CIPU CSPPV711 User manual

READ AND FOLLOW ALL INSTRUCTIONS IN THIS OWNER’S

MANUAL AND ONEQUIPMENT.

This equipment must be installed and serviced by aqualified technician or professional,

in accordance with the National Electrical Code and all applicable local codes and

Ordinances. Improper installation can create electrical hazards which could result in

property damage, seriousinjury or death. Improper installation will void the warranty.

Notice to Installer

This manual contains important information about the installation,operation and safe

use of this product. Once the product has been installed this manual must be given to

the owner/ operator of this equipment.

Inground

VS Pumps

Item # CSPPV711

Water temperature in excess of 100°F(37.7°C) may be hazardous to your

health. Prolonged immersion in hot water may induce hyperthermia.

Hyperthermia occurs when the internal temperature of the body reaches a

level several degrees above normal body temperature of 98.6°F(37°C.).

Effects of hyperthermia include: (1) Unawareness of impending danger. (2)

Failure to perceive heat. (3) Failure torecognize the need to leave the spa. (4)

Physical inability to exit the spa. (5) Fetal damage in pregnant women. (6)

Unconsciousness resulting in danger of drowning. The use of alcohol, drugs,

or medication can greatly increase the risk of fatal hyperthermia in hot tubs

and spas.

To reduce the risk of injury, do not permit children to use or operate this

equipment.

When setting up pool water turnovers or flow rates, the operator must consider

local codes governing turnover as well as disinfectant feed ratios.

If this pump is intended for use in other than single-family dwellings, a clearly

labeled emergency switch shall be provided as part of the installation. The switch shall be

readily accessible tothe occupants and shall be installed at least 5 feet (1.52 m) away,

adjacent to and within sight of this pump.

RISK OF ELECTRICAL SHOCK OR ELECTROCUTION:

PUMPS REQUIRE HIGH VOLTAGE WHICH CAN SHOCK, BURN, OR

CAUSEDEATH. Before working on pump, always disconnect power tothe

pool pump at the circuit breaker before servicing the pump. Failure to do so

could result in death or serious injury to service person, pool users or others

due to electric shock.

Pumps improperly sized or installed or used in applications other than for

which the pump was intended can result in serious personal injury or death. These risks may

include but not be limited to electric shock, fire, flooding, suction entrapment or serious injury

or property damage caused by a structural failure of the pump or other system component.

Never exceed the maximum stated pump flow rating.Only use a pumping

system rated for the corresponding flow. FAILURE TO DO SO CAN RESULT INHAIR OR

BODY ENTRAPMENT WHICHCAN CAUSE SERIOUS PERSONAL INJURY OR DEATH. If in

doubt about the rating of your system, consult a qualified pool service professional.

Pumps are not a substitute for properly installed and secured pool drain covers.

An ANSI/ASME A112.19.8 approved anti-entrapment drain cover must be used for each drain.

Pools and spas should utilize a minimum of two drains per pump. Regularly inspect all covers

for cracks, damage and advanced weathering. If a cover becomes loose, cracked, damaged,

broken or is missing, closethe pool or spa immediately, shut off the pump, post a notice and

keep the pool or spa closed until an appropriate VGB 2008 certified cover is properly installed.

Covers deteriorate over time due to exposure to sunlight and pool chemicals. This cover must

be replaced within seven (7) years from installation (or earlier if the cover becomes damaged

in any way).

1

Hair Entanglement –When the hair tangles or knots in the drain cover, trapping the swimmer

underwater. This hazard is present when the flow rating of the cover is too small for the pump

or pumps.

Limb Entrapment –When a limb is sucked or inserted into an opening resulting in a

mechanical bind or swelling. This hazard is present when a drain cover is missing, broken,

loose, cracked or not properly secured.

Body Entrapment –When a portion of the body is held against the drain cover trapping the

swimmer underwater. This hazard is present when the drain cover is missing, broken or the

cover flow rating is not high enough for the pump or pumps.

Evisceration/Disembowelment –When a person sits on an open pool (particularly a child

wading pool) or spa outlet and suction is applied directly tothe intestines, causing severe

intestinal damage. This hazard is present when the drain cover is missing, loose, cracked, or

not properly secured.

Mechanical Entrapment –When jewelry, swimsuit, hair decorations, finger, toe or knuckle is

caught in an opening of an outlet or drain cover. This hazard is present when the drain cover is

missing, broken, loose, cracked, or not properly secured.

GENERAL SAFETY RULES

1. The products mentioned in this manual are specially designed for the pre-filtering and

re-circulation of water in swimming pools and spas.

2. They are designed towork with clean water at a temperature not exceeding 104 40!!

3. The installation should be carried out in accordance tothe safety instructions of swimming

pools, especially Standard HD 384.7.702 , and the specific instructions for each facility.

4. The compulsory rules on accident prevention should be carefully followed.

5. Any modification of the pump requires the prior consent of the manufacturer. Original

replacement parts and accessories authorized by the manufacturer ensure a high level of

safety. The manufacturer of the pump assumes no liability for the damage and injuries caused

by un-authorized replacement parts and accessories.

6. During operation, some parts of the pump are subject to dangerous electric voltage. Work

may only be performed on each pump or on the equipment connected to it after disconnecting

them from the main power and after disconnecting the starting device.

7. The user should make sure that assembly and maintenance tasks are carried out by

qualified authorized persons and that these persons have first carefullyread the instructions

for service and installation.

2

WARNINGS AND IMPORTANT SAFETY PRECAUTIONS

SUCTION ENTRAPMENT HAZARD

8. The operating safety of the pump is only guaranteed ifthe installation and service

instructions are correctly followed.

9. The limit values stated inthe technical table should not be exceeded under any condition.

10. Inthe event of defective operation or fault, contact the technical support department of the

manufacturer or it’s nearest authorized agents.

11. Ifthe supply cord is damaged, it must be replaced by the manufacturer or its service agent

or a similarly qualified person to avoid a hazard.

12. The pump must not be used when people are in the water.

13. The pump must be supplied through a residual current device (RCD) having a rated

residual operating current not exceeding 30mA.

14. Children should be under close supervision to prevent them from playing with the pump.

15. This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety.

16. The pump must be protected from running dry.

Important Electrical Notice

The electrical installation isto be done by a licensed electrician.

Each pump requires a circuit breaker to separate the pump from the electrical supply.

