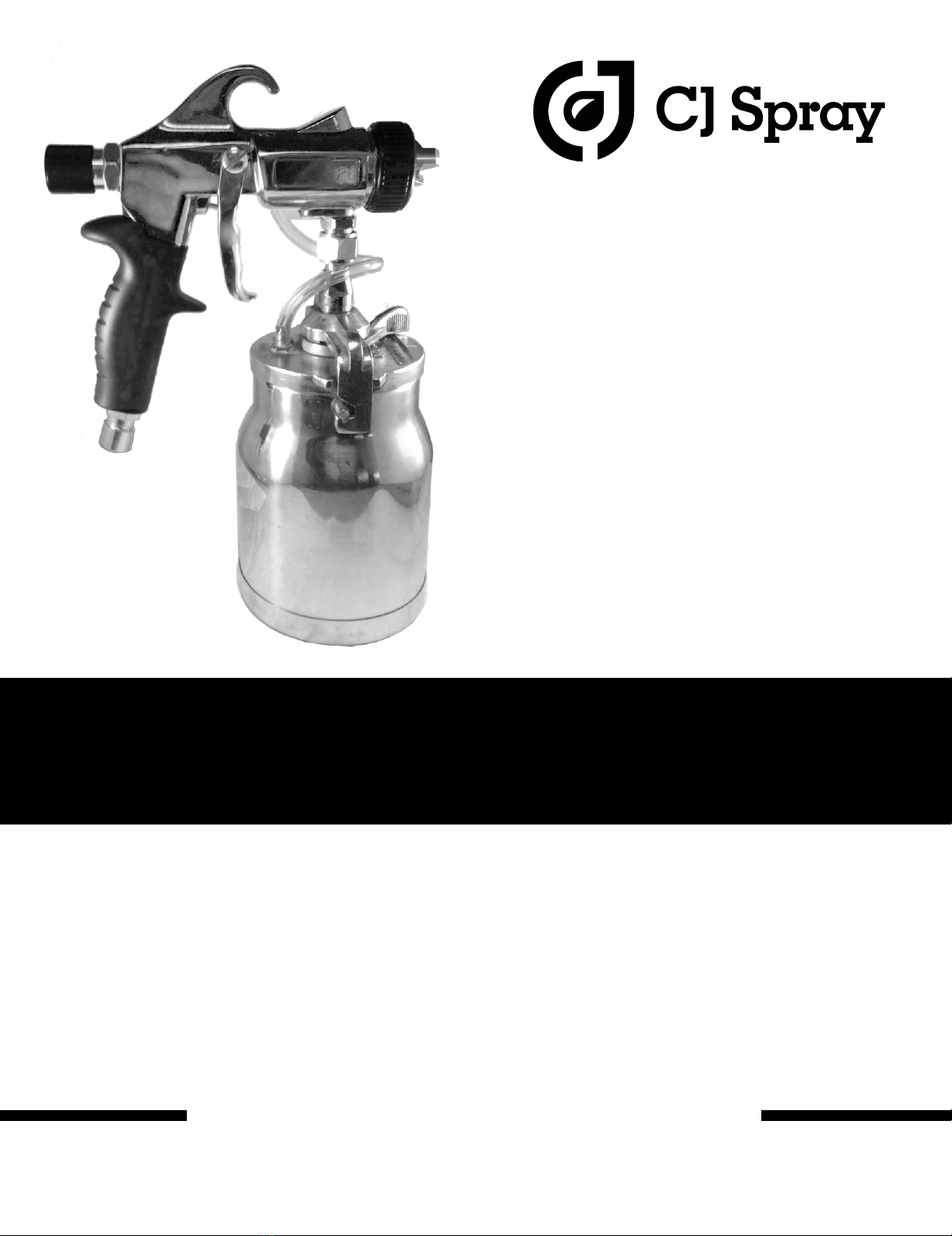

CJ Spray 710 User manual

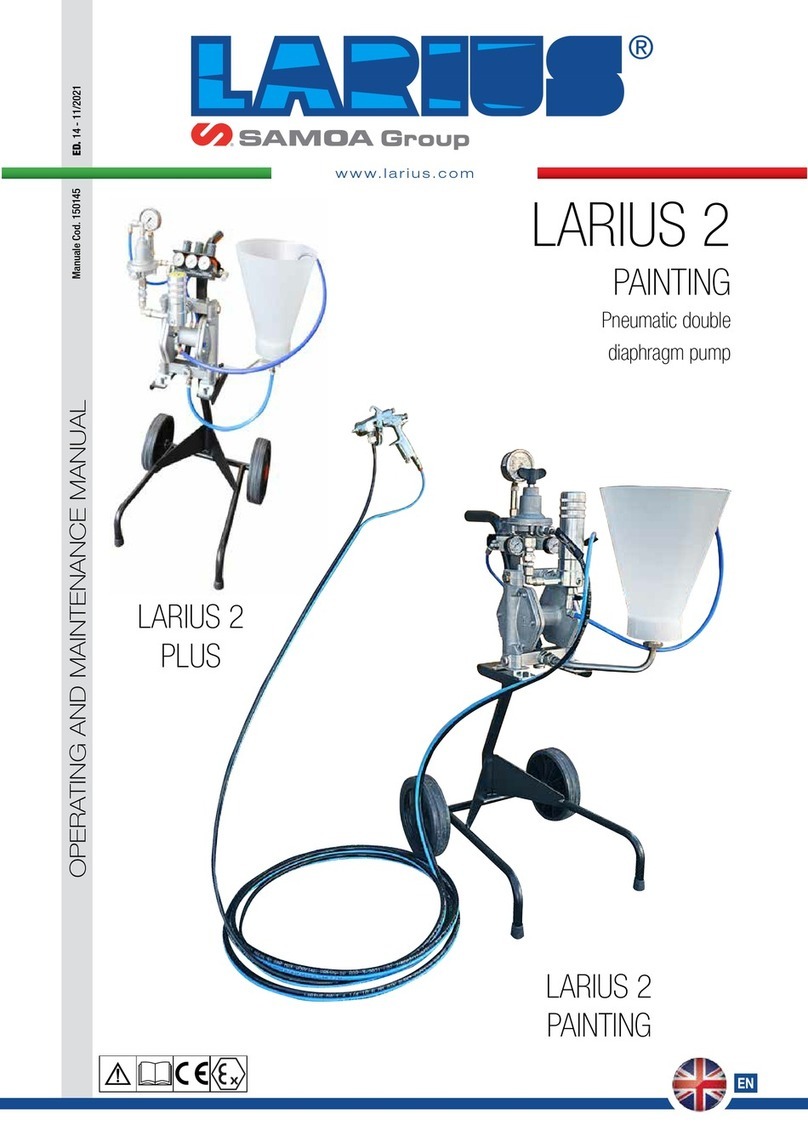

710 and 966 Turbine Spray Guns

Owner’s Guide & Parts List

CJ Spray, Inc.

6270 Claude Way East

Inver Grove Heights, MN 55076

1-888-CJSpray (888-257-7729)

SAVE THESE INSTRUCTIONS!

TM

Read andunderstand all instructionmanuals beforeoperating equipment.

For

ProfessionalUse Only. Observe

All

Warnings.

EQUIPMENT MISUSE

HaZARD

General Safety

Any misuse of the spray equipment or accessories,

such as improper usage, over pressurizing, modifying

parts, using incompatible chemicals and fluids, or

using wornor damaged parts,can

cause

themto rup-

ture and resultinserious injury, fire, explosion or

property damage.

Never point the spray gunat anyone or at any part

of the body.

System Pressure

This gun hasa

Marimum

Met

Fluid

Pressure of

100

psi (7 bar) anda

Maximum

lnletAir Pressure of

50

psi

(3.5 bar).

The

accessory remote pressure pots have a

Maximum

hletAir Pressure of

50

psi(3.5 bar). Never

exceed the maximum pressures of

the

gun, pressure

pot, or any other component or accessory usedinthe

system.

Never puthandorfingersoverthespraynozzle.PressureRelief

0

Nevertry tostop or deflectleakswithYourhandorThespray gun cups and accessory remote pressure

body.potsremainpressurized untilpressureismanually

Always turn

off

the air supplytothe gun before relieved. To reduce the risk of serious injury from

pressurizedfluidor accidental spray from the gun,

always relieve pressureinthe cupor pressurepot

removing the spraygun cup.

0

Check all spray equipment regularly and repair or before checking or servicing anypartof the spray

system; before installing, cleaning orchangingfluid

nozzles: before loosening or removing the accessory

replace wornor damagedpartsimmediately.

OnlyusegenuineGracoreplacementpartswhenremotepressure potcover;andwheneveryoustop

servicingthegun.spraying.

Never alter

or

modifyany part ofthis equipment:

doing

so

could causeit

to

malfunction.

Spray

Gun

Cup

Read and follow thefluidand solvent manufactur-

er’s literature regarding the use of protective

eyewear, gloves, clothing, respirator and other

equipment.

To

relieve pressure:

1. Turn

off

the air supplytothe gun.

2.

Unlatch the cup cover and loosen or remove the

cup from thecover.

FluidCompatibility

Be sureall fluids and solvents used are chemicallv

compatible with the “Welted Parts” showninthe

Technical Data on the backcover. Always read the

fluidand solvent manufacturer’s literature before

using thefluidor solventinthis gun.

Do

not usel,l,l-trichloroethane, methylene chloride,

other halogenated hydrocarbon solvents or fluids con-

taining such solventsinthe turbine spray system,

which contains aluminum and/or galvanized-coated

parts. Such usecould resultinaserious chemical

reaction, with thepossibilityof explosion, whichcould

cause death, serious injury, andlor substantial prop-

erty

damage.

Accessory

Remote

Pressure

Pot

To

relieve pressure:

1.

Turn

off

the air supplytothe pressure pot.

2.

2

1/2

Gallon Remote Pot:

Pull

the pressure relief

valve ring

(206c)

until pressure

is

completely

2

Quart Remote Pot: Turn

out

the pressure relief

relieved.

knob (113) about one turn. Waituntil pressure

is

completely relieved before removing the cover.

Close the knob before using the system again.

See Fig.

4

on page

7.

2

308-336

Tightenallfluid connectionssecurelybeforeeachuse.Handleandroutehosescarefully.Do notpullon

Never

use

adamaged hose. Before each use, check

the entire hose for cuts, leaks, abrasion, bulging

cover. or damaae or movement of the hose CouDlinw.

hosesto move equipment.

Do

not use fluidsor

sol-

vents which arenot compatible with theinner tube

and cover of the hose.

If

anyofthese conditionsexist, replace the hose

immediately.

.-

FIRE

OR

EXPLOSION

HAZARD

Sparking can be expected

inthe normal operation

of

.Sparkingand FlammableVapors

Hazard

IgnitionSources

Avoidallignition sources suchas static electricity

theturbinemotor.Sparkscouldignitefumesfromfromplasticdropcloths,openflamessuchaspilot

flammableliquid,dustparticlesandotherflammablelights,hotobjectssuch

as

cigarettes,arcsfromcon-

substancesinthesprayarea,andcauseseriousnectingordisconnectingpowercordsorturninglight

injury and property damage. Be suretofollow thepre . switchesonand

off.

Extinguishor remove all sources

cautionsbelow: ofignition.

When flammableliquid issprayed or used for

flushing or cleaning equipment, the turbine must

be placed at least

20

feet

(6.1

m) away fromareas

where hazardous concentrations of flammable

vapors arelikelyto occur.

