Cipher F880ES User manual

ModelF880ES

Technical

Manual

ciplJl!l:

Caution

This

unit

requires

the

use ofashielded interface cable.

Federal

Communications

Commission

(FCC)

Notice

WARNING:

This equipment generates, uses, and can

radiate

radio frequency energy

and

if

not

installed

and

used

in

accordance with the instructions manual, may cause interference to radio

communications.

It

has

been tested and found to comply with the limits for aClass Acomputing

device

pursuant

to

Subpart

Jof

Part

15 of FCC Rules, which

are

designed to provide reasonable

protection

against

such interierence when operated

in

acommercial environment. Operation

of

this

equipment

in

aresidential

area

is likely to cause interference

in

which case users

at

their

own

expense will be required to

take

whatever measures may be required to correct

the

interference.

VDE

Statement

Hiermit

wird bescheinigt, dass

der

Model F880ES

in

Ubereinstimmung

mit

den Bestimmungen

der

Vfg 104611984 funkentstort ist.

Der Deutschen

Bundespost

wurde

das

Inverkehrbringen

dieses

Gerates

angezeigt

und

die

Berechtigung

zur

Uberprufungder Serie

auf

Einhaltung

der Bestimmungen eingeraumt.

Canadian

Radio

Noise

Emissions

Notice

This digital

apparatus

does not exceed

the

Class Alimits for radio noise emissions from digital

apparatus

as

set

out

in

the

radio

interference

regulations

of

the

Canadian

Department

of

Communications.

Le

present

appareil numerique

n'emet

pas

de

bruits

radioelectriques

depassant

les

limites

applicables

aux

appareils numeriques de Classe Aprescrites dans

Ie

reglement

sur

Ie brouillage

radioelectriqueedicte

par

Ie

Ministere Des Communications Du Canada.

Proprietary

Statement

All information contained in or disclosed by

this

document is considered proprietary by Cipher

Data

Products, Inc. By accepting this

material

the

recipient agrees

that

this

material

and

the

information contained

therein

are

held

in

confidence and

in

trust

and will not be used, reproduced

in

whole

or

in

part,

nor

its

contents revealed to others, except to meet

the

purpose for which

it

was

delivered.

It

is understood

that

no

right

is conveyed to reproduce

or

have reproduced

any

item

herein

disclosed withoutexpress permission from Cipher Data Products, Inc.

Cipher

Data

Products, Inc. provides this manual "as is," without

warranty

of

any

kind,

either

expressed

or

implied, including,

but

not limited to, the implied

warranties

of

merchantability

and

fitness for a

particular

purpose. Cipher may make improvements

or

changes

in

the product(s)

or

programs described

in

this

manual

at

any time. These changes will be

incorporated

in

new

editions

of

this publication.

Cipher

Data

Products, Inc. assumes

no

responsibility for the accuracy, completeness, sufficiency,

or

usefulness of

this

manual, nor for any problem

that

might arise from

the

use

of

the information

in

this

manual.

Notice

This

manual

is providedfor qualified technicians only.

Record

of

Revision

Edition

Description

Date

AReleased

per

ERO SD-89-0402 11/89

Loctite is aregistered

trademark

ofLoctite Corporation.

Table

of

Contents

Chapter

1

Description

Overview 1-1

General

Description 1-1

Functional

Description 1-1

P

.....

us;

""al

n

es

"""';

p4-;

"'.....

1

~')

..L LLJ.L""

~

"".a..L

"'.J.V.I..l

••••••••••••••••••••••••••••••••••••••••••••••••

...,-..

