CITROEN C8 2002 User manual

Other CITROEN Automobile manuals

CITROEN

CITROEN C5 User manual

CITROEN

CITROEN C5 X 2021 User manual

CITROEN

CITROEN AMI 2021 User manual

CITROEN

CITROEN C4 CACTUS 2016 User manual

CITROEN

CITROEN ZX 1991 User manual

CITROEN

CITROEN C3 User manual

CITROEN

CITROEN Saxo 2003 User manual

CITROEN

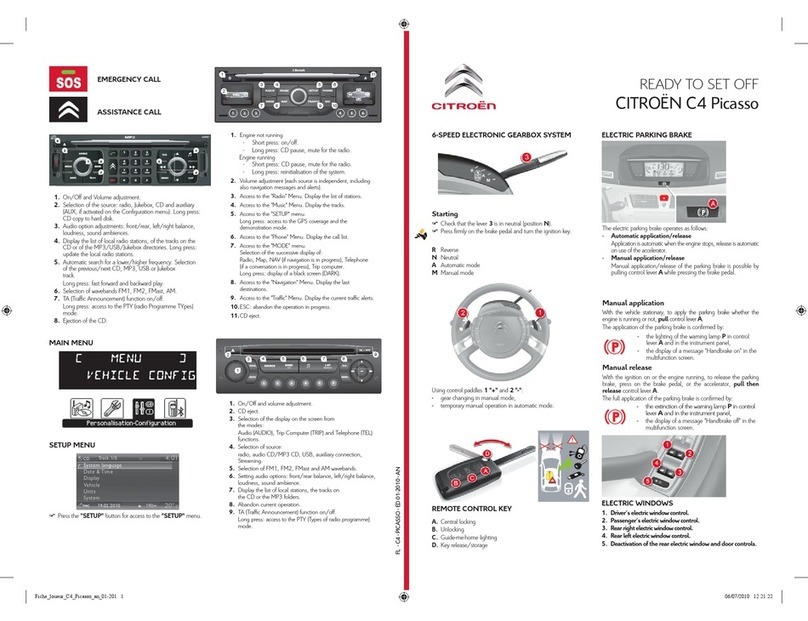

CITROEN C4 PICASSO User manual

CITROEN

CITROEN NEMO Operating and installation instructions

CITROEN

CITROEN C3 User manual

CITROEN

CITROEN 2001 XM Service manual

CITROEN

CITROEN 2 CV4 1975 User manual

CITROEN

CITROEN C4 PICASSO User manual

CITROEN

CITROEN BERLINGO MULTISPACE User manual

CITROEN

CITROEN C3 Desire User manual

CITROEN

CITROEN Jumpy Multispace User guide

CITROEN

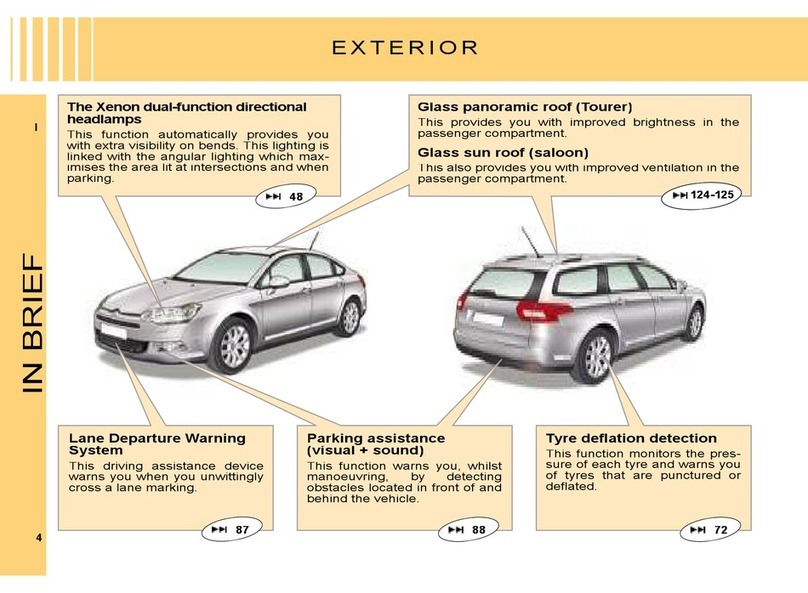

CITROEN C5 2008 User manual

CITROEN

CITROEN CX Operating instructions

CITROEN

CITROEN DS5 DSign Operating and installation instructions

CITROEN

CITROEN C5 User manual