The open contact distance of the circuit breaker is to be no less than 3mm

The pump is to be supplied by an isolating transformer, or supplied through a residual current

device (RCD) with a rated residual current not exceeding 30mA.

Checkthe pumps name plate for the following: Voltage, Amp draw and Cycle.

The power cord, including the ground wire shall have a quality of 245 IEC66 (HO7RN-F) for

models greater than 1kW power input.

For models less than 1kW input the quality shall be of 245 IEC57 (H05RN-F).

All installations must comply with local codes, based on IEC 364-7-702 requirements.

RESPECT THE MINIMUM GAUGE GIVEN IN THE CHART OF THE TECHNICAL MANUAL.

INSTALLATION

Location

Note: Do not install this pump within an outer enclosure or beneath the skirt of a hot tub or

spa unless marked accordingly.

Note: Ensure that the pump is mechanically secured tothe equipment pad.

Be sure the pump location meets the following requirements:

1. Install the pump as close tothe pool or spa as possible. To reduce friction loss and improve

efficiency, use short, direct suction piping returns.

2. Install a minimum of 5 feet (1.52 meters) from the inside wall of the pool and spa. Canadian

installations require a minimum of 9.8 feet (3 meters) from pool water level.

3. Install the pump a minimum of 3 feet (9 meters) from the heater outlet.

4. Do not install the pump more than 10 feet (3.1 meters)above the water level.

5. Install the pump inawell ventilated location protected from excessive moisture (i.e., rain

gutter downspouts, sprinklers, etc.)

3

6. Install the pump with a rear clearance of at least 3 inches (76.2mm) so that the motor can be

removed easily for maintenance and repair. See Figure 1.

Piping

1. For improved pool plumbing, it is recommended to use a larger pipe size. When installing

the inlet and outlet fittings (male adaptors), use thread sealant.

2. Piping on the suction side of the pump should be the same or larger than the return line

diameter.

3. Plumbing on the suction side of the pump should be as short as possible.

4. It is recommended that a valve, elbow or tee installed inthe suction line should be no closer

to the front of the pump than five (5) times the suction line pipe diameter. See Figure 2.

Example:

A 2 inch pipe requires a 10 inch (254 mm) straight run in front of the suction inlet of the pump.

This will help the pump prime faster and last longer

Fittings and Valves

1. Do not install 90°elbows directly into pump inlet.

2. Flooded suction systems should have gate valves installed on suction charge pipes for

maintenance, however, the suction gate valve should be no closer than five times the suction

pipe diameter as described in this section.

3. Use a check valve in the discharge line when using this ump for any application where there

is significant eight tothe plumbing after the pump.

4. Be sure to install check valves when plumbing in parallel with another pump. This helps

Figure 1:Pump Rear and Overhead Clearance

Figure 2 Recommended Piping

4

prevent reverse rotation of the impeller and motor.

Electrical Requirements

·Install all equipment in accordance with the National Electrical Code and all applicable local

codes and ordinances

·Ameans for disconnection must be incorporated inthe fixed wiring in accordance with the

wiring rules.

Note: ALWAYS reinstall the lid onto the field wiring compartment when leaving the pump

unsupervised during servicing. This will prevent foreign matter (i.e. rainwater, dust, etc.) from

accumulating in the field wiring compartment.

Wiring

1. Be sure all electrical breakers and switches are turned off before wiring motor.

STORED CHARGE - Wait at least sixty (60) Seconds before servicing.

2. Be sure that the supply voltage meets the requirements listed on the motor nameplate. If

these requirements are not met, permanent motor damage may occur.

3. For wiring sizes and general guidelines for proper electrical installation, please follow the

specifications

defined in the National Electric Code and any local codes as required.

4. Use strain relief and be sure all electrical connections are clean and tight.

5. Cut the wires tothe appropriate length so they do not overlap or touch when connected.

6. Reinstall the keypad cover after wiring the pump plugging the cover back into the drive

wiring connection and re-seating the keypad cover in the desired orientation with the four (4)

corner screws.

Note: Ensure that the keypad cable is not pinched between the drive and keypad cover during

re-seating.

