Cincinnati Fan 33S Guide

1

Form: OMM-30-0811

Supersedes Form: OMM-30-709

Part No.: 01009

Installation, Saf ty, Op ration & Maint nanc Manual and Parts List for

Mod ls 33S, 50S, 75S, 100S, 150S, 200S and 300S Portabl Dust Coll ctors

NOTICE:

R ad this compl t manual b for att mpting to ass mbl ,

install, op rat , mov , insp ct or s rvic this Dust Coll ctor.

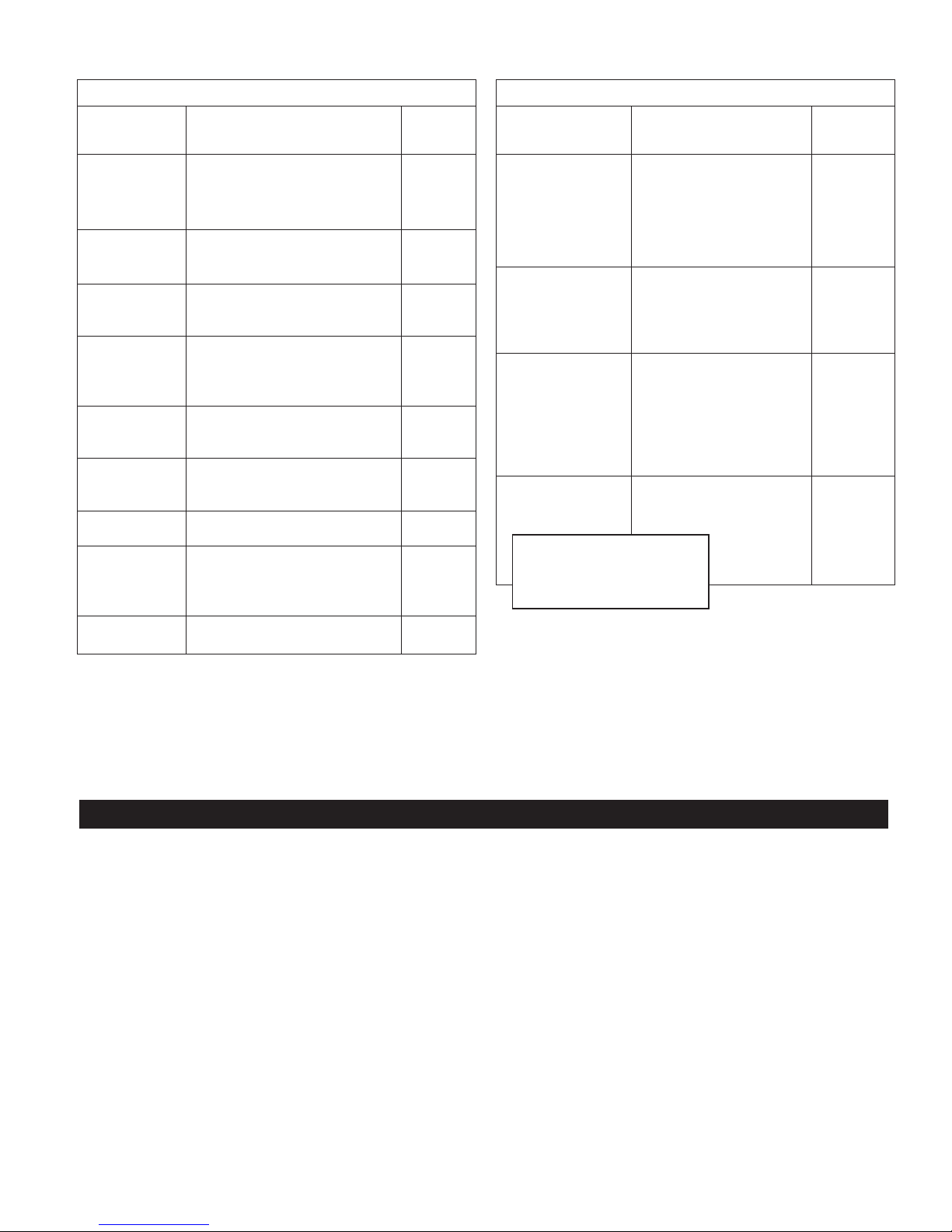

Inlet

Nozzle

Size

Approx.

Ship

Wt.

Inlet

Hose

Size

Blower

Wheel

Dia.

Max.

Drum

Dia.

Full Load Amps

4 x 4

5 x 5

5 x 5

6 x 6

7 x 7

7 x 7

7 x 7

Maximum CFM at 0” S.P. (clean drum, dust bag, with 5

feet of inlet hose and inlet nozzle).

Maximum additional static pressure (SP) at which point

there will be no air flow.

Minimum micron size at which standard dust bag will

capture 99%.

See Section V. INSTALLATION, Section A on page 6.

Starting amps are approximately 6-7 times the full load

amps. High voltage amps are 1/2 of low voltage amps.

Amp loads shown are approximate and will vary with

different motors and/or brands.

All dimensions above are nominal. For complete

dimensions, see page 15.

All Cincinnati Fan products are packaged to minimize any damage during s ipment. T e freig t carrier is responsi-

ble for delivering all items in t eir original condition as received from Cincinnati Fan. T e individual receiving t is

equipment is responsible for inspecting t is unit for any obvious or concealed damage. If any damage is found, it

s ould be noted on t e bill of lading before t e freig t is accepted and t e receiver must file a claim wit t e

freig t carrier.

ATTENTION: R c iving D partm nt

LONG TERM STORAGE NOTICE

If this dust coll ctor will NOT b install d and put into s rvic within 30 days, r f r to th “Long T rm

Storag Instructions” on pag 2. Failur to follow all applicabl long t rm storag instructions will void

your warranty. This dust coll ctor must b stor d indoors in a cl an, dry location.

Models

33S, 50S & 75S

Models

100S, 150S & 200S

Cans or Drums

ar not includ d

2

Dangers, Warnings and Cautions .......................................................................Page 3

I. Description............................................................................................................Page 4

II. Unpacking .............................................................................................................Page 4

III. General Safety Information..................................................................................Page 4

IV. Assembly

A. Models 33S, 50S and 75S................................................................................Page 4

B. Models 100S, 150S 200S and 300S ................................................................Page 4-5

C. Oversized Dust Bags ........................................................................................Page 5

“HB” Type Bags ....................................................................................Page 5-6

“DB” Type Bags ....................................................................................Page 6

V. Installation.............................................................................................................Page 6

A. Proper Cans, Drums and Unit Location............................................................Page 6

B. Exhaust Volumes Required for Different Applications ......................................Page 7

C. Duct Work Recommendations ..........................................................................Page 8

D. Electrical ...........................................................................................................Page 8

VI. Operation...............................................................................................................Page 8

VII. Maintenance..........................................................................................................Page 9

A. Motor.................................................................................................................Page 9

B. Blower Wheel and Steel Components ..............................................................Page 9

C. Cleaning the Blower Wheel...............................................................................Page 9

D. Replacing the Blower Wheel.............................................................................Page 9-10

E. Replacing the Motor..........................................................................................Page 10

F. Emptying the Can or Drum ...............................................................................Page 10

G. Emptying the Dust Bag.....................................................................................Page 10

H. Cleaning the Dust Bag......................................................................................Page 10-11

VIII. Troubleshooting....................................................................................................Page 11

IX. Exploded View Drawing & Parts List for Models 33S, 50S & 75S....................Page 12

X. Exploded View Drawing & Parts List

For Models 100S, 150S, 200S & 300S ...........................................................Page 13

XI. Exploded View Drawing & Parts List for Oversized Dust Bags .......................Page 14

XII. Dimensions and Performance Curves................................................................Page 15

XIII. Limited Warranty, Liability, Responsibility and Return Policy .........................Page 16

CONTENTS

ITEM ACTION DATE CHECKED

1 Re-inspect unit to insure any protective devices used are functioning properly.

Check for scratches in the finish which will allow corrosion or rust to form.

2 Rotate the blower wheel a minimum of ten (10) full revolutions to keep the

motor bearing grease from separating and drying out.

This step is critical.

Storage - Maintenance Schedule Log

NOTE: Failure to adhere to these instructions voids all warranties in their entirety.

