CLA-VAL 18-4 User manual

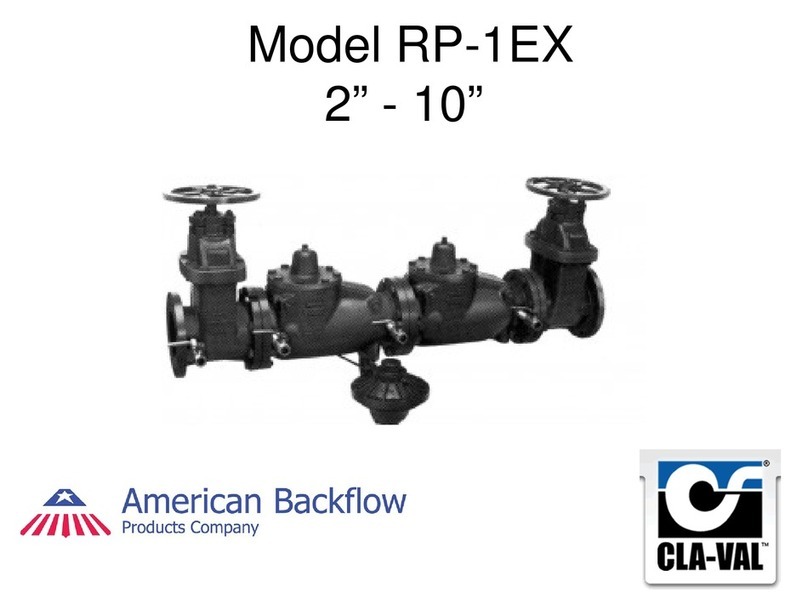

Model 18-4

3”- 10”

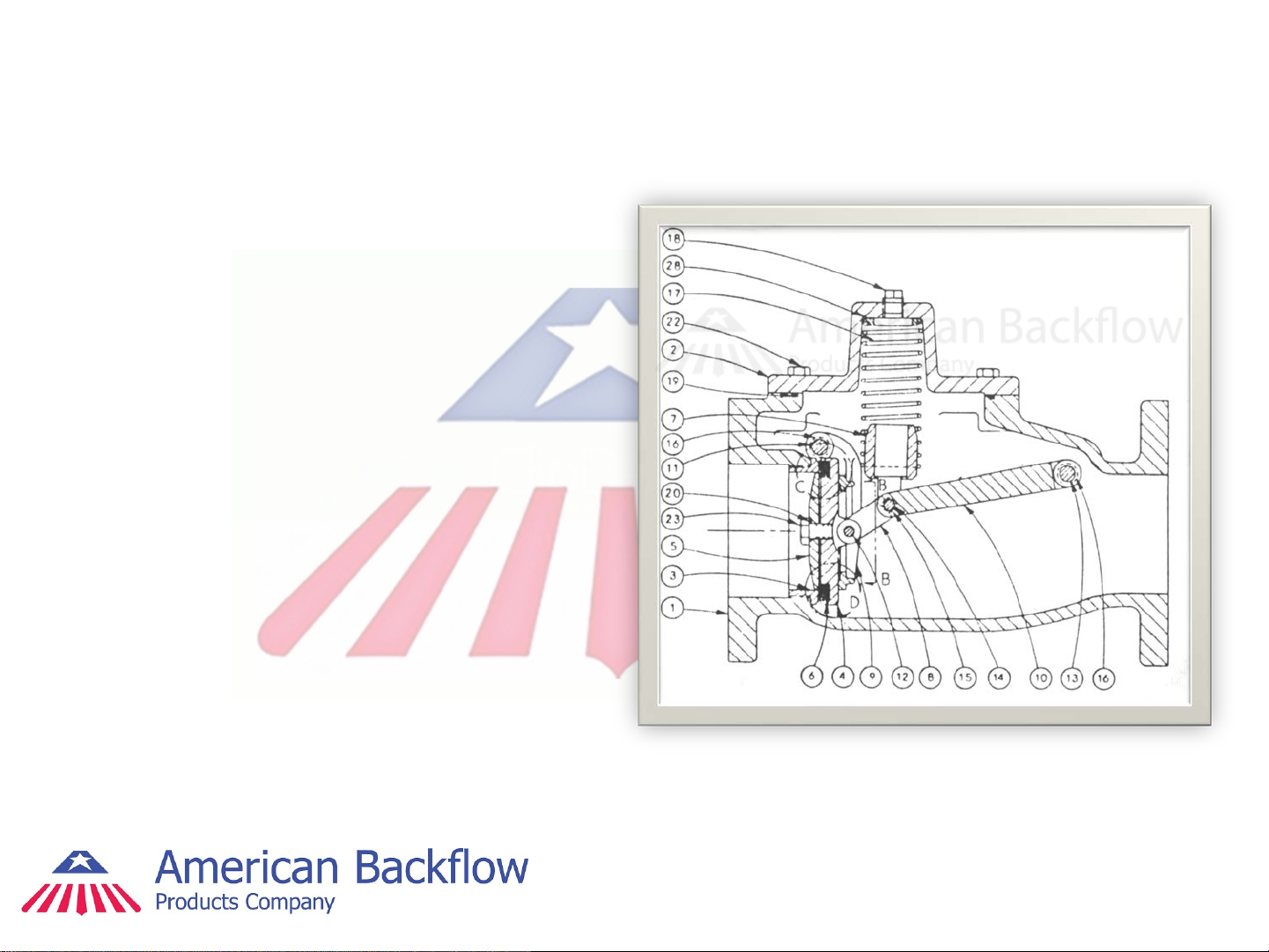

Product Overview

Model 18-4 RPDA (1991-2003) Utilized the

3084 Toggle Lever Checks and CDHS-24 relief

valve.

