Deutsch DTT-16-03 User manual

INSTRUCTION MANUAL FOR

DTT-16-03

Date: August 11th, 2010

INFORMATION Drawing No: 0425-077-0000 Revision Letter: NC

Compagnie Deutsch GmbH

Fraunhoferstr. 11 b

D-82152 Martinsried Page 1 of 4

Sym Description of Revisions Date Approved

NC Initial Release per E.O. P 20540 8/11/2010 Robin Reed

Instruction Sheet: Field Maintenance Crimping Tool DTT-16-03

BEFORE using this hand tool, please take

time to read these instructions completely!

Basic Safety Instructions

This tool may be used only for the intended application and in strict compliance with all applicable safety

rules, regulations and practices. It must be properly maintained, undamaged and in good working order.

Unauthorized modification is prohibited and shall void the manufacturer’s warranty. Always wear safety

glasses with side shields and other appropriate personal protective equipment.

CAUTION: Misuse May Cause Personal Injury. Keep Out Of Reach Of Children!

Never Insert Fingers Between Any Moving Parts Of The Tool!

Applications

Hand tool DTT-16-03 has been developed for field crimping of Deutsch Industrial stamped and formed

contacts 1060-16-12** Pin, 1062-16-12** Socket and 1062-16-14** Sleeveless Socket per Table 1:

