Cipher F880 Troubleshooting guide

Technical

Manual No.

799816-003

Revision H

MODEL F880 MAGNETIC TAPE TRANSPORT

VOLUME I

OPERATION MAINTENANCE

Cipher

Doto

Products

10225 Willow

Creek

Rood

Son Diego,

California

92138

c

Copyright

1982 by

Cipher

Data

Products,

Inc.

Printed

in U.S.A.

September

1983

NOTICE

This

equipment

generates,

uses, and can

radiate

radio

frequency

energy

and

if

not

installed

and used in

accordance

with

the

instructions

included

in

this

manual,

may

cause

interference

to

radio

communications.

Verification

of

compliance

with

Subpart

J

of

Part

15

od

FCC

Rules,

which

are

designed

to

provide

reasonable

protection

against

such

interference,

is

the

responsibility

of

the

installer.

ii

Section

VOLUME

I

TABLE

OF

CONTENTS

Title

DESCRIPTION, UNPACKING INSPECTION,

Page No.

AND

INSTALLATION...............

. • •• •• •• . . . • • •• . . . • • •

1-1

GENERAL . . •. . • . . • • • . • • ••. • •• • •••• . •• •• • •• •• • ••• •

1-1

UNPACKING AND INSPECTION . • • •• •• . • • • • . • •. • • • ••

1-1

POWER CONNECTION • ••• • . • • ••• ••• •• •• • •• •• •• •• • • 1-2

Operating

Voltage

Selection

•• •• •• •. • ••• • •• • •• • • 1-2

INITIAL CHECKOUT •• • •• •• •• •• ••• •• •• •• ••• • • . • • •• • 1-4

RACK

MOUNTING.................................

1-5

INTERFACE CONNECTION •• •• •• • ••• •• . • •• • •• • •• •• •

1-

7

MULTIPLE-TRANSPORT OPERATION ••• •• •• •• •• • •• •• 1-7

II

OPERATION

·········••e••••e••••••co••••············"~~

2-1

GENERAL . • ••. • •• ••• •• • ••• • •• ••• •• •• . • • • •• •• •• •• •

2-1

CONTROLS AND INDICATORS •••• ••• •• • •• • •. • • • . • ••

2-1

LOADING TAPE •• •• •• • •. . •• • •• . . •• •• ••• • •• •• • •• •• •

2-1

UNLOADING TAPE •••• • •. . • • • •• ••• •• •• •• . • • • •• •• •. 2-3

ERROR CONDITIONS ••• . . • • •• •• . • • •• •• ••. • • •• • . • . • 2-3

Operator

Error

Ccx::les

•• • •• •• •. • ••• •• •• •. • •• • • •• 2-3

Transport

Error

Codes •• • •• ••• •• •• •• •• • ••• •• • •• 2-3

MANUAL LOAD . . . • ••• • •• •• •• •• •• ••• • ••• . • • • •• • ••. 2-4

MANUAL UNLOAD •• •• •• •• . • • •• •• ••• •• •• • •. • • • •. • . 2-5

Ill

TESTING AND TROUBLESHOOTING • •. • ••• . • • •• • •• •• • •• ••

3-1

TESTING..........................................

3-1

Self

Test

.....................................

3-1

Diagnosti:e Mooe

Operation

•. • ••• •• •• •• •• • •• •• • • 3-1

Front

Panel

Indicators • . • •• •• ••• • . •• • • •• ••• • •. • 3-1

Diagnostic

Mode (Tape

Unloaded)................

3-2

Diagnostic

Mode (Tape Loaded) . . ••. •. • . •• . . . . ••

3-5

TRANSPORT ERROR CONDITIONS . •• •• . •• •• •• •• • • •• 3-6

Transport

Error

Codes . • . • . • • •. • . . . . • •• • . • • •. • • 3-6

iii

Section

111

TABLE OF CONTENTS (Continued)

Title

Page

No.

TROUBLESHOOTING. ••• . •. . . . . ••. . . ••• . . •. •. . . . . •. 3-8

Power

Control and System

Failure

Detect

TTP •. •. ••. . • ••. ••. •. •• •. • •. ••• . •• ••. . 3-15

Auto-Load Sequence TTP . •. . . . • . •. . . •. •. . . . . •. . 3-18

Takeup and Supply Servo TTP . . . • •••. . . . . . . . • . . . 3-20

Write

Formatter

•. . •. . . . . . . ••. • . . . . . . . . . . . . . . . 3-28

Tachometer

TTP . . . . •• . •. . . •. •. . . . . •. • •••. ••. .

3-31

Interface

Lines TTP •. ••• •• . . ••. . . . . . . . . . •. . . • . 3-34

EOT and

BOT

TTP.............................

3-37

Compliance Arm

TTP..........................

3-38

Ree

I

Seat

Sensor and

Tape-In-Path Sensor TTP •. ••. . . •. . . . . . . . . • . . . . . 3-40

Hub Lock and Door Lock TTP . . •• •••. . . . . . . . •. . . 3-43

Blower Motor

TTP............