Use

additionalair hose

if

necessary to ensure that

the turbine is operatedinaclean, dry, well venti-

latedarea.

Never place the turbine insideaspray booth!Use

this equipment outdoors or in extremely well venti-

latedareas.

To reduce the risk of static sparking, ground the tur-

Grounding

bine and all other spray equipment used or located in

the spray area. Check yourlocal electrical code for

detailed grounding instructions for your area and type

of equipment.

To

groundthe turbine: Plugthe power supply cord

intoa properly grounded outlet. Do not remove the

grounding prong from the power cord.Do notuse an

berated foraminimum of

15

amps.

adapter. Extension cords must have three wires and

IMPORTANT

United

States

Government

safety

standards

have

been

adopted

under

the

Occupational

Safety

and

Health

Act.

These

stan-

dards--particularly

the General Standards,

Part

1910

and

the

Construction

Standards,

Part

1926--should

be

consulted.

Table

of

Contents

Warnings..

....................................

2

Introduction

...................................

4

FluidSet Selection Charts

.......................

4

Shutdown

11

Setup..

6

SprayingTechniques

..........................

12

Maintenance..

................................

13

Service

......................................

16

.......................................

....................................

Troubleshooting..

.............................

18

Parts

Model710

................................

20

Models

709HS

&

71OHS

....................

22

Model71OP

...............................

24

Accessories

..................................

25

TechnicalData

........................

BackCover

Warranty

.............................

BackCover

308-336

3

Introduction

TheSeries

700

TurbineSprayGuncanspraymostanddirectsthepaintfrom thegun tothesurface,

coatings or finishes currently being used for automo-

tive

refinish, industrial, aerospace, marine, wood, minimizing overspray and increasing transferem-

plastic and architectural applications. ciency. This enables paintersto comply with new

clean air laws that are designedto reduce

VOC

(vola-

This spraygun typically utilizes

5

psi

(0.35

bar) tile organic compounds) emissions, eases paint

inbound air pressureto producehighquality paint application by requiring fewer paint passestoobtain

finishes. The gun producesacone of air that carries coverage, and savesonbothmaterial and clean-up

time.

Fluid

Set

Selection

Charts

Usingthe Charts

Unless otherwise ordered,theTurbine Spray Gun

size

of

thea/r cap, fluidnozzle, and fluid needle are

includesa

1.4

mmfluidset, part no.

M70581.

The

marked on theparts.

Use

the fluidset charts on page

5

to orderadifferent

size

fluid set ortofindthe part number of an indivi-

dual component of yourfluidset. The charts separate

fluid sets that are commonly usedincontractor

applications from those commonly usedinautomotive

applications.

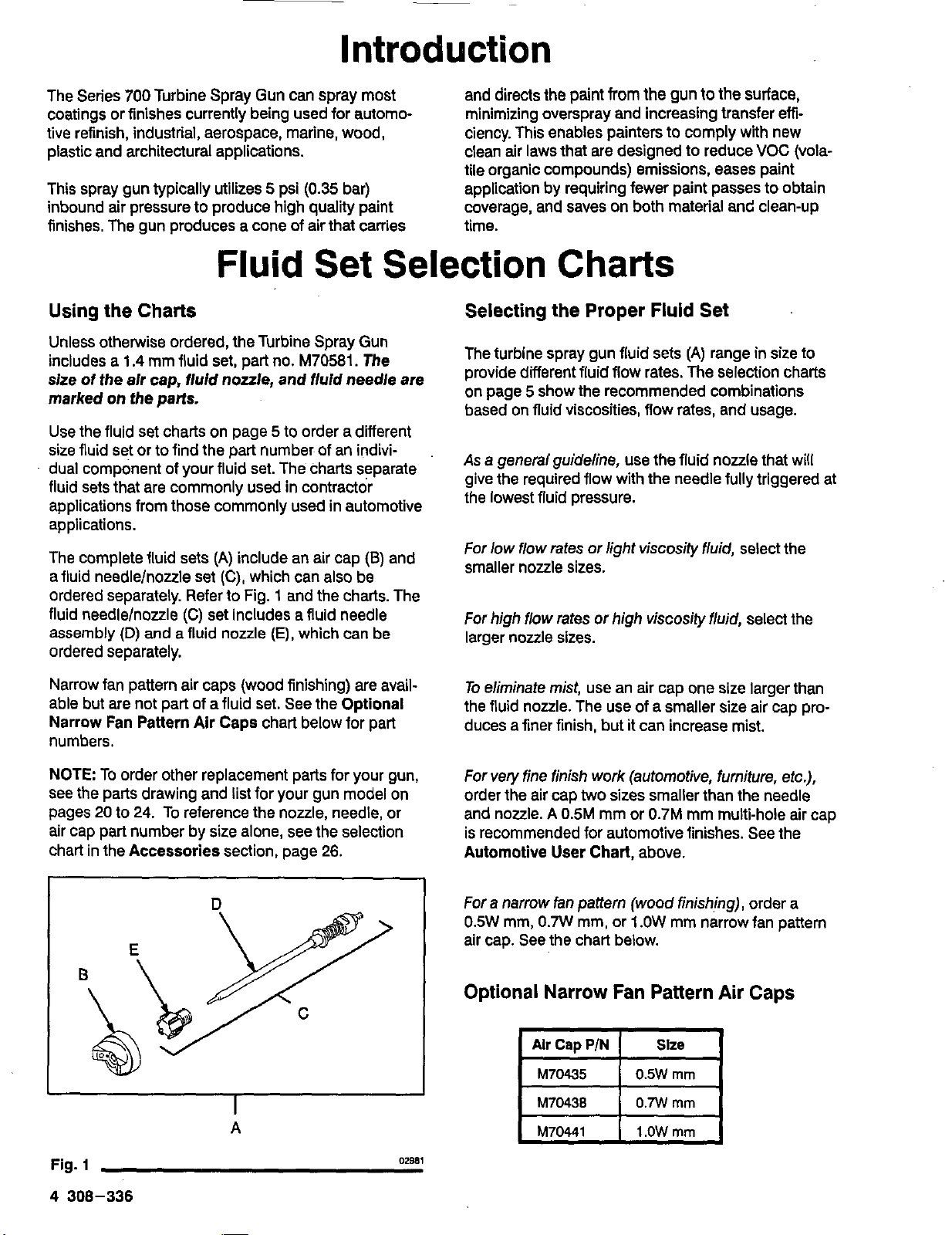

The completefluid sets

(A)

includean air cap

(a)

and

afluidneedlelnozzleset

(C),

which can also be

ordered separately. Referto Fig.

1

and the charts. The

fluidneedlelnoule

(C)

set includesafluid needle

assembly

(D)

and

a

fluid nozzle

(E),

which can be

ordered separately.

able but arenot partof afluid

set.

See the Optional

Narrow fan pattern air caps (wood finishing) are avail-

NarrowFan PatternAir Caps chart below for part

numbers.

see the parts drawing and list for your gun model on

NOTETo order other replacement parts for your gun,

pages

20

to

24.

To reference the nozzle, needle, or

air cappart number by

size

alone, seethe selection

chart in theAccessories section, page

26.

A

Fig.

1

02981

4

308-336

Selecting the Proper Fluid Set

The turbine spray gunfluidsets

(A)

rangeinsize to

provide differentfluidflow rates. The selection charts

on page

5

show the recommended combinations

based onfluidviscosities, flow rates, and usage.

As

ageneral guideline, use thefluidnozzle that will

the lowestfluidpressure.

give the required flow with the needle fully triggered at

For lowflow rates

or

lightviscosily fluid, select the

smaller nozzle sizes.

For

high

flow rates

or

highviscosity fluid, select the

larger nozzle sizes.

To

eliminate mist, use an air cap one size larger than

the fluidnozzle. The use ofasmaller size air cappro-

duces afiner finish,butitcan increase mist.

For very fine finish work (automotive, furniture, etc.),

order the air cap

two

sizes smaller than the needle

and nozzle.

A

0.5M

mm or

0.7M

mm multi-holeair cap

Automotive User

Chart,

above.

is recommended for automotive finishes. See the

Foranarrow

fan

pattern (wood finishing), ordera

0.5W

mm,

0.7W

mm, or

1

.OW

mm narrow fan pattern

air cap. Seethe chart below.

Optional Narrow Fan Pattern Air Caps

Alr

Cap

P/N

Slze

M70435

1

.OW

mm

M70441

0.7W

mm

M70438

0.5W

rnm

~

Fluid

Set

Selection

Charts

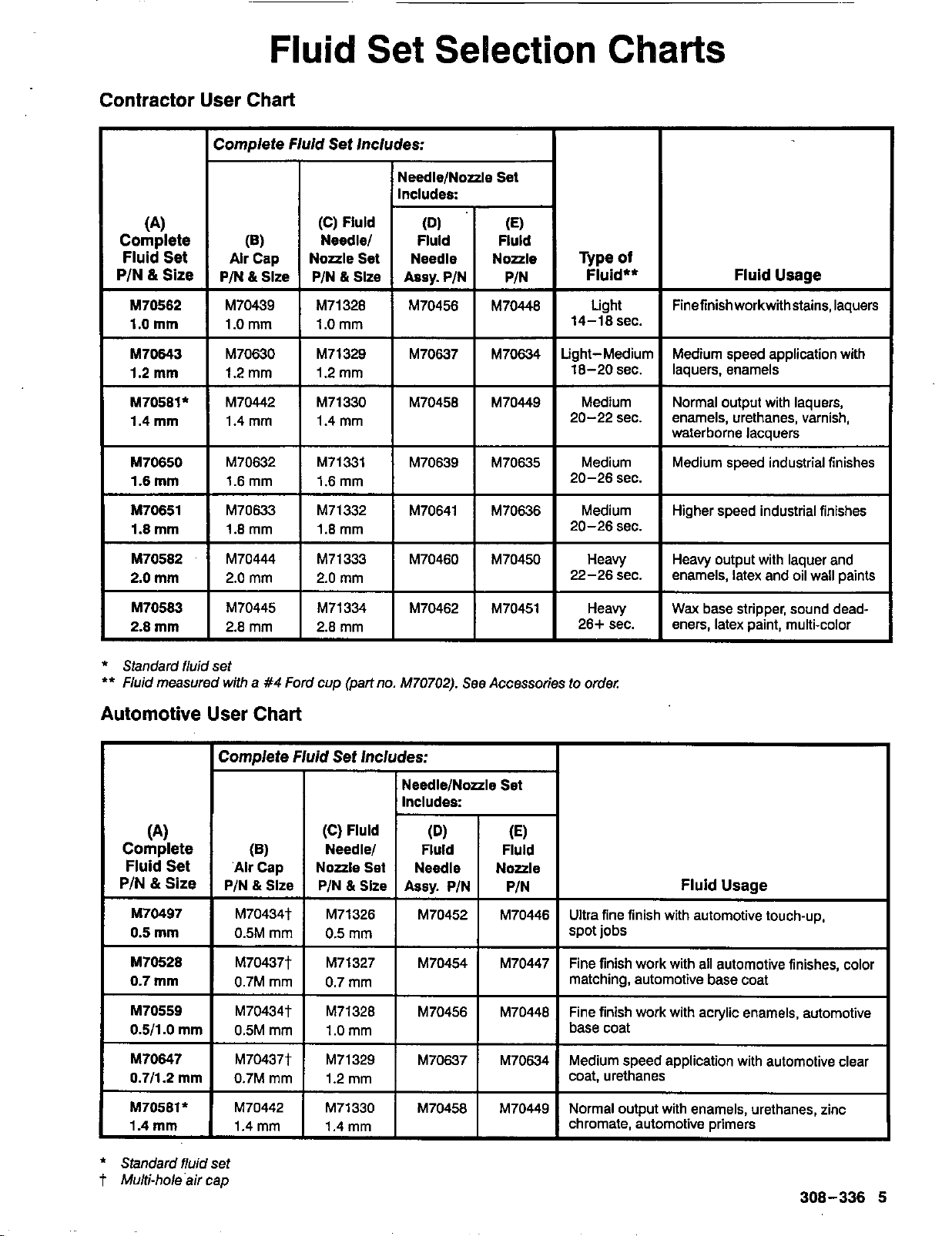

Contractor User Chart

I

Complete

Fluid

Set Includes:

NeedlelNozzleSet

(C)

Fluld

Needlel FluldFluld

(4

Complete

PIN

&

Size

Fluid Set

(6)

Alr

Cap

P/N

&

Slze

I

M71328M70456M704461.0 mm

M71329M70637M70634

M70439

1.0 mm

M70630

1.2 mm

M70442

1.4 rnm

Light

Finefinishworkwithstains,laquers

14-18 sec.

