Claas LEXION 770 2016 Installation guide

Information and Basic Field

Settings for LEXION version 14

Information and Basic

Field Settings for LEXION 2016

1

2

Contents

Pages

3

4

5 - 6

7 - 9

10- 11

12 - 21

22- 24

28 -31

30

32- 34

35

36

38- 40

41- 42

44

45 - 46

Title

Introduction

Safety

Overview

Cab and controls

Steering column

CEBIS

CRUISE PILOT

CEBIS mobile/CEMOS

Threshing

Separation

Cleaning

Straw and Chaff Management

Settings aid

Maintenance

Frequent Questions

Wet harvest recomendations

3

Introduction

This quick reference guide has been produced to aid operators with

familiarisation and settings of CLAAS LEXION combine harvesters.

CLAAS combines are designed for output and efficiency but this can only be

achieved with correct operation and maintenance of the machine.

This guide is not designed to replace the Operators Manual but merely as a

reference document. More in depth information is available in the Operators

Manual.

ALWAYS READ THE OPERATORS MANUAL BEFORE OPERATING YOUR COMBINE.

Down time costs output

To get the most from the machine, the wheels/tracks must be turning. In order to

keep downtime to a minimum, it’s vital that routine maintenance is not

neglected. As well as servicing the machine according to the operator’s manual, a

good check of the machine is essential.

It is false economy to put off the replacement of worn parts until they break. For

example, a cracked knife section will take 5 minutes to change before starting

work, but usually a minimum of 10 minutes output will be lost, once work has

begun.

Abbreviations

Throughout this guide the following abbreviations are used:

‘LHS’ and ‘RHS’ refer to the Left Hand Side and Right Hand Side of the machine

respectively, taken from the rear of the machine facing in the direction of travel.

APS –Accelerated Pre-Separation, refers to the accelerator drum in front of the

main drum.

4

Safety

Safety is of the utmost importance whilst you are operating and maintaining

your combine harvester. Make sure that all of the risks are assessed to reduce

the likelihood of an accident.

Make sure you are familiar with the controls and operation of the machine and

have read the operators manual.

The combine harvester has many moving parts, guards are designed to keep you

safe, please ensure that all guards are kept in place and in good condition when

operating the machine.

When doing any maintenance work or making adjustments outside of the

machine make sure that the engine is switched off and the battery isolator key is

removed.

If you need to go underneath the front elevator/ cutterbar to make adjustments/

clean concaves, preparation pan, etc. Make sure that the cutterbar lift cylinder

lock is in place.

Some of the maintenance has to be carried out at height, please asses the risk

that this poses and ensure that the task is carried out safely.

When operating the machine be aware of the presence of people particularly in

farmyards, always get someone to help you when reversing in confined areas.

Be aware of the size of your machine, particularly the height, you may be at risk

from contact with overhead power lines and overhead obstructions particularly

but not exclusively when the grain tank lids are up and if extra aerials have been

fitted to your machine.

For more in-depth safety information please consult your operators manual.

Other information is available on the HSE website: www.hse.gov.uk

Always read the Operators Manual before using any new machine.