Tape

Path

and

Service Access 1-3

OperatorAccess 1-3

Service Access 1-4

Parts

Locations 1-8

Front

View 1-8

Rear

View 1-9

Top View 1-10

BottomView 1-11

Chapter

2

Installation

and

Configuration

Overview 2-1

Unpacking

2-1

Installation

2-1

Rack

Mounting

2-1

Enclosure

Installation

2-4

AC Voltage Selection 2-6

Interface Cable 2-8

Configuration 2-14

SCSIID

2-14

Configuration Options 2-15

Bus

Terminator

2-16

Chapter

3

Operation

Introduction 3-1

FrontPanel

3-1

LOADIREWIND 3-2

UNLOAD 3-2

ON-LINE 3-2

WRT

ENtrEST

3-2

HI

DEN 3-2

PowerSwitch 3-2

LoadingTape 3-3

Man

ual

Load 3-3

UnloadingTape 3-6

Manual

Unload 3-6

Chapter

4

Maintenance

Introduction 4-1

Tape

Path

4-1

Sensors 4-2

Filter

4-3

Chapter

5

Troubleshooting

Introduction .

Errors

.

Error

Reporting .

Error

Codes .

D·

D'

.

rIve lagnostlcs .

Diagnostic Mode

Entry

.

Tape UnloadedDiagnostics .

Tape Loaded Diagnostics .

SCSI Diagnostics .

Sense Keys .

Additional Sense .

Status

Bytes .

Diagnostic Commands .

SCSIPower-up Diagnostics .

ii

5-1

5-1

5-1

5-1

5-2

5-2

5-3

5-9

5-9

5-9

5-9

5-10

5-10

5-10

Chapter

6

Removal,

Replacement,

and

Adjustment

Procedures

Introduction 6-1

Tools

and

Materials

6-1

Part

Numbers

6-2

Removal

and

ReplacementProcedures 6-4

Blower 6-4

Control Switches 6-5

Door 6-6

Door Lock 6-7

EOTIBOT Sensors 6-9

File-ProtectSensor 6-10

FrontPanel

6-11

Fuse 6-13

Hub

Lock Solenoid 6-14

Input

Air

Duct 6-15

Interlock Switch

"........................

6-16

Left

Output

Air

Duct 6-17

Main

CircuitBoard 6-18

Manual

Release Switch 6-19

PowerSupplyCircuitBoard 6-20

PowerSwiteh 6-22

Read/Write

Head

6-23

Right

Output

Air

Duct 6-24

Roller Guide 16-25

Roller Guide 26-26

Roller Guides 3, 4, 56-27

Supply

Hub

6-28

Supply

Hub

Bell

Crank

6-29

SupplyMotor 6-30

Tachometer 6-32

Take-Up

Hub

6-34

Take-

Up

Motor 6-35

Tape-In-Path Receiver 6-37

Tape-In-Path

Transmitter

6-38

Tension Arm, Stator,

and

Rotor 6-39

Top Cover 6-42

Transformer 6-43

Adjustment

Procedures 6-44

Interlock Disable Procedure 6-44

III

ReadThresholdAdjustment 6-45

Skew

Adjustment 6-46

Supply

Hub

Adjustment 6-48

Take-Up

Hub

Adjustment.

.................................... 6-49

Tape

Alignment

Adjustment 6-51

Tension

Arm

Output

Adjustment 6-53

Tension

Arm

Spring

Adjustment 6-55

Chapter

7

Small

Computer

Systems

Interface

Introduction 7-1

SCSI Characteristics 7

-1

Signals

7-1

Acknowledge 7-1

Attention

7-1

Busy 7-1

ControllData 7-2

Data

Bus 7-2

Input/Output

7-2

Message 7-2

Request 7-2

Reset 7-2

Select 7-2

Messages 7

-3

Status.

