Circuitron TC-1 User manual

TURNOUT CONTROLS

TC-1, TC-2

211 RocBaar Dr., Romeoville, IL 60446

(815) 886-9010 FAX: (815) 886-9076

Electronics for Model Railroads

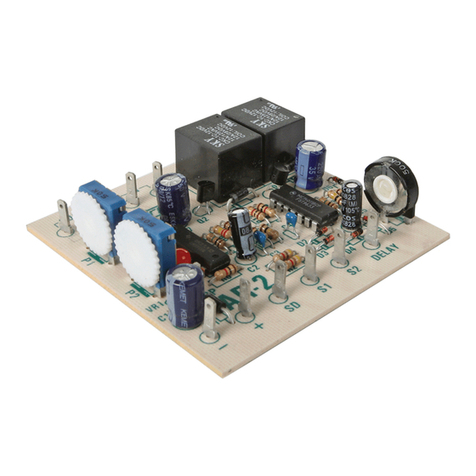

GENERAL DESCRIPTION: The CIRCUITRON TC-1 and TC-2 Turnout Controls provide automatic

activation of any dual-coil type switch machine when used in conjunction with any CIRCUITRON

Detection Circuit. Both units provide short, high-current pulses to the switch machine, protecting the

coils from burnout. The TC-1 has two control terminals and may be used to control both directions

of a turnout. In this way, the output from one Detection Circuit may be used to throw a turnout one

way, and the output of another Detection Circuit may be used to throw the turnout back. The TC-2

is CIRCUITRON’s Turnout Direction Alternator and it has only a single control terminal. When the

control terminal is connected to a Detection Circuit, the switch machine will be thrown one way the

first time a train is detected, and then the switch machine will be thrown the opposite way the next

time a train is detected. In this way, trains can be made to travel alternate routes around a layout,

automatically. Both the TC-1 and TC-2 require a 12 - 18 volt AC or DC input for proper operation.

The outputs on the TC-1 and TC-2 can activate one or two switch machine coils at the same time

depending upon the style of switch machine and the input voltage of the circuits.

CIRCUIT DESIGN: Both the TC-1 and TC-2 have capacitor discharge type outputs for high-current

snap-action of switch machines controlled by them. The capacitor is charged by a 200 ohm resistor

which will limit current to the switch machine should a circuit failure occur. The TC-1 contains two

identical one-shot multivibrator circuits that produce an output pulse of fixed length when the

corresponding control terminal is grounded. This output pulse drives a power darlington transistor

connected common emitter which connects the coil of the switch machine(s) to ground for the

duration of the pulse. The capacitor discharges rapidly through the switch machine coil and then

recharges in 2-3 seconds to await the next cycle. The TC-2 outputs are the same as the TC-1’s, but

the TC-2 also contains a toggle flip-flop circuit that changes states each time the input is activated.

There is additional conditioning incorporated in the circuit in the input section that is used to clean up

any oscillations that might be present from the output of the Detection Circuit that might create false

triggering of the circuit.

INSTRUCTIONS: Please refer to the diagrams for labeling and Opto-Sensor locations. The TC-1 or TC-2

can be connected with .110" solderless connectors or by soldering leads directly to the terminals on the

printed circuit board. If soldering, use a small pencil-type iron and electronics-grade rosin core 60/40 solder

(available at Radio Shack). Use only as much heat as necessary to obtain a good joint and do not wiggle the

terminal until the solder has cooled completely.

1) Mount the circuit board in a convenient location near the switch machine to be controlled. A

section of CIRCUITRON’s PCMT makes this a simple task, or the mounting pads may be drilled

out at the corners of the board and the circuit mounted with screws.

2) Connect a 20 gauge or heavier wire to the common terminal on the switch machine (see specific

instructions packed with your switch machine) and run it to the terminal on the circuit board

labeled [OUT].

3) Connect a 20 gauge or heavier wire to one of the remaining terminals on the switch machine and

run it to the terminal labeled [1] on the circuit board.

4) Connect a 20 gauge or heavier wire to the remaining terminal on the switch machine and run it to

the terminal labeled [2] on the circuit board.