1. Storage Site Selection:

a. Level, well drained, firm surface in clean, dry, location with a temperature range of 50°F (10°C) to 90°F (60°C).

b. Isolated from possibility of physical damage from construction vehicles, erection equipment, etc.

c. Accessible for periodic inspection and maintenance.

2. Carton should be supported under the entire bottom and open at the top allowing it to “breath”

3. If dust collector will be stored for more than three (3) months, the entire unit must be loosely covered with plastic.

4. Storage Maintenance:

A periodic inspection and maintenance log, by date and action taken, must be developed and maintained for each unit.

See example below. Each item must be checked monthly.

EXAMPLE:

Long Term Storage Instructions

BE SURE TO READ ALL DANGER, WARNING AND CAUTION NOTICES BELOW BEFORE PROCEEDING WITH

ANY INSTALLATION OR OPERATION OF THIS DUST COLLECTOR. MA E SURE YOU ARE IN COMPLIANCE

WITH ALL LOCAL, STATE, FEDERAL AND SAFETY GUIDELINES, REGULATIONS AND STANDARDS.

The National Fire Protection Association (NFPA) has

defined the following materials as “reactive metals”:

Aluminum, Magnesium, Tantalum, Titanium and

Zirconium.

Improper handling, machining, collection and disposal of

these materials can result in a severe explosion and/or fire

resulting in death, severe personal injury and extensive,

immediate and surrounding property damage. Consult the

NFPA for current standards. Review of your application

and future type of installation must be completed by

your local Fire Marshal or an Authorized Fire Department

Official prior to the installation of any equipment for this

purpose.

This Standard combines the following previous Standards

into one Standard: NFPA 480, NFPA 481, NFPA 482, NFPA

485 and NFPA 651. NFPA 484 was approved as an

American National Standard on July 19, 2002.

We have reviewed the latest NFPA Standard 484 for

“Combustible Metals, Metal Powders, and Metal Dusts, 2002

Edition” and we have determined:

Cincinnati Fan Dust Collectors A E NOT designed to

collect any ”reactive metal” material. They DO NOT meet

NFPA Standard 484.

According to the National Fire Protection Agency

(NFPA), this dust collector CANNOT be used to collect

any wood dust or chips AND metal dust or chips. It can

be used for either type of material, but not both.

Hot metal dust or chips from grinders can start a fire or

cause an explosion if mixed with wood dust or chips. Also,

this dust collector CANNOT be used with sanders or

abrasive planners that have mechanical material feeds.

For clarification, see “NFPA standard 664, NFPA Standard

for the Prevention of Fires and Explosions in Wood

Processing and Woodworking Facilities 2007 Edition” for the

proper design, installation, operation and maintenance of

dust collectors and dust collection systems.

There is a high speed blower wheel inside the blower hous-

ing and another one on top of the motor. Both can amputate

fingers or grab loose clothing or neckties. Always wear safety

glasses when operating this dust collector.

eep dust bag clean.

A clogged dust filter bag may prevent collection of harmful

dust. Read this manual for proper cleaning procedure.

Replace worn or damaged dust bag immediately. NEVER

operate this dust collector without a dust bag in place.

This dust collector is not designed to be used out doors

where it will be subjected to the elements. eep indoors or in

a covered area not subject to rain or snow.

This dust collector is not designed to collect fumes or pow-

ders less than 1 micron in size. This dust collector should

NEVER be used to collect ANY liquids.

The motor has a cooling fan and fan cover on top of the

motor. DO NOT place anything on top of the cooling fan

cover at any time. Doing so will cause the motor to overheat

and fail.

This dust collector, when fully assembled, will be top heavy.

It can be overturned if bumped or not placed on a clean, flat,

level surface.

DO NOT use this dust collector to collect ANY type of yard

waste, i.e. leaves, paper, mulch, berries, etc.

Read this entire manual.

This manual contains information you

need to insure your safety and satisfactory

operation of your dust collector.

Plastic drums should not be used as they will not support the

weight of the dust collector. DO NOT use any PVC pipe or

hose in any part of the duct system.

3

Hazardous voltage. High speed rotating Lock out / Tag out.

Can cause electrical equipment. To prevent any

shock and death. Can cause severe personal injury

personal injury. Never before performing

operate this equipment any inspection or

without all required service.

safety guards in place.

I. DESCRIPTION

This dust collector is designed to help maintain clean, safe

conditions around dust creating machines in workshops and

factories. The flexible hose, included with each unit can be

connected directly onto the dust creating machine.”

See page 7 for exhaust volumes required for different

applications.

This dust collector is not designed to be used in a system that

requires high static pressures. Avoid using any hose or duct

less than 3” in diameter. It will require much higher static

pressure and will restrict air flow.

DO NOT collect any material that could ignite any plastic

or cloth parts of this dust collector.

II. UNPAC ING

Carton must be in upright position before opening. Inspect for

any shipping damage and advise freight carrier immediately if

any damage is found. Check Parts List for any missing or

damaged parts.

III. GENERAL SAFETY INFORMATION

A. Follow all local, state and federal safety codes including

the National Electrical Code (NEC), the National Fire

Protection Agency (NFPA) standards, the Occupational

Safety and Health Act (OSHA) and the Environmental

Protection Act (EPA).

B. All electrical wiring should be performed only by

qualified personnel or a licensed electrician.

C. Make sure the power source conforms to the

requirements of the dust collector motor.

D. Exercise caution when the unit is in operation. There is a

high speed blower wheel inside the blower housing and

another one on the top of the motor. Both can amputate

fingers or grab loose clothing or neckties. Always wear

safety glasses when operating this dust collector.

IV. ASSEMBLY

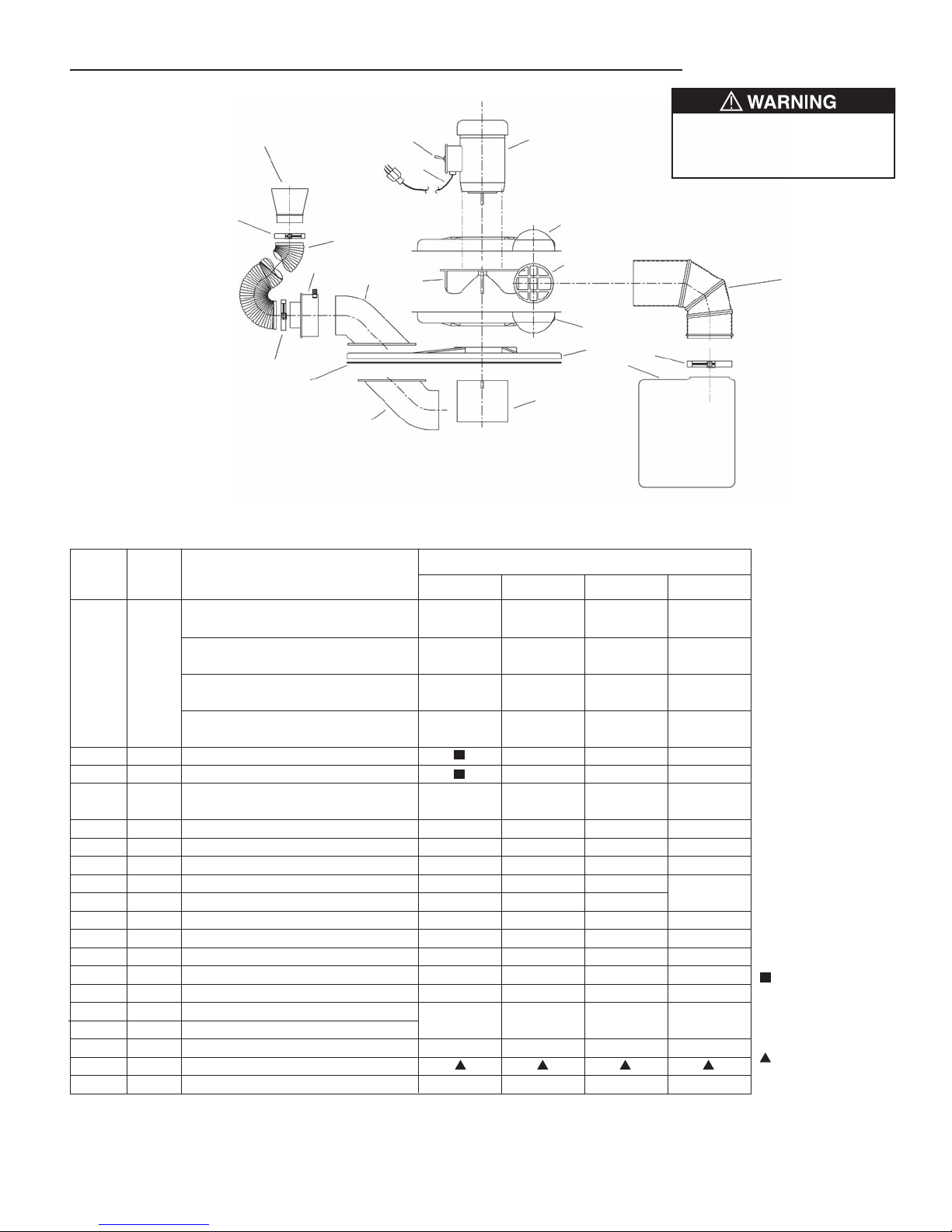

A. MODELS 33S, 50S and 75S (Refer to Figure 1 on

Page 12)

Assembly includes the installation of the air baffle, lid

gasket, discharge elbow, dust bag, hose and nozzle.