MediumNormaloutputwithlaquers,

waterborne lacauers

M70562

1.0

mm

M70643

1.2

mm

M70581'

1.4

mm

1.2 mm

I

M71330

I

M70456

I

M70449

1.4 mm

M70650

I

1.6mm

I

?ilz

I

I

M70632M70639M70635 1.6

mm

20-26 sec.

Medium Medium speed industrial finishes

I

M70651

I

M70633

I

M71332

I

M70641

I

M70636

1.8

mm

1.8 mm 1.8 mm 20-26 sec.

Medium Higher speed industrial finishes

I

M70444M71333

I

M70460

I

M70450

2.0

mm

22-26 sec. enamels, latex and oil wall paints

Heavy

I

Heavy output with laquer and

26+sec.eners.latexDaint.multi-color

Heavy

Wax

base stripper, sound dead-

I

M70583 2.8mm2.8

mm

2.8

mm

M70451 M70462

M71334 M70445

*

Standardfiuidset

**

Fluid

measured with

a

#4

Ford cup(part no.

M70702).

SeeAccessories to order:

Automotive User Chart

I

ComdeteFluidSetIncludes:

I

I

I

I

Includes:

I

~~

NeedleINoale

Set

(4

Complete

PIN

&

Size

Fluid Set

(C)

Fluld

PIN

Assv.

PIN

PIN

&

Slze NoaleNeedle

Noale

Set

Fluld

Fluld

Needlel

(E)

(Dl

(6)

'Alr

Cap

PIN

&

Slze

Fluid Usage

~ ~~~~

Ultrafine finish with automotive touch-up,

spot jobs

M70497 M70434t 0.5 mm

0.5

mm

0.5M mm M70446 M70452

M71326

~ M70437t

~ 0.7Mmm

M70434t

0.5M mm

M70437t

0.7M mm

M70442

1.4 mm

0.7

M71327

mm

I

M70454

M70447 Fine finish work with all automotive finishes, color

matching, automotive base coat

M70528

0.7

mm

M70559

0.511

.O

mm

M70647

0.711.2

mm

M70581*

1.4

mm

M70446 Fine finish work with acrylic enamels, automotive

base coat

M71328M704561.0 mm

1.2 mm

M71330M70458

M70634 Medium speed application with automotive clear

coat, urethanes

M70449 Normal output with enamels, urethanes, zinc

chromate, automotive primers

*

Standardfluidset

t

Multi-hole'aircao

308-336

5

Setup

Connect the Fluid

and

Air Supply

1.

Connect the gun air supply hose

(A)

between the

turbine air outlet

(D)

andthe gun air inlet. See

Fig. 2.

2.

If

using

aspray

gun

cup

(B),

connect the cupto

the gunfluidinlet.

3.

Musing

an

accessory remote pressurepot (C),

connect the fluid supply hose

(G)

between the

gun fluid inlet and the remote pressure pot.

Connect the air hose

(E)

between the pressure

potair inlet and the compressor air outlet

(F).

E

2-112

Gallon Remote Pressure Pot

Part

No.

M70604

(see

Accessories)

E

2

Quart Remote Pressure Pot

Part

No.

M70585

(see Accessories)

CX-8Turblne shown

Fig.

2

02859

6

308-336

Setup

Prepare the Fluid

1.

Always strain thefluid before spraying; this

includescolor, reducer and hardeners

if

used.

2.

When usingaturbine spray system, you need

to

usea slower drying reduceror thinnerto compen-

sate for the fasterdrying timecaused by the

warm air ofthe turbine.

Do

notover reduce.

PaintReduction

-

AutomotiveType Finishes

Reduce and catalyze all paintto manufacturer’s spec-

turbine systems, useareducer one-step slower than

ifications.To compensate for the faster drying time

of

what isused for conventional airspray.

PaintReduction

-

Industrial

or

DomesticCoatings

ifications.

If

noreductionsare given, first thoroughly

Reduce and catalyze all paintto manufacturer’s spec-

mix thefluid

to

be sprayed. Then gradually mixinthe

proper reducer,testing the fluid until youhave thecor-

rect spraying consistency.

To

test the consistency: Remove the stir stick from the

thinned paint.When the paint stream running

off

the

stir stick breaksintodroplets, the firstfew drops

should be about one second apart.

Fill

the Cup

or

Remote Pressure

Pot

Spray Gun Cup

WARNING

The spray gun cup is pressurized by the gun’s air

supply. To reduce the risk of serious injury from

pressurizedfluidor accidental spray from the gun,

always turn

off

the air supplytothe gun before

removing the spraygun cup.

Only fill the cup

3/4

fullto help keep thefluid tube

alatch

(H)

to secure it to the cup. The over-cup hasa

clean, then install the cover. The under-cup cover has

ringwith notches

(J)

that secures the cup hoodinto

place when lockedinplace on the cup.

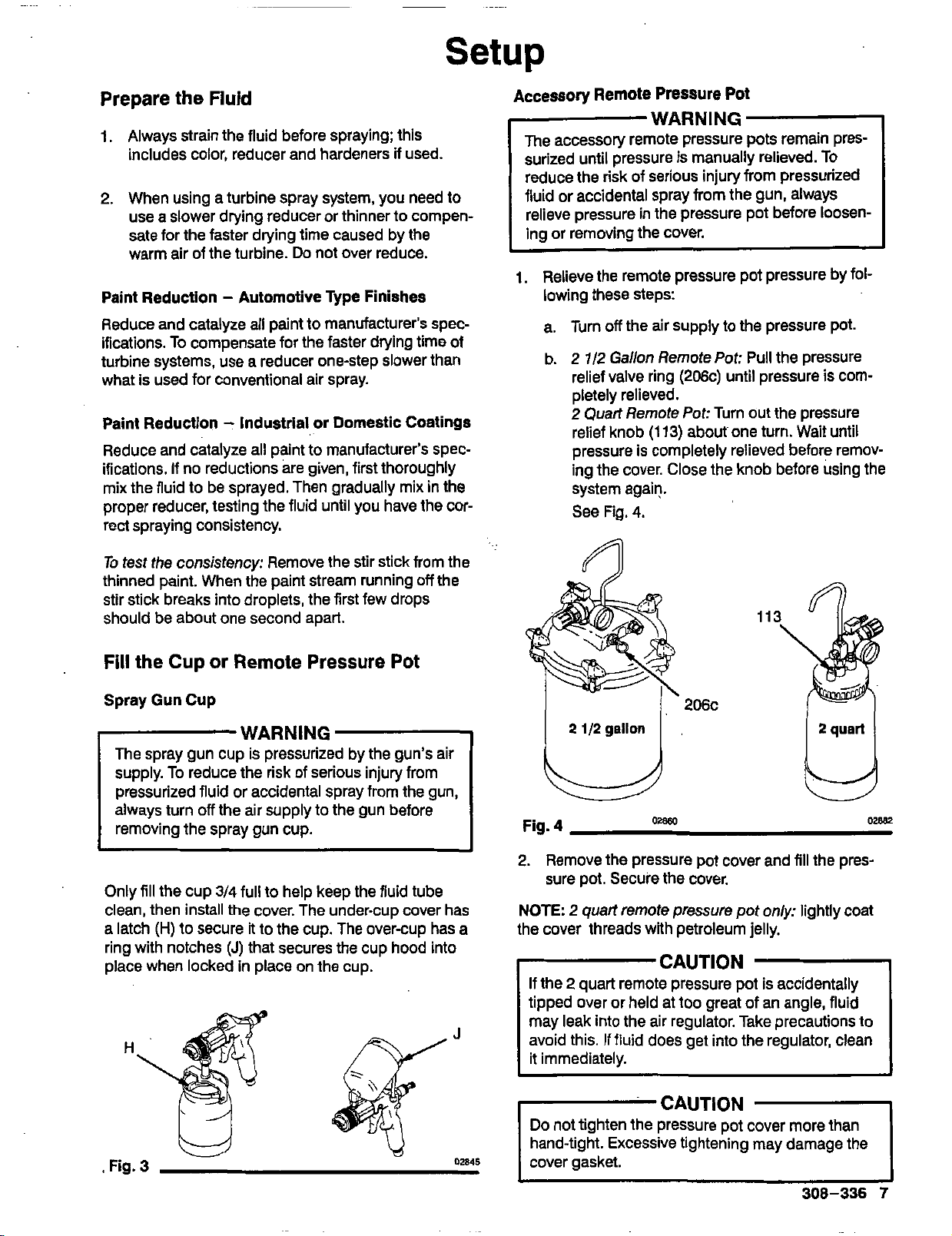

AccessoryRemotePressurePot

WARNING

The accessory remote pressure pots remain pres-

surized until pressureismanually relieved.TO

fluid or accidental spray from the gun, always

reduce the risk of serious injury from pressurized

relieve pressure in the pressure pot before loosen-

ingor removing thecover.

1.

Relieve the remote pressurepot pressurebyfol-

lowing these steps:

a. Turn

off

the air supply to the pressure pot.

b.

2

7/2Gallon Remote

Pot:

Pull the pressure

relief valvering (206c) until pressureiscom-

pletely relieved.

2

Quart Remote

Pot:

Turn out the pressure

relief knob

(113)

about one turn. Wait until

pressure

is

completely relieved before remov-

ingthe cover. Close the knob before using the

system again.

See Fig.4.

Fig. 4

2.

Remove the pressurepot cover andfill the pres-

sure pot.Secure the cover.

the cover threads with

petroleum jelly.

NOTE:

2

quart remotepressurepot

only:

lightlycoat

CAUTION

tipped over orheldat too great of

an angle,fluid

If the2 quart remote pressure pot

is

accidentally

may leakinto theair regulator. Take precautionsto

avoid this. Iffluiddoes getinto theregulator, clean

it immediately.

Do

not tighten the pressure pot cover more than

hand-tight. Excessive tightening may damage the

cover gasket.

308-336

7

Setup

Prepare the Surface

to

be Sprayed

To achieve proper adhesion, make sure the Surface

to

be sprayed

is

completely clean.