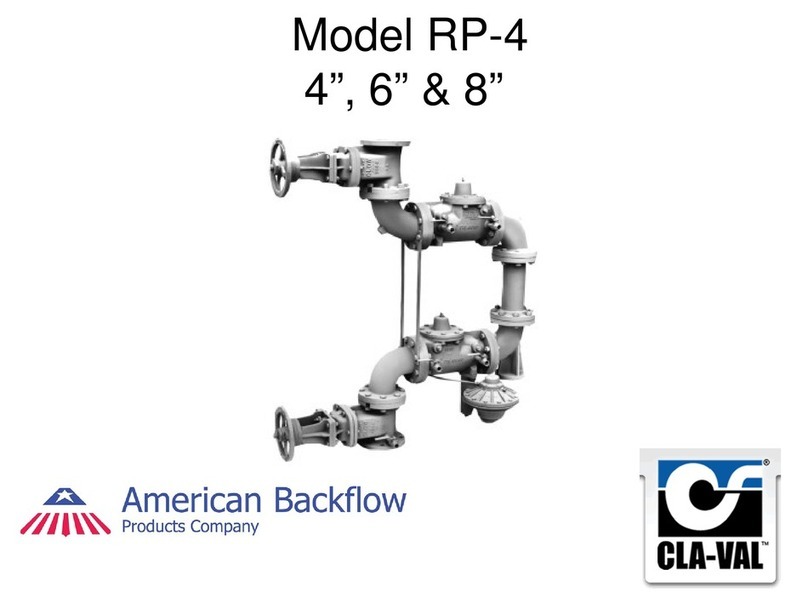

Produced in 3”-10” sizes only. Bypass was a ¾”

RP-2 or a Wilkins 975XL.

Replacement hardware parts were discontinued

in 2005. Only Repair kits with rubber parts are

available.

Check Cover Removal

The check covers are secured by bolts and sealed by an o-ring.

3” through 6” sizes remove all but two cover bolts, leaving two bolts 180

degrees apart. Press down on the cover while removing the last two

bolts to prevent the cover from being forcibly ejected by the spring.

8” and 10 sizes, it is suggested that all-thread rod and nuts (jack screws)

be used when removing or replacing the covers. The 8” size uses two

5/8”-11 all-thread approximately 8” long. The 10” size uses two ¾” -10

approximately 8” long. Remove two cover bolts on opposite sides of the

cover, and install all-thread rod. Install and tighten nuts down to cover.

Remove remaining cover bolts. Simultaneously, back the jack screw nuts

off until the spring tension is completely released. Remove the cover.