5

6

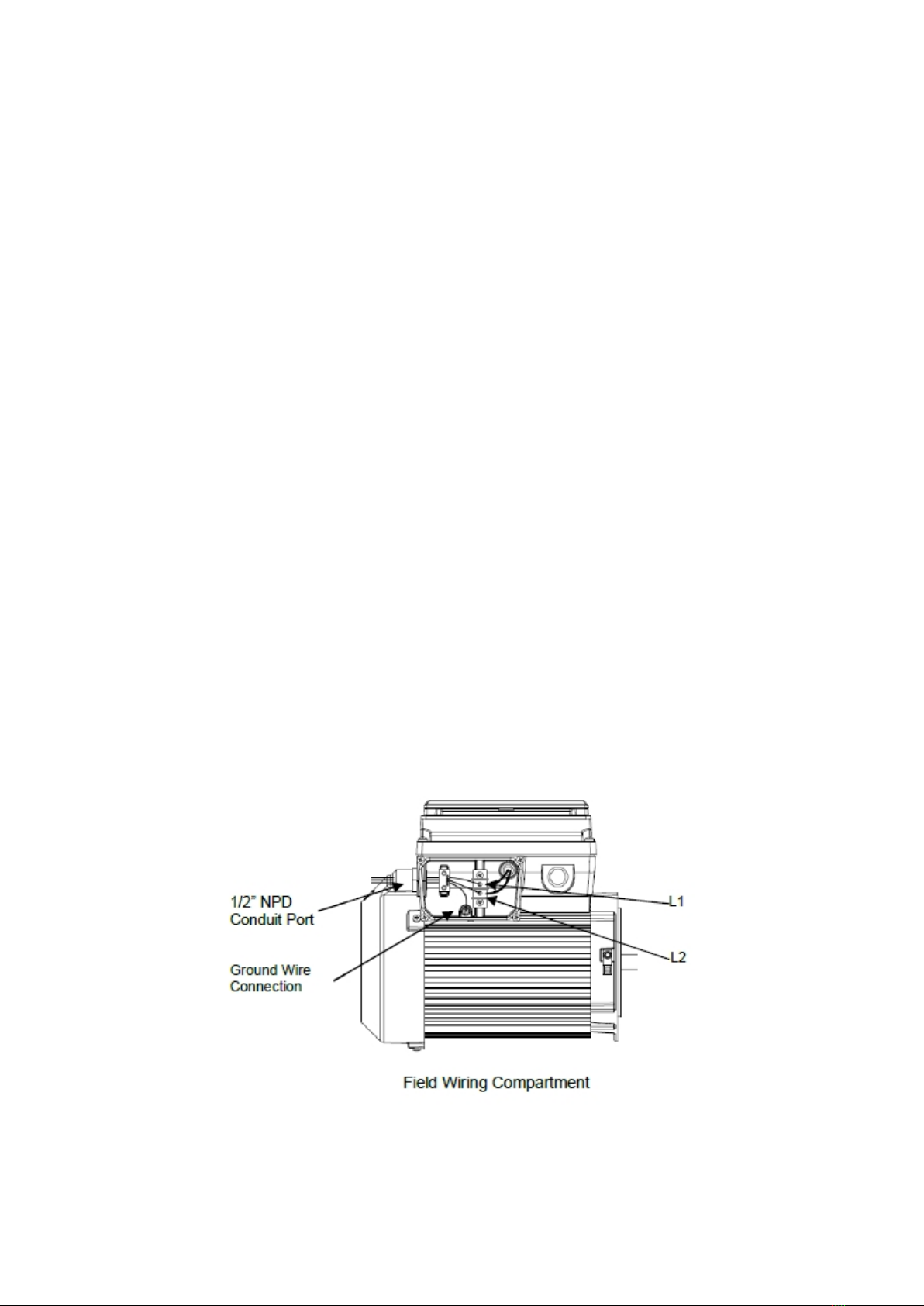

Grounding

1. Permanently ground the motor using the green ground screw, as shown below. Use the

correct wire size and type specified by National Electrical Code. Be sure the ground wire is

connected to an electrical service ground.

2. The pump should be permanently connected to a circuit breaker, 2-pole timer or 2-pole relay

Note: If AC power is supplied by a GFCI circuit breaker, the pump should be wired on its own

independent circuit unless the pump is operated in tandem with a salt chlorine generator.

Bonding

Bond the motor tothe structure in accordance with the National Electrical Code. Use a solid

copper bonding conductor not smaller than 8 AWG. For Canadian installations, a 6 AWG or

larger solid copper bonding conductor is required. Run a wire from the external bonding screw

or lug tothe bonding structure.

2. Connect the wire from the accessible bonding lug on the motor to all metal parts of the

swimming pool, spa, or hot tub structure and to all electrical equipment, metal conduit, and

metal piping within 5 feet (1.52 meters) of the inside walls of the swimming pool, spa, or

hot tub. Run a wire from the external bonding screw or lug tothe bonding structure.

Note: When the pump is started and stopped by removing power with a relay or timer, a

two-pole device should be used

to apply and remove power to both POWER LINE TERMINALS. While meeting 2008 to current

NEC Standards for Pool Pumps.

PRODUCTIONINTRODUCTION

This variable speed pump is designed to operate your swimming pool filtration system

as well as your spa, waterfall, cleaner, heater, salt chlorine system and other water

applications.

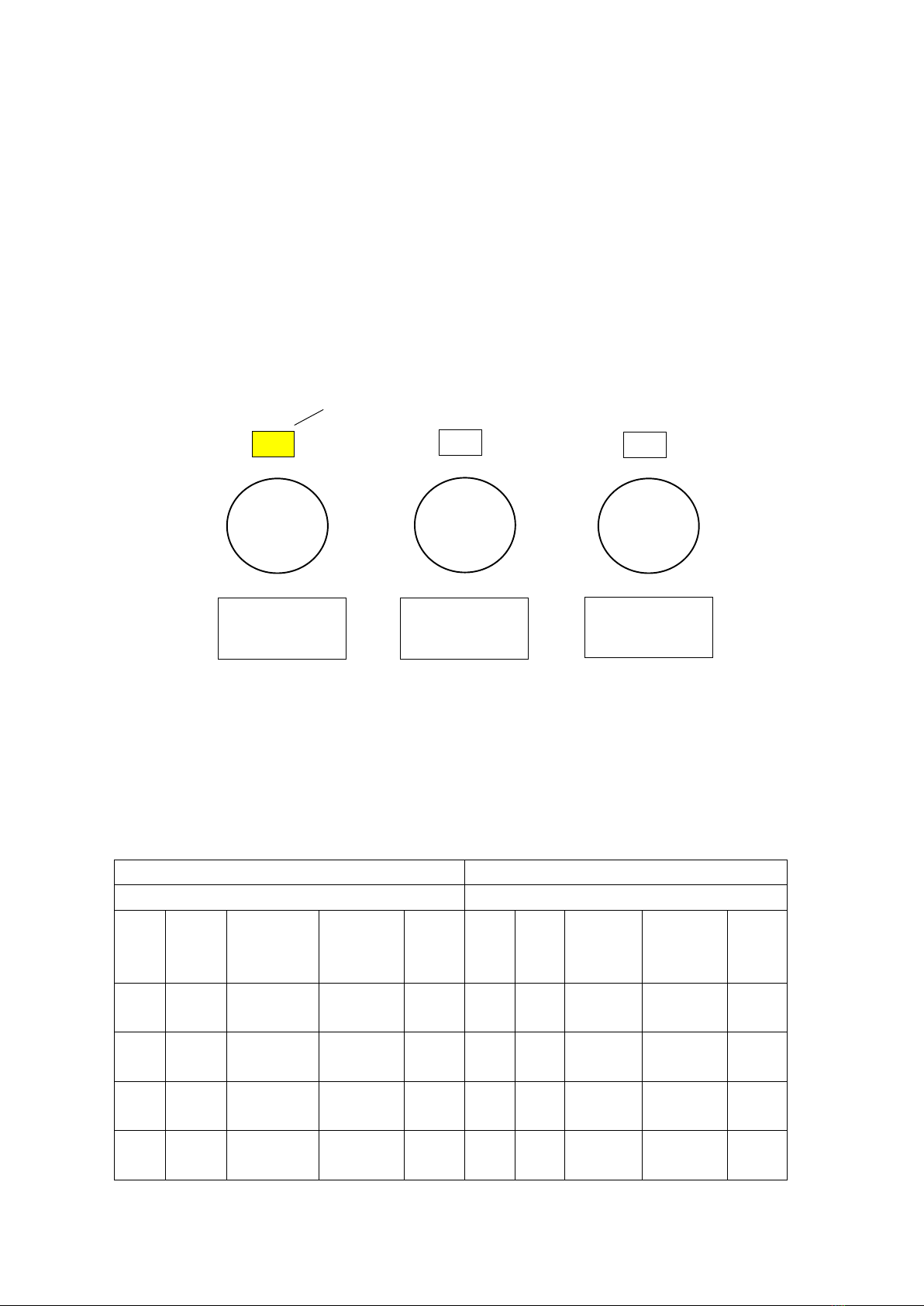

Using the control panel, you can run your pump on one of three scheduled programs:

1. Regular mode: use three quick start buttons.

ECO (default 1500RPM)/CLEAN (default 2400RPM)/ BOOST (default 3250RPM), and then

adjust the pump torunat the speeds you selected.