............................................................ 7-3

Commands 7-4

Command DescriptorBlock 7-5

Copy (18h) 7-6

Erase

(19h) 7-8

Inquiry

(12h) 7-9

LoadlUnload (1Bh) 7-10

Mode Select(15h) 7-11

Mode Sense

(lAh)

7-13

Read(08h) 7-14

ReadBlock Limits(05h) 7-15

Read Reverse

(OFh)

7-16

Receive Diagnostic (1Ch) 7-17

Recover Buffered

Data

(14h) 7-18

Release

Unit

(17h) 7-19

iv

RequestSense (03h) 7-20

Reserve

Unit

(16h) 7-27

Rewind

(0

1h) 7-28

SendDiagnostic

(lDh)

7-28

Space

(llh)

7-30

Test

U

ni

tReady

(OOh)

7-31

Verify (13h) 7-32

Write

(OAh) 7

=34

Write

File

Mark

(10h) 7-35

Chapter

8

Specifications

Performance 8-1

Interface 8-2

Mechanical Specifications 8-2

Power 8-2

Environmental

Specifications 8-3

Acoustic Noise Emission 8-3

Shock 8-3

Interface Cable 8-3

Engineering

Drawings

Main

CircuitBoard .

PowerSupply .

Harness

.

W

··

D'

IrIng

Iagram

.

Rack

Mounting

.

966129-300

960877-300

360101-320

966104-300

960264-000

v

Regulatory Requirements 8-3

Safety 8-3

ElectromagneticEmissions 8-3

Tape 8-4

List

of

Figures

1-1.

F880ES

Rack-MountTape Drive 1-2

1-2. Location

of

Rack Latch

and

Cover

Retainer

Arm

1-3

1-3. Location

of

Deck

Plate

Retainer

Screws 1-5

1-4.

Inserting

Safety

Pin

Into Support

Arm

1-6

1-5.

Front

Parts

1-8

1-6.

Rear

Parts

1-9

1-7. Top

Parts

1-10

1-8. Bottom

Parts

1-11

2-1. Rack

Mount

2-2

2-2.

Installation

into

an

Enclosure 2-5

2-3.

Installation

ofaSCSI Cable

in

an

Enclosure 2-6

2-5.

Termination

for Single-EndedDevices 2-9

2-6.

Termination

for Differential Devices 2-9

2-7. DIP Switches U2C

and

U4A 2-14

2-8.

Installation

of

Terminator

Plug

2-16

3-1.

Front

Panel

3-1

3-2. Location

of

Manual

Release Switch 3-4

3-3. Tape

Path

3-5

4-1. Tape

Path

and

Sensors 4-2

4-2.

Air

Filter

4-3

5-1.

Bit

Significance of

Front

Panel

Indicators 5-1

5-2.

Front

Panel

Switches Decimal Numbered 5-3

5-3. Tachometer

Phase

Quadrature

5-4

5-4. Location ofDiagnostic LEDs 5-11

6-1. Blower 6-4

6-2. Control Switches 6-5

6-3. Door 6-6

vi

6-4. Door Lock .

6-5. EOTIBOT Sensors .

6-6. File-ProtectSensor .

6-

7.

Fran

t

Panel

.

6-8.

Fuse

.

6-9.

Hub

Lock Solenoid .

6-10.

Input

Air

Duct .

C.

11

T_~~rl~~lp

Sw:~_l-

u-

~ ~

•

.I..l.l1"C

.1

U\;A.

.lI,A;.l.l.

•••••••••••••••••••••••••••••••••••••••••••••••••

6-12. Left

Output

Air

Duct .

6-13.

Main

CircuitBoard .

6-14.

Manual

Release Switch .

6-15. Power Supply CircuitBoard .

6-16. PowerSwitch .

6-17. ReadIW

ri

te

Head

.

6-18.

RightOutputAirDuct

.

6-19. Roller Guide 1 .

6-20. Roller Guide 2 .

6-21. Roller Guides

3,4,

5 .

6-22. Supply

Hub

.

6-23. Supply

Hub

Bell

Crank

.

6-24. SupplyMotor .

6-

25. Tachometer .

6-26. Take-Up

Hub

.

6-27. Take-UpMotor .

6-28. Tape-In-Path Receiver .

6-29. Tape-In-Path

Transmitter

.

6-30. Tension

Arm

.

6-31. Top Cover .

6-32. Transformer .

6-33. Location ofReadThresholdPotentiometer .

6-34. Location

of

SkewAdjustmentScrew .

6-35. SkewAdjustmentWaveform .

