10

d. Rinse the cup under warm running water until clean.

e. Fill the cup about ¼ full with water. Reconnect Spray Gun to Air Hose. Turn on the T100 Turbo Unit. Direct

the Spray Gun to a safe area and spray the clean warm water through the Spray Gun until the cup is empty.

f. Turn off the T100 ™Turbo Unit. Disconnect the Spray Gun. Unscrew the cup.

g. Wipe all exposed areas dry.

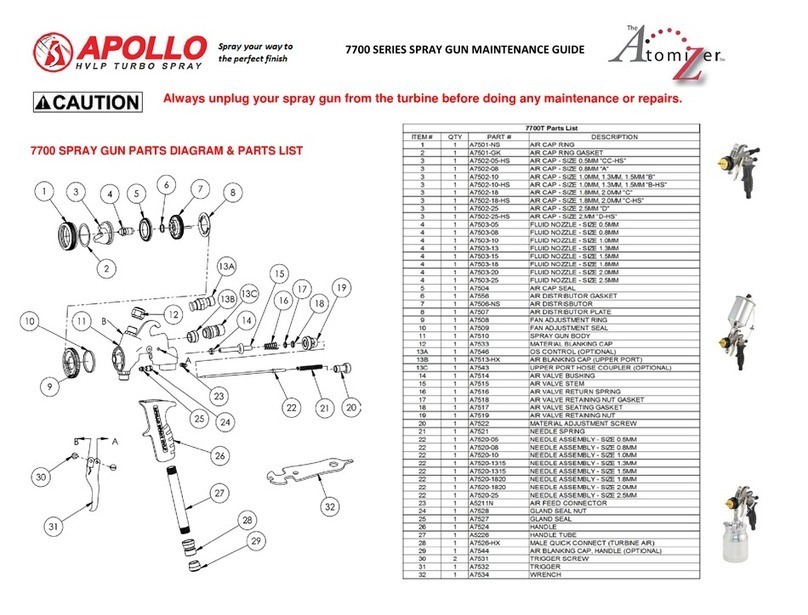

h. Unscrew and remove the Air Cap Ring (#1). Rinse the threads under warm running water. Wipe, clean the

threads and dry. Add a small amount of Spray Gun lube to the threads.

i. Remove the Air Cap (#2). Rinse under warm running water. Wipe, clean and dry.

j. If necessary, remove Air Distributor Plate (#5). Rinse under warm running water. Wipe clean, dry and

lubricate with Spray Gun lube.

k. Reinstall the three pieces you just removed by reversing the removal procedure. Your Spray Gun should be

ready for the next use. Store the Mist Applicator ™ in the holder on the T100 Turbo Unit.

l. The Solution nozzle (#3) can be removed for additional cleaning if necessary. Be careful. There is a Solution

nozzle gasket (#4) around the threads of the Solution nozzle. Be sure to reinstall or leakage will occur.

Removal of the Solution nozzle is not necessary on a daily basis. You should however remove it once a

week and rinse under running water. The Solution nozzle can be easily removed with an adjustable wrench

or spanner. Place the tip of your adjustable wrench or spanner on the two flat areas of the nozzle and twist

anti or counter clockwise.

m. The Solution needle (#8) can also be removed for additional maintenance. To remove: Turn the Solution

Flow Screw anti or counter clockwise until it comes out of the Spray Gun. Be careful when removing the

Solution Flow Screw as there is a small spring (#9) around the needle. Do not lose it. This is important to the

operation of the Spray Gun. Set the spring aside and pull the trigger all the way back until you can grab the

needle with your finger tips and pull it out from the back of the Spray Gun. Once removed, rinse under warm

running water, Clean and dry. Reinstall reversing the removal procedure. NOTE: Occasionally it is necessary

to lubricate the needle (#8) where it slides through the needle packing screw (#7). Simply rub a few drops of

Spray Gun lube around the needle shaft and reinsert into the back of the Spray Gun.

7 Troubleshooting

Q1. T100 Turbo unit turned ON. Air blows out of T6000 Spray Gun?

A. This is correct. Air blows constantly when Turbo unit is ON.

Q2. T100 Turbo unit turned ON. Unit does not operate or blow air?

A. Check that the unit is plugged in to proper electric source. Be sure there is power at the electric

source. If there is no problem with electric supply, call for technical support.

Q3. T100 Turbo unit is turned ON, the trigger is pulled back on Spray Gun, but no solution comes out?

A1. Check that the cup is screwed firmly to Spray Gun.