Operating the Turbine

WARNING

Sparking can be expectedinthe normal operation

of the turbine motor. Sparks could ignite fumes

from flammable liquid, dust particles and other

flammable substancesinthe spray area, and

cause seriousinjury and propertydamage. Be

sure

to

follow the precautions below:

0

When flammableliquid

is

sprayed or used for

flushingor cleaning equipment, the turbine

must be placed at least 20 feet

(6.1

m) away

from areas where hazardous concentrations of

flammable vapors are likely

to

occur.

0

Useadditionalair hose

if

necessary

to

ensure

that the turbine

is

operated inaclean, dry, well

ventilatedarea.

0

Never place the turbine insideaspray booth!

Use this equipment outdoors or in extremely

'

well ventilated areas.

0

Avoid all ignition sources suchas static eles-

tricity from plastic drop cloths, open flames

such aspilot lights, hot objects suchas ciga-

rettes, arcs from connecting or disconnecting

power cords orturning light switchesonand

off.

Extinguishor remove all sources of ignition.

1.

Turn the turbine onafew minutes before you start

spraying

to

allow for warm-up time. Turn the tur-

bine

off

when it

is

not inuse; it doesnot shut

off

automatically.

2. Be sure the turbine filter is clean before operating.

See

page

13

to

check and clean the filter.

Cold

Weather Operation

Turbine Spray ModelCX-8, CX-12, and CX-20 havea

diaphragm compressor. When these compressors are

new,the diaphragm will become

stiff

incoldweather.

If

cold enough, the stiff diaphragm will not allow the

compressor

to

start (theunit will hum).

If

thisoccurs,

follow these steps:

1.

Turnthe turbine and compressor

Off.

2. Unplug the turbine from the power source.

3.

Loosen the four main filter screws and remove the

filter; replace the main filter andprefilter

if

they

are dirty.

4.

Handspin the coolingfan on the compressor for

afew revolutions.

5.

Reassembletheturbine.

6.

Plug in the turbine and turn

it

on. The compressor

should start.

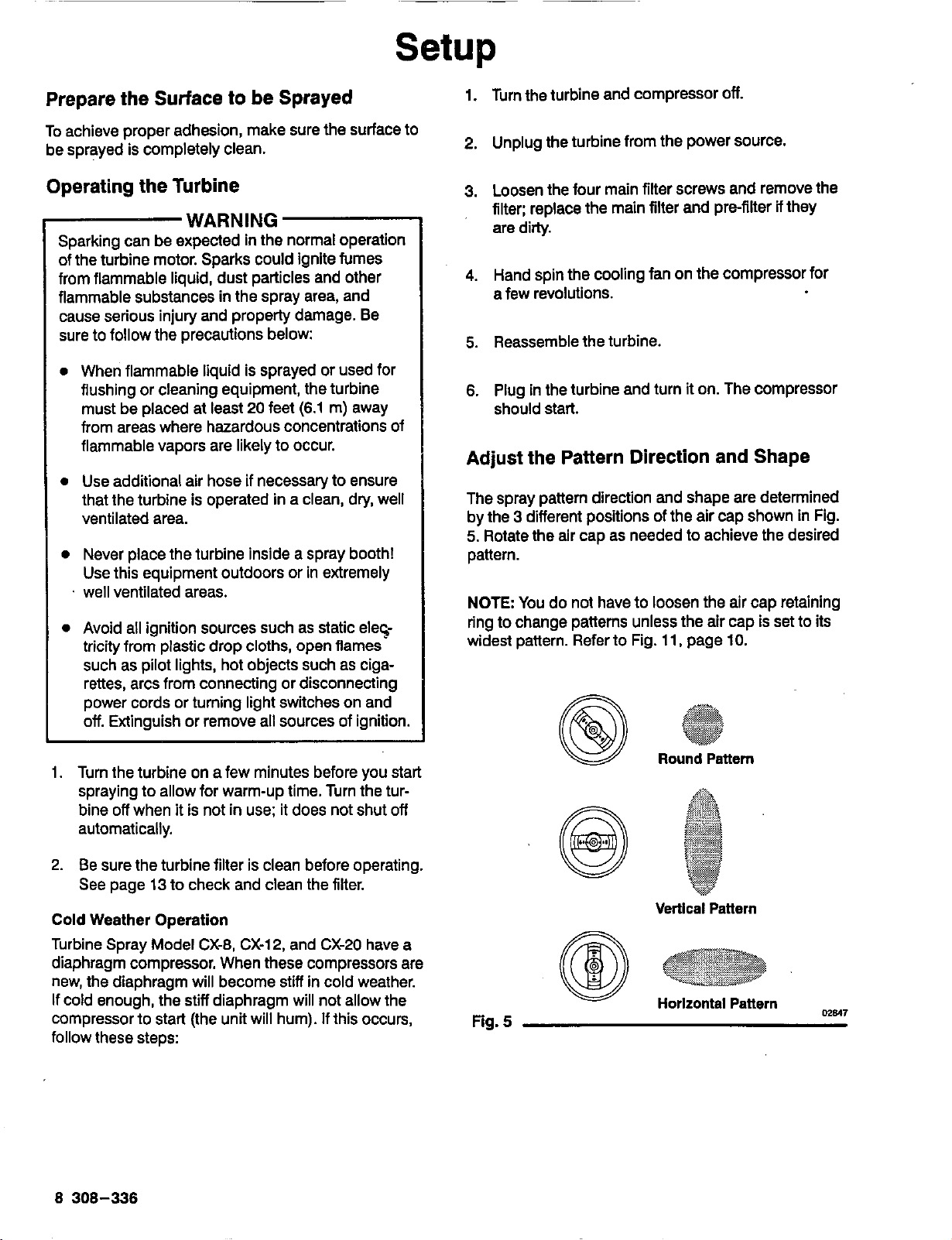

Adjust the Pattern Direction and Shape

The spray pattern direction and shape are determined

5.

Rotate the air cap as needed

to

achieve the desired

by the

3

different positions of the aircapshown inFig.

pattern.

NOTE

You do not have

to

loosen the air cap retaining

widest pattern. Refer

to

Fig.

11,

page

IO.

ring

to

change patterns unless the air cap

is

set

to

its

Round Pattern

Vertical

Pattern

Horlzontal

Pattarn

m817

Fig. 5

8 308-336

Setup

Adjust

the

Spray

Paitern

WARMING

FluidlnletPressure and

100

psi

(7

bar)

Maximum

Do

not exceed the gun's

50

psi

(3.5

bar)

Maximum

Air

inlet

Pressure. Higher pressurescan cause

partstorupture and resultinserious injury or

properlydamage.

L

To

establish the correctfluid

flow:

1.

Turnthefluidadjustment knob

(20)

counterclock-

wise until no restriction of the trigger movementis

felt. See Fig.

6.

u

Fig.

6

U

me45

2.

Ifa remote pressurepot

is

used, holdthe gun par-

alleltothe floor and adjustthe fluid pressureto

yield

a

12

to

18

inch

(305

to

457

mm) fluid stream.

See Fig.

7.

A

2

quart remote pressurepottypically should be

set at

2

to

4

psi

(0.14

to

0.28

bar).

A

2

1/2

gallonremote pressurepottypically

shouldbeset at

4to

8

psi (0.28to

0.56

bar).

Heavierfluidor a long fluidhose

will

require more

Dressure,

WARNING

To

reduce the risk of over-pressurizing the acces-

sory

remote pressure pots, which could cause

serious injury, never exceed

50

psi

(3.5

bar)

Maxi-

mum

Air

InletPressure.

Fig. 7

FluidVelocity

of

FluidNozzles

atthe Same FlowRate

m1u8

Orlflce

Size

In

Millimeters

Fig.

8

3.

if

further fluidadjustmentisneeded at the gun,

turn the fluid adjustment knob

(20)

clockwiseto

reduce the volume

of

fluid output and obtain the

desired results. See Fig.

9.

02849

20

U

Fig.

9

me45

CAUTION

continuously spraying

with thefluid adjustment

Restricting the trigger

and fluidneedle travel by

knob closed (turned clockwise), will cause

accelerated abrasive wear on thefluid needleand

wear onthe trigger.

Forthe best results, adjust the fluid flow at the

nozzlelair cap combination.

pressure source or useadifferent

size

needle/

308-336

Setup

Adjust

the Spray Pattern

(continued)

To

establish thecorfectair

flow:

4.

Test the spray pattem and atomization while hold-

ingthe gun about

6

to

8

inches(150 to

200

mm)

from the test piece.

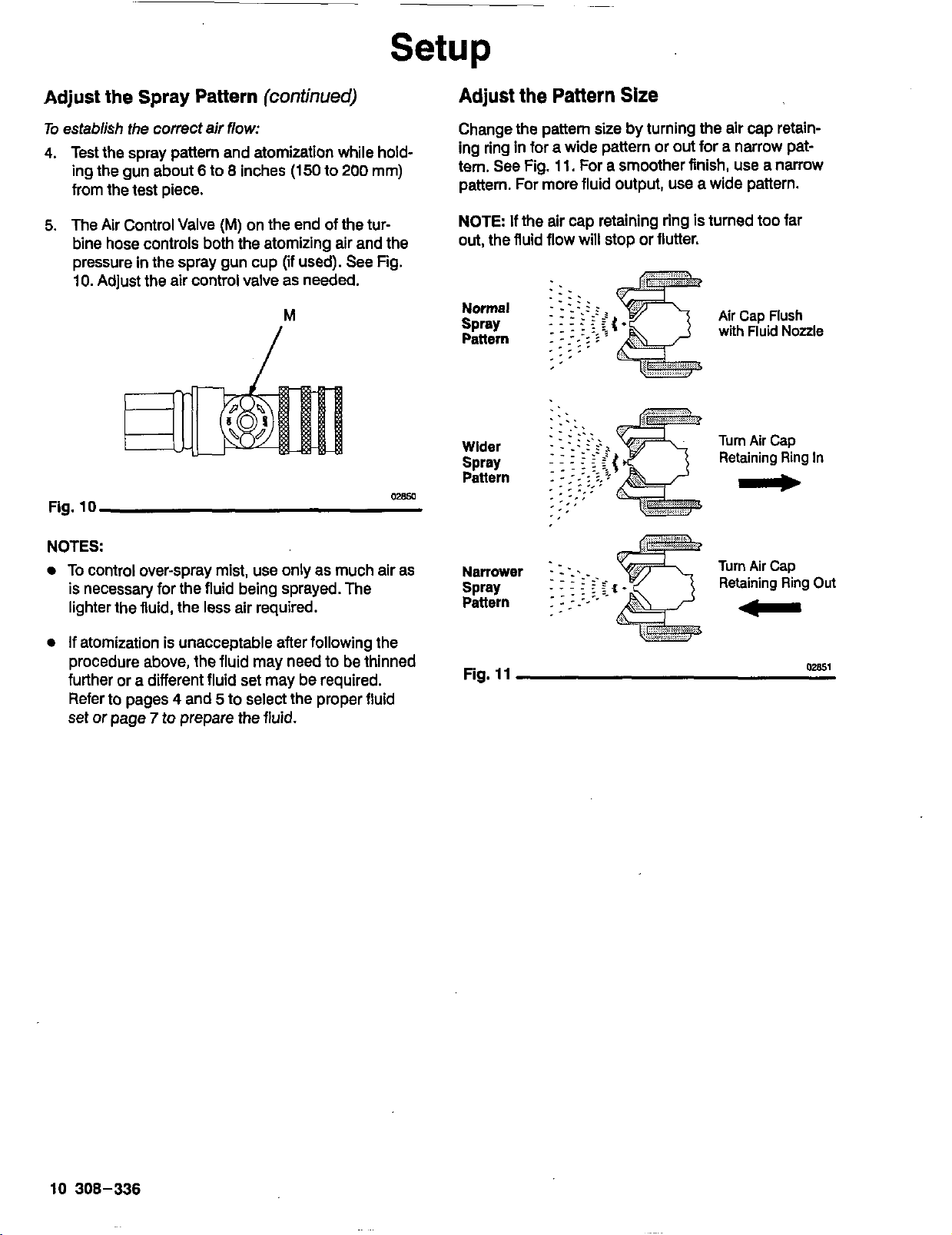

5. The Air ControlValve

(M)

on the end of thetur-

bine hose controls both the atomizing air and the

pressureinthe spray gun cup (if used). See Fig.