6-36. Supply

Hub

Adjustment .

6-37. Take-Up

Hub

Adjustment .

6-38. Tension

Arm

Adjustment .

6-8

6-9

6-10

6-12

6-13

6-14

6-15

6-16

6-17

6-18

6-19

6-21

6-22

6-23

6-24

6-25

6-26

6-27

6-28

6=29

6-31

6-32

6-34

6-36

6-37

6-38

6-40

6-42

6-43

6-45

6-46

6-47

6-48

6-49

6-53

VII

List

of

Tables

2-1.

ACVoltageSelection

2-8

2-2. Single-EndedUnshielded

and

Alternative 1

Pin

Assignments 2-10

2-3. Single-EndedAlternative 2

Pin

Assignments 2-11

2-4. Differential

Alternative

1

Pin

Assignments.

.......................... 2-12

2-5. Differential

Alternative

2

Pin

Assignments

..

......................... 2-13

2-6.

SCSIID

Switch

Settings

2-14

2-7. Configuration Options, DIPSwitch U4A 2-15

5-1.

Error

Codes 5-2

5-2. Service Aids 22

and

23 Conversion

Chart

(1

of2) 5-5

5-3A. Service Aid 24 Low-Order BitsConversion

Chart

5-8

5-3B. ServiceAid 24 High-OrderBitsConversion

Chart

5-9

5-4. Level 0Diagnostics

Error

Codes 5-11

6-1. SpecialTools

and

MaterialsList 6-1

6-2.

Part

Numbers

of

Replaceable Items

(1

of2) 6-2

6-3A.

Value

of

Tension

Arm

Output

Voltage (HI DEN LED on) 6-54

6-3B.

Value

of

Tension

Arm

Output

Voltage

(ill

DEN LED

off)

6-55

7-1. Message

Set

7-3

7-2.

Status

Bytes 7-3

7-3. Command

Set

7-4

7-4. Command Descriptor Block

Format

7-5

7-5. Copy Command 7-6

7-6. Copy Command

Parameter

List

Header

7

-7

7-7.

Segment

Descriptorfor Copy Function Codes

OOh

and

01h 7-7

7-8.

Erase

Command 7-8

7-9.

Inquiry

Command 7-9

7-10.

Inquiry

Data

7-10

7-11. LoadJUnload Command 7-10

7-12. Mode SelectCommand 7-11

7-13. Mode Select

Parameter

List

Header.

................................ 7-12

7-14. Mode SelectBlock Descriptor 7-12

7-15. Mode Select

Page

0Descriptor 7-13

7-16. Mode Sense Command 7-13

7-17. Mode Sense

Parameter

List

Header

7-14

7-18. Read

Command.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

7-19. Read Block LimitsCommand 7-15

VIII

7-20. Read Block Limits

Data

.

7-21. Read Reverse Command .

7-22. Receive Diagnostic Command .

7-23. Receive Diagnostic Results

Data

.

7-24. Recover Buffered

Data

Command .

7-25. Release U

ni

tCommand .

7-26. RequestSense Command .

,..,

0""

E--ten..l dS---se

T""'ata

~o--

All

r'tomman.:l-

nyte-

n,..,

I-~

I•X

ae

en'

J..J

11

r1'\.11 v

as,

DS

U-

I

•••••••••••••••••••

7-28. ExtendedSense

Data

for aCopy Command .

7-29. ExtendedSense

Data

for aNon-Copy Command .

7-30. Sense Keys .

7-31. Additional Sense Codes .

7-32. Tape

Status

Port

3 .

7-33. DMA

Status

.

7-34. Reserve

Unit

Command .

7-35. Rewind Command .

7-36. Send Diagnostic Command .

7-37. SendDiagnostic

Data

.

7-38. Space Command .

7

-3

9.

Test

UnitReady Command .

7-40.Verify Command .

7-41. Write Command .

7-42. Write File

Mark

Command .

8-1.

Operating

Times .

