3EATON ET5040 Operator´s Manual E-EQCR-TT002-E1 July 2015

Safety instructions

1. Prevent unauthorized

operation

Do not permit anyone

to operate this machine

unless they have read and

thoroughly understand

this manual. Failure

to follow operating

instructions could result

in injury or damage to the

equipment

2. This machine should

be operated by only 1

trained operator at any

time

3. Wear safety glasses

Risk of eye injury! Eye

protection required at

all times during the

installation, operation

and maintenance of this

machine.

4. Avoid pinch points

Stay clear of the crimp

ring, keep your hands

clear of all moving parts.

Do not allow anyone,

other than the operator,

to stand close to the

machine

5. Maintain dies with care

Dies used in the crimp

machine are hardened

steel, offering the best

combination of strength

and wear resistance for

long life. Hardened dies

are generally brittle and

care should be taken to

avoid any sharp impact.

Never strike a die with a

hardened instrument

6. Use only specified Eaton

products

Use only Eaton or Eaton

approved products.

7. Verify correct crimp

diameters

Check and verify correct

crimp diameters of all

fittings after crimping.

Do not put any hose

assemblies into service

if the crimp diameters

do not meet Eaton crimp

specifications

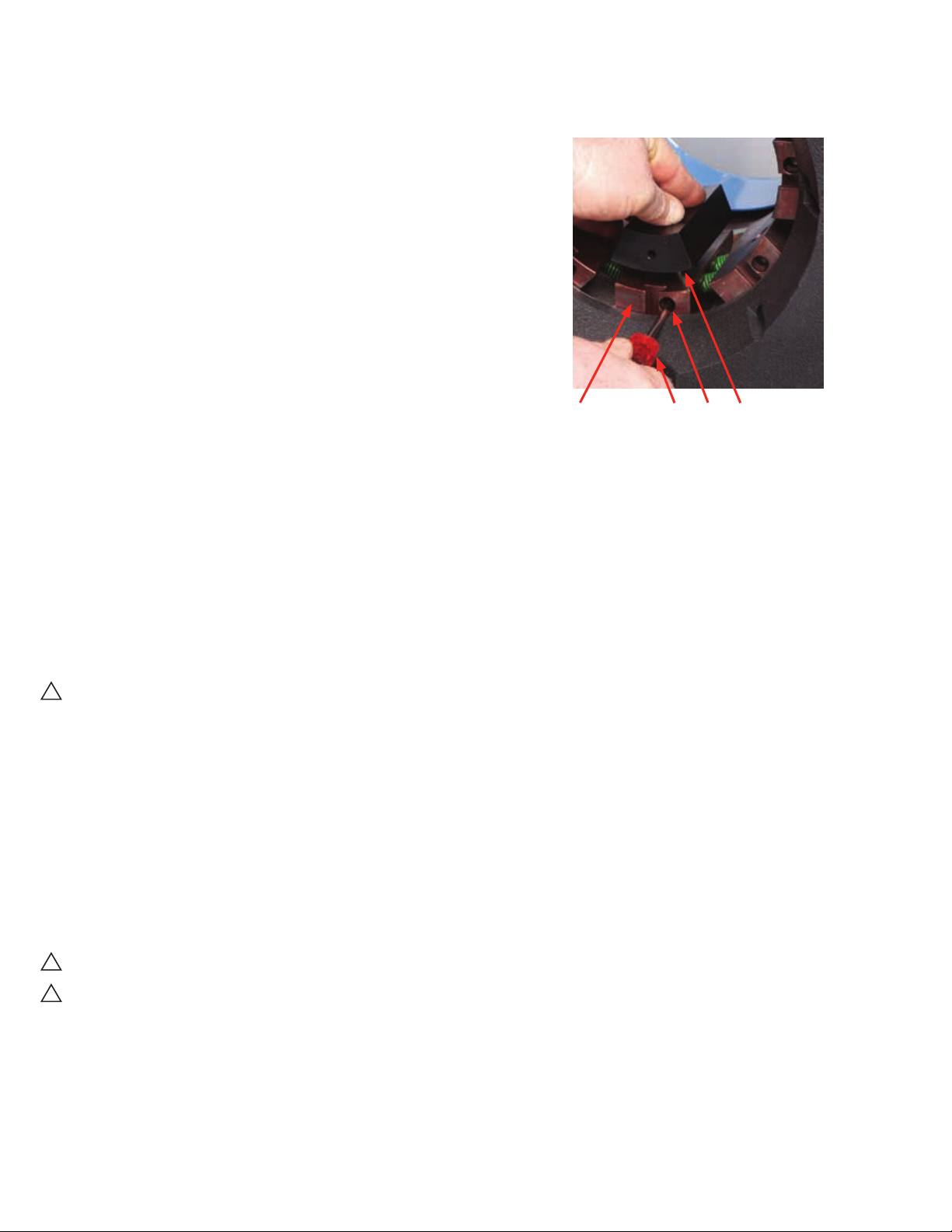

8. Die change

Follow prescribed

directions regarding

tooling change in the

manual

9. Keep work area clean

Cluttered areas and

benches invite accidents

10. Emergency stop button

The controller is provided

with an emergency stop

button. In case of an

emergency, actuate the

emergency button on the

front of the controller.

After the emergency

stop button has been

activated, the production

area is without function,

but all assemblies are still

energized. De-energize

the equipment via the

main switch

11. Never reach into crimp

tooling when power is on

Always make sure there is

adequate safety distance

of at least 4.75" (120mm)

to the crimp tooling during

the crimping process

12.Crimping with base dies

When crimping with base

dies only, the uncrimped

coupling diameter cannot

exceed crimp range

(6"/160m)

Read and understand the operator’s manual before attempting to operate this machine. Failure to follow operating instructions

could result in injury or damage to the equipment.

Failure to follow Eaton process and product instructions and

limitations could lead to premature hose assembly failures,

resulting in property damage, serious injury or death.

Eaton fitting tolerances are engineered to match Eaton

hose tolerances. The use of Eaton fittings on hose supplied

by other manufacturers and/or the use of Eaton hose with

fittings supplied by other manufacturers may result in the

production of unreliable and unsafe hose assemblies and

is neither recommended nor authorized by Eaton. Read

and understand the operator’s manual before attempting to

operate any equipment.

Eaton hereby disclaims any obligation or liability (including

incidental and consequential damages) arising from breach of

contract, warranty, or tort (under negligence or strict liability

theories) should Eaton hose, fittings or assembly

equipment be used with the hose, fittings or assembly

equipment supplied by another manufacturer, or in the event

that product instructions for each specified hose assembly

are not followed.

Please note that ET5040 is not a field serviceable machine.

For issues beyond the preventive maintenance described

below, customers are instructed to contact Eaton. Any

additions or modifications to the machine may affect the

operation of the machine, could result in injury or damage to

the machine, and will void Eaton warranty.

Warning

!