6 Safety information

See from page 2 on

7 Faults and fault correction

See page 13

15

15

Crimping head 10 6298

Operating instructions

Original operating instructions

9 EC Declaration of

Conformity

We as producers of the product

declare that the exchangeable item of

of equipment named below conforms to

the following directives listed.

Name of product

Crimping head

Type of appliance

CIMCO article no. 10 6298

Directive

2006/42 EC

Responsible for documentation

Arnd Diedrichs

Remscheid, 28.02.2014

CIMCO-Werkzeugfabrik - 42855 REMSCHEID

Joachim Quirl

Geschäftsführer

Producer

CIMCO-Werkzeugfabrik

Carl Jul. Müller GmbH & Co.KG

D - 42855 Remscheid

1 Technical product data

Name: Crimping head

Type: 10 6298

Max. pressing strength: 60 kN

Max. cable cross-section: (for crimping use as per DIN 48086-6M)185 mm2

Dead weight: 1.5 kg.

Use: exclusively in CIMCO GENiUS 2.0 pressing tool

2 Description of crimping head

The 10 6298 crimping head forms part of the CIMCO pressing tool GENiUS 2.0.

3 Intended use

The 10 6298 crimping head is used for crimping connecting materials.

4 Residual risk

If the tool is used improperly, the operator may

crush his/her fingers.

5 Functional principle

See from page 4 on

6 Safety information

See from page 2 on

7 Faults and fault correction

See page 13

17

16 17

Cutting head 10 6306

Operating instructions

Original operating instructions

1 Technical product data

Name: Cutting head

Type: 10 6306

Max. cutting strength: 60 kN

Max. cable diameter: 50 mm

Dead weight: 2.9 kg

Use: exclusively in CIMCO GENiUS 2.0 pressing tool

2 Description of cutting head

The 10 6306 cutting head forms part of the CIMCO pressing tool. GENiUS 2.0.

3 Intended use

The 10 6306 cutting head is used for cutting electrical cables.

4 Residual risk

If used improperly, the machine operator may cut his/her fingers.

5 Functional principle

See from page 4 on

6 Safety information

See from page 2 on

7 Faults and fault correction

See page 13

9 EC Declaration of

Conformity

We as producers of the product

declare that the exchangeable item of

of equipment named below conforms to

the following directives listed.

Name of product

Cutting head

Type of appliance

CIMCO article no. 10 6306

Directive

2006/42 EC

Responsible for documentation

Arnd Diedrichs

Remscheid, 28.02.2014

CIMCO-Werkzeugfabrik - 42855 REMSCHEID

Joachim Quirl

Geschäftsführer

Producer

CIMCO-Werkzeugfabrik

Carl Jul. Müller GmbH & Co.KG

D - 42855 Remscheid

17

17

Punching head 10 6308

Operating instructions

Original operating instructions

1 Technical product data

Name: Punching head

Type: 10 6308

Max. punching pressure: 60 kN

Max. punching area: ISO63 or 92 x 92 mm

Dead weight: 1.6 kg

Use: exclusively in CIMCO GENiUS 2.0 pressing tool

2 Description of punching head

The 10 6308 punching head forms part of the CIMCO pressing tool. GENiUS 2.0.

3 Intended use

The 10 6308 punching head is used for punching sheet metal.

4 Residual risk

If the tool is used improperly, the operator may

crush his/her fingers.

5 Functional principle

See from page 4 on

6 Safety information

See from page 2 on

7 Faults and fault correction

See page 13

9 EC Declaration of

Conformity

We as producers of the product

declare that the exchangeable item of

of equipment named below conforms to

the following directives listed.

