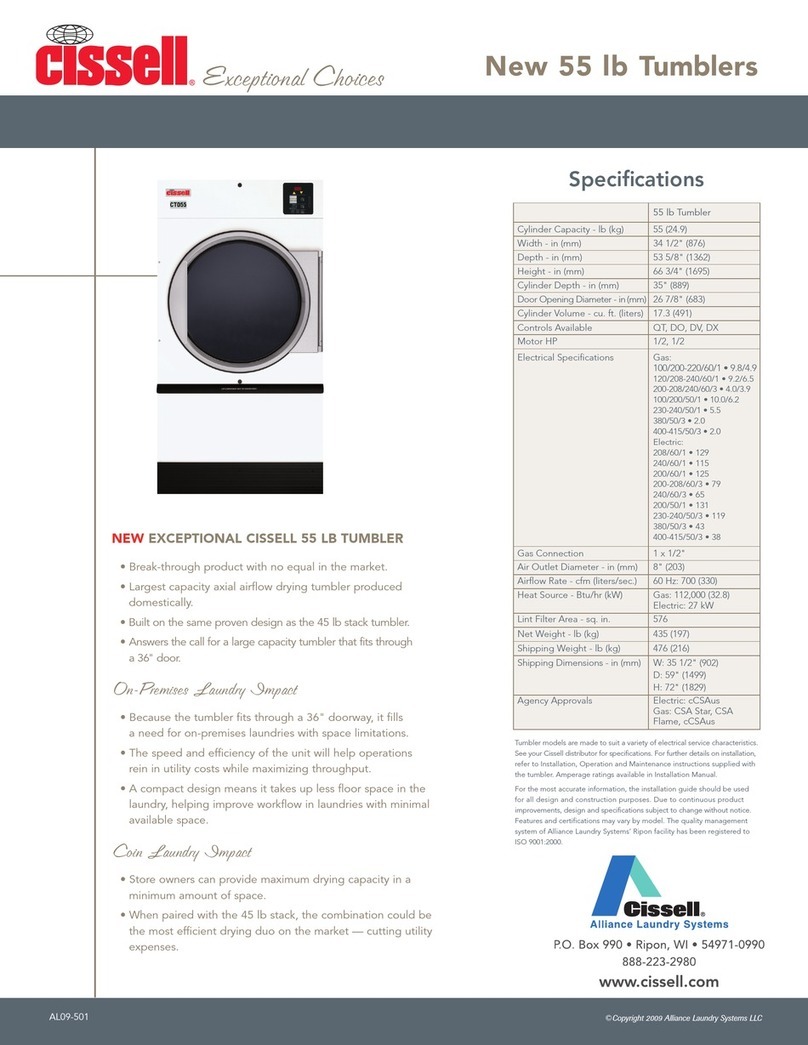

8

3

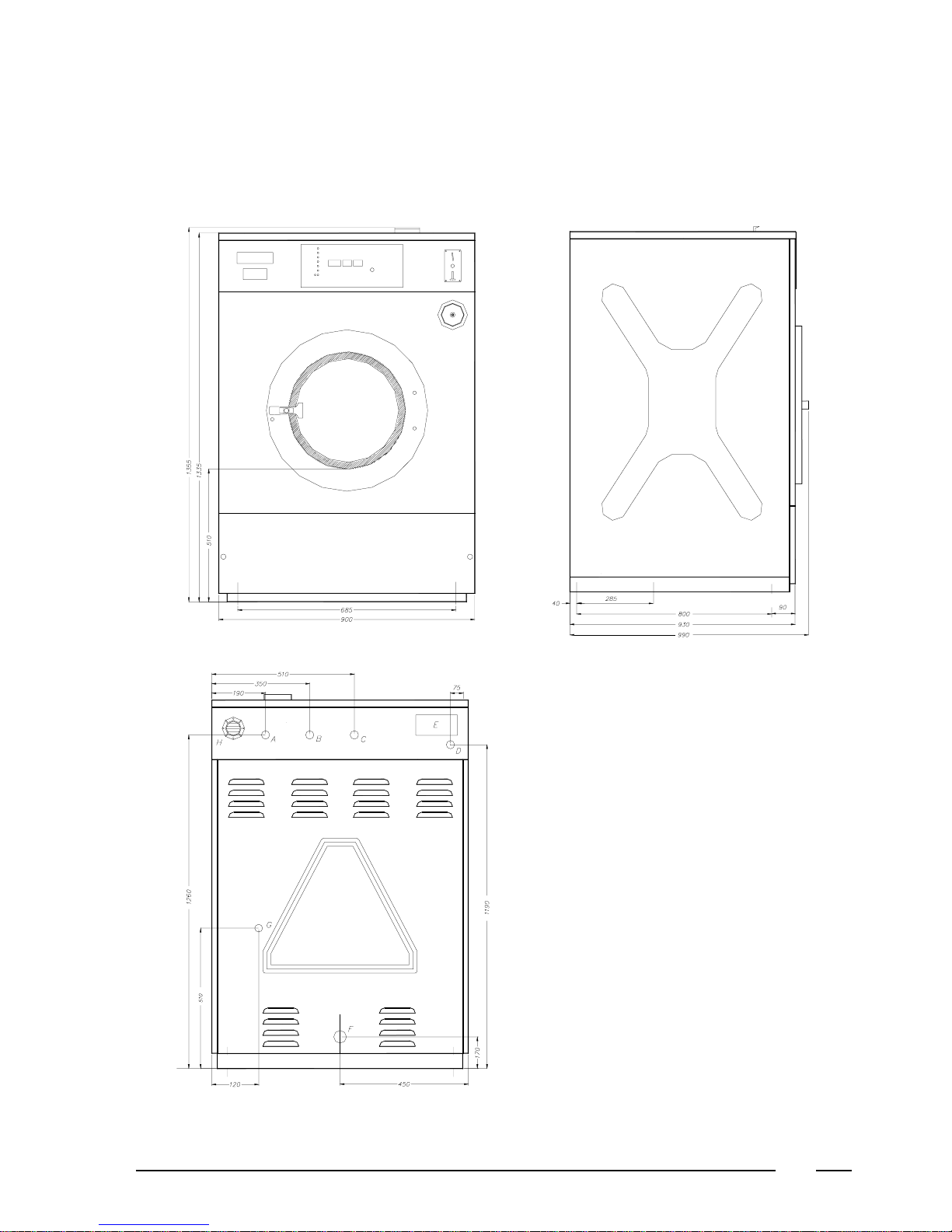

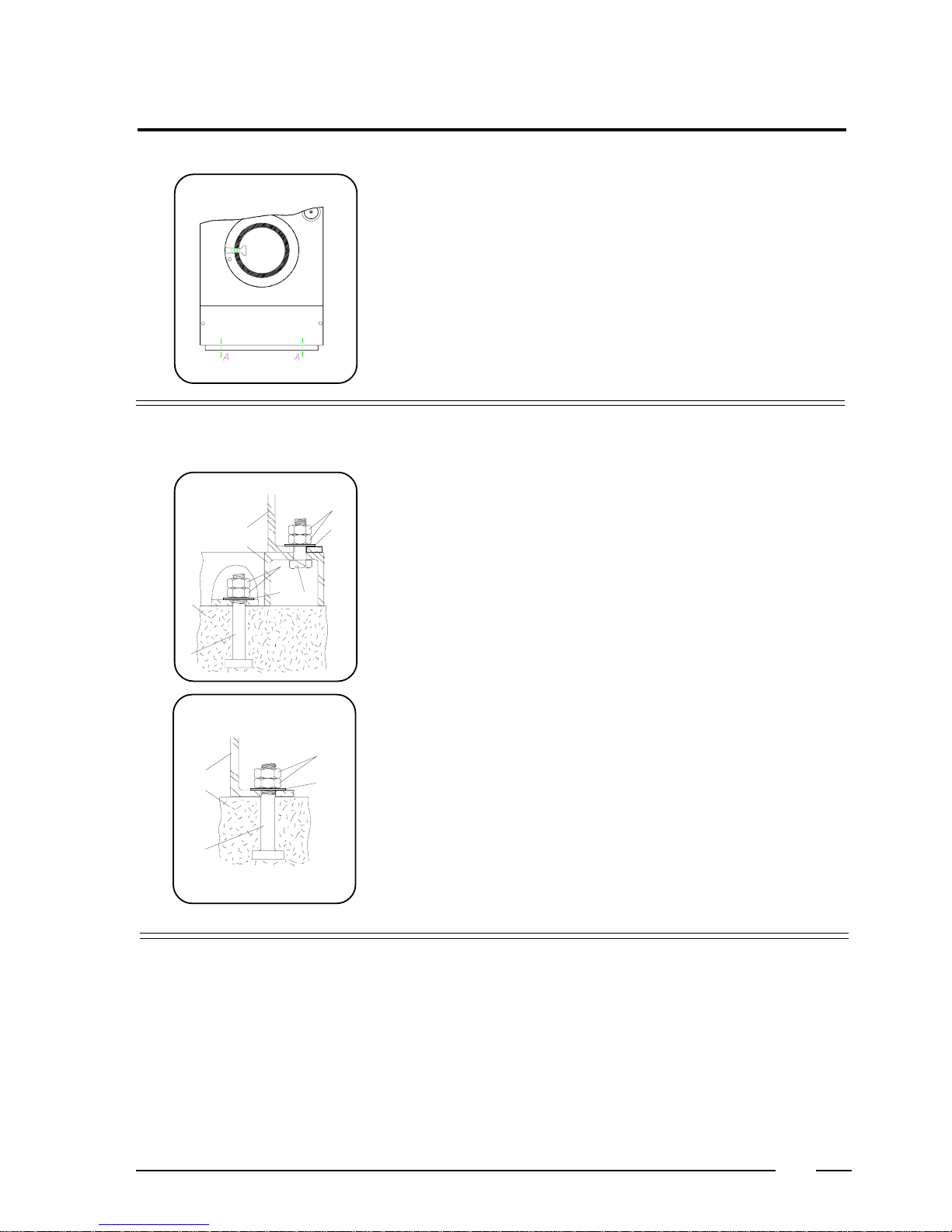

Remove the cover plate at the back of the machine. (See dimensions (E)).

Connect the power cable to the connectors.

220V 3AC

220V 3 phase (3AC) should be connected to the connectors “L1,L2,L3”.

The green/yellow grounding clamp has to be connected to the grounding

wire “PE”.

380 V 3AC + N

380 V 3 phase (3AC + N) has to be connected to the connectors

“L1,L2,L3”, the blue neutral to the “N” connector.

The green/yellow grounding clamp has to be connected to the groun-

ding wire “PE”.

After connection, check the spin direction. The cylinder must spin in

the direction of the arrow, showed on the sticker on the door window

(clockwise).

A wrong spin direction can damage the motor, and can also cause water

to spurt from the soap dispenser.

In case of wrong spin direction: switch the terminal clamps of the motor

circuit “R” and “S” of the connecting cable.

The diameter of the main drain should be adapted to the water flow and

the number of machines. It should be sufficient to handle at least 160L/

min. per machine.

It is necessary to connect the main drain at least on one side to an open

air-brake to allow ventilation.

The machine is equipped with a drain valve with 3" outer diameter (80 mm).

This drain valve should be connected to the drain by means of the drain

elbow which is delivered with the machine.

S

S

Main power connection

Water drain

S

S

S

Power of the breaker plugs: machine with steam heating or boiler fed machines without additio-

nal electrical heating

Heating: 220V3AC 380V3AC + N

12 kW 40 A 20 A

15 kW 50 A 25 A

18 kW 50 A 32 A

21 kW ---- 40 A

24 kW ---- 40 A

machine with electrical heating

220V 3AC 380V 3AC + N

16 A 16 A

S