5) Connect the Control Terminals ([C1] & [C2] on the TC-1, [C] on the TC-2) to the output(s) of any

CIRCUITRON Detection Circuit using light gauge wire. The DT-4 is ideal for this application. The

Opto-Sensor supplied with the Detection Unit should be located at the point where it is desired to

have the switch machine activated. In this way, the switchpoints will be thrown when the first

piece of rolling stock passes over the Opto-Sensor.

6) Connect a source of 12-18 volts AC or DC to the INPUT Terminals. CAUTION: See Notes Below

7) Manual pushbuttons may be connected as shown in the diagrams below.

NOTES:1) Input must be DC if the Turnout Control and the DT-4 are to be powered by the same

supply. 2) Maximum power will be attained in the Turnout Control Circuit when it is powered by an AC

or unfiltered DC supply. Use of a filtered or regulated supply is not recommended since inadequate

power may be stored in the capacitor with this type of supply. Separate supplies for the Turnout

Control and the DT-4 may be used if they share a common ground connection as shown in Figure 2.

3) Pushbuttons for manual operation may be added to the Turnout Controls by connecting them

between the Negative power supply connection and the Control Terminal(s) [C1, C2 or C] as shown in

Figure 1. If an AC supply is being used, the Negative connection is obtained by hooking the wire to the

Negative lead on the large capacitor near the Control terminals on the board (see Figure 2.) 4) The TC-

1and TC-2 circuits may be triggered by reed switches mounted in the roadbed and activated by a

magnet mounted below the locomotive. Connect the reed switch between (-) and the Control Terminal

as in the Manual Pushbutton example above. The Detection Unit such as the DT-4 is not needed in this

case. 5) Please note the direction of train traffic necessary with the TC-2. Traveling in the opposite

direction may cause derailments when the train crosses the Opto-Sensor. This is not a factor with the

TC-1 and bi-directional traffic is possible. 6) If the switch machine throws in the wrong direction in the

TC-1 hookup, reverse the [1] and [2] leads.

In the application in Figure 1. above, a train approaching the turnout on track A will throw the points

automatically so as to prevent derailment. Similar action will occur for trains approaching on track B,

but the points will be thrown the opposite way. As the train proceeds and approaches the second

turnout, the TC-2 will throw the points to direct

the train onto track C or D. The next train to

approach this turnout will activate the TC-2 which

will then throw the points the opposite way. This

action will continue with each successive train

taking track C and D

alternately.

WARRANTY

CIRCUITRON warrants this device against defects in materials and workmanship for a period of one year from the date of

purchase. This warranty covers all defects incurred in normal use of the device and does not apply in the following cases:

a) damage to the device resulting from abuse, mishandling, accident or failure to follow operating instructions.

b) if the device has been serviced or modified by other than the CIRCUITRON factory.

EXCEPT AS MENTIONED ABOVE, NO OTHER WARRANTY OR GUARANTEE, EXPRESS OR IMPLIED INCLUDING

MERCHANTABILITY, ON THE PART OF THE UNDERSIGNED OR ANY OTHER PERSON, FIRM OR CORPORATION, APPLIES

TO THIS DEVICE.

CIRCUITRON, INC.

Figure 1.

Figure 2. Connecting a

common ground between

different power supplies.