. . . . . . •. . . •• •. . . . 3-44

Drive Selection TTP •••. . . . . . ••. .

..

•. . . . ••. . •. . • 3-45

Command Lines

TTP............

. . . . •. . •• . . . . . . 3-47

Read

Formatter

TTP . . •• . . . . . . . . . . . . . . . . . . . . . . 3-48

IV

MAINTENANCE . . . . . . . . •••. . . •. •. . . . . ••. ••. . . . . . •• . . . . .

4-1

GENERAL . • . . . . . . . . . •. . . ••. • . . . •. •. . . . •. •. . . • •. •.

4-1

DRIVE POSITIONS FOR SERVICING ACCESS ••. . • . . . . •

4-1

Operator

Maintenance

Access...................

4-1

Service Access. . . •. . . ••. . . . . •. . . . . . . . •. ••• . . . • 4-3

OPERATOR PREVENTIVE

MAINTENANCE............

4-3

Tachometer

Roller . . . . •. . . . . ••. •. . . . •• •• •• . •. . 4-6

Takeup Hub . . . • . •. . •. •. . •. . . . . . . . •• •• . •. . . . . • 4-6

Ro

11

er

G

uides • • • • • • • • • • • • • •• • • • • • • • • •• • • • • • • • •

4-6

Head . . . . . . . . •. . • . . •. •. . . . . . •. . . ••• •• . . . ••• . • 4-7

Ree

I-Hub Pads ••. . •. •. •. . . . . . . . ••. . . •• •• •. •• . • 4-7

Tape

Cleaner

. . . • . . ••. • . . . . . •• ••. ••••. • ••. • •. • 4-7

FiI

ter.

. . . . . . •••• •• . •••••. . . . . . •. •. . •• •. • •• •• . 4-7

SERVICE TECHNICIAN PREVENTIVE MAINTENANCE.. 4-8

iv

Section

IV

TABLE OF CONTENTS (continued)

Title

Page

No.

CORRECTIVE MAINTENANCE 4-9

emoval an

Read

Thresho

Id

Adjustment

•••••••••••.•••••••••

REPAIR

AND

REPLACEM

-=

PARTS

AND

COMPONENTS . ••• •• •• •••••• ••• ••••• ••• 4-10

FRONT PANEL ASSEMBLY •. •••• ••• ••• •••••• •• •• ••• 4-11

Power Switch

Replacement

••• ••• ••• ••••• ••• •• •• 4-11

Touch Switch

Replacement

••• •• ••• ••••• •• •• •• •• 4-17

Front

Panel Subassembly

Replacement

••••••••• •• 4-17

_,_..

...

-...E.eoloY

I and Replacment

of

Door Assembly ••• ••• 4-18

,/

{_

SUPPLY

HU~

~SSEMBL

Y

•••••••••

.°.

_...

~

..._ .....

RemovOf, ep

ement

and Adjustment ••• •• ••• •• 4-19

HEAD ASSEMBLY. •••• ••••••••• •• •• ••• ••• ••• •••••• • 4-20

Removal and

Replacement

of

Assembly

and

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

ROLLER GUIDE

ASSEMBLY.........................

4-22

Removal and

Replacement

of

Assembly ••• •. •• ••• 4-22

EOT/BOT SENSOR

ASSEMBLY.......................

4-22

Removal and

Replacement

••• ••••• •••••• ••••• •• 4-22

TACHOMETER

ASSEMBLY..........................

4-24

Removal and

Replacement

•• •••••• ••• ••• ••••• •• 4-24

COVER ASSEMBLY •••• ••. . •••••••• •••••••• ••••• •• . 4-24

Removal and

Replacement

of

Assembly

and/or

Parts..................................

4-24

,,.,..,-::-;-:-:-.:-:-::~:-:::-----------------~--------~~

........

~~

I

TAKE

UP

HUB

••.••••••••••••••••••••••••••••••••••

_emoval,

Replacement,

and Adjustment

••••••••••

roMPL!ANCE

ARM AND A!R CAPACITOR

-----

-----

SEMBLIES

••••••••••••••••

_·

•••••••••••••••••••••

Removal and Disassembly

•.•••.••••••••••••••••

Reassembly, Installation, and Adjustment

•••..•••.

TAPE-IN-PATH

SE-NSOR,

TRANSMITTER

•••••••••

~-

•••

-

Removal and

Replacement

•••••••••••.•••••••••

v

Section

IV

TABLE OF CONTENTS (continued)

Title

Page

No.

TAPE-IN-PATH SENSOR, RECEIVER • . •• . . • •. • • . . . . . . 4-32

Rem

ova

I

and

Rep

I

acement

• • • . • • . • . • . • . • • . . • . . • 4-32

COMPLIANCE ARM BUMPER ASSEMBLY. •. • . . . . . • . • • 4-32

Removal

and

Replacement

. . •• . • . . . • . • . . . . . . . . • 4-32

ROLLER TAPE GUIDE ASSEMBLY

(SOLID)............