7-16

7-16

7-17

7-18

7-19

7-19

7-20

7-21

7-22

7-23

7-25

7-26

7-27

7-27

7-28

7-28

7-29

7-30

7-31

7-32

7-32

7-34

7-36

8-1

IX

Chapter 1

INTRODUCTION

Description

This

chapter

provides general, functional, and physical descriptions of

the

F880ES

tape

drive.

It

also

has

instructions on how to open up the drive to gain access for operation

and

servicing,

and

a

seriesofillustrationsshowingthe locations ofall

the

major

parts

ofthe tape drive.

GENERAL

DESCRIPTION

The Cipher Model F880ES is adual-density

(l600

and

3200 bits

per

inch) magnetic

tape

drive

designed to provide backup for high-capacity disk drives

and

data

interchange between systems.

The

F880ES exchanges

data

with

other

components ofaSCSI system

and

transfers

that

data

to

and

from half-inch tape reels

of7,

8.5, and 10.5 inches.

Figure

1-1

is

an

illustration

of

an

F880EStapedrive.

FUNCTIONAL

DESCRIPTION

The F880ESdrive is made up of

three

functional components: the interface,

the

drive electronics,

and

the

drive mechanism. These

three

elements

interact

to accomplish

the

various functions

performedby

the

drive.

The drive records on tape

data

transmitted

across

the

SCSI bus

and

reads recorded

data

from

tape

and

transfers

it

to

the

SCSI bus. To

perform

these

functions amicroprocessor

interprets

commands from

the

interface, accelerates and decelerates

the

tape, positions

the

tape

at

the

read/write head, detects tape position, controls formatting,

and

provides

status

outputs.

The drive writes

data

to tape using

the

phase encode method ofrecording. Nine

tracks

are

written

simultaneouslyacross the width

of

the

tape, eighttracks of

data

and

a

parity

track.

The tape drive is self-loading. The operator inserts areel oftape

in

the

opening

of

the

front panel

and

presses aload switch. The drive

then

automatically

seats

the reel on

the

supply hub,

threads

the

tape

around

the

tension

arm,

across the read/write head, and around

the

take-up hub. The

tape is positioned

at

BOT

and

properly tensioned.

The

interface

translates

SCSI commands

arriving

on

the

SCSI

bus

into

drive

executable

commands, and

it

also

translates

tape drive

data

and

status

signals into

the

appropriate format for

the

SCSI bus.