2. Mode 1: 16 hour s for each clean cycle.

3. Mode 2: 24 hour s for each clean cycle.

The control pane l also has LED indicators for speed as well as alarm indicators and error

messages towarn the user against under and over voltage, high temperature, over current

and freeze protection.

1. Features of LEDControl Pane l

1!Display and changetime

2!Display and changerunning speed

3!Quick-start button of ECO/CLEAN/BOOST to run on different speed

4!MODE1/MODE2 for scheduled program (16 hours or 24 h ours clean cycle)

5!Re-start and reset to normal schedule after over current, over voltage, over heat, or

unexpected power off.

6!Keep records of scheduled programs for maximally 15 days after power off.

7!Run 5 minutes high speed when first start the pump

8!Step-by-step acceleration and deceleration of the speed to extend the use life of the

motor and control panel

2. Introduction of LED Control Board

!ECO: Press to select and run on default speed 1500 PRM, can adjust from 1000 to 2400

RPM

"CLEAN: Press to select and run on default speed 2400 PRM, can adjust from 2400 to 2850

RPM

#BOOST: Press to select and run on default speed 3250 PRM, can adjust from 2850 to 3450

RPM

$STOP: Press to stop the pump. The screen displays the present time

%MENU: Accesses the pump menu ifthe pump is stopped

&MODE 1: To run the programmed 16 hours clean cycle.

'MODE 2: To run the programmed 24 hours clean cycle.

(Enter: Save and exit the menu.

)ARROW BUTTONS:

•UP ARROW –Move up on e level in the menu or to increase a digit when changing a

setting

•DOWN ARROW –Move one level down in the menu or to decrease a digit when

changing a setting.

•LEFT ARROW –Moves the cursor left one digit when changing a setting

•RIGHTARROW –Movesthe cursor right one digit when changing a setting

*LED Screen: Composed of four digital tubes. Display current time when in standby. And

display the current and running speed back and forth in operation.

+AM/PM: Designed for 12-hours system. If pump run on 0:0 0 -11:59, AM light on ;

run on 12 :00 - 23:59, PM light on.

,MODE1 and MODE 2 have 4 stages, S1/S2/S3/S4 is the speed for each stage. Ifthe S1

light is on, the pump is run on first stage, if the light twinkles, the time for the stage is not

arriving yet or the pump is no t running. If SPEED light is on, the screen will display the current

RPM. If HOUR light twinkles; you are ready to set the running time for each stage. If ALARM

light is on, an alarm condition exists.

-Press MODE 1,the light will be lit and one light of S1/S2/S3/S4 will be on or twinkle.

(Light twinkle means the current time is no t du ring the set running period), and on e of AM or

PM light will be on.

.Press MODE2, the light will be lit and the one light of S1/S2/S3/S4 will be on o r

twinkle.(Light twinkle means the current time is not during the set running period), and one of

AM or PM light will on.

/When the pump is in standby switch MODE 1andMODE2, the corresponding light will be

lit, and the pump run accordingly.

7

3.Stop And Run The Pump

3.1 Start the Pump

1) Make sure the pump is connected with electricity. When power is on, the display screen will

display the time.

2) Press one of ECO/CLEAN/BOOST, the pump will run. The light on the corresponding

program will be lit. Nomatter what program you select, the pump will run on 2850RPM for 5

minutes to eliminate the air in the pump, so the impeller will not dry grind thus to cause leakage.

After high-speed running, the pump will run the default speed of the selected program.

3.2 Stop the Pump

Press STOP of the running pump, the pump will stop. The lights on the screen twinkle.

3.3 Change Pump Running Speed

1) When the pump is running ECO/CLEAN/BOOST, press arrow buttons up or down to change

the speed, each press is for 50RPM. It will save automatically, no need to press ENTER.

2) Switch ECO/CLEAN/BOOST during pump operation, the pump will not run 5 minutes high

speed again.

3) For MODE 1 and MODE 2, to change speed of S1 and S3, first press CLEAN, if not

work, you will need to stop the pump first. After 5 minutes high speed running, press

CLEAN, then press arrow button to increase or decrease RPM. When press MODE 1 or

MODE 2 again torun the pump, S1 and S3 will run as just selected.

To adjust S2 and S4, first press ECO, if not work, you will need to stop the pump. After

10 minutes high speed running, press ECO, then press arrow button to increase or decrease

RPM. When press MODE 1 or MODE 2 again, S2 and S4 will run as just selected.

8

10

7

8

4

3

2

1

5

9

6

9

NOTE: PRM for S2 and S4 or S1 and S3 are always the same.

The default for S1 and S3 is2400RPM, the adjustable range is 2400 to 2850RPM.

The default for S2 and S4 is 1500RPM.The adjustable range is 1000 to 2400PRM.

3.4 Pump Run Under Pre -programmed Conditions

Pump has three quick start button ECO/CLEAN/BOOST, as below figure. The default speed is

1500, 2400, 3250RPM respectively.

1) Be sure the pump is power on.

2) Press one of ECO/CLEAN/BOOST, the LED light on screen will be lit.

3) The screen will display STOP for 1 second, and run 2850PRM for 5 minutes. After 10

minutes, the pump will run on the selected speed.