4-34

Rem

ovaI

and

Rep

I

acement

• • . • . . • . • . . • • • • • • • . • • 4-34

FILE

PRO

TE

CT

SENSOR.

• • • • • • • • • •• •• • • • • • • • • • • • . • . 4-35

Remova

I

and

Rep

I

acment

• • • . • . . • • • • • • • • • • • • • • • 4-35

DRIVE

MAIN

PRINTED

WIRING BOARD . • . . • • • • . • • . • . 4-36

Remova

I

and

Rep

I

acment

. • • • • • • • . . • • • • • • • • • • • • 4-36

POWER

SUPPLY

ASSEMBLY • • • • • • • • • • . • • • • • • . • . . . • • 4-37

Removal

and

Replacement

. • • • • • • . • • • • • • • • • • . . . 4-37

POWER

SUPPLY

PWB

•• • • • • • • • • . . . . . • . • • • • • . . • . . . • • 4-40

Remova

I

and

Replacement

• . • • . • • • • • • • . . . • • • • • • 4-40

--

TAKEUP MOTOR

ASSEMBLY.........

. . •. . . . • . . •• . • . 4-40

Removal,

Replacement

and

Adjustment

. . • . • •. . . . 4-40

AIR DUCT TOP

PLATE

•• • • • . • • . • . • . • • • • • . • • . • • . • • • • 4-42

Removal

and

Replacement

•• • • • • . . • • • • • • • • •• • • • 4-42

Front

Panel

Air

Duct

•• • • • • • • • • • . • • • . • • • . . . • • • • 4-42

Air

Intake

Tube

•• • • . . • • • • • • • • • • . . . • . • •• • • . • • • . 4-44

SUPPLY MOTOR ASSEMBLY • • . • • • • •• • • • •. • • • • • • • • . • 4-44

Removal

and

Replacement

. • • • . • • • • . • . • . • . . • . • • 4-44

HUB LOCK ASSEMBLY • • • • • • • •. • • • • • • • • • • • • • •• . • . • . 4-46

Disassembly,

Removal

and

Replacement..........

4-46

Reassembly

and

Installation

•• • • • • • • • . • • • • . . • . . . 4-46

MANUAL UNLOCK

ASSEMBLY......................

4-46

Removal

and

Replacement

. • . . •. . • • . . • • • • • . • • • . 4-46

DOOR LOCK ASSEMBLY • • . • • . • • • • . . • • • • • • . • • . • • . • . 4-47

Removal

and

Disassembly

. • • • • • • • . • • . • . • • • • • • • • 4-47

TRANSFORMER ASSEMBLY . . . . . •• • • •. • . . • . . •. • • • . . 4-48

Remova

!

and

Rep

I

ocement

•••••••••••••••••••••

/.,'1!111'~~·~-...,..~.---......--,-·~~..;-...,,.=nr-......

.......,.

" TAPE ALIGNMENT

.•.•.•••.•.....••......•..•......

~

Head

Azimuth

Adjustment

....•.................

~"

......

•)r.,,,,1;_,.,..,,_-.

..

,,~

-.·:..'""~~___,--·-·------·--··;-·-·

--

-··

··---·-----·-·--------·---··-,----·

'·-

- -

vi

4-48

4-49-...,

4-52

TABLE

OF

CONTENTS (continued}

Section

Title

Page No.

V ILLUSTRATED PARTS BREAKDOWN.... •••••. ••. •. •. . ••••

5-1

INTRODUCTION. . •••••. ••••••••• •••. ••. ••. •••••. •.

5-1

EXPLANATION

OF

THE

PARTS LIST. •. •. •. . . •••. •••• 5-2

VI

GLOSSARY

OF

TERMS

••• •••••••••. •• ••••••••. •. •••••. •.

6-1

vii

LIST

OF

ILLUSTRATIONS

Figure No.

Title

Page No.

1-1

Rock Mounting

Details...................................

1-7

1-2

Daisy Chain

Configuration..

•••••••• . . •. •. . •. . . ••. . . •. ••••

1-9

1-3

Daisy Chain with Embedded

Formatted

Drive •••. . . •••• . ••••

1-9

1-4 Daisy Chain Cable

Configuraton...........................

1-10

2-1

Control

Panel...........................................

2-3

2-2 Tape Threading

Path..

••••. •••. •••••••••

..

•••••••••••••. •• 2-5

3-1

Front Panel Controls and

Indicators..

. •. •. •. •••. •••. ••. •. •• 3-2

(Diagnostic Mode)

3-2 Tachometer Phase Quadrature ••••. •••. •. ••••••. . ••••••••• 3-3

4-1

Operator Maintenance

Access..

••••. ••••••••••••••. ••. •. •. 4-2

4-2 Service

Access..

••••. ••. . • . •••• . ••. •••. . ••••••. ••• ••••. . 4-4

4-3 Tape

Path

and Related

Parts..