1. To install the air baffle and lid gasket, gently place

unit upside down on a cardboard covered flat area.

a. Attach the air baffle (17) as shown using the bolts

included.

b. Remove the paper protection from the sticky side

of the lid gasket (18). Install the gasket on the

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

All the assembly instructions on the following pages

are based on standard units as catalogued.

With all of the available accessories or options,

we cannot include every combination.

underside of the drum lid/inlet guard assembly (11)

so that the side of the gasket is against the lip of

the lid.

2. Carefully turn over the assembly so the motor is on

top and place it on top of a 30-35 gallon can or drum.

NOTE:

If you are installing the standard dust bag, (Models 33S, 50S

and 75S) continue with Step 3 below.

If you are installing an oversized dust bag, (Available on

Models 50S & 75S only) go to Section C on page 5.

3. a. The discharge elbow (8) has two 1/8” holes at one

end of the elbow. Slide the end with the two holes

over the discharge guard (5) on the blower housing.

Line up the two holes in the elbow with the two

holes in the guard. Install and tighten the 2 self

tapping screws included in the plastic bag of

hardware.

b. Slide the dust bag clamp (9) over the inlet collar of

the dust bag (10). Slide the dust bag collar over the

end of the discharge elbow (8). The dust bag inlet

collar should overlap the end of the bag elbow by

about 2”. The clamp should be centered in between

the two ends. Tighten the clamp with a screw driver

or nut driver.

c. Model 33S ONLY. (For models 50S & 75S, go to

Step e)

Mount 4” to 3” sheet metal inlet reducer (15) onto

inlet collar of drum lid (11). Tighten draw lug nut &

screw.

d. Slide hose clamp (13) over one end of hose (14)

and slide hose over inlet reducer (15). Tighten

clamp.

e. Model 50S & 75S:

Slide hose clamp (13) over one end of hose (14)

and slide hose over inlet collar of lid (11). Tighten

clamp.

f. Models 33S, 50S and 75S.

Slide hose clamp (13) over opposite end of hose

(14) and slide hose onto inlet nozzle (12). Tighten

clamp.

B. MODELS 100S, 150S, 200S and 300S (Refer to

Figure 2 on Page 13)

Assembly includes the installation of the inlet deflector,

intake cylinder, lid gasket, discharge bag elbow, dust bag,

hose and nozzle.

1. To install the intake cylinder, deflector elbow and lid

gasket, gently place the unit upside down on a

cardboard covered flat area. Two people should

perform this function.

a. To attach the inlet deflector (16B), remove the two

1/4-20 nuts and washers that hold the inlet elbow

(16A) onto the drum lid (11). Install the inlet

deflector (16B) over the same bolts that hold the

inlet elbow (16A). Reinstall the 1/4-20 nuts and

washers and tighten.

4

5

b. Attach the intake cylinder (19) with the four 1/4-20

bolts and lock washers that were supplied in the

hardware packet. The four bolts go through the four

mounting lugs on the intake cylinder and are

screwed into the 4 threaded inserts in the drum lid

(11).

c. Remove the paper protection from the sticky side of

the lid gasket (18). Install the gasket on the

underside of the drum lid (11) so that the side of

the gasket is against the lip of the lid.

2. Two people should turn over the assembly so the

motor is on top and place it on top of a 55-gallon can

or drum.

3. Attach inlet hose and nozzle.

Step 3 is for Model 100S ONLY. For Models 150S,

200S and 300S, go on to Step 4 below.

a. Mount the 6” to 5” metal reducer (15) onto the inlet

elbow (16A). Tighten the draw lug nut on the

reducer.

b. Slide hose clamp (13) over one end of hose (14)

and slide hose over inlet reducer (15). Tighten

clamp.

4. Slide hose clamp (13) over opposite end of hose (14)

and slide hose over inlet nozzle (12). Tighten clamp.

NOTE:

If you are installing the standard dust bag, (Models 100S,

150S and 200S) continue with Step 6 below.

If you are installing an oversized dust bag, (Available on

Models 100S, 150S and 200S) go to Step C below.

All Model 300S units require an oversized dust bag. Go to

Step C below.

6. a. The discharge elbow (8) has two 1/8” holes at one

end of the elbow. Slide the end with the two holes

over the discharge guard (5). Line up the two holes

in the elbow with the two holes in the guard. Install,

and tighten, the 2 self tapping screws included in

the plastic bag of hardware.

b. Slide the dust bag clamp (9) over the inlet collar of

the dust bag (10). Slide the dust bag collar over

the end of the bag elbow (8). The dust bag inlet

collar should overlap the end of the bag elbow by

about 2. The clamp should be centered in between

the two ends and above the rib of the bag elbow.

Tighten the clamp.

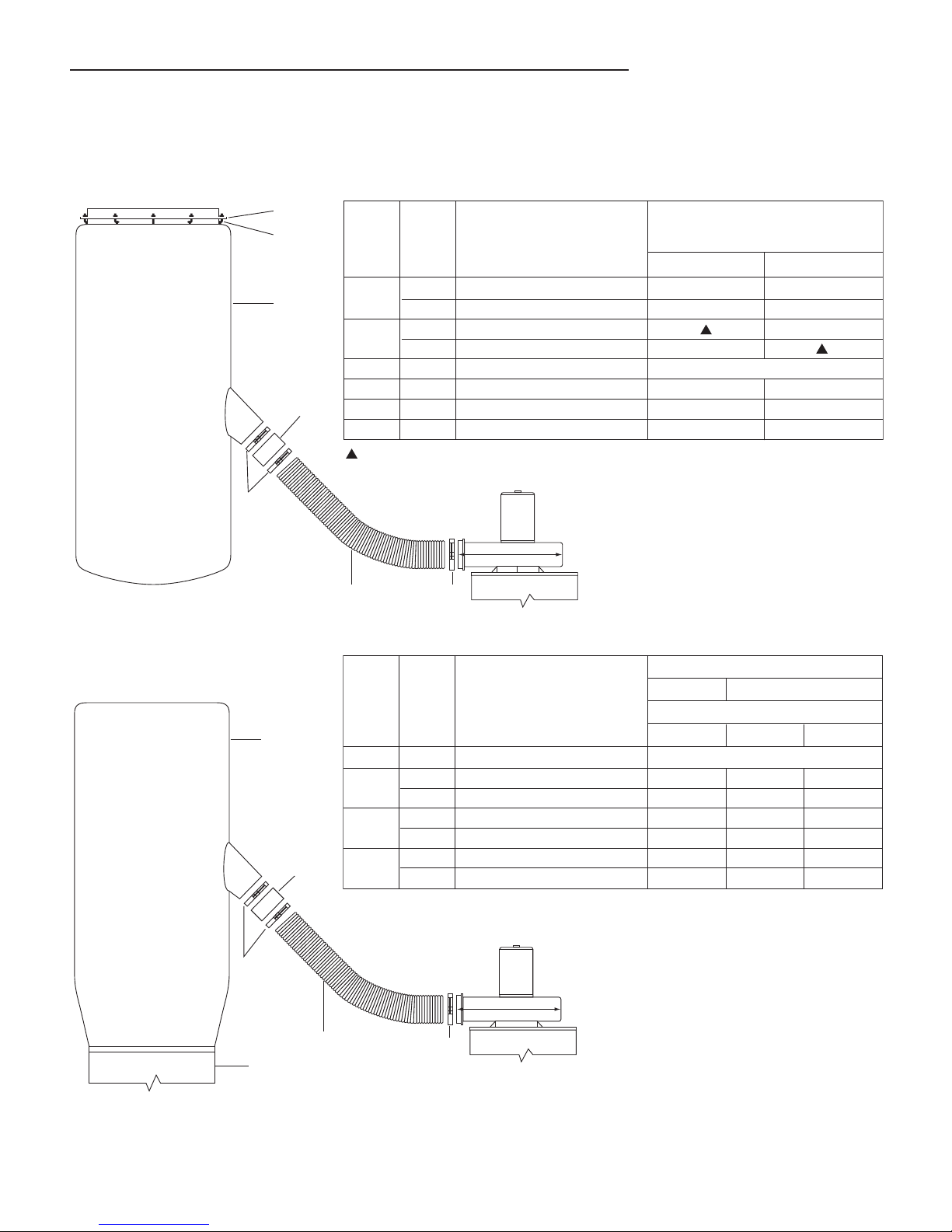

C. INSTALLING OVERSIZED DUST BAGS (Refer to

Figures 3 or 4 on page 14).