This manual suits for next models

1

Table of contents

Other Circuitron Controllers manuals

Popular Controllers manuals by other brands

LOVATO ELECTRIC

LOVATO ELECTRIC RGAM40 instruction manual

Carel

Carel pCO3 series Technical leaflet

National Instruments

National Instruments FELDPoint FP-2000 quick start guide

Druck

Druck PACE5000 instruction manual

Milesight

Milesight UC300 user guide

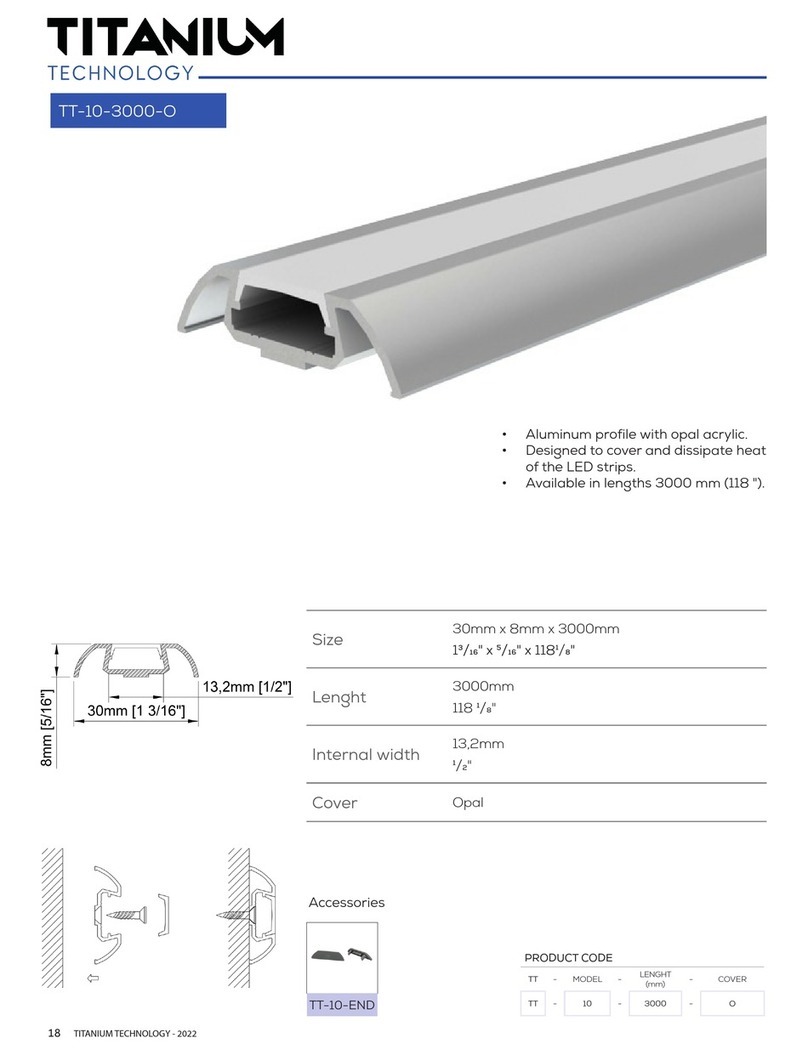

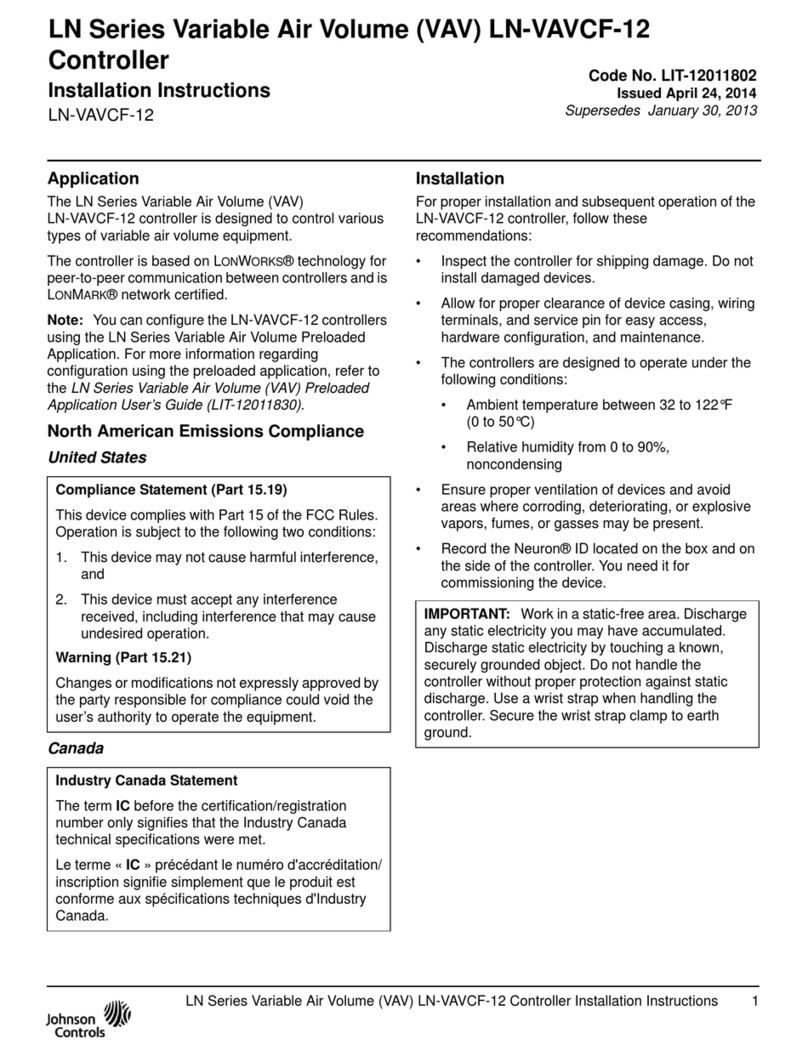