10.

Adjust the aircontrolvalve

as

needed.

M

Fig.

10

NOTES

To

control over-spray mist, use onlyas much airas

02850

isnecessary for thefluid being sprayed.The

lighter the fluid, the

less

air required.

If

atomization

is

unacceptable after following the

further ora differentfluidset maybe required.

procedure above, thefluidmay need

to

be thinned

Refer

to

pages

4

and

5

to select the proper fluid

set

or

page

7

toprepare the fluid.

Adjust

the

Pattern

Size

Change the pattem sizebyturning theair cap retain-

tern. See Fig. 11. Fora smoother finish, use a narrow

ing ringinfor a wide patternor out for a narrow pat-

pattern. For morefluidoutput,use a wide pattern.

NOTE

If

the aircap retainingring

Is

turned

too

far

out, the fluid flowwillstop or flutter.

Normal

Pattern

Spray

Wider

Spray

Pattern

Narrower

spray

Pattern

Air Cap

flush

with

Fluid Nozzle

Turn

Air

Cap

Retaining RingIn

c

Turn Air Cap

RetainingRing

Out

-

Fig.

11

02851

10

308-336

Shutdown

WARNING

The spray gun cups and accessory remote pres-

sure pots remain pressurized until pressure is

manually relieved.To reduce the risk of serious

injury from pressurized fluid or accidental spray

from the gun, always relieve pressureinthe cup or

pressurepotbefore checkingor servicingany part

of the spray sysfem; before installing, cleaning or

changing fluidnozzles: before loosening or remov-

ingthe accessoly remote pressure potcover; and

whenever you stop spraying.

1.

When spraying

is

finished, turn

off

the air supply

tothe gun.

2.

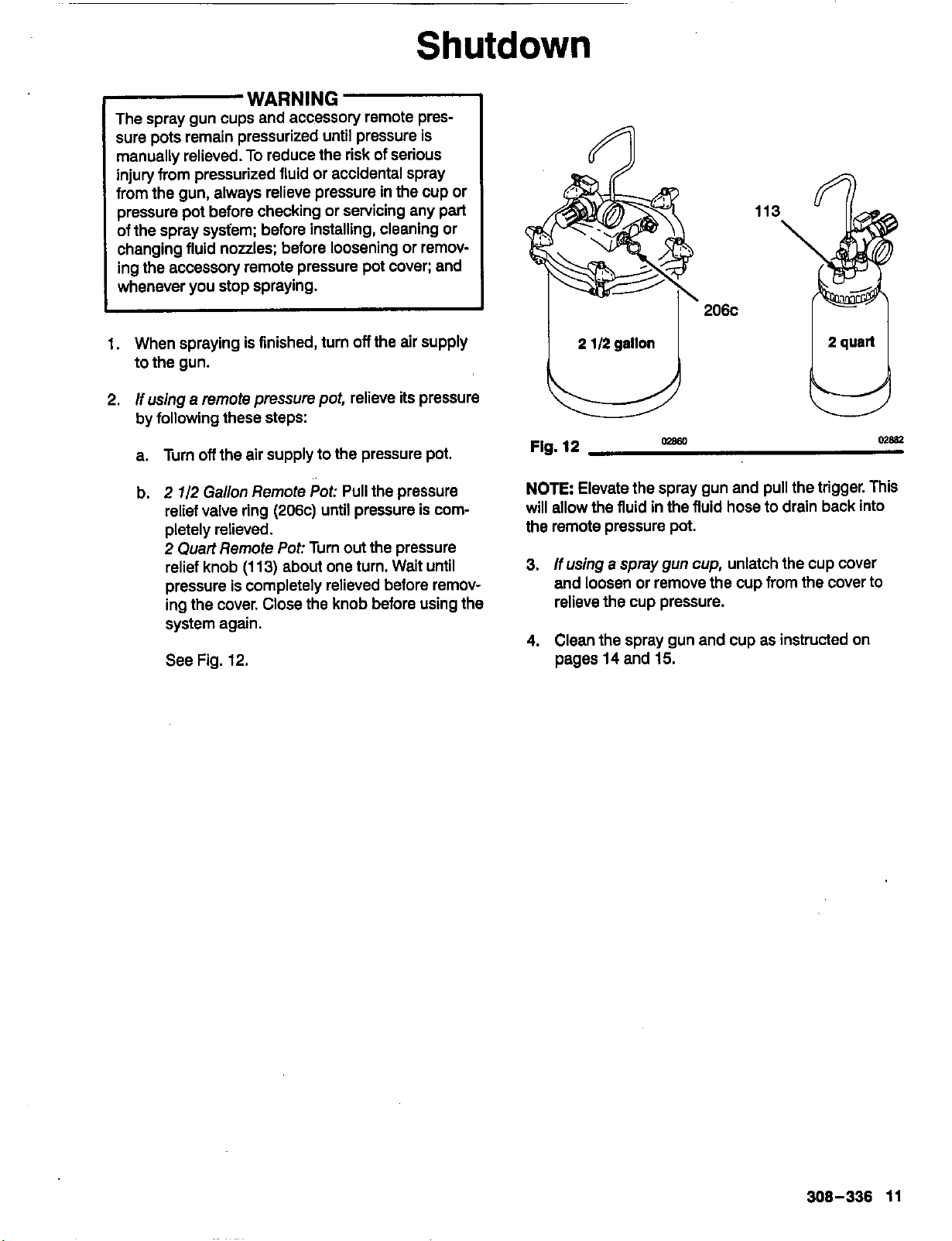

If

usingaremote pressure pot, relieve

its

pressure

by following thesesteps:

a. Turn

off

the air supplytothe pressure pot.

b.

2

1/2

Gallon Remote

Pot:

Pull

the pressure

relief valvering (206c) until pressure

is

com-

2

Quart

Remote

Pot:

Turn

out

the pressure

pletely relieved.

relief knob

(1

13)

about one turn. Wait until

pressure

is

completely relieved before remov-

ingthe cover. Close theknobbefore using the

system again.

See Fig. 12.

113

206c

ULJ

2

1/2

gallon

Fig.

12

NOTE

Elevate the spray gun and pull the trigger.

This

will allow thefluidinthefluidhose to drain back into

the remote pressure pot.

3.

If

using

a

spray gun cup, unlatch the cup cover

and loosenor remove the cup from the cover to

relievethe cuppressure.

02860

MBB2

4.

Clean the spray gun and cupas instructed on

pages14and

15.

308-336

11

Spraying

Techniques

General Spraying Techniques

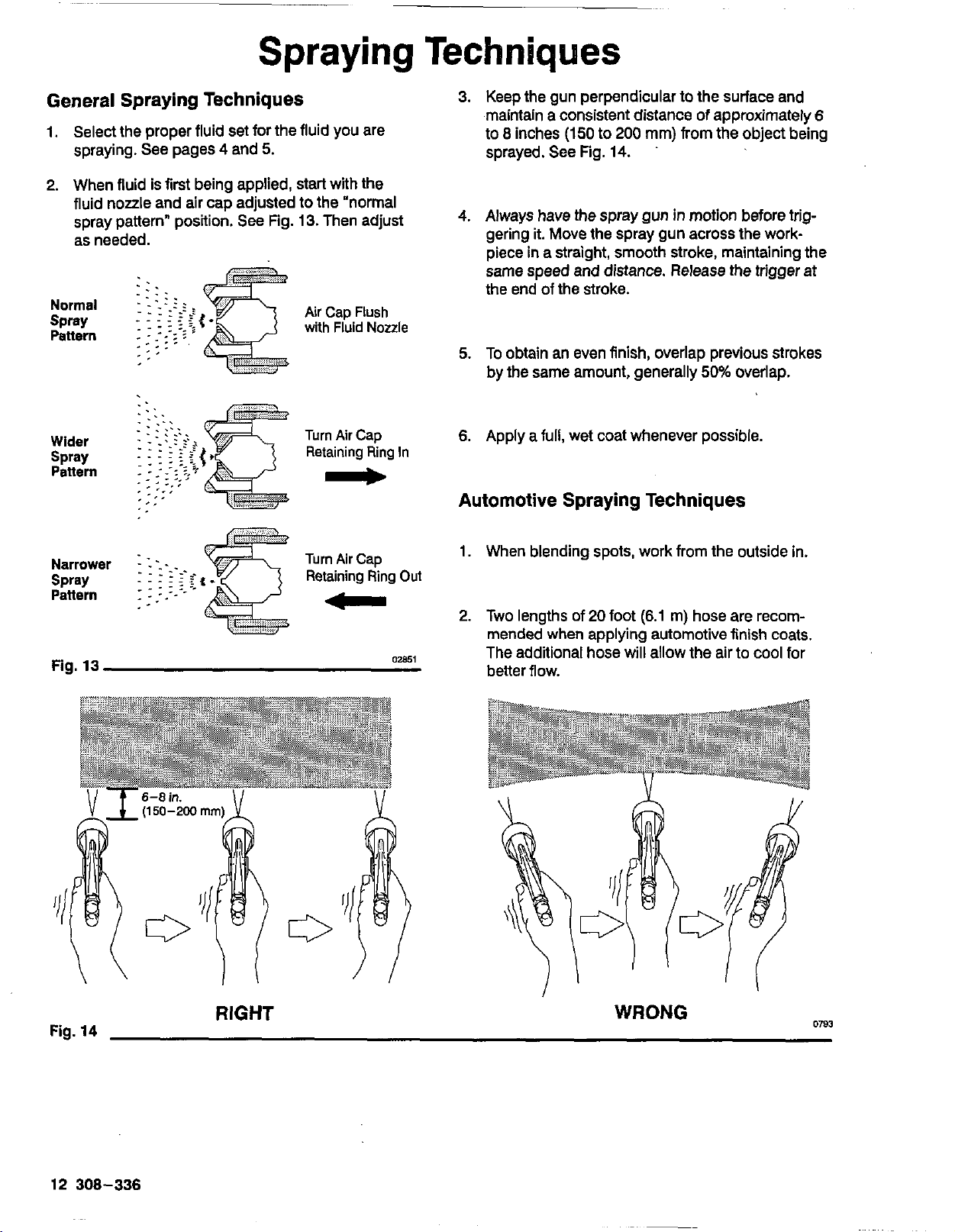

1.

Select the proper fluid set for thefluidyou are

spraying.See pages

4

and

5.