** Note: Surface plating of the contacts is characterized in the final 2 digits of the part number.

** Examples: 22 = Nickel Plate, 44 = Gold Plate, 77 = Tin Plate

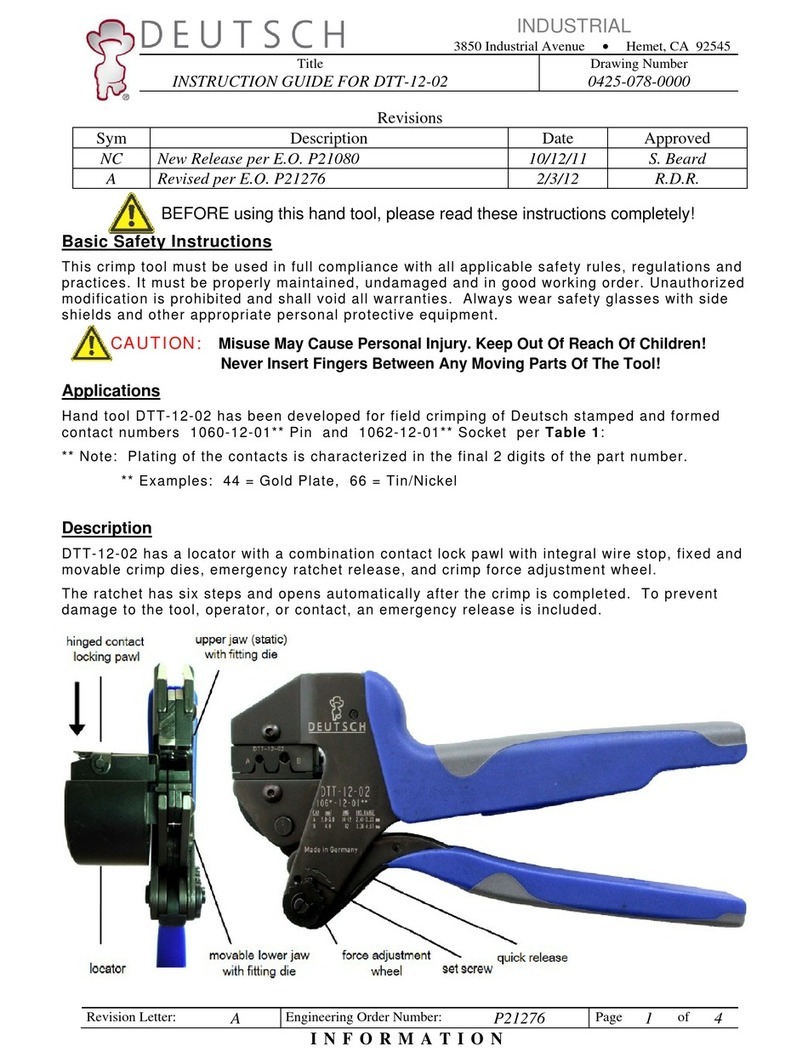

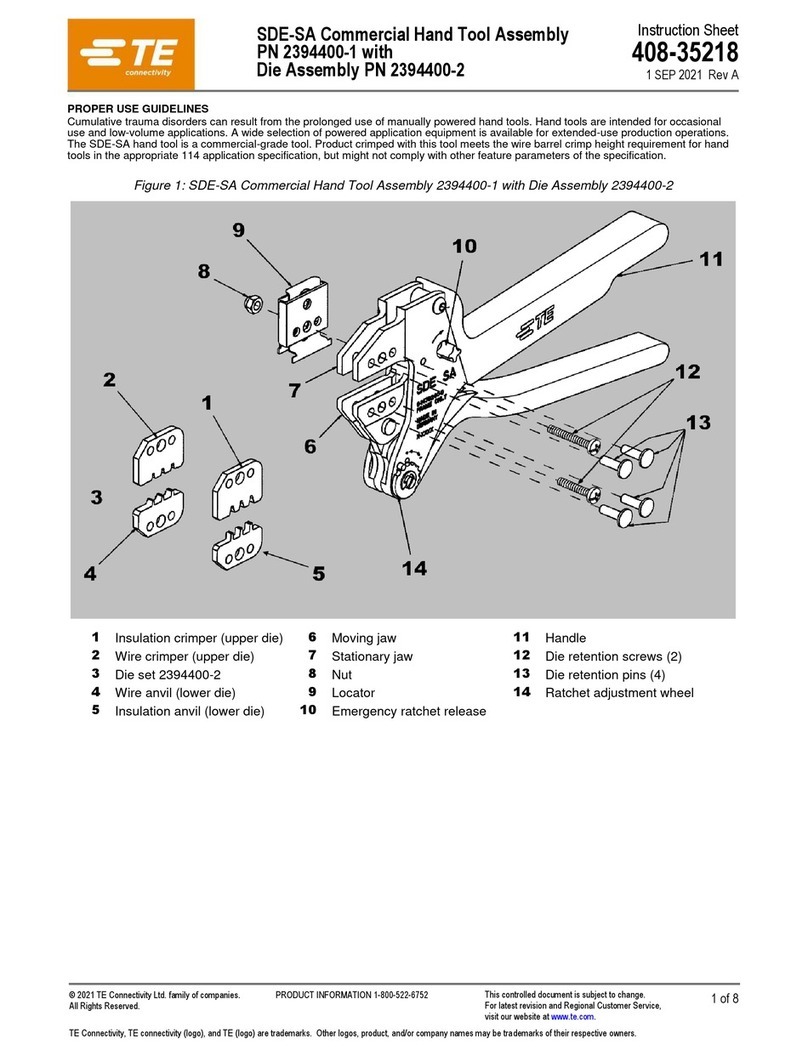

Description

Hand tool DTT-16-03 has a locator with a combination contact locking pawl with integral wire stop, fixed

and movable crimp dies, emergency ratchet release, and a crimp force adjustment wheel.

Crimping force can be adjusted (refer to “Hand Force Adjustment”). The ratchet has six steps and opens

automatically after the crimp is completed. To prevent damage to the crimping die or contact, the built-in

emergency release enables the tool to be opened prior to the full six step ratchet release.

emergency release

hinged contact upper jaw (static)