Johnson Controls

Johnson Controls LN Series installation instructions

WAREMA

WAREMA BACnet 4M230.8I AP installation instructions

Victron energy

Victron energy Bluesolar-5 manual

Pacific Power Source

Pacific Power Source UPC-3 Operation manual

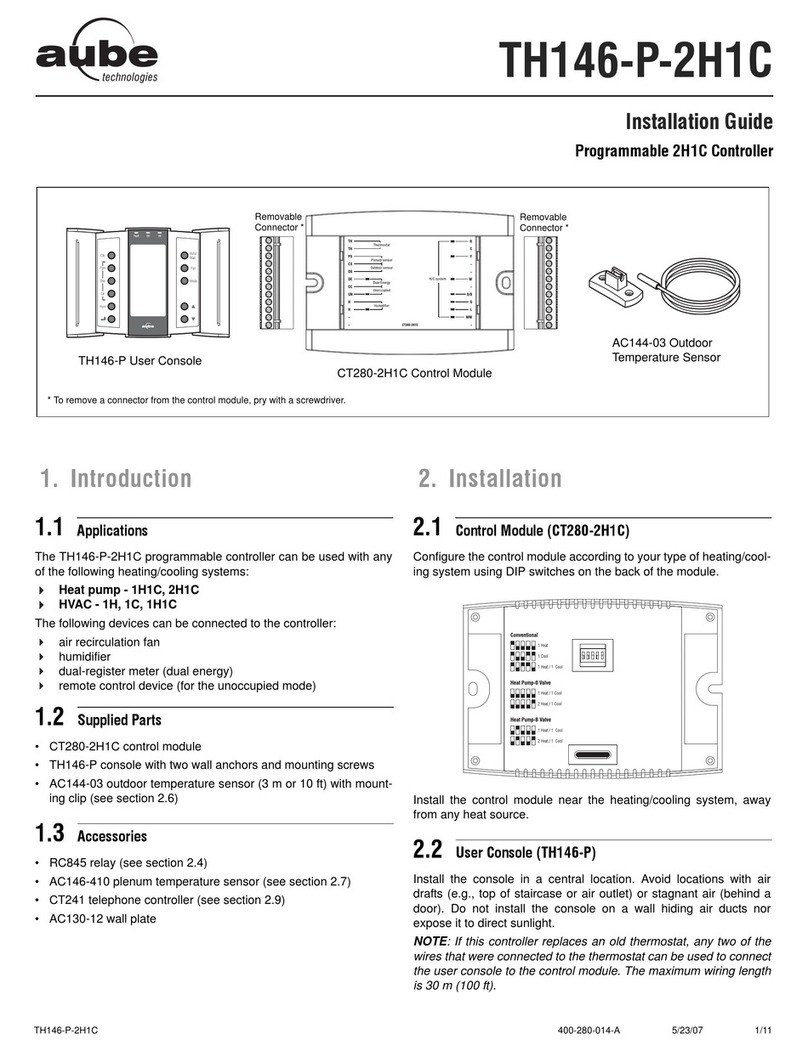

Aube Technologies

Aube Technologies TH146-P-2H1C installation guide

Barber-Colman

Barber-Colman DYNA 8000 Technical manual

Biegler

Biegler autopress e Instructions for use