Steps 1a through 1d are for all Models 50S, 75S, 100S,

150S, 200S and 300S.

1. a. The discharge bag elbow (8) is not used. The

discharge bag elbow is never used on Model 300S.

b. Slide a hose clamp (4 or 9) onto both ends of the

dust bag connector hose (6 or 10).

c. Slide one end of the hose over the guard (5) on

the blower housing discharge. Tighten the hose

clamp.

d. Slide the hose connector (5or 8) into the other

end of the hose so that half of the connector

length is inside the hose. Tighten the hose clamp

around the hose and connector.

For “HB” Hanging Bags (Figure 3), proceed with Step

2. DO NOT use “HB” Bags on Models 50S & 75S.

For “DB” Drum Bags (Figure 4) proceed to Step 5 on

Page 6.

2. “HB” type Hanging Bags are only recommended

when there is not enough floor space for a second

55 gallon drum next to the dust collector. However,

they are more cumbersome to empty and require

emptying much more often. A “DB” type bag will be

much easier to empty and will not require being

emptied as often.

a. Assembly of the “J” hooks (2) onto the angle iron

ring (1).

Thread a 1/4-20 nut all the way onto a “J” hook.

Install a 1/4” flat washer. Put threaded end of the

“J” hook nut and washer assembly through a hole

in the angle iron ring. Install a second washer on

top of the ring hole. Install a second 1/4-20 nut

on top of the flat washer and tighten. Repeat

these steps for each “J” hook.

3. a. Slide a hose clamp (4) over the inlet collar in the

side of the HB dust bag (3).

b. Slide the inlet collar of the dust bag over the

exposed end of the hose/bag connector (5) that

you connected in Step C-1,d above.

c. Secure the dust bag collar to the hose connector

with the hose clamp.

4. This step will be performed much more safely

with two people on separate ladders.

a. Put one bag grommet over each “J” hook in the

ring/hook assembly.

b. Carefully start climbing the ladders while holding

onto the ring/bag/hose assembly.

c. Raise the ring/bag/hose assembly high enough

above the ground without putting to much tension

on the bag or the hose entering the side of the

bag. Also make sure the hose (6) is not “kinked”

at the discharge of the dust collector. This is the

proper height for the ring to hang off of the

ground.

d. Measure the distance from the ring to the ceiling

joist, rafter or truss.

e. Securely hang the ring from a ceiling joist, rafter

or truss with approved cable or chains.

f. The bag should be hanging so it doesn’t

touch the floor AND it doesn’t pull on the

dust collector discharge hose. See Figure 3

on page 14.

IV. ASSEMBLY (Continued)

The intake cylinder/guard (#19) in Step 1b below, MUST

be installed. Failure to install this part will GREATLY

reduce the airflow (CFM) of the dust collector.

NOTE

6

NOTE:

Never let an HB type hanging bag collect over 12” of dust or

chips in the bottom of the bag. When dust or chips reach a

depth of 12”, the bag must be emptied. If not, the weight of the

material inside the bag may cause the bag to tear from the

grommet straps at the top or at the zipper in the bottom.

See Dust Bag Cleaning Instructions on page 11.

For “DB” Drum Bags (Figure 4) proceed with Step 5.

5. The “DB” type Drum Mount dust bags come in

three sizes. Approximate dimensions are:

DB24x40 is 24” diameter x 36” high for models 50S

and 75S. Available in two fabric types.

DB24x80 is 24” diameter x 72” high for models

100S, 150S, 200S and 300S. Available in three

fabric types.

DB48x80 is 48” diameter x 72” high for models

100S, 150S, 200S and 300S. Available in three

fabric types.

a. You should have completed Steps C-1,a through

C-1,d on page 5.

b. Slide a hose clamp (9) over the inlet collar in the

side of the dust bag.

c. Slide the inlet collar of the dust bag (7) over the

exposed end of the hose connector (8) that you

installed in Step C-1,d on page 5. Secure the

dust bag collar to the hose connector by

tightening the hose clamp.

d. The “DB” type Drum Mount dust bag has an

outer and an inner sleeve in the bottom opening

of the bag. There is also a belt on the outside of

the bag. Loosen the belt as far as possible.

e. Roll back the outer sleeve and slide the inner

sleeve inside an open top 55 gallon drum. Now,

unroll the outer sleeve down over the outside of

the drum so that the bottom of the bag overlaps

the top of the drum by 4-6”. Tighten the belt as

tight as possible

NOTE:

If you will be collecting dust smaller than 10

microns, we recommend you remove the belt

from the bag and install a 55 gallon drum lid

clamp around the top of the drum. This will

provide a better seal between the drum and the

dust bag.

f. There is a single grommet in the top, center of

the bag. Connect one end of a rope or cable

through the eye of the grommet and connect the

other end to a rafter or truss in the ceiling. This is

only needed to hold the bag up when the dust

collector is turned off. Leave about 12” of slack

in the rope or cable.

V. INSTALLATION

A. Proper Cans, Drums and Unit Location

Models 33S, 50S and 75S should be mounted on top of a

25-30 gallon garbage can or a 30-35 gallon drum. The

garbage can or drum should have a diameter no less than

18” and not more than 20”. Do not use plastic cans or

drums. A fiber can or drum may be used if it has a fire

resistant foil liner and it can support the weight of the dust

collector.

Models 100S, 150S, 200S and 300S should be mounted

on top of a 55 gallon, roll-top, steel drum only. The drum

should have a diameter no less than 22” and not more than

24”. Do not use plastic or fiber drums. Place the

assembled dust collector as near as possible to the dust

generating source.

IV. ASSEMBLY (Continued)

(2) CFM's required are minimums per each equipment type. Duct

velocity should not be less than 3500 FPM to prevent wood dust

from settling in duct work.

(3) Requires 2 nozzles or hoods. CFM’s shown are total CFM for

both nozzles or hoods.

(4) For all metalworking applications, duct velocity should be at least

3500 FPM for light grinding or buffing and at least 4500 FPM for

heavy grinding or buffing to prevent settling in duct work.

(5) The wheel hood should cover at least 75% of the wheel to be

considered a good enclosure.

WOODWORKING METALWORKING

Equipment Size

Min. CFM

Required

(2) Equipment Size

Min. CFM

Required

(4)

Jointer Knife Length = Up to 6" 350

6+" to 12" 440

12+" to 20" 550

over 20" 800

Sander, Belt Belt Width = Up to 6" 790 (3)

(Horizontal) 6+" to 9" 900 (3)

9+" to 14" 1240 (3)

Sander, Disc Disc Diameter = Up to 12" 350

12+" to 18" 450

18+" to 26" 550

Sander, Drum Drum Surface = Up to 200 350

(in square inches) 201 to 400 550

401 to 700 785

701 to 1400 1100

Saw, Band Blade Width = Up to 2" 700 (3)

2+" to 3" 900 (3)

3+" to 4" 1350 (3)

Saw, Radial Hood behind blade = 430

From port on blade guard = 70

Total = 500

Saw, Swing Blade Diameter = Up to 20" 350

over 20" 440

Saw, Table Blade Diameter = Up to 16" 350

16+" to 24" 440

over 24" 550

Variety with dado = 550

Planer, Single Knife Length = Up to 20" 785

20+" to 26" 1100

Buffing, Belt Belt Width = Up to 3" 220

3+" to 5" 300

5+" to 7" 390

7+" to 9" 500

9+" to 11" 610

11+" to 13" 740

Buffing, Wheel Wheel Width = 2" 300

(5) 3" 500

4" 610

5" 740

6" 1040

Grinding Wheel Wheel Width = 1" 220

Wheel speeds (5) 1-1/2" 220

below 6500 sf/m 2" 390

3" 500

4" 610

5" 880

6" 1200

Grinding Wheel Wheel Width = 1" 220

Wheel speeds (5) 1-1/2" 390

above 6500 sf/m 2" 610

3" 740

4" 880

5" 1200

(1) The exhaust volume (CFM) requirements shown are “American

Conference of Governmental Industrial Hygienists (ACGIH®),

Industrial Ventilation: A Manual of Recommended Practices,

19th Edition. Copyright 1986. Reprinted with permission.”