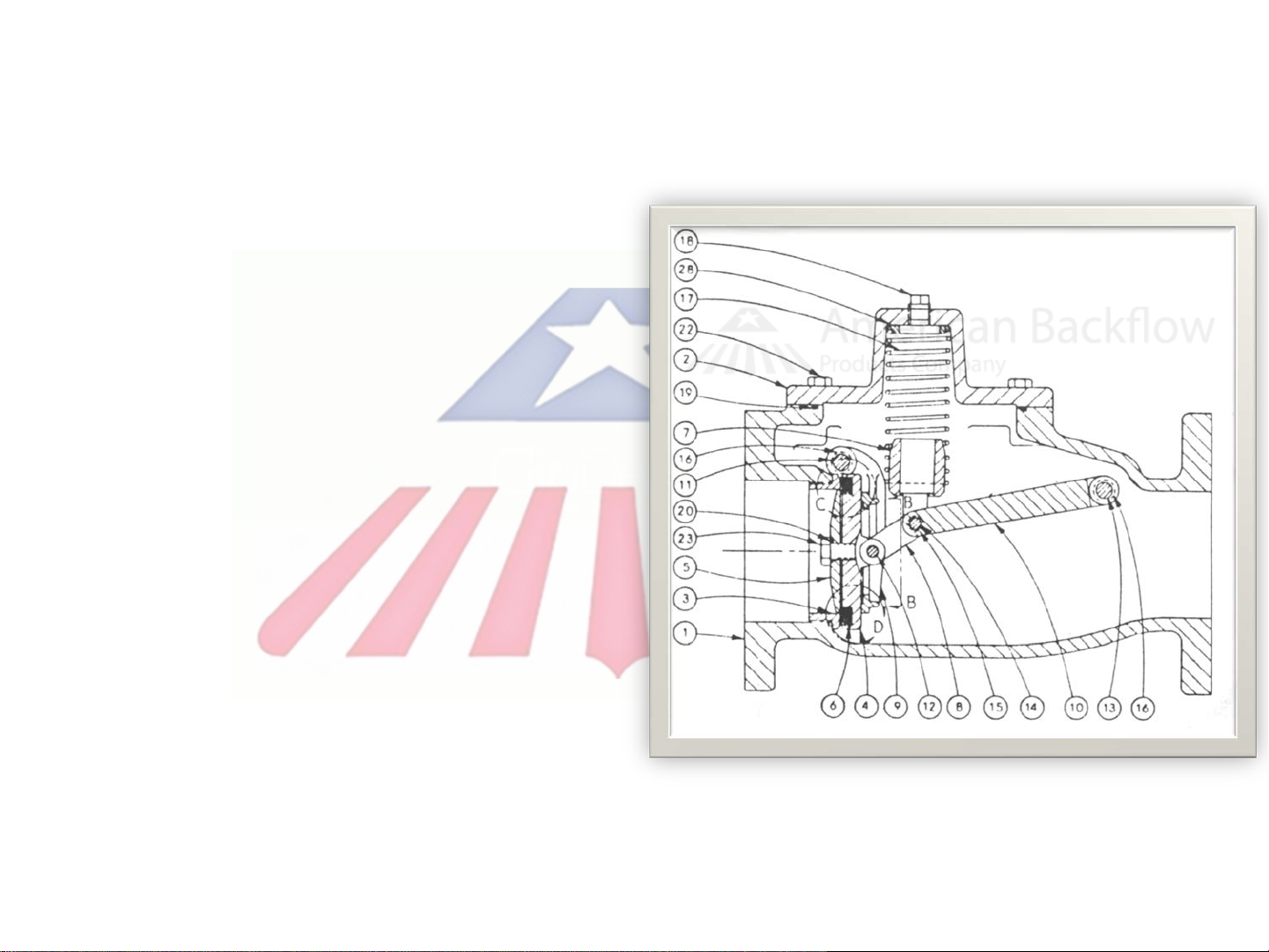

Check Valve Removal

Remove the two pipe plugs on

each side of the valve body, to

expose the lever arm pin (item

13) and the hinge pin (item 11).

Using a brass rod (smaller in

diameter than the pins), gently

tap out the rear lever arm (item

13) pin first.

CAUTION: Support the lever arm

(item 10) while completely

removing the lever arm pin. Let

the lever arm rest gently in the

bottom of the check valve.

Check Valve Removal

Grasp the yoke (item 7) with

one hand, while removing the

front hinge pin (item 11). Lift out

the toggle- lever clapper

assembly, being careful that the

brass seat is not dented.

NOTE: On 8” and 10” sizes, a

lever arm spacer (item 26) is

installed between the two lever

arms to maintain proper

distance between them, and

prevent binding.

Check Valve Disassembly

2” through 8” sizes remove the

retaining bolt (item 23) from

the center of the disc guide.

10” sizes (only) remove sixteen

retaining screws from the disc

guide (item 5).

The check disc is free once the

guide is separated from the

disc retainer (item 4).

NOTE: An o-ring (item 20) is

installed on the retaining bolts

for sizes 21/2”, 3”, 4”, 6”, and

8”.

Check Seat Service

Check seats are o-ring sealed and pressed into

the body.

Replacement seats are no longer in production.

Very fine nicks on the seating edge can be

restored by slowly working 400 wet or dry

sandpaper back and forth on both sides (top and

inner throat) of the seat.

Check Disc Replacement

When installing a new check disc, fiber spacer

washers between the retainer and guide MAY or

MAY NOT be required.

Fiber spacer washers (item 33) are installed to

ensure the proper “squeeze” on the disc (item 6).

Too many washers will not allow sufficient

squeeze on the disc (not a water tight seal). This

will cause the check valve to fail.

Too few washers between the guide and retainer

can generate TOO MUCH squeeze on the disc,

causing it to bulge around the guide. This will

also cause the check to fail.

Proper squeeze on the disc is achieved when

the disc cannot be rotated and no bulge

appears.

