Contents

1About this documentation....................................................... 3

2General safety instructions...................................................... 4

2.1 Intended use.........................................................................................................4

2.2 The following is not permitted............................................................................4

2.3 Machine dangers..................................................................................................4

2.4 Operational hazards.............................................................................................4

2.5 Hazard sources.....................................................................................................4

2.6 Safety equipment.................................................................................................5

2.7 Warning signs at and on the machine or components......................................5

2.8 Residual risks........................................................................................................5

2.9 Safety measures at the installation site .............................................................5

2.10 Notes for the operating company.......................................................................5

2.11 Noise.....................................................................................................................6

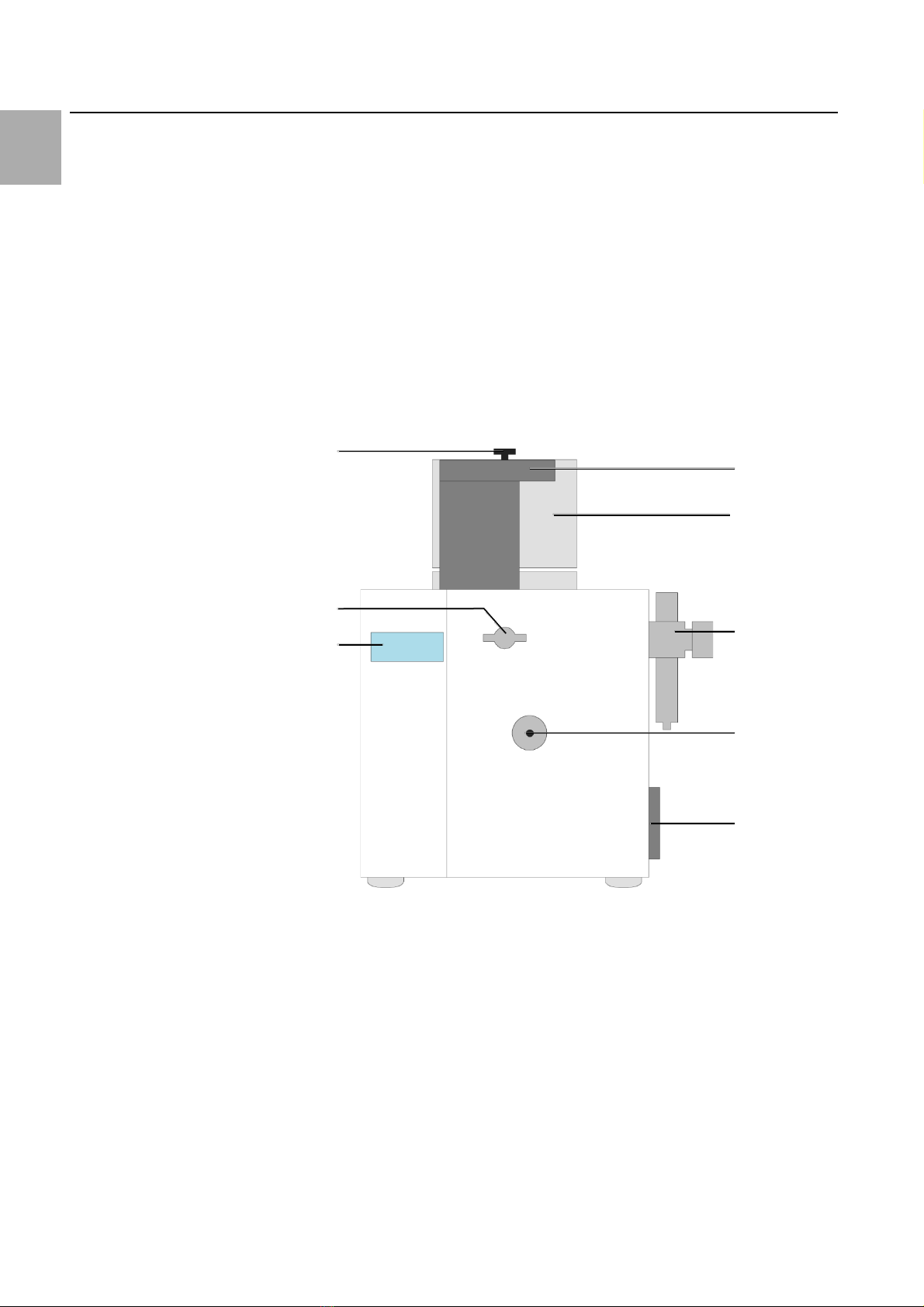

3Device description................................................................... 6

3.1 Overview...............................................................................................................6