••. •••. •••••••••••. •••••. •• • 4-5

4-4 Air

Filter

Removal . •. ••••••. •• •••. •••••••••. ••. •••••••. • 4-8

4-5

Mode

I F880 Tape Transport (Top View) ••. ••••••••••••••••. • 4-13

4-6

Mode

I F880 Tape Transport (Bottom View). . . •. . • ••••••••••. 4-15

4-7 Front Panel

Assembly....................................

4-16

4-8 SuppIy Hub Assembly ••••••••• ••••••. ••••••. ••. •. •. •••• . . 4-19

4-9 Supply

Hub

Adjustment •••••••••••••. . •. . . •••••••••••••. • 4-20

4-10 Head Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-21

4-11

Roller Guide

Assembly..

••••. •••. ••• •••••••••••. •••••. ••. 4-22

4-12

EQT

/BOT Assembly •. •••. ••••••••••. ••••••. •. . ••••••. •. . 4-23

4-13 Tachometer Assembly . •. •• •••••••••. ••••••• . •. . . ••••. ••• 4-25

4-14 Top Cover Assembly . . •••••. . •• ••••••••••••. . . ••. •••. . •. . 4-26

4-15 T

aket.Jp

Hub

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

4-16 Takeup Hub Adjustment •. •••••. •••. . ••. •••. . ••••. •••••••• 4-28

4-17 Compliance Arm and Air

Capacitor........................

4-29

4-18 Tape-In-Path Sensor,

Transmitter

•••. . •••••. . . . . . ••••. •. •. 4-32

4-19 Tape-In-Path Sensor, Receiver . •. . •. . . . ••. . •. ••. •••. •. •. •• 4-33

4-20 Compliance Arm Bumper

Assembly........................

4-33

4-21

(Solid) Tape Guide Assembly ••••. ••. ••••••.

..

••.

..

. .

..

••. •••• 4-34

4-22 Fi

i

e

Protect

Sensor . . . •. . . •. . . . •. . . . . . . . . . . . . . . . . . . . . •. . . 4-35

viii

LIST

OF

ILLUSTRATIONS

(Contirued)

Figure

No.

Title

Page No.

4-23 Drive Main Printed-Wiring Board . . •. . . •. . . •. ••. . • . . . . . ••. . 4-36

4-24 Power Supply Assembly . . . . •. . . . . . . •. . . . . •. . . . . . . . . •. . . . . 4-38

4-25 Power Supply

PWB

. . •. . . • . •. . . . . •. •••. . . •. •••. • . . . . . . . . . 4-39

4-26 Takeup Motor Assembly . . ••••

..

. . . •. •••. . . . •. . •. . ••. . . •. . .

4-41

4-27 Top

Plate

Air Duct, Front Panel Air

Duct...................

4-43

Air Intake Tube

4-28 Supply Motor Assembly . ••. ••. . •. . ••. . . •. . . . . . ••. . . . . . ••. 4-45

4-29

Hub

Lock Assembly. •. • . . . . •. •. . ••. . •. . . . . ••••. • . . . . . . . . . 4-45

4-30 Door Lock

Assembly...................................

. . 4-47

4-31

Transformer Assembly •. ••. •. ••. •. •••••. . ••. . ••. •. . •. . . . . 4-49

4-32 Tape

Path

Adjustment . . •. . . . . . . . . . •. . ••. . . . •. . . •. . . •••. .

4-51

4-33 Skew Adjustment Waveform . . . . . . . ••. . . •. . . . . . •••. . •. . . . . 4-53

4-34 Reference Edge Measurement Waveform . . . •. . . . •. . . . . . . . •• 4-54

(TP48) Using Pericomp Tracking Tape

5-1

Model F880 Magnetic Tape

Streamer

Unit...................

5-5

(Assembled View)

5-2 Model F880 Magnetic Tape

Streamer

Unit...................

5-11

(Assembled View)

5-3 Front Panel Assembly (Exploded

View)......................

5-16

5-4 Top Cover Assembly (Exploded View).. . . . . . ••• . . . . •. . . . ••. . 5-18

5-5 Top Plate/Chassis Assembly (Exploded View). . •• . . •. . . . . . . . •

5-21

5-6 Drive

Formatter

PWB

Assembly (Exploded

View).............

5-43

5-7 Harness Assembly (Orthographic View). . •. . •• . . •. . . . •. . . . . • 5-47

5-8 Power Supply Assembly (Exploded View). . . . . . •. . . •. •. . . . . . .

5-51

S-9 Supply Hub Assembly (Exploded View). •. . . •. . . . . •. • . . •. •. . . 5-55

5-10 Power Supply

PWB

(Orthographic View).. . •. •. . . . . •. . . . •. . . . 5-57

5-11

Drive

Formatter

PWB

(Orthographic).......................

5-59

ix

LIST

OF

TABLES

Table

No.

Tit

le

Page

No.

1-1

Operating Voltage

Selection

•. •. . . • . . . . • . . • •. . •. . . . . • . . • . .