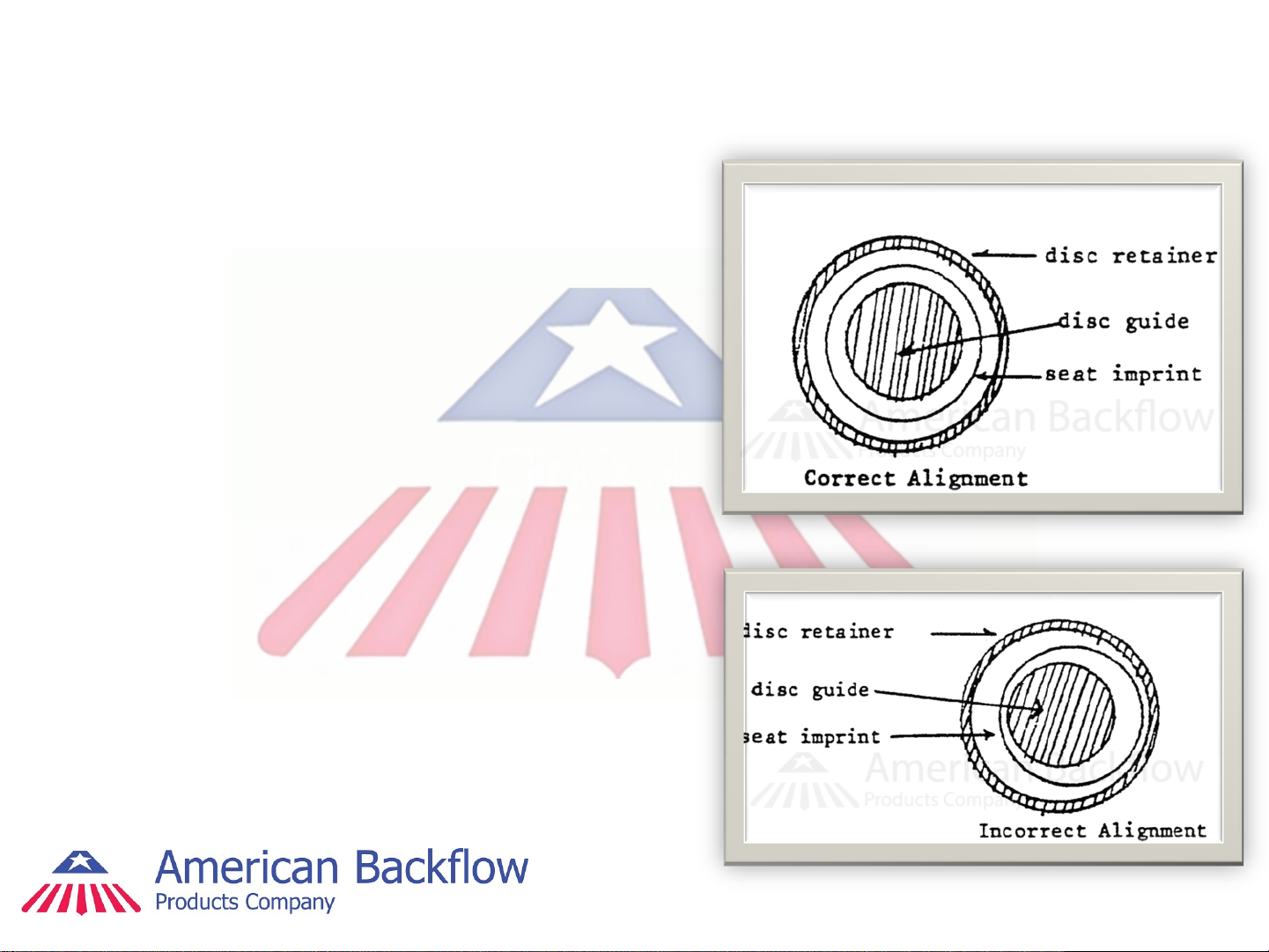

Check Valve Alignment

Re-install clapper assembly. Be

careful not to damage check seat.

Support clapper assembly with

one hand and install hinge pin.

With clapper assembly supported

by hinge pin only, exert pressure

to force disc against the seat, and

leave an imprint of the seat in the

disc.

Remove clapper assembly.

Inspect disc to ascertain that

alignment is correct.