locking pawl with fitting die

force adjustment wheel set scre

w

INSTRUCTION MANUAL FOR

DTT-16-03

Date: August 11th, 2010

INFORMATION Drawing No: 0425-077-0000 Revision Letter: NC

Compagnie Deutsch GmbH

Fraunhoferstr. 11 b

D-82152 Martinsried Page 2 of 4

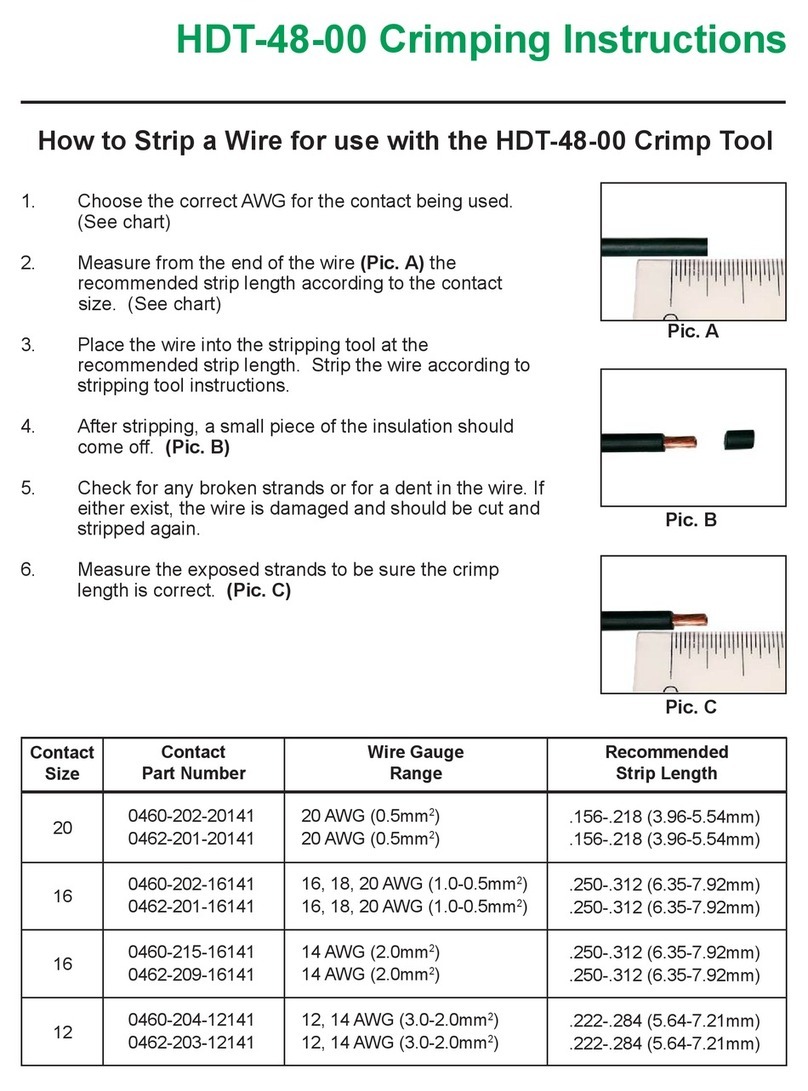

Wire preparation

Prior to crimping contacts, insulation must be stripped to a length of 5.08 ± 0.64mm. Wire should have

no insulation tearing or stretching and no conductor strands missing or damaged.

Hazard Warning

Contacts may have Sharp Edges. Use Finger Protection To Avoid Cuts. Do Not Place Fingers

In Tool Areas Which May Pinch During Crimp Cycle. Use Safety Glasses To Avoid Eye Injury.