1-3

1-2 Address Line Decoding . • . •. •. •. . . •• •• ••• ••• •. . ••. . •• . . . . • 1-8

2-1

Controls and Indicators . •• . •. •. . . •• . •• •. . •• •. . •• •• . . . . . • • 2-2

2-2

Operator

Error

Front

Panel

Indications.....................

2-4

3-1

Compliance Arm Voltage

Display..........................

3-4

3-2 System

Fault

Codes •. ••. . •. . •. . . . •. •• . . •• •• •. . . . . . •. • •. . 3-7

3-3 Power-Up Malfunction

Symptoms.......

•• . . • •• ••• . ••• •• •• • 3-8

3-4

Operator

Error

Symptoms . ••. •. •• . •. • •. . . . . . . •. •. •. • . . . . . 3-9

3-5 Transport

Fa

iiure Symptoms • •• ••• • •• •. . • . • • •• • •• •• . • . . • . . 3-10

3-6 System

Failure

Symptoms . •• . •. . . •• ••• ••. •. . . • •• •• •. . . . . • 3-13

4-1

Preventive

Maintenance Schedule . . . . . • •. . •. . . . ••. • •• ••• . . 4-6

4-2

Reference

Edge

Distance......

. ••. . •. •• . . . •. •. •• . . . . . . . . . 4-54

x

SECTION I

DESCRIPTION, UNPACKING, INSPECTION, AND INSTALLATION

GEl\ERAL

1-1. The Model F880 Magnetic Tape

Streamer

Unit (MTSU)

is

a dual-speed, dual-

density,

tape

transport

manufactured

by Cipher

Data

Products

Inc., San Diego,

California.

It

incorporates

a dual-gap

head,

providing

read-after-write

capability.

Read/write,

control, and

formatting

electronics

are

all

incorporated

in a single

printed-wiring board (PWB). The

transport

is

designed

to

operate

on 85-

to

132-Vac

or

195-

to

263-Vac, single-phase, 48-

to

61-Hz line power.

Reels

to

10.5 inches in

diameter

can

be

accommodated.

Tape

speed

and

density

capabilities

are

as

follows:

a.

Model F880

MTSU

(1600 bpi)

(I)

25 ips

at

1600 bpi

(2)

I00 ips

at

1600

bpi

b. ModeI F880 M

TSU

(3200 bpi)

(I)

25 ips

at

1600

bpi

(2)

50 ips

at

3200 bpi

(3)

I00 ips

at

1600

bpi

This

section

presents

instructions for unpacking, inspecting, and installing

the

MTSU.

l.)\jpACJ<ING AND INSPECTION

1-2. The

MTSU

is

shipped in a single

carton

reinforced

by

eight

corner

blocks

to

minimize

the

possibility

of

damage

during shipping. Unpack as foilows:

a. With shipping

container

on floor

or

workbench,

cut

side and

center

tapes

securing

top

of

outer

box.

b. Pull box-top flaps down along sides

of

box.

Lift

upper foam

corner

blocks

off

MTSU, remove

MTSU

and

place

on

table.

Remove

manual,

1/0

connector

retainer,

and

rack

latch

bracket

from shipping

carton.

c.

Check

contents

of

shipping

container

against packing slip, and

inspect

for

possible

damage.

If

dcmoge

exists,

notify

carrier.

1-

I

d.

Refer

to

the

illustration

taped

to

the

front

door. Remove

tape

holding

top cover and

front

door in

place.

Open top cover by lifting sides

directly

behind

front

panel.

Place

cover

stay

(left

rear

of

top cover)

in

the

slot

provided. This

is

the

maintenance

access

position. Pull

tachometer

(spring loaded

arm

at

left-rear

of

unit) away from hub and discard

the

foam cushion.

Carefully

replace

tachometer

assembly

against

hub.

e.

Examine

the

hubs,

tachometer,

and

other

components in

tape

path

area

for

foreign

matter.

f. Using a

screwdriver,

loosen

two

captive

screws

at

front

sides

of

top

plate

casting.

Close

the

top cover.

Lift

front

panel (and top

plate

casting) by

grasping

the

two

lower

corners.

Lift

unit

to

its maximum upright

position.

Latch

mechanism will

automatically

engage when unit is

lowered

approximately

one inch. Insert

the

safety

pin provided through

both holes

in

the

top

plate

support

from

outside

inward (Figure 4-2). This

is

the

service

access

position.

g. Remove 3 pieces

of

foam packing

material

from

PWB.

Check

PWB

and

all

connectors

for

correct

installation.

h. To

release

latch

mechanism,

remove

the

safety

pin and lift

front

panel

before

lowering it. Open top

cover

and

tighten

captive

screws.

Close top

cover.

i. Do not

replace

packing

tape

or

foam cushion

materials.

j.

Verify

that

the

operating

voltage

indicated

on

the

manufacturers

label

(rear

of

chassis)

matches

the

power

outlet

voltage

for

the

unit.