1-1

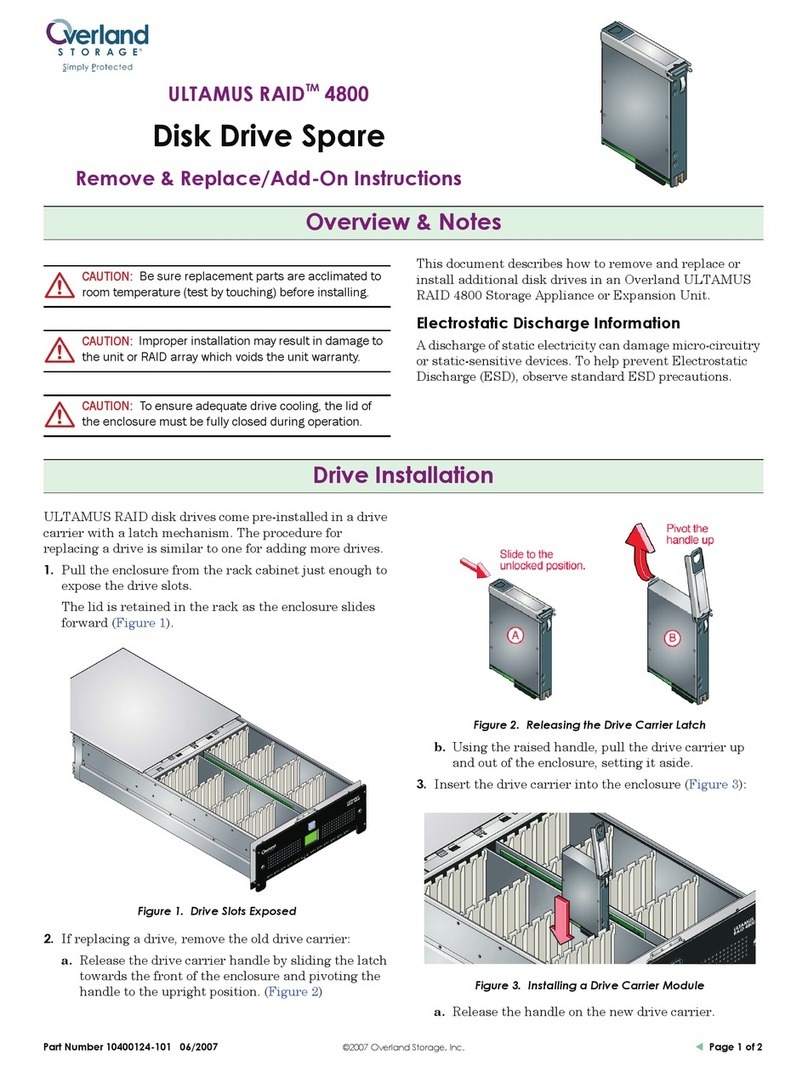

Figure 1-1.

F880ES

Rack-MountTape Drive

PHYSICAL

DESCRIPTION

The

F880ES

tape

drive

consists of

three

main

assemblies:

the

chassis,

the

deck

plate,

and

the

printed

circuit

board.

All components

and

subassemblies

are

mechanically fastened to a

cast-aluminum

deck

plate,

including

two direct-drive dc motors with reel hubs, apower supply,

the

read/write

head, sensors,

the

tension

arm,

and

the

front panel. The deck

plate

is mounted to hinges inside a

metal

chassis

that

encloses critical

parts,

as

well

as

the

printed

circuit

board, which

contains

all

drive

control

circuitry

and

the

SCSI interface. The drive's top cover protects

the

parts

attached

to

the

top of

the

deck

plate,

as

well

as

the

tape

path

and

the

tape.

Designedfor

mounting

in

a

standard

19-inch RETMA

equipment

rack

or

atable-top enclosure,

the

drive

is 8.75 inches high, 19 inches wide,

and

22.7 inches deep

and

weighs 82 pounds. Slides for

mounting

the

drive

in

a

rack

are

included with drives

that

are

not ordered

with

the

optional

enclosure.

1-2

TAPE

PATH

AND

SERVICE

ACCESS

Access is

available

to

the

tape

path

and

to

the

internal

components

of

the

tape

drive. Access to

the

tape

path

is

often

referred

to

as

operator

access,

and

to

the

internal

components

as

service

access.

Throughout

this

manual

it

will be

taken

for

granted

that

the

reader

is

a

trained,

qualified

technician

who knows how to

obtain

access to

the

drive

in

both

ways.

The

procedures

are

explained

below.

Operator

Access

Rack-Mounted Drive

1.

Release

the

rack

latch

located

under

the

left

side

of

the

front

panel.

See

Figure

1-2.

~1~/~_'~_1

-~~~~~

Figure 1-2. Location

of

Rack

Latch

and

Cover Retainer

Arm

2.

Pull

the

tape

drive

out

of

the

equipment

rack.

3.

Raise

the

top cover

and

place

the

cover

retainer

arm

(Figure

1-2)

in

the

slot

next

to

the

tape

path.

1-3

Reinstall

the

tape

drive

in

the

rack

as

follows:

1.

Close

the

top cover.

2.

Press

the

slide locks

inward

and

push

the

tape

drive into

the

equipment

rack.

Enclosured Drive

1. Open

the

lid

of

the

enclosure fully.

Push

down on

the

front corners to

release

the

catchesbefore lifting

the

lid.

2. Raise

the

top cover

and

place

the

cover

retainer

arm

(Figure 1-2)

in

the

slot

next

to

the

tape

path.