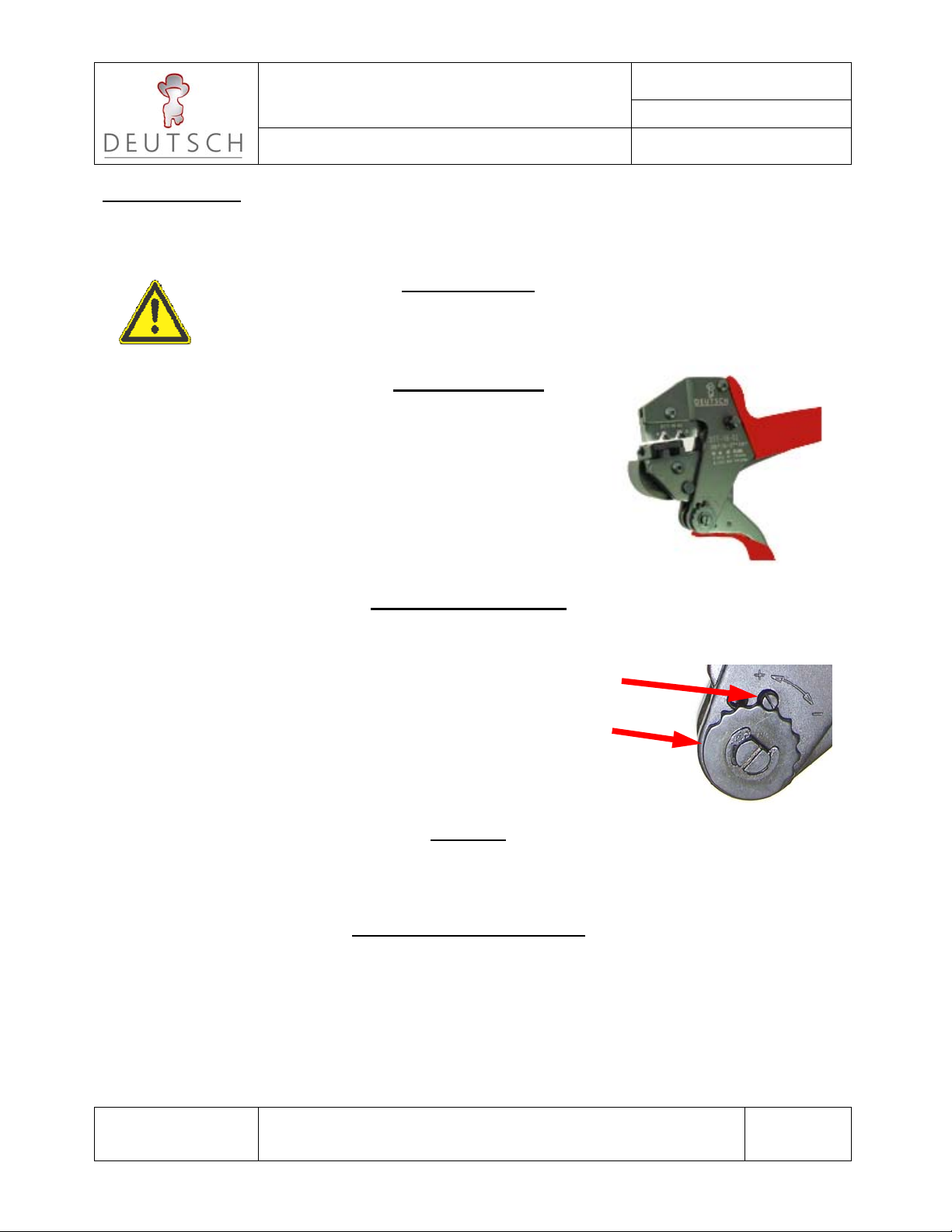

Hand-Crimp Cycle

(1) Close handles to release ratchet pawl (spring opens handles).

(2) Press the contact locking pawl to expose the locator cavities.

(3) Place the contact into the cavity indicated by Table 1.

(4) Release contact pawl and check alignment with crimp tool path.

(5) Insert the prepared wire up to the wire stop edge of locking pawl.

(6) Squeeze handles until ratchet releases (not completely closed).

(7) Fully open tool, press contact locking pawl, remove crimped contact.