Consult manual for more detailed recommendations. Contact

them at www.acgih.org.

How To Select The Proper Size Dust-Master Dust Collector

Although Cincinnati Fan Dust-Master dust collectors will give you

excellent results in collecting wood chips, fine dust and metal shavings,

they are not designed to work in large central system applications. These

are portable units that can be moved from machine to machine. To select

the proper size Dust-Master, use the criteria below:

1. Add the “CFM REQUIRED” for each machine per the above chart. This

is your TOTAL CFM REQUIRED.

2. Now, select the Dust-Master model from page 1 with a “Max. CFM”

greater than your TOTAL CFM REQUIRED in Step 1. If none of the

models on page 1 have a Max. CFM greater than your TOTAL CFM

required, you will need more than one unit.

3. If the unit will be in a “fixed installation” all ductwork should be sheet

metal duct instead of flexible hose. The pressure drop through flexible

hose can be 2-3 times that of smooth wall pipe. DO NOT use any PVC

or plastic pipe. It can deliver a severe static electric shock caused

by high velocity dust passing through it.

4. The Dust-Master should be located as close to the machine as possible

and preferably no more than 10 feet away.

5. Use as few elbows as possible in your ductwork. The loss through one,

90° elbow is equal to approximately 10 feet of straight, smooth wall pipe.

6. If the dust collector will be used for more than one machine, install slide

gate dampers in the duct at each machine to “close off” that section of

duct when using another machine. This will allow the dust collector to pull

from only one machine at a time and thus increase the dust collector

performance.

7. Typically, a Model 150S will work with up to 20 total feet of duct, a model

200S will work with up to 30 total feet of duct work and a 300S will work

with up to 75 total feet of duct. These values are based on having

dampers at each machine connection (as in note 6 above) and all duct

work is smooth wall, sheet metal.

Abbreviations used in charts:

CFM = Cubic feet of air per minute

FPM = Feet per minute

sf/m = Surface feet per minute

Also see Section C on Page 8.

7

B. Exhaust Volumes Required for Different Applications (1)

C. Duct Work Recommendations

The maximum CFM rating for each model dust collector

should be greater than the minimum required CFM as

listed in the Exhaust Volumes equired for Different

Applications chart on page 7.

If you will be connecting the dust collector into a piping

system for more than one machine, the dust collectors

maximum CFM should be greater than the minimum CFM

required for each machine in the system. If the piping

system will have slide gate dampers at each machine, with

only one machine operating at a time, then the dust

collector can handle more machines as long as the CFM

required does not exceed the maximum CFM of the dust

collector. As a rule of thumb, one dust collector can handle

multiple machines as follows:

Model 33S & 50S

..

One machine only.

Model 75S ...........Two machines if within 5 feet of each other.

Model 100S .........Two machines if within 10 feet of each other.

Model 150S .........Two machines if within 20 feet of each other.

Model 200S .........Up to 30 feet of 5” duct, and 3 machines.

Model 300S .........Up to 75 feet of 5” duct, and 3-4 machines.

NOTE:

The number of machines you can collect from will depend on

the CFM required per machine.

General Recommendations for Ductwork Systems:

1. The National Fire Protection Agency (NFPA) will no

longer permit a single dust collector to be used to

collect BOTH wood dust or chips AND metal dust or

chips because of the possibility of a fire and/or

explosion.

2. DO NOT use any PVC pipe or flexible hose for

duct work. This is no longer permitted by the

National Fire Protection Agency (NFPA). Dust

traveling through PVC pipe or hose can build up a

static electric charge.

3. Limit the use of flexible hose in any duct work to as

little as possible. The pressure drop (resistance)

through flex hose can be 2-3 times greater than

smooth wall sheet metal pipe.

4. If connecting a dust collector to more than one

machine, you should install slide gate dampers at

each machine so the dust collector is only pulling

from one machine at a time.

5. eep the number of duct elbows to a minimum. A

90° elbow has the same pressure drop (resistance)

as 10 feet of straight pipe.

6. Estimate 2 CFM reduction in air flow for each foot of

straight pipe and 20 CFM reduction for each 90°

elbow.

7. Pneumatic conveying of wood dust requires a

minimum air velocity of 3500 feet per minute (FPM)

in the duct or hose. For metal dust, the velocity can

be from 3500 FPM to 4500 FPM. Velocities less than

these will allow the dust to settle in the duct work or

hose. Therefore, the CFM must not be reduced

below these velocities.

8. Connect the dust collector inlet hose to the

connector port built into the dust producing machine.

If there is no port on the machine, place the inlet

hose and inlet nozzle as close as safely possible

where it will collect the most dust.

9. DO NOT use any duct or hose smaller than 3”.

D. Electrical

All electrical connections and wiring must be

performed by qualified personnel or a licensed

electrician. Models 33S, 50S, 75S and 100S, with single

phase, TEFC motors are pre-wired at the factory with a

cord, plug and switch to operate on a 115 Volt, 1 Phase, 60

Hertz power supply. These motors are also connected for

the proper blower wheel rotation.

All other motors must be wired by the user for the

operating voltage as stated on the motor nameplate and

wiring diagram. All wiring must be in accordance with

Underwriters Laboratories (UL) and the National

Electric Code (NEC). After all wiring is properly

completed, apply power to the motor for 1-2 seconds and

then turn it off. As the motor slows down, observe the

rotation of the motor cooling fan on top of the motor. The

proper rotation for all dust collector motors is Clockwise

(CW) when looking down on top of the motor. If the motor

is turning Counter-Clockwise (CCW), lock out the power to

the motor and then make the wiring changes per the motor

wiring diagram either on the motor nameplate or inside the

motor conduit box.

VI. OPERATION

The only operation steps that need to be monitored are

emptying the can or drum and the dust bag. The can or

drum should never be allowed to become over 1/3 full. The

bag should never be more than 1/4 full.

8

HAZARDOUS VOLTAGE CAN CAUSE ELECTRICAL

SHOC AND DEATH.

Always disconnect or lock out power to the motor and let

the wheel come to a complete stop BEFORE attempting

any inspection, service, maintenance or

moving of this dust collector.

HIGH SPEED ROTATING EQUIPMENT CAN CAUSE

SEVERE PERSONAL INJURY.

There is a high speed blower wheel inside the blower

housing and another one inside the fan cover on top of the

motor. Always disconnect or lock out power to the motor

and let the wheel come to a complete stop BEFORE

attempting any inspection, service, maintenance or moving

of this dust collector.

WEAR EYE PROTECTION.

Always wear eye protection when operating, servicing or

cleaning this dust collector with a high pressure air hose.

A. Motor

The bearings in the motor are lubricated and sealed for life so

they will not require any additional lubrication during the life of

the motor. eep the motor clean as excessive dirt may prevent

proper cooling of the motor. Use no more than 40 PSI air to

blow off excessive dirt.

B. Blower Wheel and Steel Components

The cast aluminum wheel and steel components are generally

maintenance free during the life of the unit. It is possible that

very fine, sticky dust particles can build up on the blades and

back plate of the blower wheel. When the unit is lifted off of the

can or drum for emptying of the can or drum, you should also

inspect the blower wheel for any material buildup. Using a

flashlight, look into the blower inlet underneath the lid. Any

material that has built up on the wheel must be removed to

prevent the wheel from an imbalance situation that could

cause a premature motor bearing failure and/or dangerous

wheel failure. For proper cleaning instructions, see the

following section.