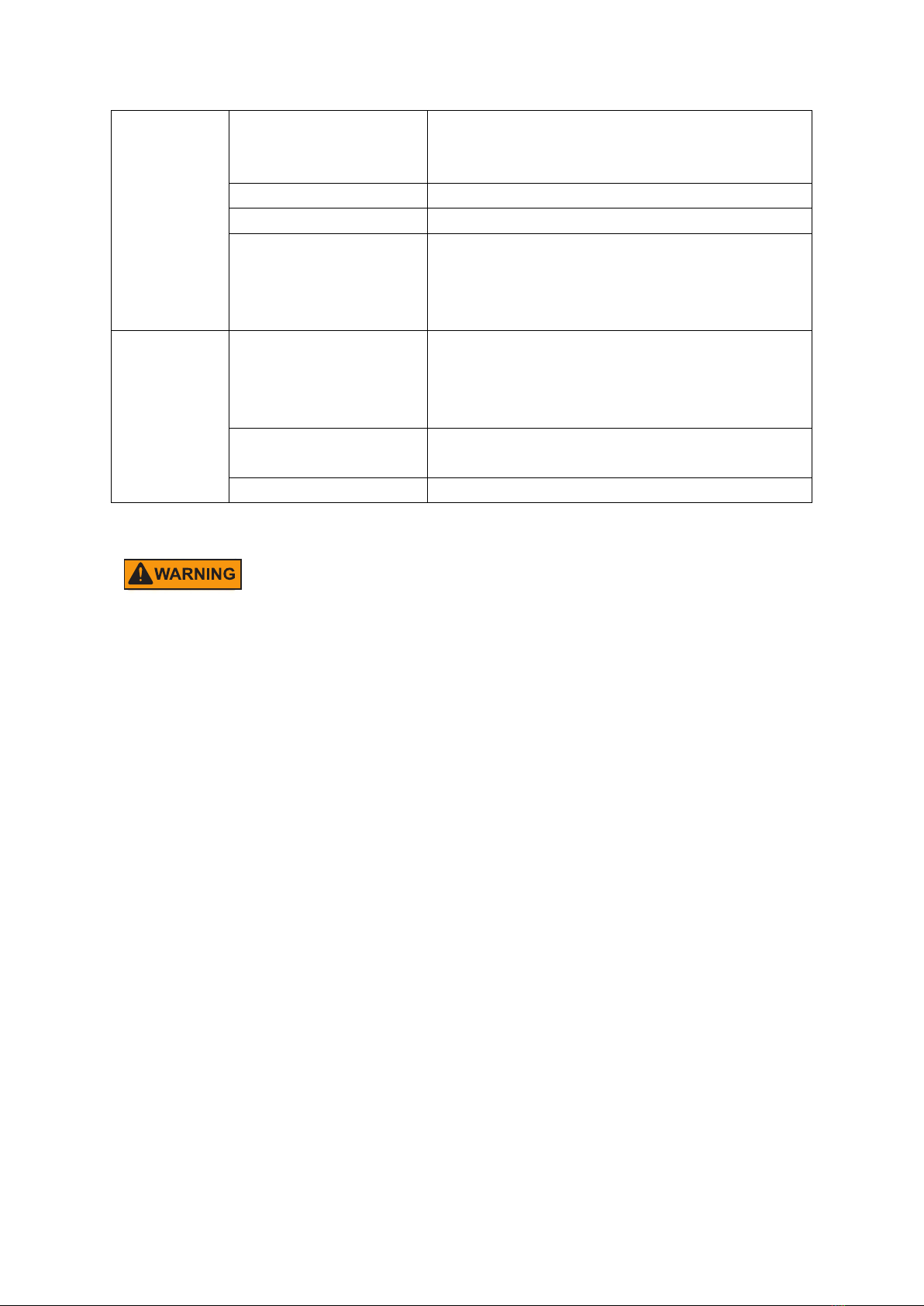

4. Pump Run under MODE1/MODE2

4.1 MODE 1/MODE2 Introduction

MODE 1 MODE 2

16 hours running cycle 24 hours running cycle

Stage Start

Time

Running Hour Default

Speed

Quick

Start

Button

Stage Start

Time

Running

Hour

Default

Speed

Quick

Start

Button

S1 6:00AM 3

(adjustable)

2400RPM

(adjustable)

CLEAN S1 12:00

PM

6

(adjustable)

1500PM

(adjustable)

ECO

S2 9:00AM 5

(adjustable)

1500PM

(adjustable)

ECO S2 6:00

AM

3

(adjustable)

2400RPM

(adjustable)

CLEAN

S3 6:00PM 3

(adjustable)

2400RPM

(adjustable)

CLEAN S3 9:00

AM

9

(adjustable)

1500PM

(adjustable)

ECO

S4 9:00PM 5

(adjustable)

1500PM

(adjustable)

ECO S4 6:00

PM

6

(adjustable)

2400RPM

(adjustable)

CLEAN

1000-2400RPM

DEFAULT: 1500

CLEAN

2400-2850RPM

DEFAULT: 2400

2850-3450RPM

DEFAULT: 3250

ECO BOOST

Indicator Light

10

4.2 How to Set and Change Specification of MODE1/MODE2

1) Make sure STOP button is pressed before set up, and pump is not working. Press MENU,

LED screen will display the current time (time will not count during set-up), use arrow buttons

to adjust the time. LEFT and RIGHT to move the cursor one digit, and UP and DOWN to

increase or decrease one digit.

(Remarks: 0:00-11:59 is one cycle). For example, the current time is 6:00 and AM light

is lit, when change the time after 11:59, the time change to 0:00, PM light will be lit.

2) After time set-up, press ENTER to save and exit.

Don't press ENTER if to continue change the specification of MODE1 and MODE 2.

Press MENU again, the light of MODE 1 and S1 will be lit, screen display 6:00, and

AM light is lit. Use arrow buttons to adjust the time. Whenthe time is over 11:59, PM

light will be lit, AM light extinguished.

3) Press ENTER to save and exit after start time set-up. To continue and adjust the

running hour, press MENU, then use arrow buttons to increase and decrease running

hours. Each press is for 1 hour. Press ENTERto save and exit. Or press MENUto

adjust S2/S3/S4, the same adjustment method as S1.

4) Follow MODE 1's adjustment methods to adjust MODE 2.

5) Could not change speed using arrow buttons whenrunning MODE1/MODE2. Can

only change the speed of MODE 1 and MODE 2 by pressing CLEAN/ECO/BOOST,

and then use arrow button UP and DOWN to change the RPM. When it is done, the

corresponding speed in MODE 1/MODE 2 will also change.