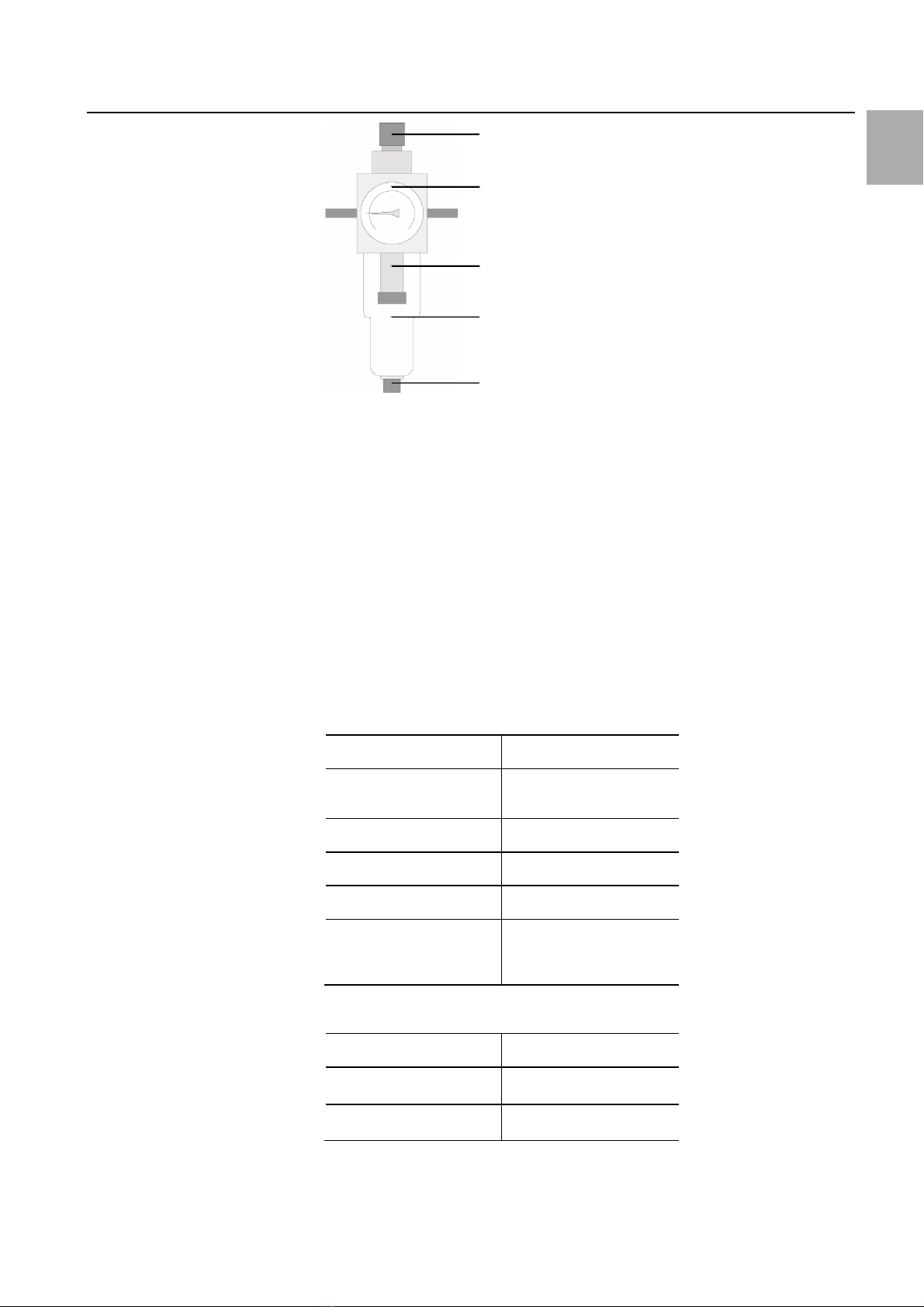

3.2 Technical data.......................................................................................................7

4Operating instructions............................................................. 8

4.1 Setting up the machine........................................................................................8

4.2 Switch on the machine ........................................................................................9

4.3 Menus...................................................................................................................9

4.4 Conductor insertion / conductor cutting..........................................................11

5Tools......................................................................................12

5.1 Ferrule feed........................................................................................................12

5.2 Triggering unit....................................................................................................13

5.3 Insulation stripping blade and cam...................................................................13

6Maintenance .........................................................................14

6.1 Maintenance notes............................................................................................14

6.2 Daily maintenance..............................................................................................14

6.3 Weekly maintenance .........................................................................................15

6.4 Monthly maintenance........................................................................................18

6.5 Quarterly maintenance......................................................................................21

6.6 When required...................................................................................................22

7Troubleshooting.....................................................................22

7.1 Machine does not start......................................................................................22

7.2 No start for inserted wire..................................................................................22

7.3 The wire is only stripped....................................................................................23

7.4 Large number of rejects.....................................................................................23

7.5 Error messages...................................................................................................23

8Pneumatic connection diagram ..............................................26

9Electrical connection diagram.................................................27

10 Spare parts ............................................................................28

11 Disposal.................................................................................28