C. Cleaning the Blower Wheel

This operation is best performed with the dust

collector sitting on top of the can or drum.

1. Lock out and disconnect power to the motor.

2. Disconnect the discharge bag elbow (8) from the

blower housing discharge. On units with oversized

dust bags, disconnect the flex hose from the blower

discharge.

3. There are two pop rivets that connect the discharge

guard (5) to the top section of the blower housing

discharge (4). These pop rivets should be drilled out

with a 3/16” drill bit.

4. Using a 7/16“ socket and wrench, loosen and

remove all the 1/4-20 nuts & bolts holding the two

housing halves (4and 7) together around the blower

housing flange.

5. After removing all the nuts and bolts, use a screw

driver or pry bar to carefully break the sealant in

between the two housing halves.

6. After the sealant is loosened, lift the motor side

housing (4) and motor assembly off of the inlet side

housing (7).

7. Set the blower housing/wheel/motor assembly on a

work bench resting on the side of the motor.

8. If possible, clean the blower wheel (6) with a wire

brush while the wheel is still on the motor shaft. Use

an air hose to blow off the wheel when finished. If it

is not possible to clean the wheel while on the motor

shaft, see Section D. eplacing The Blower

Wheel below.

9. If cleaning the blower wheel while on the motor shaft

was successful, use a putty knife to clean the

excess sealant caulk off of the flanges of both

blower housing halves (4and 7).

10. Apply a fresh bead of silicone sealant to the housing

flange on the blower housing inlet side (7).

11. Carefully reset the blower housing motor side (4) on

top of the blower housing inlet side (7) so that the

outside of the flanges and the discharges line up.

12. Reverse Steps 5 through 1, at left, to complete

reassembly.

D. Replacing the Blower Wheel

This operation is best performed with the dust

collector sitting on top of the can or drum.

1. First complete Steps 1 through 7 for Step C.

Cleaning the Blower Wheel, at left.

2. Now, follow the following steps to replace the blower

wheel.

3. Measure the distance from the front of the wheel

hub to the end of the motor shaft. eep this

dimension.

4. There are two set screws in the blower wheel. Using

a 5/32” Allen wrench, remove the two set screws

from the wheel hub.

5. Using two pry bars, place the pry bars behind the

back plate of the wheel so that the pry bars are

located behind two opposite wheel blades. This will

give you the most leverage. Pry the wheel off of the

motor shaft being careful not to damage or distort

the blower housing.

6. After removing the wheel, clean it thoroughly with a

wire brush if you will be reusing it.

7. If the wheel is eroded, DO NOT reuse it. It will be

out of balance and will damage the motor bearings.

8. If you can reuse the wheel, you MUST replace the

set screws in the wheel hub. Set screws can never

VII. MAINTENANCE

9

be used more than once. Replace them with 5/16-

18 set screws with a knurled head and a nylon

locking patch on the side of the screw.

9. File any burrs on the motor shaft from the previous

set screws and dress up the keyway in the motor

shaft with a file.

10. Using a rubber or raw hide hammer, reinstall the

present wheel or install a new wheel onto the motor

shaft. Locate the wheel hub on the motor shaft to the

same dimension you took in Step 3 on page 9.

DO NOT use a steel hammer. It can damage the

wheel and/or the motor bearings.

11. Line up the keyway in the motor shaft with the keyway

in the wheel hub.

12. Install a new 3/16” square shaft key into the keyway.

The key should be no longer than 1-1/2”. The key

should be positioned so it is flush with the end of the

wheel hub.

13. Spin the wheel by hand to make sure it is not rubbing

against the motor side of the blower housing.

14. Tighten the set screw over the shaft key first. Then

tighten the set screw onto the motor shaft. Both

screws should be tightened to 165 inch pounds.

15. Use a putty knife to clean the excess sealant caulk off

of the flanges on both blower housing halves.

16. Apply a fresh bead of silicone sealant to the housing

flange on the blower housing inlet side (7).

17. Carefully reset the blower housing motor side (4) on

top of the blower housing inlet side (7) so that the

outside of the flanges and the discharges line up.

18. Look into the discharge to make sure the blower

wheel is not touching the inlet side of the blower

housing.

19. Reverse Steps 5 through 1, on page 9 to complete

reassembly.

E. Replacing the Motor

Before you attempt to replace the motor, make sure you have

the correct replacement motor in your possession. All dust

collector motors have the following characteristics:

a. All Models 33S through 200S have a 56C frame

with a C-Face mounting and a 5/8” shaft.

b. Model 300S has a 145TC frame with a C-Face

mounting and a 7/8” shaft.

c. All motors used in the U.S.A. and Canada are

3450 RPM.

d. All motors are Totally Enclosed (TEFC) or

Explosion Proof (EXP). NEVER replace an EXP

motor with a TEFC motor.

e. The motor horsepower (HP) should match the HP

of the motor you are replacing

f. Make sure the new motor matches the operating

voltage, phase and hertz of the old motor.

To replace the motor, follow Steps 1 through 8.

This operation is best performed with the dust collector

sitting on top of the can or drum.

1. First complete Steps 1 through 7 for Cleaning the

Blower Wheel, on page 9.

2. Now, complete Steps 3 through 8 for Replacing the

Blower Wheel, on page 9-10.

3. Before removing the motor, notice the location of the

motor conduit box with relation to the blower

housing.

4. With a 9/16” socket wrench, remove the four 3/8-

16UNC bolts that hold the motor onto the motor side

blower housing (4).

5. Remove the old motor.

6. Install the new motor onto the blower housing with

the conduit box in the same orientation as noticed in

Step 3 above.

7. Replace or reinstall the four motor bolts and lock

washers through the blower housing and into the

four holes in the motor C-Face. Thread all bolts by

hand and then tighten them with the socket wrench.

8. Follow Steps 10 through 19 for Replacing the

Blower Wheel, at left, to complete the reassembly

of the dust collector.

F. Emptying the Can or Drum

NEVE ATTEMPT TO EMPTY A CAN O

D UM WHILE THE UNIT IS OPE ATING.

Empty the dust collector can or drum when it becomes 1/3

full. If the can or drum becomes too full, it will reduce the

suction of the dust collector.

G. Emptying the Dust Bag

NEVE ATTEMPT TO EMPTY A DUST

BAG WHILE THE UNIT IS OPE ATING.

If you are collecting heavier chips, they will settle in the

can or drum. Finer, lighter dust will go on into the dust bag.

Therefore, the dust bag must also be emptied. The

National Fire Protection Association (NFPA) states in their

Standard 664, that wood dust in dust bags MUST be

emptied “every day or less if warranted.” They should

then be checked for holes, rips or loose seams that could

leak. Emptying of the dust bag should only be performed

by trained personnel wearing the proper clothing and the

proper respiration equipment. How often you should empty

the dust bag is really a judgment call. It will vary with the

weight of the material you are collecting. No matter what

you are collecting, NEVER let the bag get more than 1/4

full. The major cause of having to replace dust bags is

due to ripping because of too much weight in the

bottom of the bag.

H. Cleaning the Dust Bag

NEVE ATTEMPT TO OPE ATE A DUST COLLECTO

WITHOUT THE DUST BAG IN PLACE.

WARNING:

If dust collector has been used to collect ANY materials

included in the following list, it should NOT be cleaned. The

dust bag must be disposed of using approved methods and

procedures as adopted by the proper regulatory agency or

agencies.

A. Any carcinogenic or biological materials.

B. Any flammable materials.

C. Any explosive materials.

D. Any water reactive materials.

E. Any nuclear materials.

10

F. Any materials with cleaning instructions that are in

contradiction with the following cleaning instructions.

G. Any materials considered to be unsafe if they come

in contact with the body.

Cleaning Instructions

Acrylic Coated Polyester Felt, Teflon® Coated Polyester

Felt or Nomex® Felt Dust Bags:

Because of the special coatings that have been applied to

these materials, we do not recommend that these bag types be

cleaned. They should be replaced when necessary or at least

annually.

Cotton Sateen & nit Polyester Dust Bags:

1. Inspect dust bag for holes. If any holes are found the

bag must be replaced.

2. Unzip any zipper in the bag.

3. Turn bag inside out.

11

4. Shake bag well to dislodge any material sticking to

the pores of the bag.