You could only change according tothe matching quick start button. For example, in

MODE 1, S1 and S3 isCLEAN, S2 and S4 is ECO; inMODE 2, S1 and S3 isECO, S2

and S4 is CLEAN.

5. How toOperate the Pump?

Totally three pre-programmed schedules: Regular Mode (including ECO; CLEAN; BOOST)

and MODE 1/MODE2.

1000-2400RPM

DEFAULT: 1500

CLEAN

2400-2850RPM

DEFAULT: 2400

2850-3450RPM

DEFAULT: 3250

ECO BOOST

Indicator Light

11

12

6. Control Panel Menu Structure

7.Alert and Warnings

The pump displays all alerts and warnings on the control panel. When an alarm or warning

condition exists, the corresponding LEDswill be lit on the display. All control panel buttons are

disabled until the alarm or warning is acknowledged with the ENTER button. Disconnect power

to the pump and wait untilthe screen has all turned off.

POWER OUT FAILURE–Incoming supply voltage is less than 190 VAC.

PRIMING ERROR –Ifthe pump is not defined as primed within the maximum priming time it

will stop and generate a priming alarm for 10 minutes, then attempt to prime again. If the pump

cannot prime within 5 attempts it will generate a permanent alarm and have to be manually

reset.

OVERHEAT ALERT –If the drive temperature gets over 103 Degrees Fahrenheit the

pump will slowly reduce speed until the drive temperature condition drops.

OVER CURRENT –Indicates that the drive is overloaded or the motor has an electrical

problem. Ifthey do not clear after multiple restart attempts the drive should undergo a hard

power cycle. Disconnect main power by turning off the breaker long enough for the keypad

LEDs toturn off. After power is reconnected if this error continues toreappear, the drive may

need service.

OVER VOLTAGE –Indicates excessive supply voltage or and external water source is

causing the pump and motor torotate thereby generating excessive voltage in the drives

internal DC bus. Ifthey do not clear after multiple restart attempts the drive should undergo a

hard power cycle. Disconnect main power by turning off the breaker long enough for the

keypad LEDstoturn off. After power is reconnected if this error continues toreappear, the

drive may need service.

1.Alert Code Details

Code Error Remarks

1 Get blocked or short circuit overheat

2 Voltage input exceeds limit

4 High input voltage

8 Low input voltage

16 Exceeds maximum speed

32 Speed is 0

64 Motor phase loss

128 Abnormal start-up

256 System configuration error

512 Stall at startup

1024 System operation error Contact the manufacturer

4096 Hardware test error Contact the manufacturer

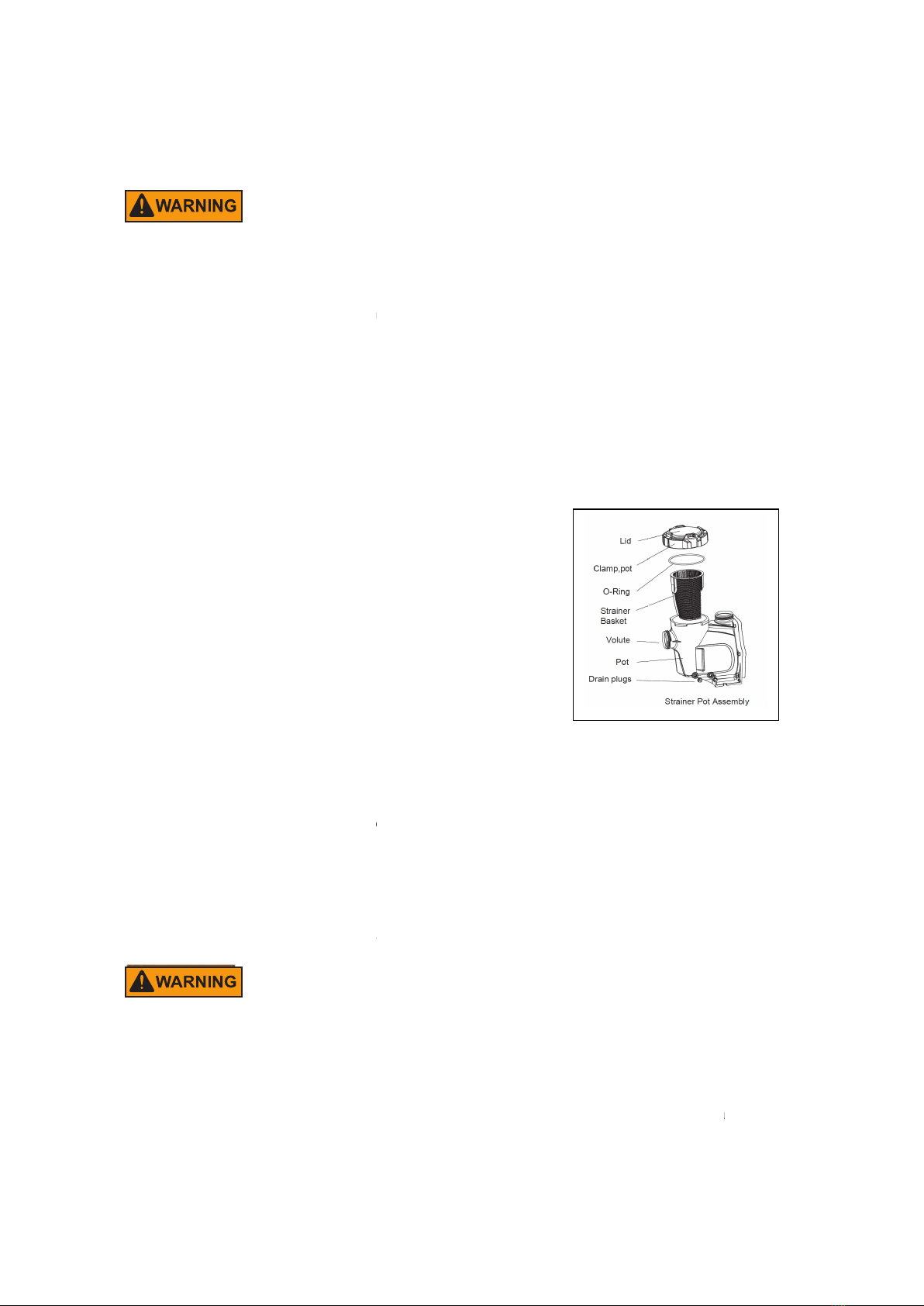

8.Priming

The pump will prime and pre-prime providing the filter tank water and there is sufficient supply

from the suction point.