2.

Whenfluid

is

first being applied, start with the

fluidnozzle and air cap adjustedtothe "normal

spray pattern" position.

See

Fig.

13.

Then adjust

as needed.

Normal

spray

Pattern

Wider

Pettern

Spray

Air

Cap

Flush

with

Fluid

Nozzle

Turn

Air

Cap

Retaining

Ring

In

-

Turn Air Cap

Retaining

Ring

Out

-

Fig.

13

02851

3.

Keep the gun perpendicular

to

the surface and

to

8

inches

(150

to

200

mm) from the object being

maintainaconsistent distance

of

approximately

6

sprayed. See Fig.

14.

4.

Always have the spray guninmotion beforetrig-

gering

it.

Move the spraygun across the work-

pieceinastraight, smooth stroke, maintaining the

the end of the stroke.

same speed and distance. Release the trigger at

5.

To obtainan even finish, overlap previous strokes

by the same amount, generally

50%

overlap.

6.

Apply afull, wet coat whenever possible.

Automotive Spraying Techniques

1.

When blending spots, work from the outside in.

2.

Two lengths

of

20

foot

(6.1

m) hose are recom-

mended whenapplying automotive finish coats,

The additional hose will allow the airto coolfor

better flow.

RIGHT

WRONG

0783

12

308-336

~~

Spraying

Techniques

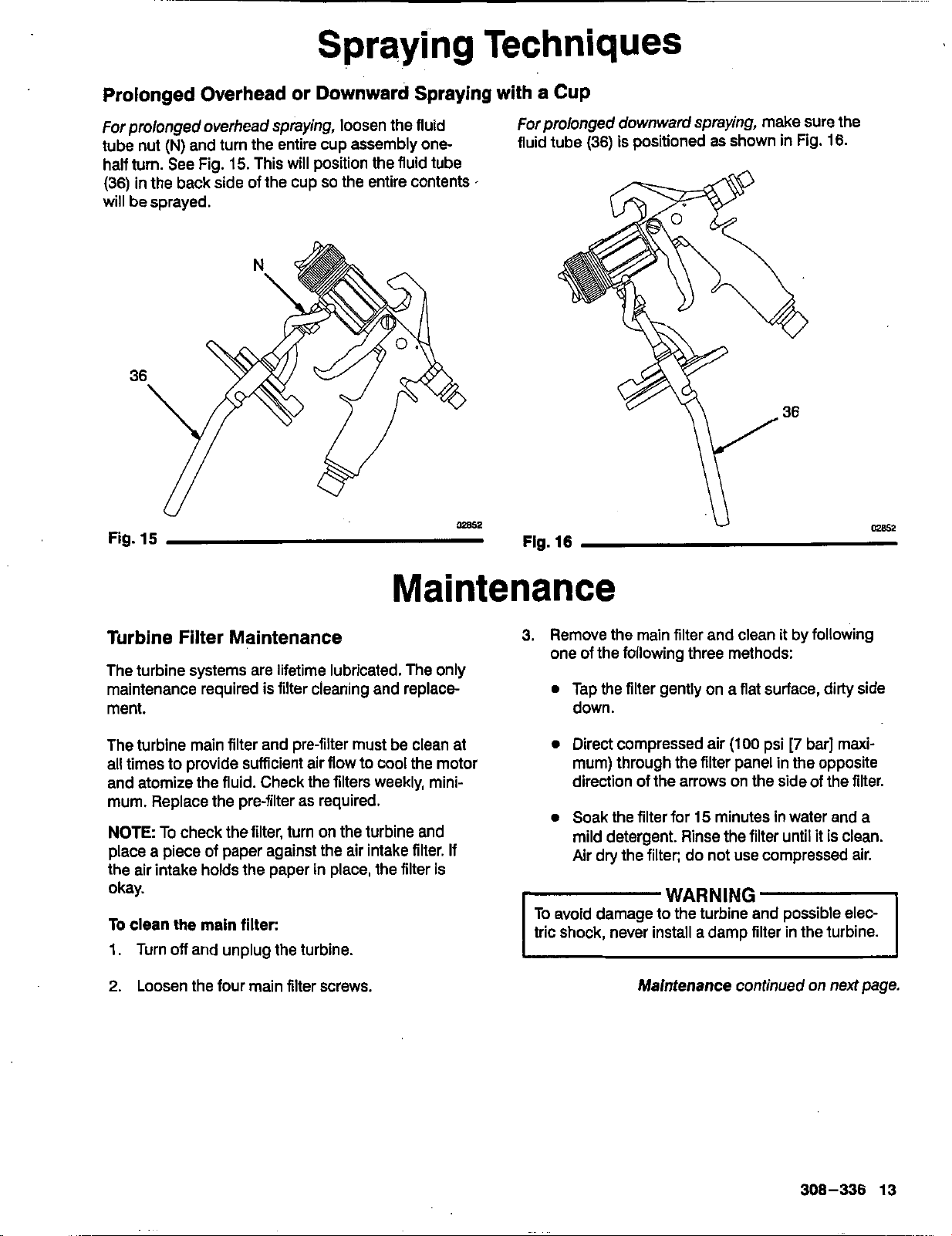

Prolonged Overhead or Downward Sprayingwith a

Cup

For

prolongedoverhead spraying, loosen thefluid

tube nut

(N)

and turn theentire cup assembly one-

half turn. See Fig.

15.

This willposition the fluid tube

(36) inthe back side of the cup

so

the entire contents

I

will besprayed.

36

Fig.

15

Forpro/ongeddownwafd spraying, make sure the

fluid tube(36)

is

positioned

as

shown inFig. 16.

W2

Flg.

16

Turbine Filter Maintenance

The turbine systems are lifetime lubricated. The only

maintenance requiredisfilter cleaning andreplace

ment.

The turbine main filter and pre-filter must be cleanat

all times

to

provide sufficient air flowtocoolthe motol

and atomize the fluid. Check the filters weekly, mini-

mum. Replace theprefilteras required.

NOTE

To

check the filter, turn on the turbine and

the air intake holds the paperinplace, the filter

is

placeapiece of paper against the air intake filter.

If

okay.

To

clean themainfilter:

1.

Turn

off

and unplugthe turbine.

2.

Loosen the four main filter screws.

3.

Remove the main filter and cleanit by following

one ofthe following three methods:

0

Tap the filter gently onaflat surface, dirty side

down.

0

Direct compressed air

(100

psi

[7

bar] maxi-

direction of the arrows on the side of the filter.

mum) through the filter panelinthe opposite

0

Soak thefilter for

15

minutesinwater anda

Air drythe filter; do not use compressed air.

milddetergent. Rinse the filter untilit

is

clean.

-

WARNING

To avoid damage

to

the turbine and possible elec-

tric shock, never installadamp filterinthe turbine.

Maintenancecontinued on

next

page.

308-336

13

Maintenance

WARNING

The spray gun cups and accessory remote pres-

sure pots remain pressurizeduntilpressureis

manually relieved. To reducethe risk of serious

injury from pressurized fluid or accidental spray

from the gun, always relieve pressureinthe cupor

pressure pot before checkingor servicingany part

of the spray system; before installing, cleaning or

changingfluidnozzles; before loosening or remov-

whenever you stop spraying.

ing the accessory remote pressure pot cover; and

NOTES

0

Check forany fluid leakage from the gun and fluid

hoses. Tighten fittingsor replace equipmentas

needed.

Flush the gun before changing colors and when-

ever youare done spraying.

CAUTION

fluid being sprayed and compatible with the spray

Clean all parts witha solvent Compatible with the

gun and cup or accessory remote pressurepot

wetted parts. See theTechnical

Data

on the back

cover.

Flushing the Spray Gun Using

a

Remote

Pressure Pot

1.

Turn

off

the air supplyto the gun.

2.

Relievethe pressure pot pressure by following

these steps:

a. Turn

off

the air supplyto the pressure pot.

b.

2

7/2

Gallon

RemotePot: Pull the pressure

relief valvering (206c) until pressure

is

com-

2

Quart

Remote

Pot:

Turn out the pressure

pletely relieved.

relief knob

(113)

about one turn.Wait until

pressure

is

completely relieved before remov-

ing the cover. Close the knob before using the

system again.

See Fig.

12,

page

11.

3.

Fill the pressure potwith compatible solvent.

4.

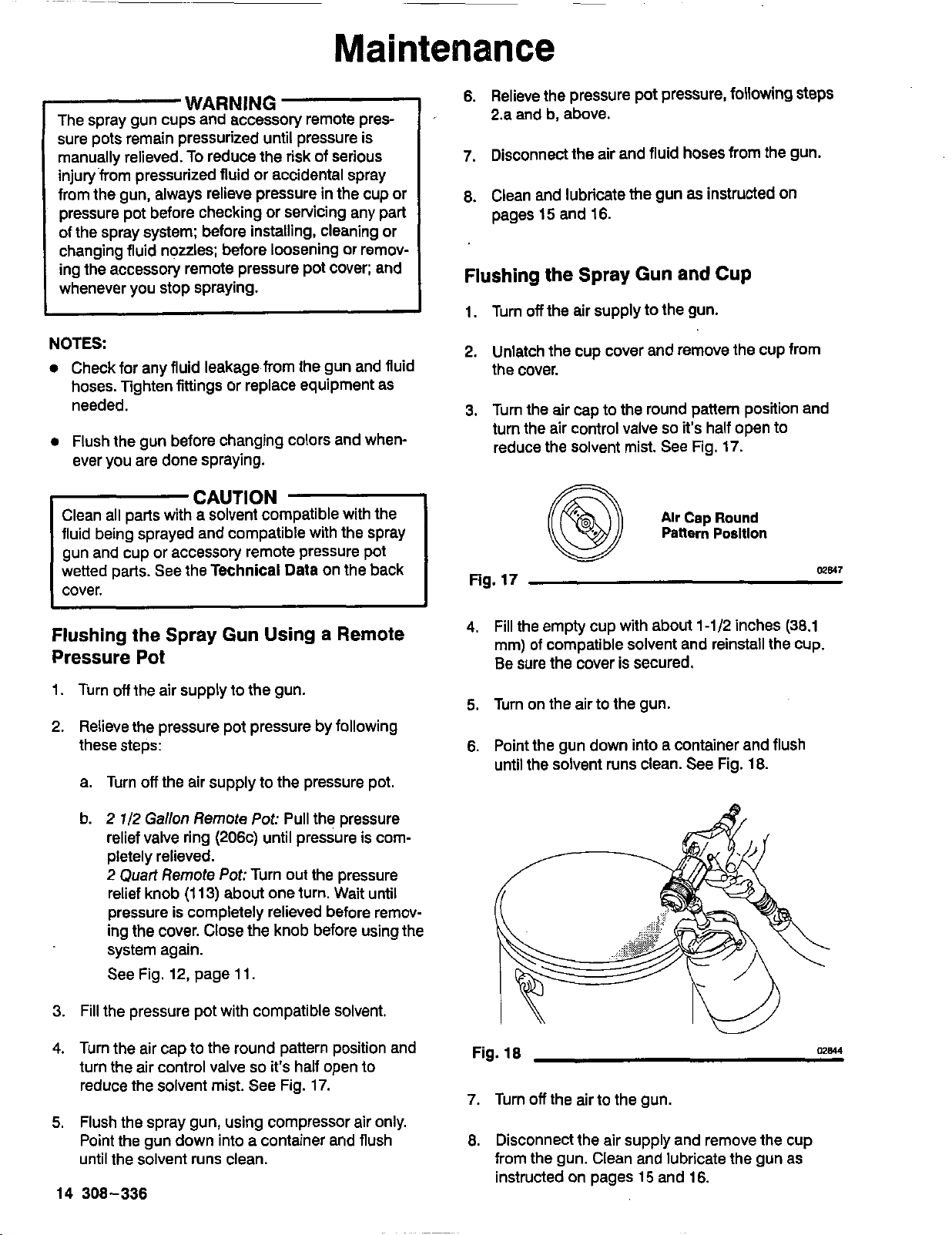

Turn the air cap tothe roundpattern position and

turn theair controlvalve

so

it's

haif opento

reduce

the

solvent mist. See Fig.