If

not,

refer

to

paragraph 1-4

for

instructions

to

change

the

operating

voltage.

POWER CON\ECTION

To

prevent

damage

to

the

MTSU

and ensure

proper

operation,

be

sure

the

outlet

voltage

is

correct

before

applying power

to

the

MTSU.

1-3. A power cord

is

supplied only for

the

voltage range indicated

on

the

manufacturers

label.

1-4.

Operating

Voltage

Selection.

The M

TSU

can

be

operated

over a wide range

of

line voltages by

selection

of

the

appropriate

power supply

voltage

option. To change

the

power supply option,

proceed

as follows:

i-2

When

MTSU

is

to

be

extended

on slides from

equipment

rack,

ensure

that

rack

is

mounted

securely.

Weight

of

MTSU

in

extended

position

could upset

an

inadequately mounted equipment

rack.

a.

Switch

transport

power OFF and remove power

cord

from

outlet.

b.

Open unit

to

service

access

position.

Refer

to

paragraph 1-2

(f).

c.

Place

a shop

cloth

or

similiar

item

over

the

PWB

in

the

area

of

the

power

supply assemblye .

WARNING

I

Dangerous voltages

can

be

encountered

in

the

next two

steps

if

the

power cord

is

connected

to

an AC

source

or

if

the

unit has had power

applied

in

the

last

two minutes.

d.

Refer

to

Figure 4-23. Remove two phillips head

screws

securing

power

supply cover, noting position

of

chassis ground cable.

Pivot

cover

to

the

right and slide forward

to

remove.

e.

Remove

voltage

selection

card

(4,

Figure

4-24) from

J9

on power supply

PWB.

Noting position

of

key

slot

on

voltage

selection

card,

reinstall

the

card

in

J9

to

correspond

to

the

desired

voltage.

Refer

to

Table

1-1.

f.

Reverse

steps

c and d.

g.

Replace

the

fuse, if

required,

with one

of

the

correct

current

rating

for

the

voltage

selected.

Refer

to

Table 1-1. Use a slo-blo, 250V

type.

The

fuse holder is

located

on

the

right-front

of

the

power supply assembly.

Replace

the

power cord if required.

h. Adjust

the

+5V

regulator

circuit

on

the

main PWB.

Refer

to

paragraph

4-16.

i.

Note in a

prominent

location on

the

unit

that

the

"operating

voltage

(has

been) changed

to

11

NOMINAL LINE SELECTION FUSE

VOLT

AGE (TOLERANCE) CARD (AMPS) FREQUENCY

(Hz)

100

-

(85

-110)

100

3.0 49-63

120

-(102 -

132)

120

3.0 49-63

208

~I

,..._,.

""'""'

220

i.5

49-63

-

\ltj/

-

LLtj}

220 -(187 -242) 220

1.5

49-63

230 -(207 -253) 240 1.5 49-63

..,.,

,.,.

'"r"\.

I

"""'

""'I

\.

~·

~

. -

• -

.a!"'-

L4U

-

\LU4

-

Lf:>q}

LLl-0

I

.:>

4~-6j

Table 1-1.

Operating

Voltage

Selection

1-3

INITIAL

Ct-EO<OUT

1-5. Section

II

contains

a

detailed

description

of

all

controls.

To

check

for proper

operation

before

installation,

proceed

as follows:

1-4

a.

Connect

power

cord.

b. Clean

tape

path

as

directed

in

paragraphs

4-4

through 4-10.

c.

Apply power to

l.X"lit

and

verify

that

UNLOAD indicator

is

illuminated.

(Allow for normal delay

of

2 seconds).

For

other

indications

refer

to

paragraphs 2-6 and

2-

7.

d. Ensure

that

tape

is

wound

completely

onto

reel.

Both top cover and

front

paneI door

are

Iocked

during

tape-loaded

fl.X"lctions.

Any

attempt

to

open

either

top cover

or

front

panel door

before

tape

is

unloaded will

result

in mechanical

damage

to

the

locking mechanism.

e.

Open

front

panel door by pressing down

gently

on

top

(center)

of

door.

f. Insert

tape

into

front

panel

of

lX"lit

with

write-enable

ring side down.

g. Close

front

panel door.

h.

Actuate

LOAD

switch.

Access doors

are

now locked.

When

load

sequence

is

completed,

LOAD indicator will

remain

illuminated.

i.

Initiate

Service Aid

22

as described in

paragraphs

3-3 and 3-27. Allow

transport

to

cycle

tape

for a

sufficient

length

of

time

to

ensure

proper

servo

operation.

(It requires

about

30 minutes

to

make

a full pass on a

10.5 inch reel and

complete

a rewind sequence).

j.

Exit Service Aid 22.

Refer

to

paragraph

3-4.

k.

Check

that

LOAD indicator remains illuminated following rewind

sequence.

I.