If you lose water from the filter tank it will be necessary tore-fill it before starting.

1. Remove the translucent lid and fill the filter tank withwater.

13

2. Replace the lid ensuring the o-

ring is correctly located and start the pump.

After you have done this allow a few minutes (maximum) running for the pump to start

delivering water.

High suction lift or long suction lines will require additional time to prime and can severely

affect the performance of the pump. Ifthe pump does not

above. Mechanical seals ifrunning dry can be damaged rapidly and may need tobereplaced.

ENSURE that there is always adequate water in the filter tank before you start up.If you are

unable to prime the pump please see t

ENSURE that all suction and discharge valves are open before you start the pump, otherwise

will result in damage tothe pump.

9.Maintenance

The strainer basket inthe filter tank should be inspected and cleaned at regular interv

1. Remove lid and lift out basket.

2. Remove debris and hose off with clean water if necessary.

3. Inspect the lid gasket, lubricate with silicon based grease

only if needed. If it is damaged, pls replace.

4. Replace the strainer.

5. Re-prime the filter tank.

6. Correctly locate the o-ring.

7. Replace the lid hand tighten

only.

8. Switch on pump.

In Climates where the pump may be exposed to frost or freezing,

the pump is protected from damage.

winter period it should be drained completely and store pump in a dry location. Do not replace

the drain plug. Store it in a safe place when not use. An example would be store plug in the

filter tank basket.

When you are activa

ted the pump ensures all seals and o

re-

grease if necessary, replaced if unsure of condition.

Checkthat the motor shaft moves freely before re

1. When connecting electric cables tothe motor of the pump,

them inside the connection box, verifythat no bits of cable are left inside the box on closing it.

See that the

ground wire is correctly connected.

diagram supplied with the pump.

2. Be especially careful

that no water enters the motor or electrical parts under voltage.

3. Inthe event that the planned use is not as specified, adaptations and supplementary

technical rules may be necessary.

ring is correctly located and start the pump.

After you have done this allow a few minutes (maximum) running for the pump to start

High suction lift or long suction lines will require additional time to prime and can severely

affect the performance of the pump. Ifthe pump does not

prime, please repeat step 1 and 2

above. Mechanical seals ifrunning dry can be damaged rapidly and may need tobereplaced.

ENSURE that there is always adequate water in the filter tank before you start up.If you are

unable to prime the pump please see t

he trouble-shooting guide.

ENSURE that all suction and discharge valves are open before you start the pump, otherwise

The strainer basket inthe filter tank should be inspected and cleaned at regular interv

2. Remove debris and hose off with clean water if necessary.

3. Inspect the lid gasket, lubricate with silicon based grease

only if needed. If it is damaged, pls replace.

only.

In Climates where the pump may be exposed to frost or freezing,

c

are must be taken to ensure

the pump is protected from damage.

It is recommended that if

the pump is not used during

winter period it should be drained completely and store pump in a dry location. Do not replace

the drain plug. Store it in a safe place when not use. An example would be store plug in the

ted the pump ensures all seals and o

-

rings are in operational condition,

grease if necessary, replaced if unsure of condition.

Checkthat the motor shaft moves freely before re

-activation.

1. When connecting electric cables tothe motor of the pump,

be careful to correctly arrange

them inside the connection box, verifythat no bits of cable are left inside the box on closing it.

ground wire is correctly connected.

When connecting the motor, follow the wiring

that no water enters the motor or electrical parts under voltage.

3. Inthe event that the planned use is not as specified, adaptations and supplementary

After you have done this allow a few minutes (maximum) running for the pump to start

High suction lift or long suction lines will require additional time to prime and can severely

prime, please repeat step 1 and 2

above. Mechanical seals ifrunning dry can be damaged rapidly and may need tobereplaced.

ENSURE that there is always adequate water in the filter tank before you start up.If you are

ENSURE that all suction and discharge valves are open before you start the pump, otherwise

The strainer basket inthe filter tank should be inspected and cleaned at regular interv

als.

are must be taken to ensure

the pump is not used during

winter period it should be drained completely and store pump in a dry location. Do not replace

the drain plug. Store it in a safe place when not use. An example would be store plug in the

rings are in operational condition,

be careful to correctly arrange

them inside the connection box, verifythat no bits of cable are left inside the box on closing it.

When connecting the motor, follow the wiring

that no water enters the motor or electrical parts under voltage.

3. Inthe event that the planned use is not as specified, adaptations and supplementary

14

4. Before starting the pump, verifythe c

motor and that

the protections against electrical and mechanical contacts are correctly

positioned and attached.

5. It is advisable to follow the steps listed below before handling the pump in any way.

a) Turn off the voltage tothe pump.

b) Lock starting devices.

c) Verify that there is no voltage in the circuits, including ancillary devices and auxiliary circuits.

d) Wait until motor stops completely.

The above list should be considered indicative and

specific safety

rules may exist in particular regulations.

Assembly Instructions (some parts may be pre

Follow the step below and the corresponding diagrams for assembly.

Step 1.

Place the strainer baske

t tothe strainer housing. Be sure that the opening the basket is

aligned with the opening inthe housing. Secure Lid

Step 2.

The water level of the inground

swimming

In order to prevent water from

flowing

First screw the adapter into the

water

assembly.

Step 1 Step 2

REGULARLY VERIFY

1. The correct a

ttachments of the mechanical parts and of the support screws of the pump.

2. The correct position, attachment and condition of the supply cables and of the insulating

parts.

3. The temperature of the motor. Inthe event of any excessive high, stop immediat

have it repaired.

4. The vibration of the pump. Inthe case of any excessive high, stop immediately and have it

repaired.

4. Before starting the pump, verifythe c

alibration of the electrical protection devices of the

the protections against electrical and mechanical contacts are correctly

5. It is advisable to follow the steps listed below before handling the pump in any way.

a) Turn off the voltage tothe pump.

c) Verify that there is no voltage in the circuits, including ancillary devices and auxiliary circuits.

d) Wait until motor stops completely.

The above list should be considered indicative and

not binding for the purpose of safety,

rules may exist in particular regulations.