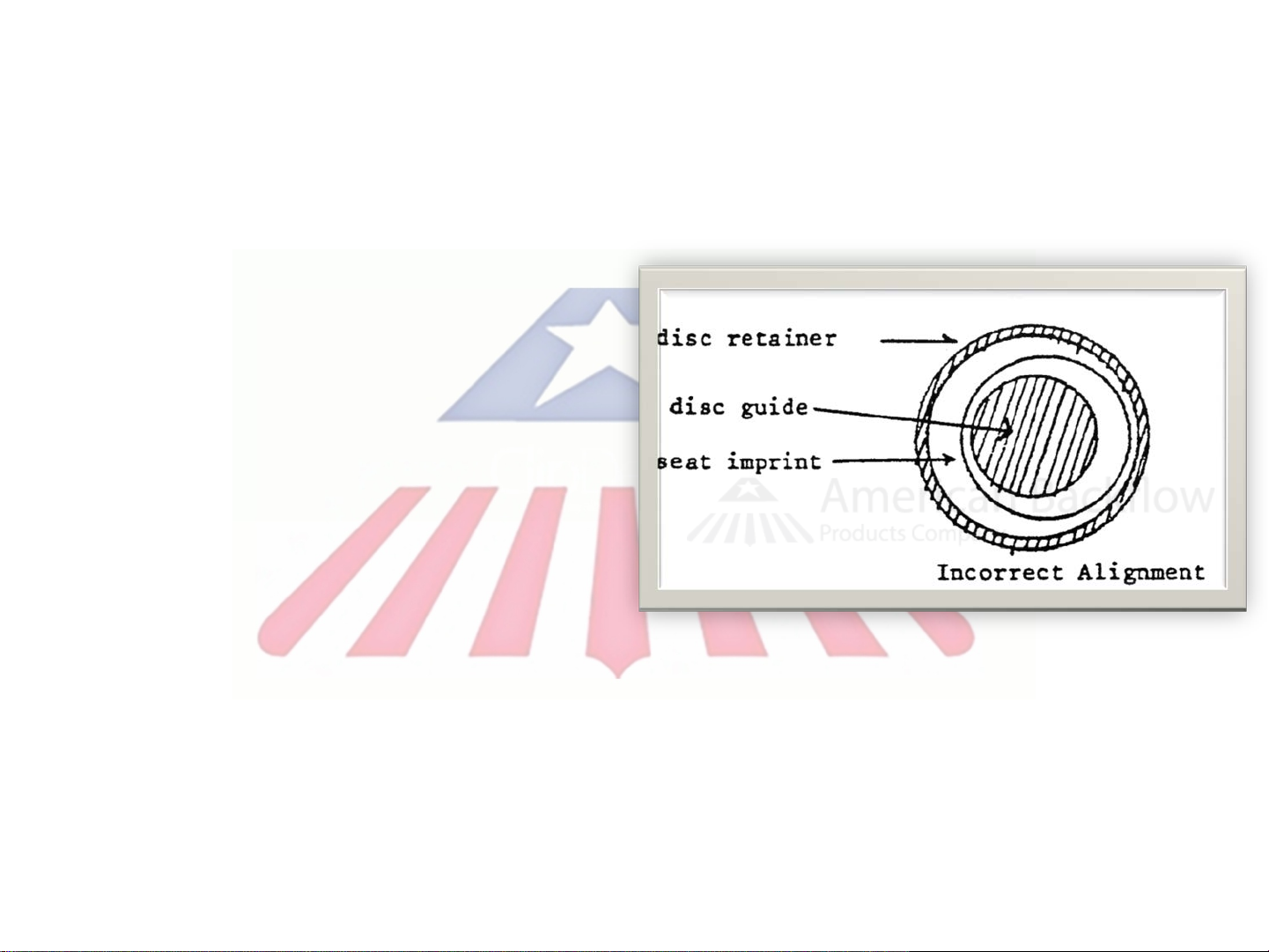

Check Valve Alignment

In the event the seat imprint

indicates an incorrect

alignment, adjust hinge pin

bushing OUT, on the side that

corresponds to the least

distance between the seat

imprint and disc guide.

In this figure, adjust hinge pin

bushing on the RIGHT side

outward.

Alignment is correct if the

seat leaves an imprint on the

disc equi-distant on all sides

of the disc guide.

Check Reassembly Notes

When the two pins that

hold the toggle-lever

(clapper) assembly are

installed, be sure to note

that the yoke (item 7) and

the lever arm pivots

upward freely.