5. Lay bag flat on table or floor.

6. Vacuum bag on both sides.

7. Put bag in washer.

8. Set washer for Gentle cycle.

9. Set water temperatures to COLD for wash and rinse

cycles.

10. Add 1/4 cup of Woolite® detergent.

11. After washing is completed, hang bag on line to dry.

DO NOT put in dryer.

12. After bag has dried, turn it right side in.

13. Do not use dust bag until it has thoroughly dried.

NOTICE: Overwashing, harsh detergents and/or drying too

fast will cause bag to shrink and the inlet collar might

become too small to fit back onto the unit. Shrinkage is a

non-warranty claim. Dust bags can typically only be

washed one time.

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

VIII. Troubleshooting Chart

1. Improper electrical connection.

2. Defective fuse or circuit breaker.

3. Loose wiring connections.

4. Power turned off elsewhere.

5. Defective motor.

1. Voltage supplied to motor too high

or too low.

2. Improper electrical connection.

3. Dust bag and/or hose not in place.

1. Wheel rubbing inside of housing.

2. Worn or eroded blower wheel.

3. Accumulation of material on wheel.

4. Worn motor bearings.

1. Incorrect blower rotation.

2. Suction hose too long.

3. Dust bag dirty

1. Turn OFF and lock out power to the motor. Check

wiring to make sure it conforms to wiring diagram for

the motor for the operating voltage.

2. Check and replace any defective or blown fuse or

circuit breaker. DO NOT oversize for the circuit.

3. Check for loose wiring connections.

4. Check for other power control locations.

5.`Have motor checked at authorized motor repair shop.

NOTE: A normal motor will operate at 174° F.

1. Turn OFF and lock out power to the motor. Check

actual incoming voltage to motor.

2. Turn OFF and lock out power to the motor. Check

wiring to make sure it conforms to wiring diagram for

the motor for the operating voltage.

3. Must have dust bag and 5 foot hose minimum.

1. Turn OFF and lock out power to the motor. Check

wheel location inside housing. If rubbing, see Section

VII-D on pages 9 and 10.

2. Turn OFF and lock out power to the motor. Check

wheel. Clean or replace if necessary.

3. Turn OFF and lock out power to the motor. Check

wheel. Clean or replace if necessary.

4. Replace motor. See Section VII-E on page 10.

1. MOST COMMON CAUSE

Turn unit OFF and observe the rotation of the motor

cooling fan on top of the motor. It must be turning

Clockwise (CW). If it is turning Counter Clockwise

(CCW), reconnect the motor wiring leads for CW

rotation. See motor wiring diagram.

2. Place unit closer to dust source and shorten hose.

3. DO NOT remove dust bag while unit is operating.

Turn OFF power to the motor. Remove dust bag and

clean or replace it per the instruction in Section H on

pages 10 and 11.

Unit will not operate.

Motor overheating.

Excessive noise.

Low suction.

12

11

9

6

5

8

3

18

17

15

21

4

14

7

12

10

13

13

Ref.

No.

Qty./

unit Description

Part Number for Model

Standard Replacement Parts List for Models 33S, 50S and 75S

33S 50S 75S

NOTES

(1) Includes 8 foot cord,

switch and 3 prong

grounded plug for use

on 115Volt, 1 Phase,

60 Hertz power

supply only.

(2) Price includes both

sides of stamped

steel blower housing

with an ABS

discharge guard. This

is only sold as an

assembly for liability

reasons. Only the

discharge guard (5)

can be purchased

separately.

Must be purchased

from the local motor

manufacturers repair

shop for the motor

brand on your unit.

Standard hardware

store item. Purchase

locally.

Motor, 1 Phase, 115/230 Volt, 37753 37754 372193

60 Hz., 56C, TEFC (1) (1) (1)

Motor, 3 Phase, 230/460 Volt, 371126 37154 37207

60 Hz., 56C, TEFC

1 1 Motor, 1 Phase, 115/230 Volt, N/A 37152 372009

60 Hz., 56C, EXP

Motor, 3 Phase, 230/460 Volt, N/A 371679 372169

60 Hz., 56C, EXP

2 1 Switch, 115 Volt, TEFC only

3 1 Cord & Plug, 115 Volt, 60 Hz. only

4, 5 & 7 1 Blower Housing & Guard Assy. 34025DC 34025DC 34025DC

See note 2 at right

5 1 Discharge Guard (only) 29330 29330 29330

6 1 Blower Wheel 5500102 5500402 5530602

8 1 Discharge Elbow 51269 51269 51269

9 1 Dust Bag Clamp 31379 31379 31379

10 1 Dust Bag 25035 25035 25035

11 1 Drum Lid & Inlet Guard Assy. 12062 12062 12062

12 1 Inlet Nozzle, Square 51014 51015 51015

13 2 Nozzle & Hose Clamp 31013 31379 31379

14 1 Hose, Inlet, 60"" long 31623PP 31624PP 31624PP

15 1 Inlet Reducer 51048 — —

16 1 Does not apply to these models — — —

17 1 Air Baffle 51078 51078 51078

18 1 Lid Gasket

Part numbers 5, 8, 9 and 10

must be in place at all times

during operation.

IX. Exploded View Drawing Parts List for Models 33S, 50S and 75S

Fig. 1

13

13

13

11

14

8

2

4

9

19

10

18

6

7

5

16A

15

16B

1

3

12

Ref.

No.

Qty.

Unit Description

Part Number for Model

Standard Replacement Parts List for Models 100S, 150S, 200S and 300S

100S 150S 200S 300S (1)

NOTES

(1) Model 300S always

requires an oversized

dust bag. See page 14

for the oversized bags

and bag connector

parts.

(2) Includes 8 foot cord,

switch and 3 prong

grounded plug for use

on 115Volt, 1 Phase,

60 Hertz power supply

only.

(3) This motor is a 145TC

frame All other motors

are 56C frame.

(4) Price includes both

sides of stamped steel

blower housing with an

ABS discharge guard.

This is only sold as a

complete assembly for

liability reasons. Only

the discharge guard

(5) can be purchased

separately.

Must be purchased

from the local motor

manufacturers repair

shop for the motor

brand on your unit.

Standard hardware

store item. Purchase

locally.

Motor, 1 Phase, 115/230 Volt, 37755 373175 373677 N/A

60 Hz., 56C, TEFC (2)

Motor, 3 Phase, 230/460 Volt, 37254 37304 37353 374155

60 Hz., 56C, TEFC (3)

1 1 Motor, 1 Phase, 115/230 Volt, 37252 373118 N/A N/A

60 Hz., 56C, EXP

Motor, 3 Phase, 230/460 Volt, 3725462 37305 37354 N/A

60 Hz., 56C, EXP

2 1 Switch, 115 Volt, TEFC only — — —

3 1 Cord & Plug, 115 Volt, 60 Hz. only — — —

4,5 & 7 1 Blower Housing & Guard Assy. 34029DC 34029DC 34029DC 34029DC

(See note 4 at right)

5 1 Discharge Guard (only) 29318 29318 29318 29318

6 1 Blower Wheel 5530602 5500702 5501002 5510304

8 1 Discharge Elbow 51228 51228 51228 —

9 1 Dust Bag Clamp 31244 31244 31244 See page

10 1 Dust Bag 25071 25071 25071 14

11 1 Drum Lid 12060 12060 12060 12060

12 1 Inlet Nozzle, Square 51016 51017 51017 51017

13 2 Nozzle & Hose Clamp 31016 31244 31244 31244

14 1 Hose, Inlet, 60" long 31625PP 31626PP 31626PP 31626PP

15 1 Inlet Reducer 51110 — — —

16A 1 Inlet Elbow 12061 12061 12061 12061

16B 1 Inlet Deflector

17 1 Does not apply to these models — — — —

18 1 Lid Gasket

19 1 Intake Cylinder/Guard 51074G 51074G 51074G 51074G

Fig. 2

X. Exploded View Drawing Parts List for Models 100S, 150S, 200S and 300S

Part numbers 5, 8, 9, 10 and 19

must be in place at all times

during operation.

14

4

64

5

3

2

1

Hanging

Bag

10

9

9

8

7

Drum

Bag

drum

not included

XI. Typical Oversized Dust Bag Connection Diagrams for Model 300S

OPTIONAL FOR MODELS 50S, 75S, 100S, 150S, & 200S

NOTE: DUST BAG FOR MODEL 300S MUST BE ORDERED WITH THE DUST COLLECTOR

Ref.