Assembly Instructions (some parts may be pre

-assembled)

Follow the step below and the corresponding diagrams for assembly.

t tothe strainer housing. Be sure that the opening the basket is

aligned with the opening inthe housing. Secure Lid

swimming

pool is lower than the water inlet of the

pump.

flowing

backward, this pump equipped a check

valve.

water

inlet of the pump, and then install the

connector

Step 1 Step 2

ttachments of the mechanical parts and of the support screws of the pump.

2. The correct position, attachment and condition of the supply cables and of the insulating

3. The temperature of the motor. Inthe event of any excessive high, stop immediat

ely and

4. The vibration of the pump. Inthe case of any excessive high, stop immediately and have it

Please ensure this direction

towards the pump

alibration of the electrical protection devices of the

the protections against electrical and mechanical contacts are correctly

5. It is advisable to follow the steps listed below before handling the pump in any way.

c) Verify that there is no voltage in the circuits, including ancillary devices and auxiliary circuits.

not binding for the purpose of safety,

t tothe strainer housing. Be sure that the opening the basket is

pump.

valve.

connector

ttachments of the mechanical parts and of the support screws of the pump.

2. The correct position, attachment and condition of the supply cables and of the insulating

ely and

4. The vibration of the pump. Inthe case of any excessive high, stop immediately and have it

15

16

CAUTION

Owing tothe complexity of the cases covered, the instructions for installation, use and

maintenance contained inthis manual do not attempt to examine all possible and imaginable

cases of service and maintenance. If supplementary instructions are required or if special

problems arise, do not hesitate to contact the distributor or to address directly the

manufacturer of the pump.

TECHNICAL DATA

Item CSPPV711

Input Power 125w

H. Max 59ft

Q. Max/min 366L

V 230

HZ 50/60

IP IPX5

17

ILLUSTRATED PARTS LIST

Ref.No. Part. No. Description QTY Remark

1 647253571 Cover 1

2 65431042080 O-Ring 1

3 647252704 Basket 1

4 647253501 Pump Housing 1

5 65431032080 O-Ring 1

6 65212025000 Screw ST4.2*38 2

7 647254703 Diffuser 1

8 647274871000 Impeller For CSPPV711 1

9 65431168080 O-Ring 1

10 65028014000 Seal Assembly 1

11 647254702 Pump Cover 1

12 65244015000 Gasket M10 10

13 65244032000 Spring Washer M10 6

14 65225003000 Screw 3/8-16*1 1/2 UNC 6

15 65023399000 Variable Speed 1.5HP Motor For CSPPV711 1

16 65221008000 Screw M10*25 4

17 65232001106 Nut 3/8-16 6

18 65432002080 Drain Plug Gasket 2

19 648860105 Drain Plug 2

20 65231002106 Nut M6 2

21 65244016000 Gasket M6 2

22 65224003000 Screw M6*20 2

23 647254704 Mounting Foot 1

24 647254705 Supporting Foot 1

25 647253572001 1.5''Adaptor Assembly 2

26 647253573000 Check Value 1

18

TROUBLESHOOTING

Problem Cause Solution

Low flow Dirty filter Backwash or clean cartridge

Dirty skimmer and pump

strainer

Clean skimmer and pump strainer

Suction air leak Make sure water level is correct through suction

points. Ensure baskets and strainers are free of

debris. Tighten all fittings/unions on the suction

side of the pump, remove and replace mechanical

seal

Closed valve or blocked

line

Make sure water level is correct through suction

points. Ensure baskets and strainers are free of

debris. Tighten all fittings/unions on the suction

side of the pump, remove and replace mechanical

seal

Pump does

not run

Not plugged in Checkthe socket and power cord

GFCI/or main circuit

breaker tripped

Switch on the breaker. If it is immediately tripped

again,

There is a defect in pump or controls.

Faulty Pump shaft /motor Replace the pump/motor assembly.

Pump shaft is locked Checkifthe pump can be rotated by hand and

remove any blockage

Pump will not

prime

Suction air leak Make sure water level is correct through suction

points. Ensure baskets and strainers are free of

debris. Tighten all fittings/unions on the suction

side of the pump, remove and replace mechanical

seal

No water in the pump Make sure the filter tank is full

Closed valves or blocked

lines

Open all valves in the system, clean skimmer and

pump basket, check pump impeller of blockage

Motor

overload cuts

out

Motor not connected

properly

Have electrician check wiring

Low incoming voltage Voltage at motors should be no more than 6%

above or below nameplate voltage. Have

electrician check voltage; ensure pump is not

running on an extension cord. Report low supplier

to authorities.

Overload due to binding

in pump or wrong size

impeller

Contact supplier

Noise pump

operation

Bad bearing Have electrician replace

Air leak in suction Make sure water level is correct through suction

points. Ensure baskets and strainers are free of

debris. Tighten all fittings/unions on the suction

side of the pump, remove and replace mechanical

seal

Suction blockage Locate and clean blockage

Disturbance inimpeller Contact supplier

Cavitations Improve suction, reduce suction lift, reduce number

of fittings, increase pipe size, increase discharge

pressure and reduce flow by throttling discharge

valve

Motor runs

hot

Low or incorrect voltage Supply to be corrected by electrician. A motor

running hot totouch is normal. Thermal overload

protector will function toturn them off ifthere is an

overload or excessive high temperature problem

Installed in direct

sunlight

Shield from weather

Poor ventilation Do not tightly cover or enclose motor

If the pump iswithin the stated warranty period and you experience faults always contact your

supplier. Failure todothis may void warranty. Refer to warranty documentation supplied with

pump. All electrical work is to be carried out by a Qualified Electrician; under no circumstances

should you attempt repairs on the electrical components of pumps unless you are qualified to

do so.

19

Table of contents

Popular Water Pump manuals by other brands

Beckett

Beckett Fountain Pump M60AUL Specifications

Wilo

Wilo Wilo-Rexa PRO-S Installation and operating instructions

Alentec & Orion

Alentec & Orion 52510 user manual

Pentair

Pentair MYERS 7360 Installation and service manual

EarthQuake

EarthQuake WP4310 Operator's manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS SF6E Installation, operation, and maintenance manual with parts list

Pentair

Pentair JUNG PUMPEN PKS-B 800 Series instruction manual

Exhausto

Exhausto CONPUMP-AS Product information

Raider

Raider Garden Tools RD-WP 1300 user manual

Oase

Oase Aquarius 1500 Operation instructions

BRÖTJE

BRÖTJE HEP 25-180-10 Assembly instructions

Wilo

Wilo Drain LP 40 Installation and operating instructions