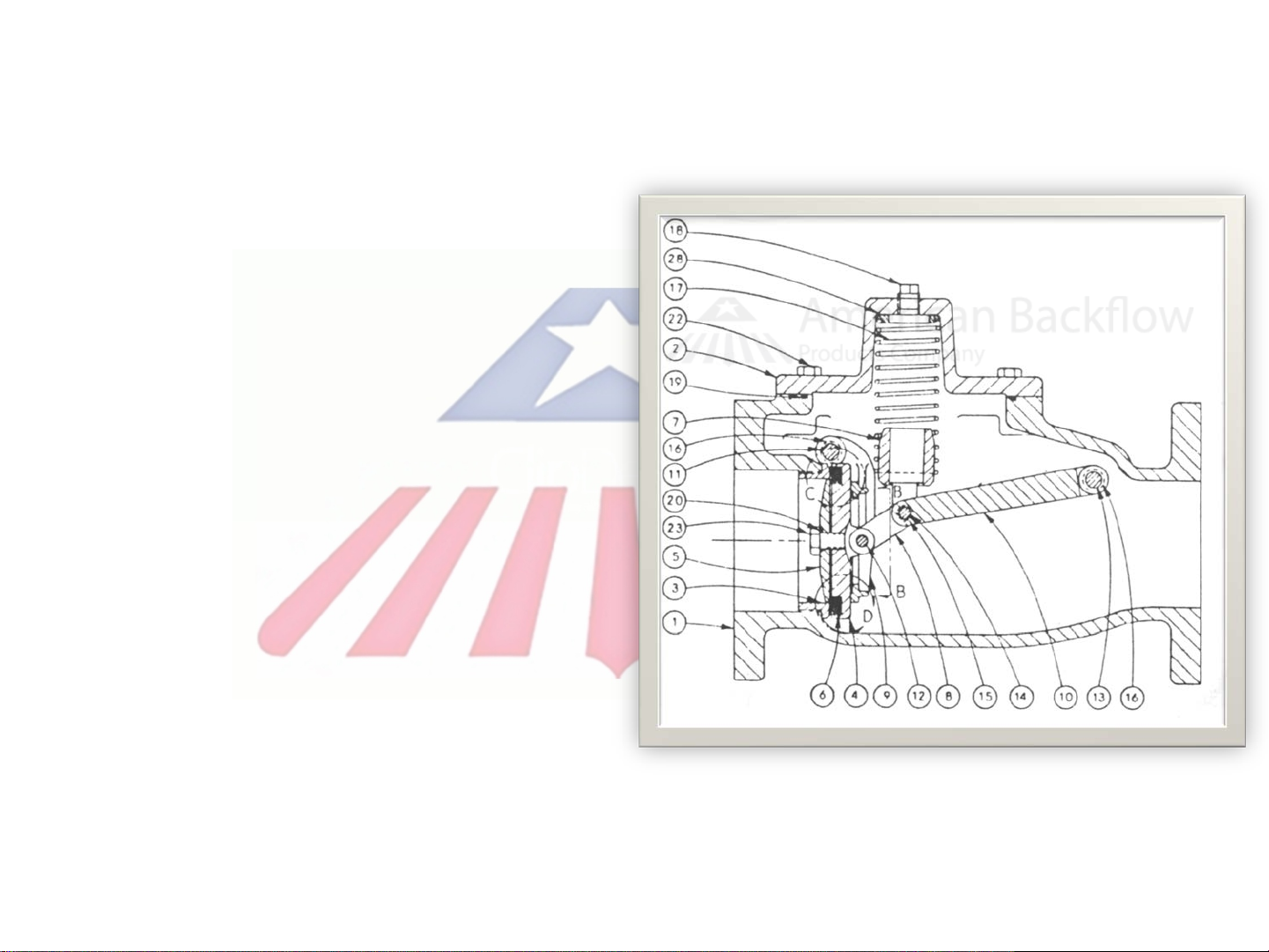

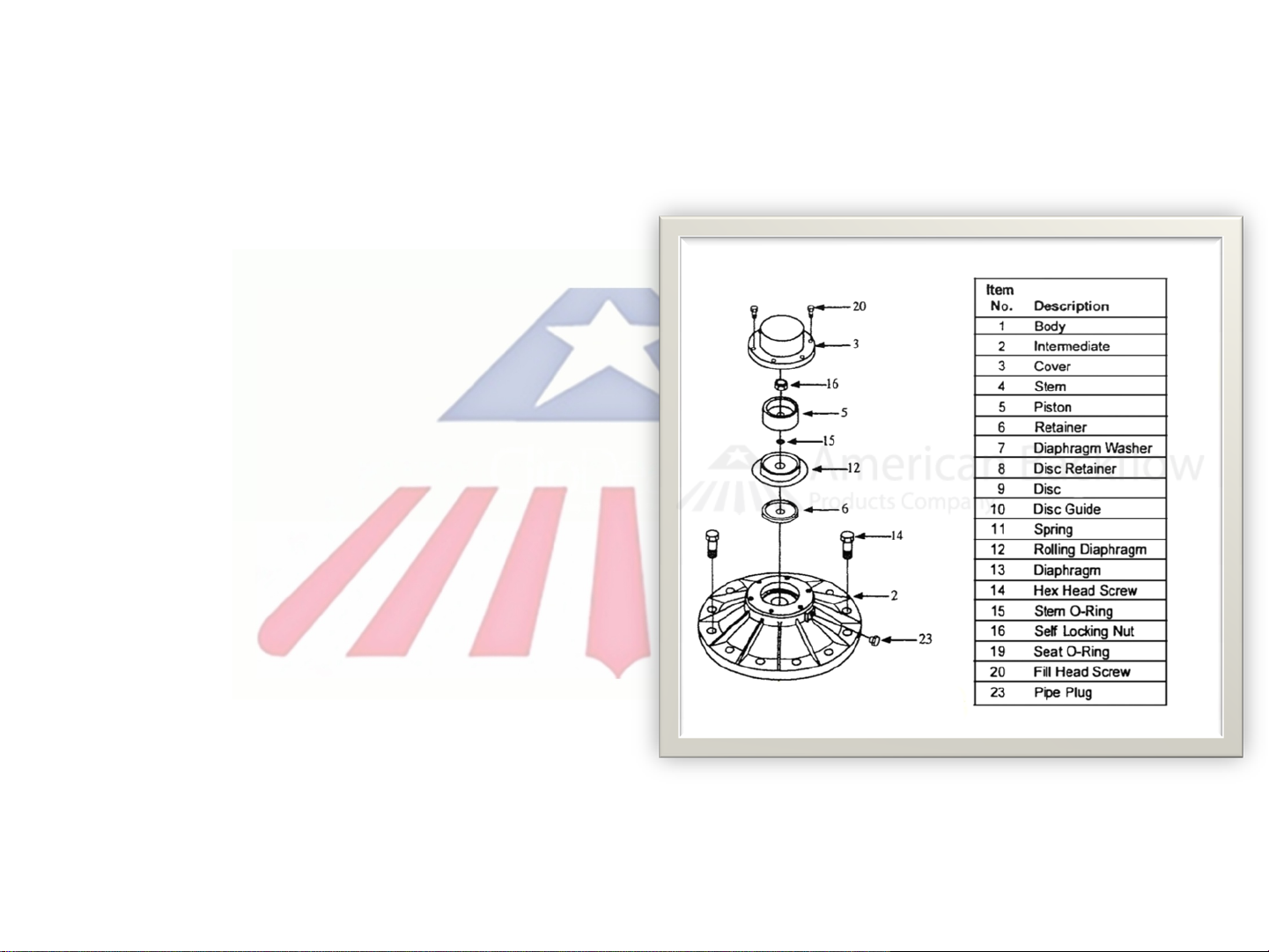

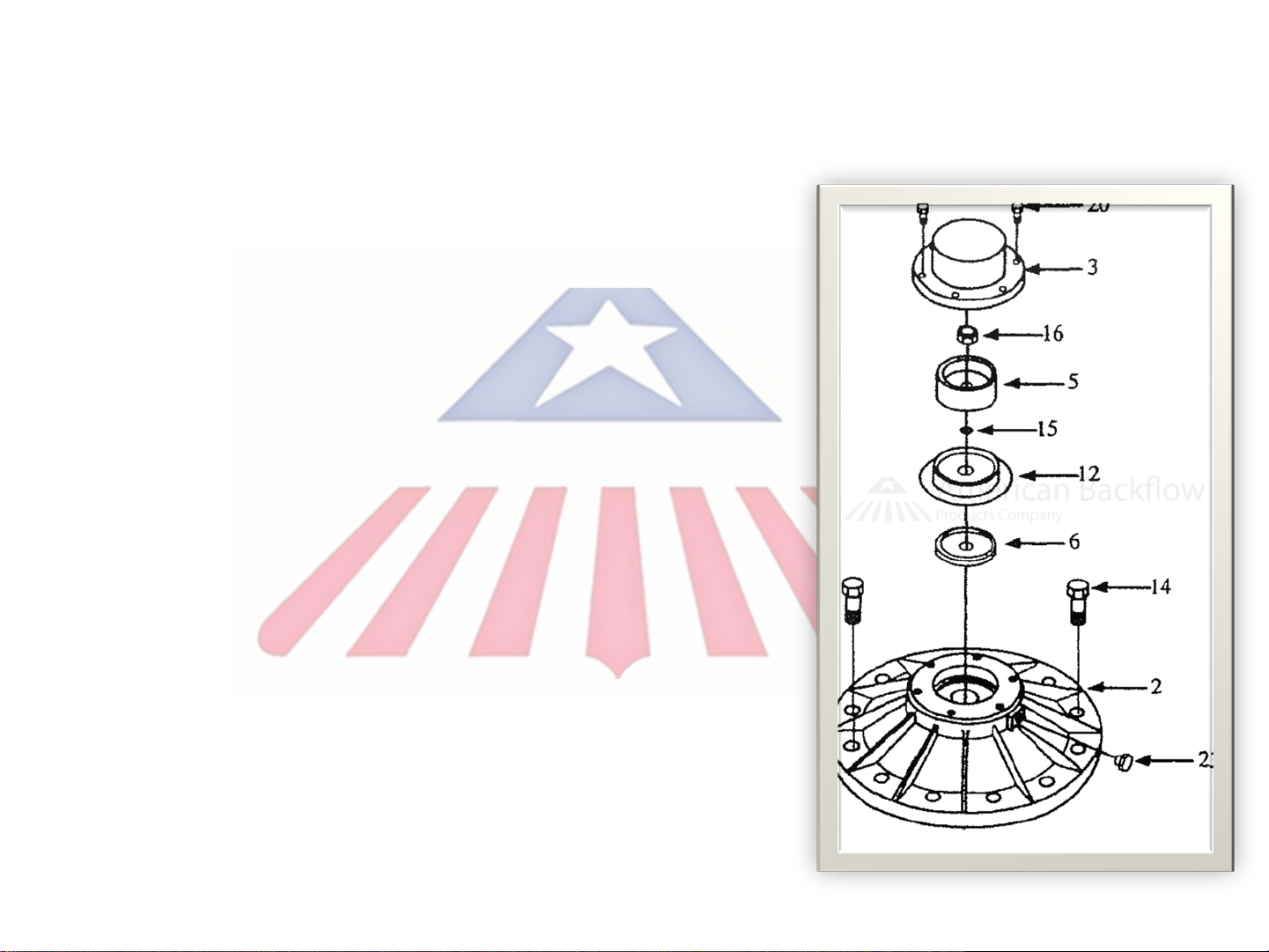

Relief Valve Cover Removal

The CDHS-20/ CDHS-24 RV

has two covers. The bellofram

cover (item 3) and the

intermediate body or “diaphragm

cover” (item 2).

The bellofram cover (item 3) is

located on top of the RV

assembly.

The bellofram cover is secured

by screws and sealed by the

bellofram.

There is no spring load on this

cover.

Relief Valve Cover Removal

The intermediate body (item 2)

is secured by cap screws and

sealed by the diaphragm.

There is a slight spring load on

this cover, so exert pressure

downward on the cover as the

cap screws are removed.

The RV stem assembly is

mounted through the

intermediate body.

The RV spring is free once

cover is removed.

Disassemble RV Stem

The stem is secured by the

upper and lower stem nuts

(item 16).

Remove the upper stem nut

first.

The bellofram, piston and

retainer can now be

removed from the upper

stem.

Remove the stem along

with the diaphragm and disc

from the body.

Disassemble RV Stem

Remove lower stem nut (item

16).

The RV disc (9), disc retainer

(8), and guide (10) are removed

as one assembly.(Simply pry

disc from retainer)

Remove the diaphragm

(item13), the lower stem o-ring

(item 15) and washer (item 7)

from stem.

RV Seat Service

The RV seat is o-ring sealed and threaded into

the main RV body.

Replacement seats are no longer in production.

Very fine nicks on the seating edge can be

restored by slowly working 400 wet or dry

sandpaper back and forth on both sides (top and

inner throat) of the seat.