17.

5.

Flush the spray gun, using compressor air only.

Point thegun downintoacontainer and flush

until the solvent runs clean.

14

308-336

6.

Relievethe pressurepotpressure, following

steps

2.a and b, above.

7.

Disconnect the air and fluid hoses from the gun.

8.

Clean and lubricate

the

gun

as

instructed on

pages

15

and

16.

Flushingthe Spray Gun

and

Cup

1.

Turn

off

the air supplytothe gun.

2.

Unlatch the cup cover and remove the cup from

the cover.

3.

Turn the air captothe round pattern position and

turnthe aircontrolvalve

so

it's half opento

reduce the solvent mist.

See

Fig.

17.

@

Alr

Cap

Round

Pattern

Posltlon

Fig.

17

1

me41

4.

Fill the emptycupwith about

1-1/2

inches

(38.1

mm)

of

compatible solvent and reinstall the cup.

Be surethe cover

is

secured.

5.

Turn on the air to the gun.

6.

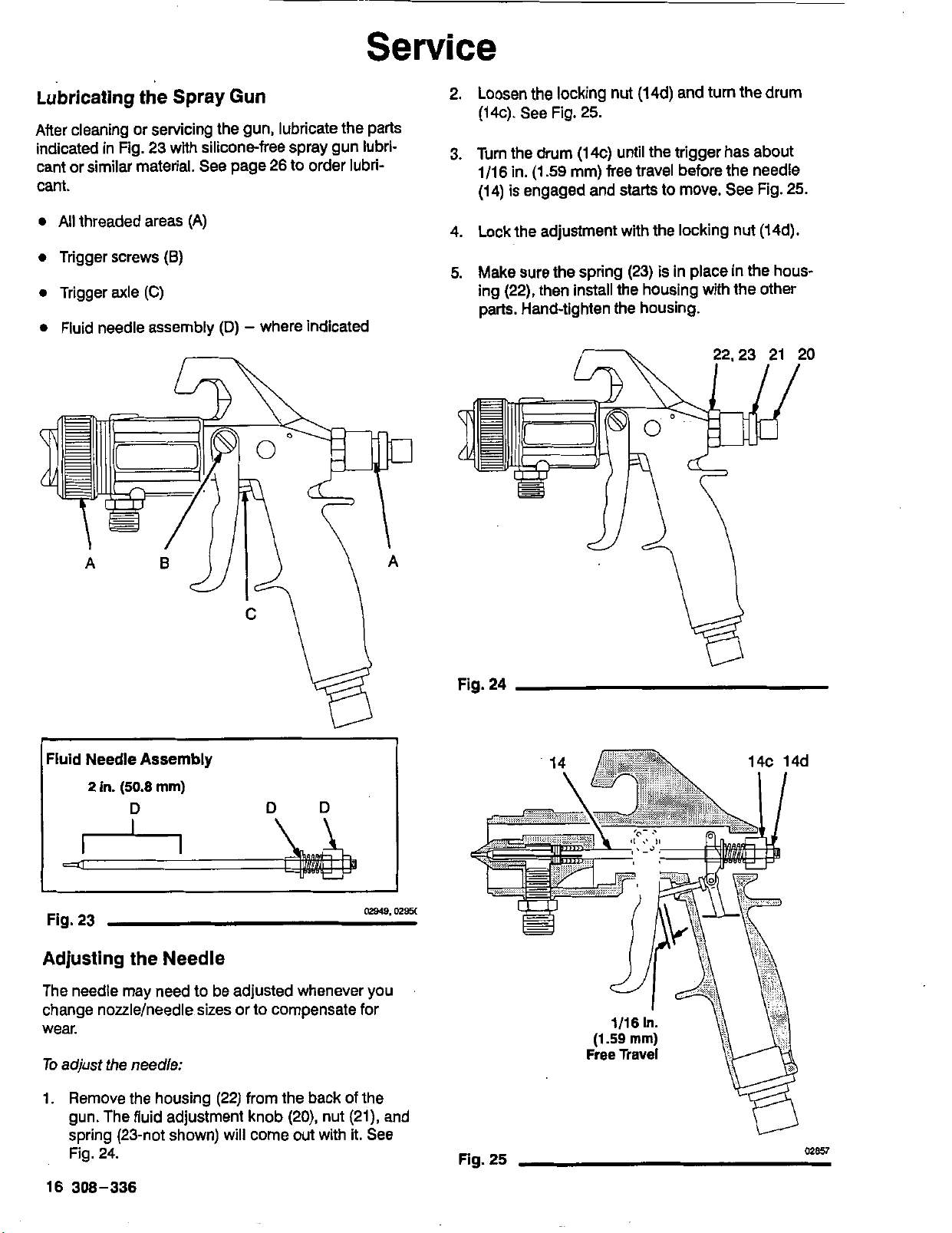

Point thegun downintoacontainer and flush

until the solvent runs clean. See Fig.

18.

Fig.

18

028u

7.

Turn

off

the air to thegun.

8.

Disconnect the air supply and remove the cup

from the gun. Clean and lubricate the gunas

instructedon pages

15

and

16.

Maintenance

Clean the SprayGun

4.

Soak the air cap, detent plate and fluid nozzlein

solvent. Clean the air car, andfluid nozzle daily,

.~

1.

Clean the gun and cup by hand witha compatible minimum, with solvent and the brush (R), pro-.

solvent or place themina gunwasher with the vided. See Fig.

21.

Some applications require

trigger held open; cycle thewasher as necessary more frequent cleaning. Keep all air cap holes

toclean the gun. clean.

CAUTION

toavoid permanently damaging them.

Clean aircap horn holes withanon-metallic item

R

Fig.

19

Me53

2.

Remove the air cap retaining ring

(29),

air cap

20.

(27).

spring

(25),

and detent plate (26). See Fig.

3.

Trigger the gun while you remove the fluid nozzle

Fig.

20.

(19)

with

the

nozzle wrench

(P),

provided. See

CAUTION

Trigger thegunwhenever you tightenor remove

the nozzle. This keeps the needle seatawayfrom

the nozzle seating surface and prevents the seat

from being scratched.

Fig.

20

OW

Fig.

21

5.

With the gun pointed down, clean the frontof the

02858

gun, using thebrush, and solvent.

6. Trigger the gun while you install the fluid nozzle

(19)

with the nozzle wrench

(P).

See Fig. 20.

7. Install the spring (25)into the frontof the gun.

8.

Install the detent plate (26)into the gun housing

with its open sockets

(S)

facing up; align the det-

ent plate tab

0

with the notchinthe gun hous-

ing. See Fig.

22.

9.

Install the air cap

(27),

aligning theair cap balls

(U)

with the detent plate sockets

(S).

See

Fig. 22.

Secure the air cap with the air cap retainingring

(29).

NOTE

If

installed correctly, the air cap will snapinto

4

definite positions, with no loose rotation between the

positions.

n

%===??=

Fig.

22

10.

Lubricate the gun after cleaning

it

as instructedon

M968

page

16.

308-336

15

Service

Lubricating the Spray

Gun

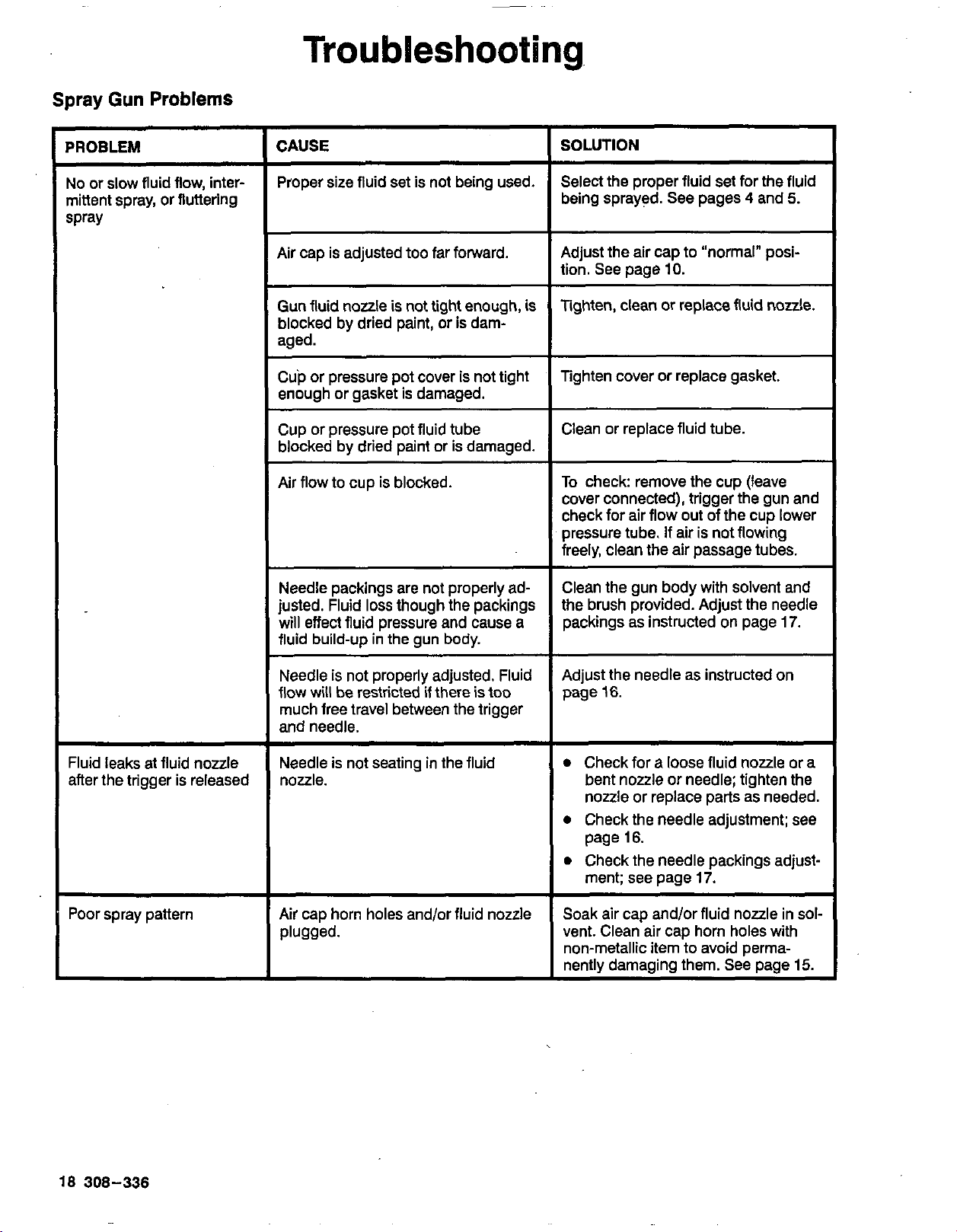

After cleaning or servicing the gun, lubricate the parts

indicated in Fig.