Check ON-LINE

switch

and indicator by depressing

repeatedly

and

observing

that

ON-Llf\E indicator

is

alternately

illuminated and

extinguished. Leave in OFF-LINE

state

(indicator extinguished).

m.

Press

UNLOAD

switch.

When

the

tape

is

lXlloaded (UNLOAD indicator

ii

luminated) open

front

panel door and remove

tape

reel. Close front

panel door.

n. Switch power

off

and remove power

cord

from

out

let.

RAO<

MOUNTING

1-6.

The

MTSU

is

designed

to

be mounted

in

a standard,

19

inch wide,

EIA

eq.Jipment rack using the slides and mounting hardware provided with each unit.

Refer

to

Figure

1-1

and drawing

in

Installation Hardware Package

to

mount

the

unit as

follows:

a.

Locate

the

front

and

rear

rail holes

to

be

used

on

the

equipment rack

(I,

Figure

1-1).

If

they

are

threaded, drill them out

to

0.281

inches.

b. Place

the

transport

in

service

access

position.

Refer

to

paragraph 4-3.

c.

Starting with

either

side, remove

stationary

section of slide

(2)

from

transport

by pulling

stationary

section

to

the

front

of

transport.

d. Remove

intermediate

section of slide

(3)

from

transport

by

pulling

intermediate section

to

the

rear

of

transport.

When

spring lock engages,

depress

to

release.

e.

Reassemble these sections by sliding front

of

intermediate

section into

rear

of

stationary

section. Depress spring lock

to

slide completely

together.

Leave these sections assembled.

f. Determine, for the depth

of

rack,

the

appropriate holes

to

use

in

the

mounting

bracket

and

secure

loosely

to

stationary

section using two

10-

32

X

3/8

binder head screws

(4)

and a nut

plate

(5).

g. Mount front flange

of

stationary

section

(2)

to

front

rail

by

placing flange

behind rack rail holes.

h. Install two

10-32

X

3/8

binder head screws (6),

first

through front

of

rail,

then through

stationary

section flange and

secure

loosely with a nut

plate

(7).

i. Mount mounting

bracket

to

rear

of

rack

by

placing flange

in

front

of

rack

rail holes.

j.

lnsta

II

two I

0-32

X

3/8

binder head screws

(8),

first

through back

of

rack,

then through mounting

bracket

flange and secure loosely with a oot

plate

(9).

k. Check a

Ii

gnment and

correct

as

necessary. Tighten

front,

rear,

and

mountirg

bracket

attachment

screws.

I.

Repeat

steps

b through j for

other

side.

m.

Install

the

bottom

edge

of

the

rack latch

bracket

(10)

on

the

left

rail

2.13

inches below

the

center-line

of

slide using two

6-32

X 7/16

flat

head

lo''

''

•

1

II"'\

1•1

I I L

/I")\

...I

1\.1

i:

L.

.a.

screws

\I

IJ,

r1ar

wasners

\IL.J,

sp1n-10C1<

wosners

\l.JJ

emu

'"°·

o

11ex

nu.s

(14).

n. Slide

intermediate

sections forward until locks engage.

1-5

Figure

1-1

R

• ack

Mounting

1-6

o.

Carefully

slide

the

MTSU's

transport-attached

chassis mount

sections

(15)

into

intermediate

sections

while checking for binding or

interference.

Release

locks and,

before

closing fully,

check

that

the

rack

latch will

engage

secure

Iy.

p. Adjust

rack

latch

bracket

(IO) or slides as

required.

To

release,

squeeze

rack

latch

plate

inside

air

duct

opening

at

lower

left

of

front

panel.

q.

Connect

the

power

cord.

A

service

loop must

be

provided. Ensure

the

cord will not

chafe

or

interfere

with

other

equipment.

INTERFACE CCN'ECTIONS

1-7. It is recommended

that

interconnection

of

the

MTSU

and

customer

equipment

be

made with a

flat

ribbon

cable

or a harness of individual

twisted

JX1irs,

each

with

the

following

characteristics:

a.

Maximum length

of

25

feet.

b. Not less

than

one

twist

per

inch when using

twisted

pair.

c.

22- or 24-gauge conductor with minimum insulation thickness

of

0.0I inch

on

twisted

pair

cables.

d. 28-gauge conductor

is

used

with

flat

ribbon

cable.

1-8. It

is

important

that

the

ground side

of

each

twisted

JXlir,

or

the

alternate

conductor in a ribbon

connector,

be grounded. The

mating

connector

(3M

ComJXlny

Part

No. 3415-0001 or equivalent)

must

be wired by

the

customer.

For

twisted-JXlir

cables,

connector

(Viking

Part

No. 3VT25/og JNH

12

or

equivalent)

should

be

used.

1-9.

Strain

relief

for flat-ribbon

interface

cables

is

provided for by

the

retainer

included

in

the

mounting

hardware

package.

Install

the

connector

retainer

as follows:

a.

Insert spring-loaded pins into holes

located

at

each

corner

of

PWB.

b.

Lift

retainer

to

allow

access

to

edge

connectors.

c.