Name of product

Punching head

Type of appliance

CIMCO article no. 10 6308

Directive

2006/42 EC

Responsible for documentation

Arnd Diedrichs

Remscheid, 28.02.2014

CIMCO-Werkzeugfabrik - 42855 REMSCHEID

Joachim Quirl

Geschäftsführer

Producer

CIMCO-Werkzeugfabrik

Carl Jul. Müller GmbH & Co.KG

D - 42855 Remscheid

19

18 19

19

19

Carl Jul. Müller GmbH & Co. KG

Hohenhagener Str. 1-5 • D-42855 Remscheid

P.O. Box 10 02 63 • D-42802 Remscheid

Tel.: +49 (0) 21 91/37 18 01 • Fax: +49 (0) 21 91/37 18 86

E-Mail: info@cimco.de • Internet: www.cimco.de

09 1852-E

This manual suits for next models

1

Table of contents

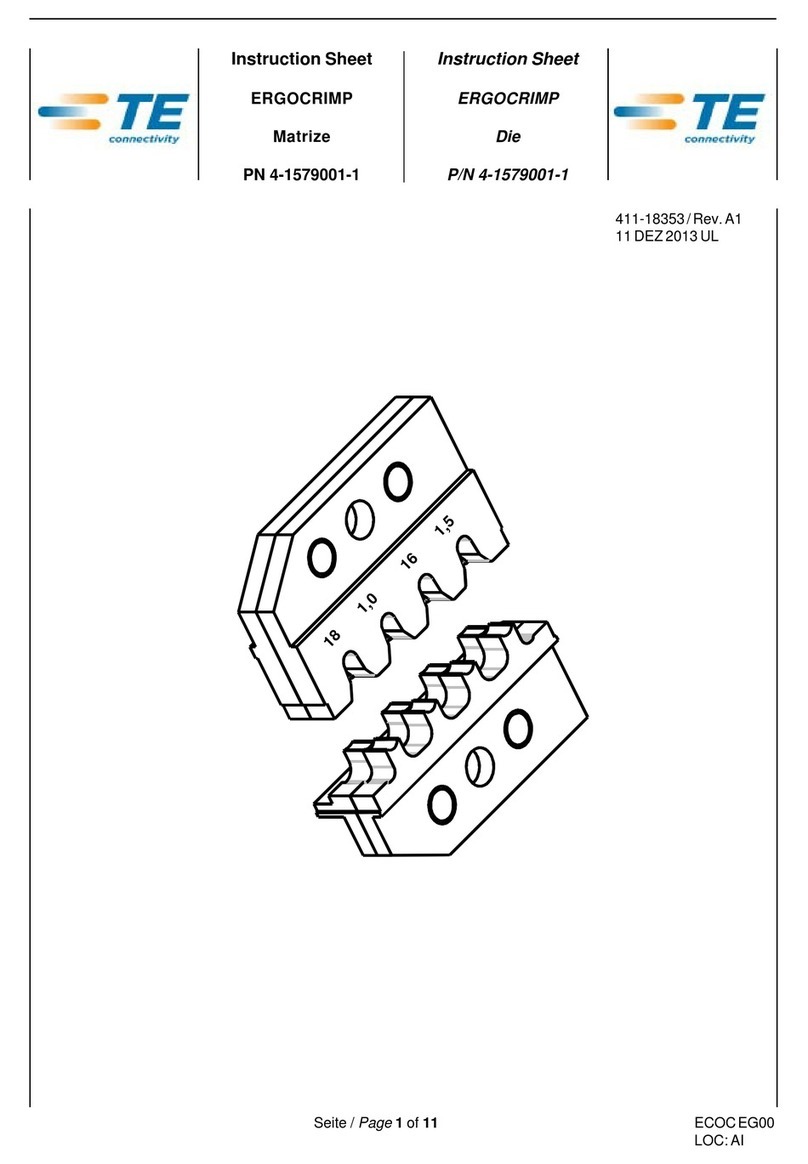

Popular Crimping Tools manuals by other brands

TE Connectivity

TE Connectivity ERGOCRIMP 4-1579001-1 instruction sheet

TOOLCRAFT

TOOLCRAFT 43 04 61 operating instructions

Greenlee

Greenlee GATOR EK628LX Operation manual

molex

molex AT-200 Operating and maintenance instructions

molex

molex 207128 Series Specification sheet

Deutsch

Deutsch DTT-16-03 instruction manual

HRS

HRS HT601/TM21P-88P operating instructions

Westward

Westward 13H894 Operating instructions and parts manual

Hilti

Hilti NPR 032 IE-A22 operating instructions

molex

molex 63816-1900 Operation manual

FRIEDHELM LOH

FRIEDHELM LOH Rittal L8 operating instructions

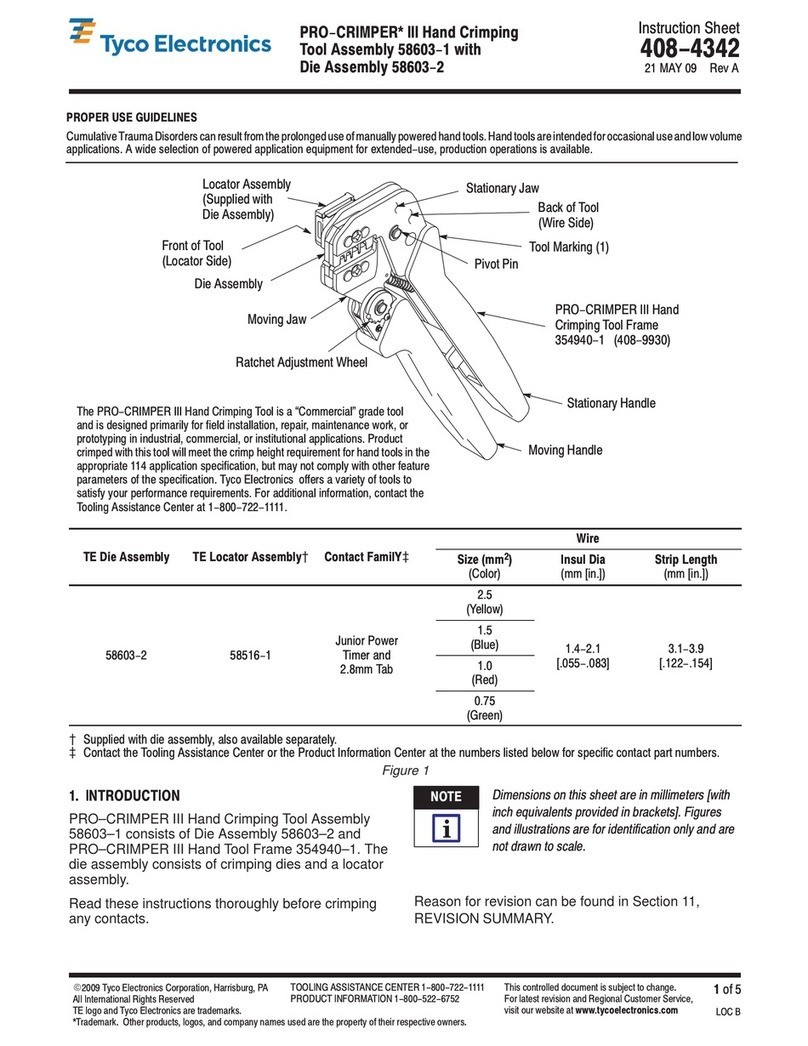

Tyco Electronics

Tyco Electronics PRO-CRIMPER III 58603-1 instruction sheet