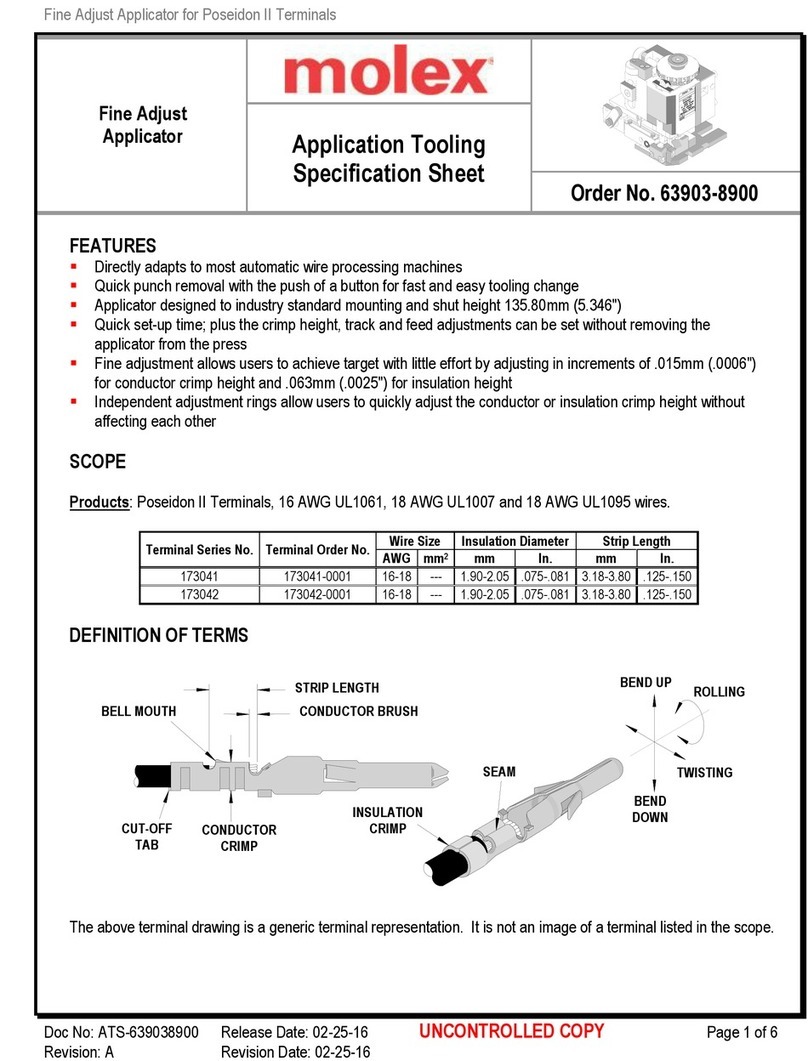

Hand Force Adjustment

Crimping Force of DTT-16-03 is factory set. Hand force idle travel is 130 N – 180 N. The tool and die

set are designed to provide optimum crimping within this range. However, if the setting is not ideal for

the contact specification, the tool can set as described below:

(1) Loosen the headless screw with a flat-blade screwdriver and set aside.

(2) Turn the adjustment wheel counter anticlockwise (+) to increase the

crimping force. (This also reduces the jaw spread).

(3) Turn the adjustment wheel clockwise (-) to reduce the strength of the

crimping force. (This also increases the jaw spread) Don’t exceed 180 N!

(4) After setting, replace the headless screw and adequately tighten.

Warranty

These tools are subject to thorough quality control measures before leaving the factory. The general

terms and conditions of warranty are available from Compagnie Deutsch GmbH.

Maintenance and Inspection

Maintenance and inspection should be performed after about 5,000 crimps (or every 6 months).

Before using the crimping tool make sure that it is in a clean and proper operating state. Remove any

crimping residue. Apply light machine oil to protect joints. Check bolts to ensure that the lock washers

are secure and intact. All other maintenance should be performed by the manufacturer. There are no

user-serviceable components inside the hand tool. Disassembly of the crimp tool shall void warranty.