Install ribbon cables so

that

cables

are

on

bottom

sides

of

mating

connectors.

d. Lower

retainer

and position over back sides

of

1/0

connectors.

MULTIPLE-lRANSPORT OPERATION

1-10. The

MTSU

may

be

configured

to

allow

operation

of

up

to

eight

transports

with

a single

controller.

Use cables similar

to

those described in paragraph 1-7 for

interconnection

of

transports.

Refer

to

Figures 1-3 and 1-4.

1-11.

To

configure

the

M

TSU

to

operate

on a multiple

transport

system,

proceed

as

follows:

a.

Place

MTSU

in

service

access

position. (See paragraph 4-4.)

I 7

I - I

b. Remove

terminator

resistor pack

U3W

and UI

OW

(Figure 1-5) from each

transport

except

last

unit.

c. Install interconnection cables

as

shown in Figure 1-5.

1-12. The transport

is

selected by a combination

of

the levels

on

the

IF

AD,

ITADO,

and IT

AD

I lines and the position

of

switches

SI,

S2,

and 54.

Refer

to

Table

1-2

for

address decocling.

ADDRESS

IFAD ITAD

0

ITAD

I

SI

S2

54

0 0 0 0 I I I

I 0 0 I I I 0

2 0 I 0 I 0 I

3 0 I I I 0 0

4 I 0 0 0 I I

5 I 0 I 0 I 0

6

I I 0 0 0 I

7 I I

I 0 0 0

0

==False

Interface

Level 0

==

Open

I

==

True

Interface

LeveI I

==Closed

Table 1-2. Address Line Decoding

1-8

TA

WI

FO

COUPLER

.....

.....-

-

l

,,

TRANSPORT

TRANSPORT

1

2

Figure 1-2.

Daisy

Chain Configuration

COUPLER

.....

--

F880 MUST

BE

FIRST

(MAX

OF

3)

~'

,~

,,

TRANSPORT

TRANSPORT

TRANSPORT

1 2

3

,~

_{

l l

TERMINATED

PE

TRANSPORT

EMBEDDED

SLAVE SLAVE

TH

EMBEDDED

FORMATTER

TRANSPORT TRANSPORT

RM

ATTE R

TRANSPORT

2 3

1 I

I I

Figure

1-3. Daisy Chain with Embedded

Formatted

Drive

TERMINATED

TRANSPORT

4

l

TERMINATED

SLAVE

TRANSPORT

4

I

1-9

0

FROM

COUPLER

OR

PREVIOUS

TRANSPORT----------

......

,...-----...,

P1

TERMINATORS

NOT

USED

DI

FIRST

OR

INTERMEDIATE

TRANSPORT

P1

P2

TERMINATORS

USED

D 0 I

LAST

TRANSPORT

Figure

1-4.

Daisy

Chain

Cable

Configuration

P1

0

Table of contents

Other Cipher Storage manuals

Popular Storage manuals by other brands

Net2Edge

Net2Edge DataBand ISU quick start guide

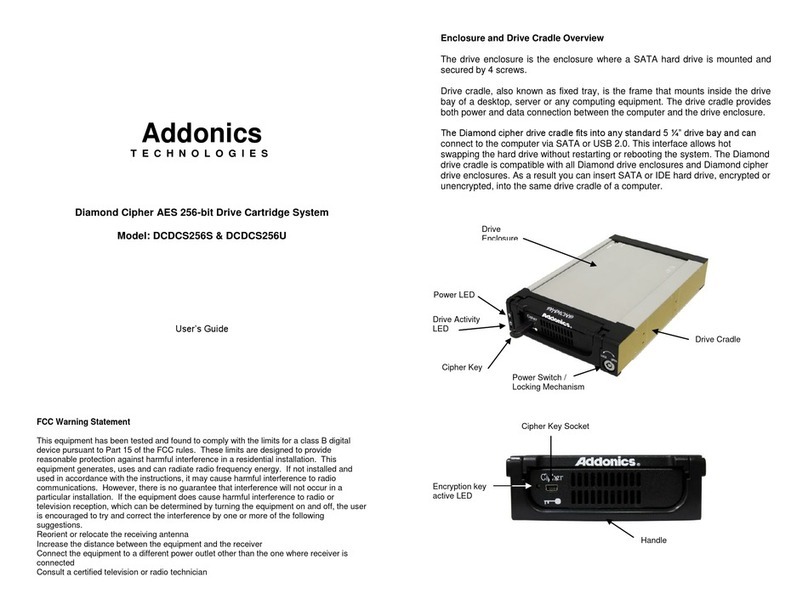

Addonics Technologies

Addonics Technologies DCDCS256S user guide

Intel

Intel SS4200-E - Entry Storage System NAS Server Technical product specification

Seagate

Seagate 2.5-inch, LD25 product manual

Onnto

Onnto RS-M4QO user manual

Microdia

Microdia Micro-Flash AluminPLUS USB 2.0 installation guide