23

with silicone-free spray gun lubri-

cant or similar material. Seepage

26

to order lubri-

cant.

0

All

threadedareas(A)

0

Triggerscrews

(8)

0

Trigger

axle

(C)

0

Fluid needle assembly

(D)

-

where indicated

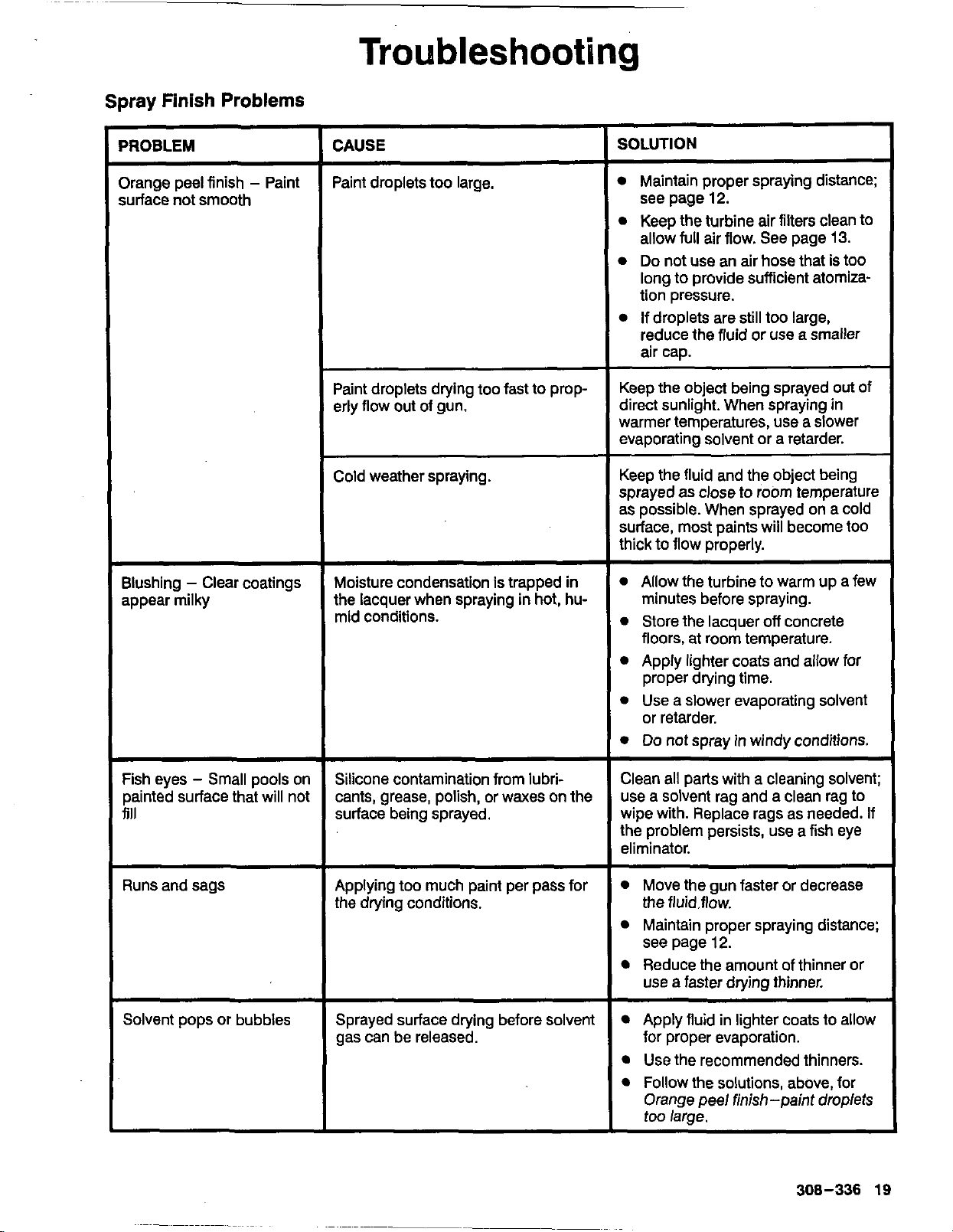

2.

Loosen thelocking nut(14d) andturnthe drum

(14c). See Fig.

25.

3.

Turn the drum(14c) until the trigger has about

1/16in.

(1.59

mm) free travel before the needle

(14) isengaged and startsto move. See Fig.

25.

4.

Lock the adjustment

with

the locking nut (14d).

5.

Make

sure

the spring

(23)

is

inplaceinthe hous-

ing

(22),

then install the housing with the other

parts. Hand-tighten the housing.

~

Fluid

Needle

Assembly

2

in.

(50.8

mm)

02949.

om

Fig.

23

Adjusting theNeedle

The needle may needto be adjustedwhenever you

change nozzle/needle sizes orto compensate for

wear.

To

adjust

the

needle:

1.

Remove the housing

(22)

from the back of the

gun. Thefluid adjustment knob

(20),

nut

(21),

and

spring (23-not shown) will come out with it. See

Fig.

24.

16308-336

Fig.

24

Fig.

25

02857

Service

Adjusting

the Needle

Packings

The needle packings require adjustment once a

month under normal usetoensure fluid does not leak

back throughtheneedle packings. The needle pack-

ings must alsobeadjusted whenever

the

needle

is

removed or adjusted.

To

adjust the needle packings:

1.

First flush thegunas instructed on page

14.

2.

Remove the air cap retainingring

(29),

air cap

26.

(27),

spring

(25),

and detent plate

(26).

See Fig.

3.

Trigger the gun while you remove the fluid nozzle

Fig.

26.

Clean the gun as instructed on page

15.

(19)

with the nozzle wrench

(P),

provided. See

ICAUTIOY

1

Trigger the gun whenever you tighten or remove

the nozzle. This keeps the needle seat away from

the nozzle seating surface and prevents the seat

from beina scratched.

K

98

5.

Trigger the gun while you install the fluid nozzle

(19)

with the nozzle wrench

(P).

See Fig.

26.

6.

Install the spring

(25)

into the front of the gun.

7.

Install the detent plate(26) into the gun housing

withitsopen sockets

(S)

facing

up;

align the det-

ent plate tab

0

with the notchinthe gun hous-

ing. See Fig.

28.

8.

Install the air cap

(27),

aligning the air cap balls

(U)

with the detent plate sockets

(S).

See Fig.

28.

Secure the aircapwith the air cap retaining ring

(29).

Fig.

26

4.

Trigger the gun while you turn the packing

nut

(9)

slightly clockwise with the packing wrench

(K),

provided.

See

Fig.

27.

This will compress the

packings.

The packings need very

little

pressure to

seal

tight; back the packing nut

off

1/16

turn. The

well. If the needle binds, the packings are

too

are over-tightened, they maybedamaged and

needle should then move freely. If the packings

need toberemoved and replaced.

02854

NOTE

If installed correctly, the air cap will snap into

4

definite positions, withnoloose rotation between the

positions.

Fig.

28

02868

308-336

17

Troubleshooting.

Spray

Gun

Problems

PROBLEM

No or slow fluid flow, inter-

mittent spray, or fluttering

spray

Fluid leaks at fluid nozzle

after the trigger is released

Poorspray pattern

CAUSE

Proper size fluid setisnot beingused.

Air cap is adjusted too far forward.

Gun

fluid

nozzle

is

not tight enough,is

aged.

blocked by dried paint,

or

isdam-

Cup or pressure pot cover is not tight

enough or gasket is damaged.

Cup or pressure pot fluid tube

blocked by dried paint or is damaged.

Air flowto cupis blocked.

Needle packings are not properly ad-

justed. Fluid

loss

though the packings

will effect fluid pressure and cause a

fluid build-upinthe gun body.

flow willberestricted if thereis too

Needle is not properly adjusted. Fluid

much free travel between the trigger

andneedle.

Needle is not seatinginthe fluid

nozzle.

Air cap horn holes and/or fluid nozzle

plugged.

SOLUTION

Select the proper fluid set for the fluid

being sprayed. See pages

4

and

5.

tion. See page

10.

Adjust the aircap

to

"normal" posi-

Tighten, clean or replace fluid nozzle.

lightencover or replace gasket.

Clean or replace fluid tube.

To

check: remove thecup (leave

cover connected), trigger the gun and

check for air flow out of thecuplower

freely, clean the air

passage tubes.

pressure tube.

If

air

isnotflowing

Clean thegunbody with solvent and

the brush provided. Adjust the needle

packingsas instructed on page

17.

Adjust the needle as instructed on

page

16.

0

Check for

a

loose fluid nozzle or

a

bent nozzleor needle; tighten the

nozzle or replace parts as needed.

0

Check the needle adjustment; see

page

16.

0

Check the needle packings adjust-

ment; see page

17.

Soak air cap and/or fluid nozzlein

sol-

vent. Clean air cap horn holes with

non-metallic itemtoavoid perma-

nently damaging them.See page

15.

18

308-336

Troubleshooting

Spray

Finish

Problems

'ROBLEM

-

)range peel finish

-

Paint

iurfacenotsmooth

3lushing

-

Clear coatings

appear milky

Fish eyes

-

Small pools on

painted surface that will not

fill

Runsandsags

Solvent pops or bubbles

~ ~~

CAUSE

Paint droplets too large.

Paint droplets drying too fasttoprop-

erly flow out of gun.

Cold weather spraying.

~~~ ~~~

Moisture condensationistrapped

in

the lacquer when spraying

in

hot, hu-

mid conditions.

Silicone contamination from lubri-

cants, grease, polish, or waxeson the

surface being sprayed.

Applying too much paint per pass for

the

drying

conditions.

Sprayed surface drying before solven

gas can be released.

SOLUTION

Maintainpropersprayingdistance:

see page

12.

Keeptheturbine air filters clean to

allow

full

air flow. See page

13.

Do

not use an air hose that isto0

longtoprovide sufficient atomiza-

tion pressure.

reduce the fluidoruse a smaller

air cap.

If droplets are still too large,

Keep

the

object being sprayed out of

direct sunlight. When sprayingin

warmer temperatures, use a slower

evaporating solvent or a retarder.

Keepthe fluid and the object being

sprayed as close

to

room temperature

as possible. When sprayed on a cold

surface, most paints will become too

thicktoflow properly.

Allow the turbinetowarm upa few

minutes before spraying.

Store the lacquer

off

concrete

floors, at room temperature.

Apply lighter coats and ailow for

proper drying time.

Use a slower evaporating solvent

or retarder.

Do

not spray

in

windy conditions.

Clean all parts with a cleaning solvent:

wipe with. Replace rags as needed. If

use a solvent rag and a clean rag to

the problem persists, use a fisheye

eliminator.

Move the

gun

faster or decrease

Maintainpropersprayingdistance:

Reduce the amount of thinner or

the fluid.flow.

see page

12.

use a faster drying thinner.

Apply fluidinlighter coatstoallow

Use the recommended thinners.

Follow the solutions, above, for

for proper evaporation.

Orangepeelfinish-paint droplets

too large.

308-336

19

2

18

19

20

21

Parts for 966 Gun

17

This manual suits for next models

1

Table of contents