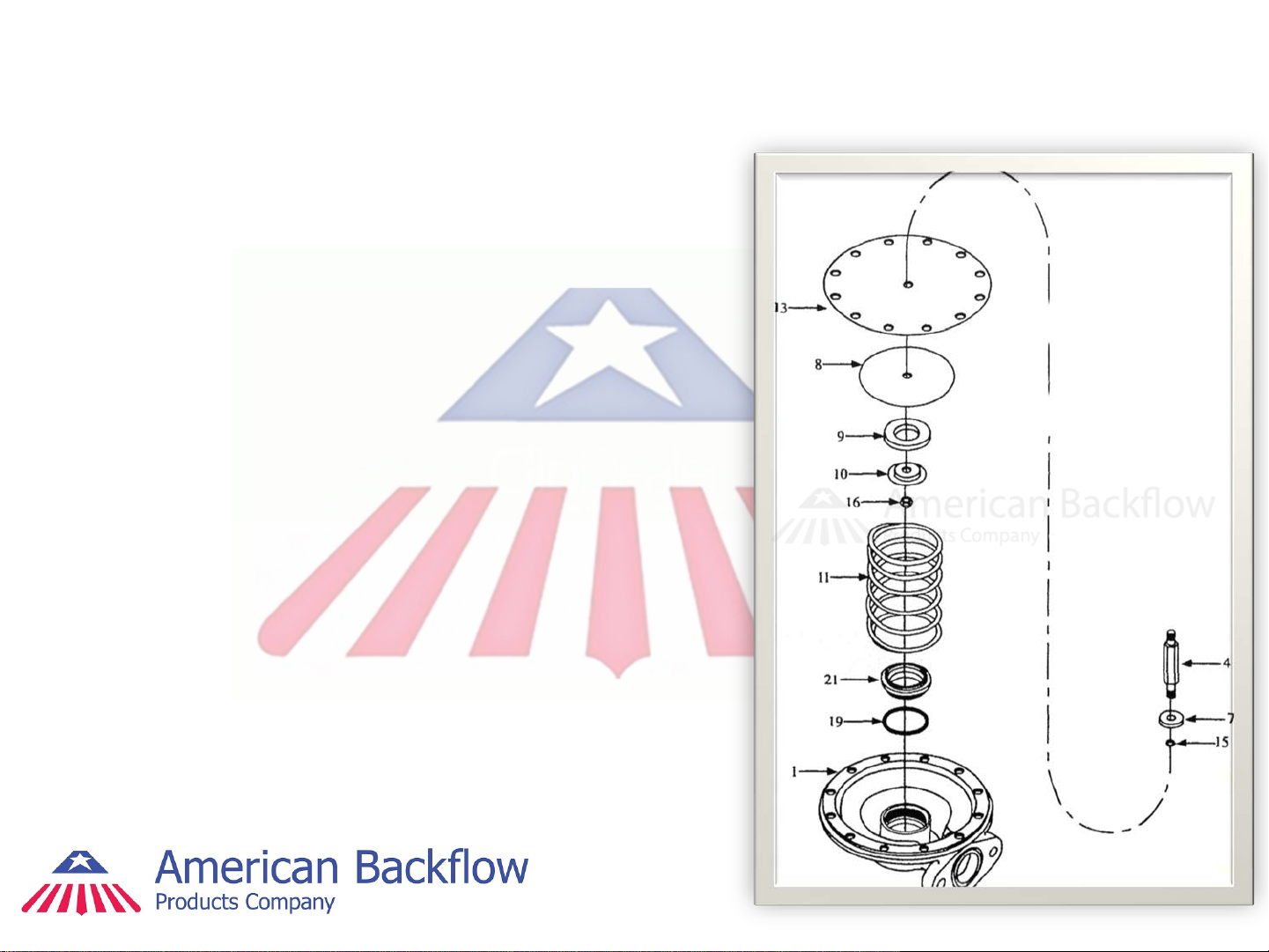

Diaphragm Reassembly

Reassemble the diaphragm (item 13),

lower stem o-ring (item 15) and washer

(item 7) on the lower stem (4).

Reassemble the RV disc, disc retainer,

and guide as one assembly on the lower

stem.

The serrated area of the disc retainer (8)

is positioned against the diaphragm.

Insert the stem (4) with diaphragm and

disc retainer intact, into the intermediate

body.

Upper Stem Reassembly

Reassemble the bellofram (12), piston

(5), retainer (6) and stem o-ring (15) on

the upper stem and replace stem nut.

Position the retainer (6) with its outer lip

facing up.

Position the bellofram with the glossy

side against the retainer(6). The fabric

side against the piston(5)

Position the piston (5) with the recess

around the stem hole facing down

toward the o-ring (15).

Intermediate Body Reassembly

Position the RV spring over the seat

in the main body.

Insert cap screws through

intermediate body and diaphragm.

Make sure the sensing passage is

aligned properly.

Press the intermediate body down

on the main body and start cap

screws.

Be sure to evenly cross tighten cap

screws.

Bellofram Reassembly

Carefully push bellofram(12)

“brim” straight down over itself so

that the “brim” is flat and smooth

against the intermediate body.

Make sure the bellofram is not

twisted or wrinkled.

Install cover (3) so that weep

hole faces out away from

backflow.

Do not rotate cover after placing

over the “brim”, this can twist and

tear the bellofram.

Table of contents

Other CLA-VAL Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Otec

Otec ECO mini dry operating instructions

Spida Machinery

Spida Machinery Mini 8 Operation & service manual

Showa Denki

Showa Denki CRN Series Operation manual

Bosch

Bosch Rexroth IndraMotion MLC operating instructions

Siemens

Siemens SINUMERIK ONE NCU 1760 Equipment manual

ABB

ABB E-kit installation instructions

Siemens

Siemens 5WG1 125-4AB23 Operating and mounting instructions

CMCO

CMCO TIGRIP THM 120 operating instructions

PCB Piezotronics

PCB Piezotronics 320C34 Installation and operating manual

ABB

ABB HT613266 Operation manual

Yamaha

Yamaha SIGMA-G5SII Service information

Doosan

Doosan 7/124 Operation & maintenance manual