Close up

the

enclosure

as

follows:

1. Close

the

topcover ofthe tape drive.

2. Release

the

lid

retainer

arm

on

the

right

side of

the

enclosure lid

and

close

the

lid.

Service

Access

Rack-Mounted Drive

1.

Release

the

rack

latch

located

under

the

leftside of

the

front panel (Figure 1-2).

2.

Pull

the

tape

drive

out

of

the

equipment

rack.

3.

Raise

the

top cover

and

place

the

cover

retainer

arm

(Figure 1-2)

in

the

slot

next

to

the

tape

path.

4.

Loosen,

but

do

not remove,

the

two screws on each side of

the

deck plate. See

Figure

1-3.

1-4

Retainer

Screw

I

Figure 1-3. Location

of

Deck Plate Retainer Screws

5.

Close

the

top cover.

6.

Grasp

the

bottom of

the

front panel and lift

it

upward

as

far

as

it

goes,

then

lower

it

slowly until the latch in the support

arm

locks.

7.

Insert

the

safety pin into the hole in the supportarm. See Figure 1-4.

1-5

Figure 1-4. Inserting Safety

Pin

Into Support Arm

Reinstall

the

tape drive

in

the

rack

as

follows:

1. Remove

the

safety

pin

from

the

support

arm.

2.

Grasp

the

bottom of

the

front panel

and

lift

it

upward to unlock

the

support

arm

latch,

then

lower

it

slowly.

3. Raise

the

top cover

and

place the cover

retainer

arm

(Figure 1-2)

in

the

slot

next

to

the

tape

path.

4.

Tighten

the

two screws on each side of

the

deck plate to secure

it

to

the

chassis.

5.

Close

the

top cover.

6.

Press

the

slide locks inward

and

push

the

tape

drive into the

equipment

rack.

1-6

Enciosured

Drive

1.

Open

the

lid of the enclosure fully.

Push

down on

the

front corners to

release

the

catches before liftingup the lid.

2.

Raise

the

top cover

and

place

the

cover

retainer

arm

(Figure 1-2)

in

the

slot

next

to

the

tape

path.

3.

Loosen,

but

do

not remove,

the

two screws on each side

of

the

deck plate. See

Figure

1-3.

4.

Close

the

top cover.

5.

Grasp

the

bottom of

the

front panel

and

lift

it

upward

as

far

as

it

goes,

then

lower

it

slowly

until

the

latch

in

the

support

arm

locks.

6.

Insert

the

safety pin into

the

hole

in

the supportarm. See

Figure

1-4.

Close up

the

enclosure

as

follows:

1.

Remove

the

safetypinfrom

the

supportarm.

2.

Grasp

the

bottom of

the

front panel

and

lift

it

upward to unlock

the

support

arm

latch,

then

lower

it

slowly.

3.

Raise

the

top cover

and

place

the

cover

retainer

arm

(Figure 1-2)

in

the

slot

next

to

the

tape

path.

3.

Tighten

the

two screws on each side ofthe deck plate to secure

it

to

the

chassis.

4.

Close

the

top cover of

the

tape drive.

5.

Release

the

lid

retainer

arm

on

the

right

side ofthe enclosure lid

and

close

the

lid.

1-7

1-8

PARTS

LOCATIONS

Front

View

Figure

1-5 shows the location

of

the major

parts

at

the front

of

the tape drive.

Top Cover

Manual

Release

Switch

Control

SWitches

Figure 1-5. Front Parts

Table of contents

Other Cipher Storage manuals

Popular Storage manuals by other brands

Eaton

Eaton Cutler-Hammer SRAM PC104 quick start guide

Dell

Dell PowerVault NF100 Getting started guide

Quantum

Quantum Superloader 3 user guide

Denios

Denios PolySafe-Depot PSR 8.8 manual

Fujitsu

Fujitsu AIRSTAGE UTY-ASGXZ1 operating manual

Overland Storage

Overland Storage ULTAMUS RAID 4800 Remove & Replace / Add-On Instructions