No. Qty. Description

For Dust Collector

Parts List for #DB-24X40, #DB-24X80 and #DB-48X80 Drum Bags

50S & 75S

#DB-24X40 #DB-24X80 #DB-48X80

#100S to 300S

Bag Type

Ref. Numbers 8, 9 and 10 (for 6" hose) come as standard parts with all Model 300S.

7 1 Dust Bag, DB Type Select material type from catalog.

81 Hose Connector, 4" 51086 — —

1 Hose Connector, 6" — 51088 51088

93 Hose Clamps, 4" 31379 — —

3 Hose Clamps, 6" — 31244 31244

10 1 Hose, 4" dia. x 60" long 31623PP — —

1 Hose, 6" dia. x 60" long — 31626PP 31626PP

Ref.

No. Qty. Description

For Dust Collector

Parts List for #HB-24X80 and #HB-48X80 Hanging Bags

#HB-24X80 #HB-48X80

100S to 300S Bag Type

11 Ring, 24" Dia., 6 holes 27131 —

1 Ring, 48" Dia., 12 holes — 27123

26 J Hooks with 1/4-20 nuts —

12 J Hooks with 1/4-20 nuts —

3 1 Dust Bag, HB Type Select material type from catalog

4 3 Hose Clamps, 6" 31244 31244

5 1 Hose Connector, 6" 51088 51088

6 1 Hose, 6" dia. x 60" long 31626PP 31626PP

Standard hardware store items available locally.

Ref. Numbers 4, 5 & 6 (for 6” hose) come as standard parts with all Model 300S.

Fig. 3 “HB” Type Dust Bags

Fig. 4 “DB” Type Dust Bags

15

XIII. Dimensions and Performance Curves

Dust-Master Performance Curves

NOTE: All dimensions are approximate for reference only. Dimensions subject to change without notice.

TOP VIEW

100S-200S

TOP VIEW

33S-75S

FRONT VIEW

MODEL A B C D E F

33S - 75S 207/832 3/4291/2401/415 4

100S - 200S 241/244 3/437 523/4183/46

Model 300S dimensions are very similar to 200S dimensions except dust bag.

Max. normal dimensions shown, varies with motor.

Approximate dimensions with standard inflated dust bag.

200

2.0

4.0

6.0

8.0

10.0

400 600 800 1000 1200 1400

SP in Inches

33S

50S

75S

100S

150S

200S

300S

CFM

MODELS 33S THROUGH 300S

Performances shown

do not include any

additional external

pressure drop.

Models 33S to 200S

were tested with

standard bags per

page 6.

Model 300S was

tested with a

DB-48 x 80 bag.

All models with 5

feet of hose and

nozzle.

*

*

DISCLAIMER

This manual, and all its content herein, is based on all applicable known material at the time this manual was created. Any

parts of this manual are subject to change at any time and without notice.

If any statements, diagrams and/or instructions contained herein, for components not manufactured by the Seller, conflict

with instructions in the manufacturer’s manual (i.e.: motors), the instructions in the manufacturer’s manual, for that component

take precedent.

Should you want the latest version of this manual, please contact us or our sales office for your area. Or, you can print a current

version by going to our website at: www.cincinnatifan.com

XII. LIMITED WARRANTY:

Cincinnati Fan & Ventilator Company (Seller) warrants products of its own manufacture, against defects of material and workman-

ship under normal use and service for a period of eighteen (18) months from date of shipment or twelve (12) months from date of

installation, whichever occurs first. This warranty does not apply to any of Seller’s products or any part thereof which has been

subject to extraordinary wear and tear, improper installation, accident, abuse, misuse, overloading, negligence or alteration. This

warranty does not cover systems or materials not of Seller’s manufacture. On products furnished by Seller, but manufactured by

others, such as motors, Seller extends the same warranty as Seller received from the manufacturer thereof. Expenses incurred

by Purchaser’s in repairing or replacing any defective product will not be allowed except where authorized in writing and signed

by an officer of the Seller.

The obligation of the Seller under this warranty shall be limited to repairing or replacing F.O.B. the Seller’s plant, or allowing credit

at Seller’s option. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES EITHER EXPRESSED OR

IMPLIED INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE AND OF

ALL OTHER OBLIGATIONS AND LIABILITIES OF THE SELLER. THE PURCHASER ACKNOWLEDGES THAT NO OTHER

REPRESENTATIONS WERE MADE TO PURCHASER OR RELIED UPON BY PURCHASER WITH RESPECT TO THE QUALI-

TY OR FUNCTION OF THE PRODUCTS HEREIN SOLD.

Removal of the Sellers nameplate or any generic fan nameplate containing the fan serial number voids all warranties, either writ-

ten or implied. Failure to complete and document all the pre-startup and post startup checks and perform the suggested routine

maintenance checks voids all warranties, either written or implied.

LIMITATION OF LIABILITY:

Notice of any claim, including a claim for defect in material or workmanship, must be given to Seller in writing within 30 days after

receipt of the equipment or other products. Seller reserves the right to inspect any alleged defect at Purchaser’s facility before

any claim can be allowed and before adjustment, credit, allowance replacement or return will be authorized. See RETURNS

below. Seller’s liability with respect to such defects will be limited to the replacement, free of charge, of parts returned at

Purchaser’s expense F.O.B. Seller’s plant and found to be defective by the Seller.

IN NO EVENT WILL SELLER BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES,

WHETHER IN CONTACT, TORT, NEGLIGENCE, STRICT LIABILITY OR OTHERWISE, INCLUDING WITHOUT LIMITATION

DAMAGES FOR INJURY TO PERSONS OR PROPERTY, LOST PROFITS OR REVENUE, LOST SALES OR LOSS OF USE

OF ANY PRODUCT SOLD HEREUNDER. PURCHASER’S SOLE AND EXCLUSIVE REMEDY AGAINST SELLER WILL BE

THE REPLACEMENT OF DEFECTIVE PARTS AS PROVIDED HEREIN OR REFUND OF THE PURCHASE PRICE FOR

DEFECTIVE PRODUCTS, AT SELLER’S SOLE OPTION. SELLER’S LIABILITY ON ANY CLAIM, WHETHER IN CONTRACT,

TORT, NEGLIGENCE, STRICT LIABILITY OR OTHERWISE, FOR ANY LOSS OR DAMAGE ARISING OUT OF OR IN CON-

NECTION WITH PURCHASER’S ORDER OR THE PRODUCTS OR EQUIPMENT PURCHASED HEREUNDER, SHALL IN NO

CASE EXCEED THE PURCHASE PRICE OF THE EQUIPMENT GIVING RISE TO THE CLAIM.

RESPONSIBILITY:

It is the understanding of the Seller that Purchaser and/or User will use this equipment in conjunction with additional equipment

or accessories to comply with all Federal, State and local regulations. The Seller assumes no responsibility for the Purchaser’s

and/or User’s compliance with any Federal, State and local regulations.

RETURNS:

Cincinnati Fan & Ventilator Company assumes no responsibility for any material returned to our plant without our permission. An

RMA (Return Material Authorization) number must be obtained and clearly shown on the outside of the carton or crate and on a

packing slip. Any items returned must be shipped freight prepaid. Failure to comply will result in refusal of the shipment at our

receiving department.

7697 Snider Road

Mason, OH 45040-9135

www.cincinnatifan.com for more information

16

1M-0811, ADV.

This manual suits for next models

6

Table of contents

Other Cincinnati Fan Dust Collector manuals

Popular Dust Collector manuals by other brands

HOLZMANN MASCHINEN

HOLZMANN MASCHINEN MABS 750 user manual

South Bend Tools

South Bend Tools SB1007 owner's manual

Nederman

Nederman FilterMax DX Series instruction manual

Impacts

Impacts Dustcom 4025 operating manual

pela tools

pela tools 512886 manual

Westinghouse

Westinghouse SweepEZE WST1800 owner's manual

U.S.SAWS

U.S.SAWS Dust Buggy operating manual

Showa Denki

Showa Denki FUMERESA FRM-H15 Operation Manual & Cautions

Bosch

Bosch Professional GDE 18V-12 Operating/safety instructions

Shop fox

Shop fox SHOP FOX D2267 user manual

Chiko

Chiko CKU-400AT-HC-V1 instruction manual

Shopsmith

Shopsmith DustCollector manual