1. Specifications

[SMF-2008-A] – 1-3 –

1.3. Performance Specifications of Driver

Item Description

Number of Controlled

Axes

1 axis, 4,194,304 pulses/rotation

Angle Setting Unit ° (degree), pulse, and number of indexes

Angle Setting Minimum

Unit

0.001°, 1 pulse (= about 0.31 sec [0.000086 deg.])

Speed Setting Unit sec, rpm

Speed Setting Range 0.01 to 100 sec/0.11 to 240 rpm

Number of Indexes 1 to 255

Maximum Instruction

Value

8 digit input ±99,999,999

Timer 0.01 to 99.99sec

Programming Language NC language

Programming Method Data setting through RS-232C port using PC

Operation Mode Auto, single block, MDI, jog, servo OFF

Pulse string input, network operation mode

Coordinate Absolute and incremental

Acceleration Curve

Modified sine (MS), Modified constant velocity (MC, MC2)

Modified trapezoid (MT), Trapecloid (TR)

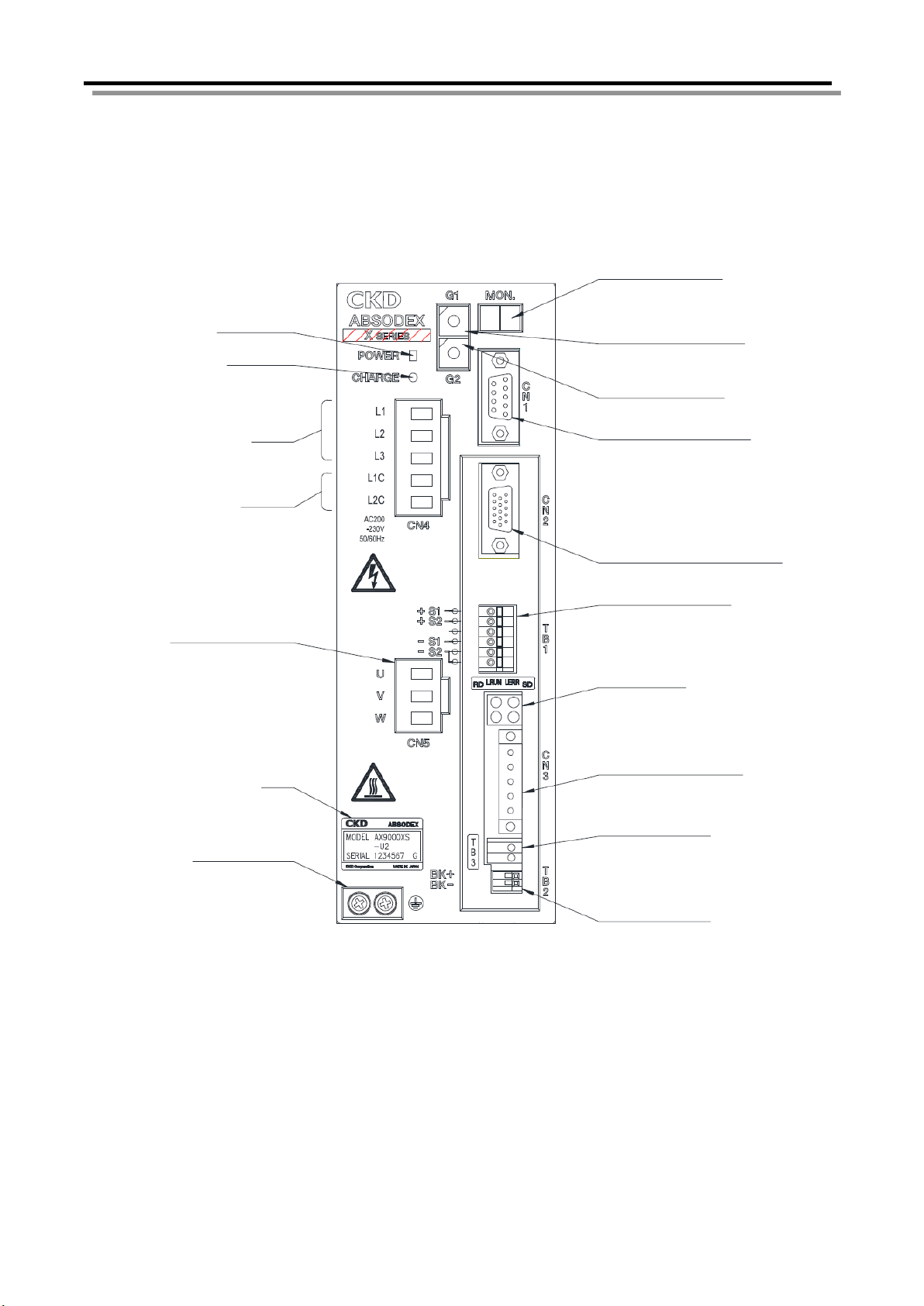

Status Display LED power lamp display

Motion Display

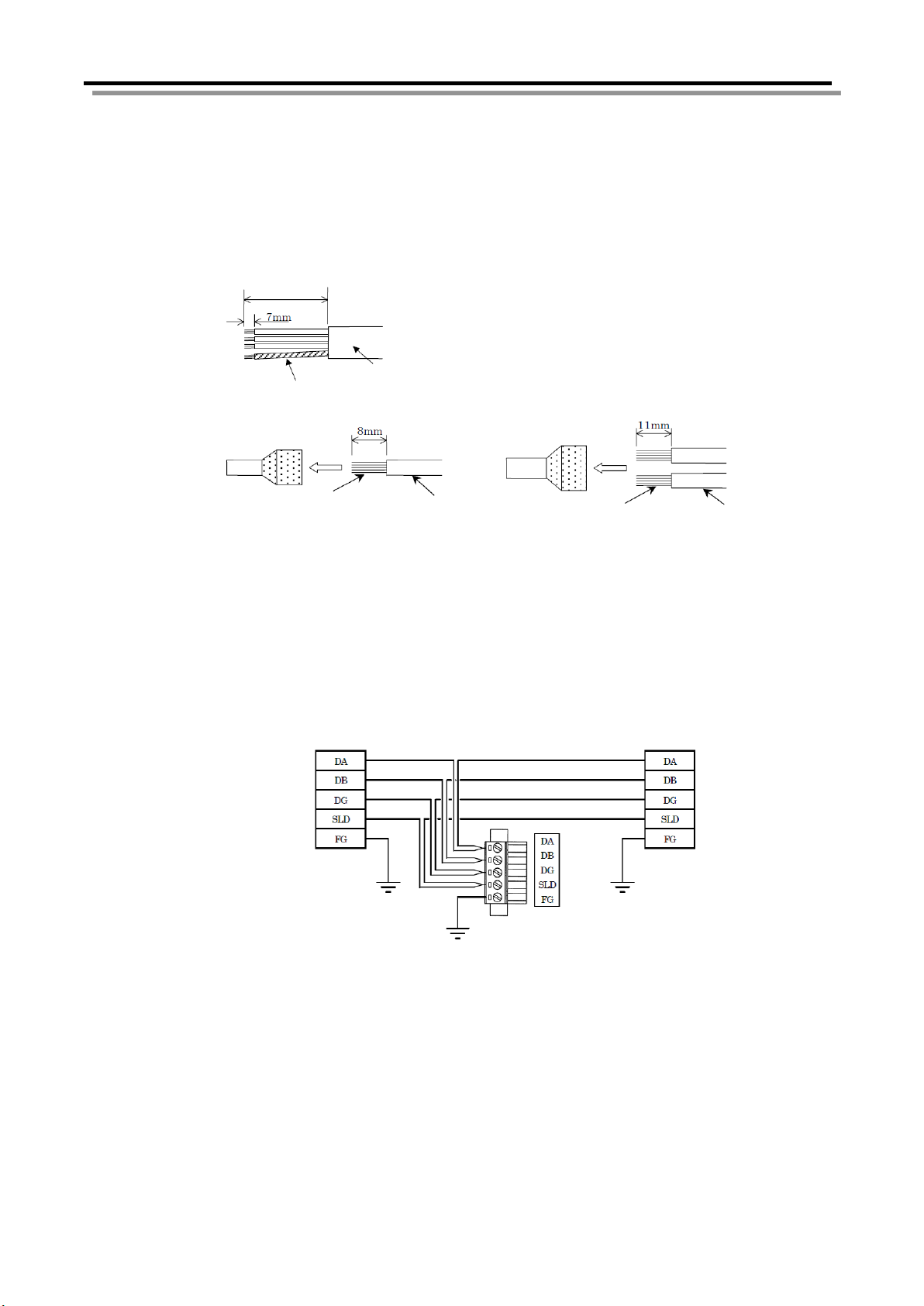

Meets RS-232C specification

CC-Link Communication

Function

(Ver. 1.10, 2 stations

occupied, remote device

station)

Home positioning instruction, reset, start, stop, continuous rotation

stop, emergency stop, answer, position deviation counter clear,

program number selection, brake release, servo ON, program

number setting, ready return

Alarm 1 and 2, positioning completion, in-position, standby for start

input, M code 8 points, output during indexing 1/2, home position

output, M code strobe, segment position strobe, servo status,

ready output

Program Capacity

<NC program>

About 6,000 characters (256 pcs.)

<Point table>

Protects the actuator from being overheated.