Do NOT

close

handles

completely

INSTRUCTION MANUAL FOR

DTT-16-03

Date: August 11th, 2010

INFORMATION Drawing No: 0425-077-0000 Revision Letter: NC

Compagnie Deutsch GmbH

Fraunhoferstr. 11 b

D-82152 Martinsried Page 3 of 4

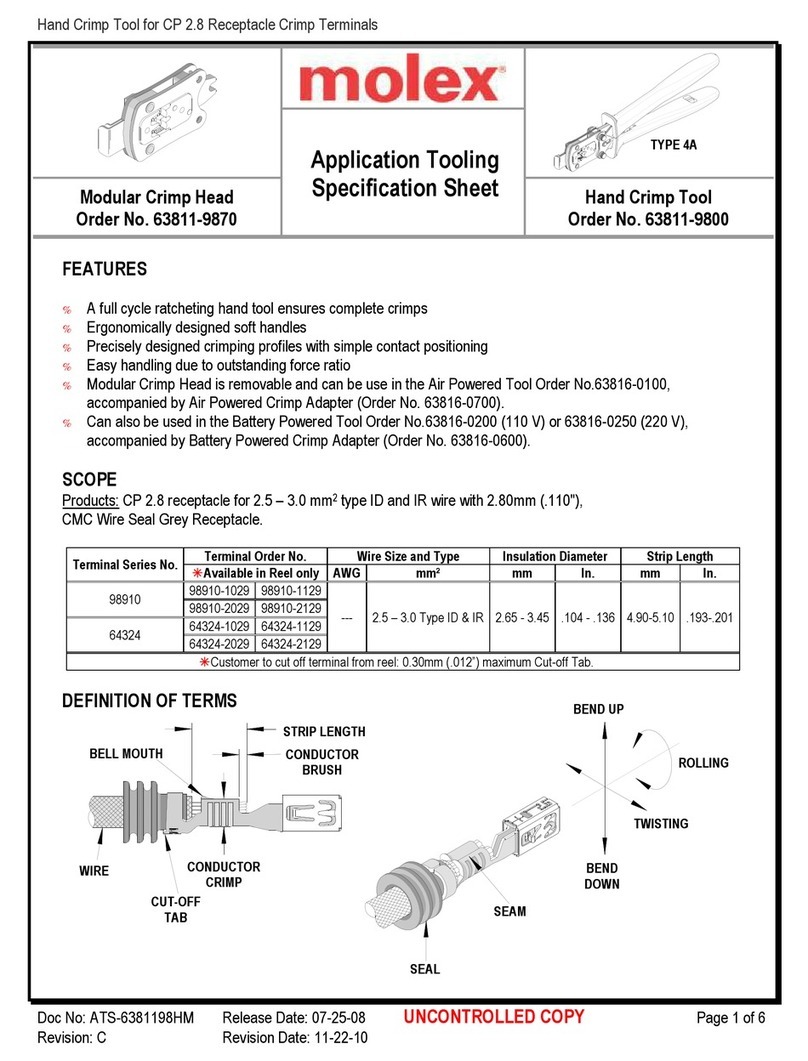

Recommended Cavity for wire Gauge and Insulation Types

Use Table 1 to insure best crimp results with DEUTSCH stamped and formed contacts of the types:

1060-16-12** PIN and 1062-16-12** SOCKET, or…..

1062-16-14** SLEEVELESS SOCKET (ref: 0425-039-0000 Information Drawing)

Table 1: Cavity, Wire size, and Insulation Types (note: Dimensions are in mm)

Stamped Contact

Part Numbers Nominal Insulation

Diameter Ranges Cavity

Rec. METRIC Wire

sizes Insulation Types

for AWG

1060-16-12** Pin

1062-16-12** Soc

1062-16-14** Soc

1.70 - 2.29 mm A 1.0 mm² 16 TXL

1.5 mm²

2.18 - 3.15 mm B 1.5 mm² 16 TXL, GXL

14 TXL, GXL

2.5 mm² 12 TXL

Dimensional Guide for Crimp Geometry development with Power-Press Applicator Dies*:

*Note: Hand-Tool crimps are NOT the same as Applicator Die crimps. Actual geometry will be

an approximation of the best-fit compromise within the 2-cavity tooling limitations,

and are significantly dependant on the tool OPERATOR skills and technique.

INSTRUCTION MANUAL FOR

DTT-16-03

Date: August 11th, 2010

INFORMATION Drawing No: 0425-077-0000 Revision Letter: NC

Compagnie Deutsch GmbH

Fraunhoferstr. 11 b

D-82152 Martinsried Page 4 of 4

REFERENCE Sizes in millimetres for sample crimps made per Table 1:

Table 2 Typical crimp dimensions (stop at ratchet-release)

Using conductor types per SAE J1128 and ISO 6722 (Metric)

Cavity

Wire

mm², AWG Insulation

Ø Nominal Conductor Insulation

Height Width Height Width

A

1.0 mm² 1.70 1.35-1.45 2.77 2.39-2.49 2.49-2.54

16 TXL 2.21 1.42-1.55 2.77-2.79 2.57-2.62 2.57-2.59

1.5 mm² 2.29 1.47-1.57 2.77 2.59-2.74 2.62-2.64

B

16 TXL 2.18 1.40-1.47 2.77 2.72-2.74 2.82-2.84

16 GXL 2.62 1.45-1.50 2.77 2.77-2.79 2.84-2.90

1.5 mm² 2.29 1.47-1.52 2.77-2.79 2.77-2.79 2.84

14 TXL 2.57 1.50-1.55 2.77-2.79 2.82 2.87-2.92

14 GXL 3.02 1.52-1.55 2.77-2.79 2.82-2.84 2.87-3.00

2.5 mm² 2.84 1.52- 1.57 2.79 2.84 2.92

12 TXL 3.15 1.60-1.70 2.79-2.84 2.92-2.97 3.07

Note: Check reference sizes after 5,000 crimps (or 6 months).

Visually inspect for loose hardware and broken or missing parts.

Measure conductor height with blade and point micrometer to prevent

false readings which might include crimp flash (burr).

Dimensions vary with different hand tools and operators. Closing handles

beyond ratchet release will reduce crimp height.

Table of contents

Other Deutsch Crimping Tools manuals

Popular Crimping Tools manuals by other brands

ABB

ABB T&B Tools TBM62CR-LI operating instructions

Milwaukee

Milwaukee M18 FORCE LOGIC 2977-20 Operator's manual

TECHMAFLEX

TECHMAFLEX PMC 32 user manual

Textron

Textron Greenlee RK1240 instruction manual

molex

molex 207129 Series Specification sheet

Tyco Electronics

Tyco Electronics 69156-1 instruction sheet