5

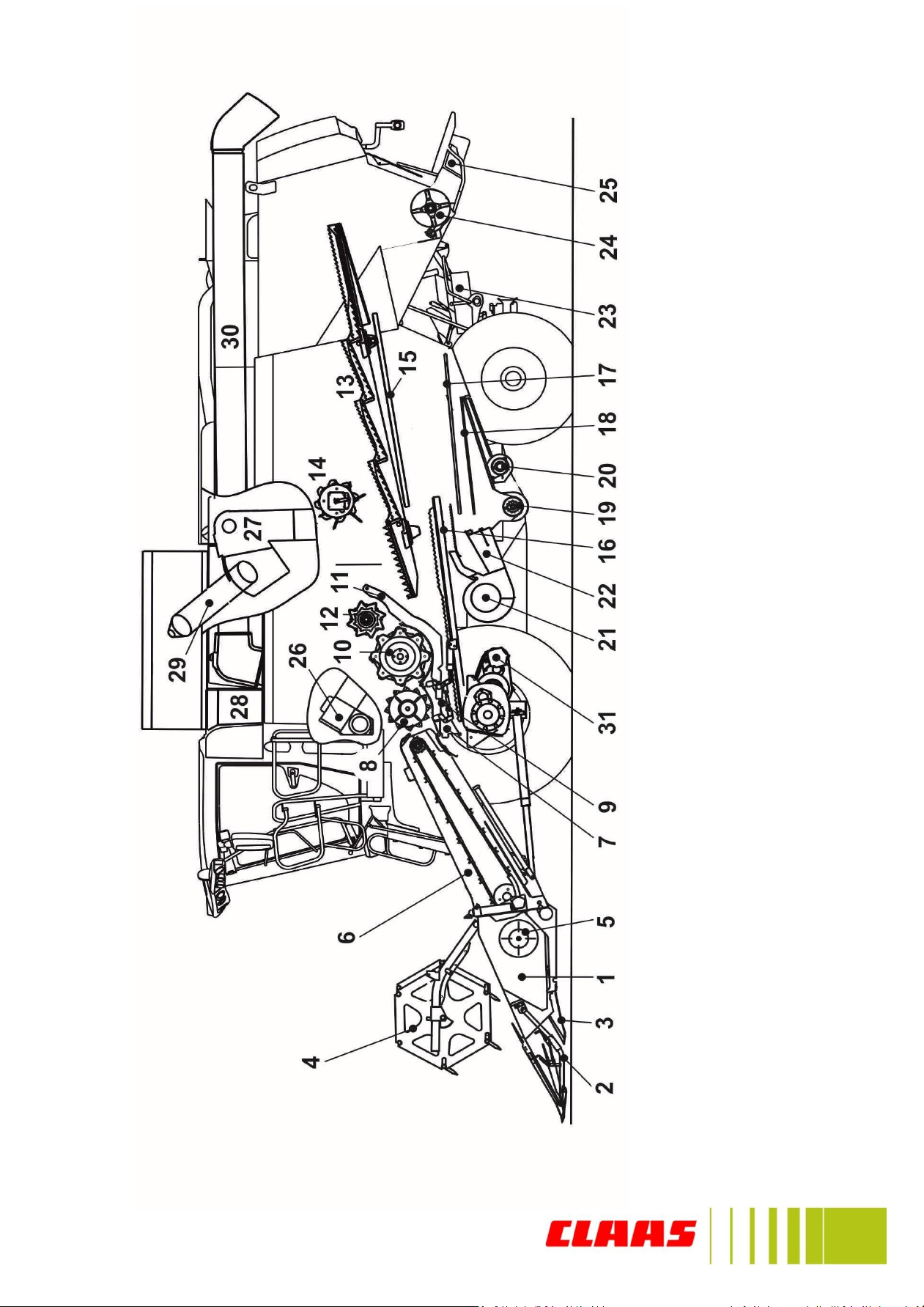

Overview Rotors

1 - Cutterbar

2 - Crop divider

3 - Crop lifter

4 - Reel

5 - Table auger

6 - Feed rake conveyor

7 - Stone trap

8 - APS Drum

9 - APS concave

10 - Threshing drum

11 - Main concave

12 - Impeller

15 - Return floor

16 - Preparation floor

17 - Upper sieve

18 - Lower sieve

19 - Clean grain cross auger

20 - Returns cross auger

21 - Cleaning fan

22 - Air duct

23 –Chaff blower

24 - Straw chopper

26 - Returns elevator

27 - Clean grain elevator

28 - Grain tank

29 - Bubble-up auger

30 - Unloading auger

31 - Gearbox

32 - Rotor concave

33 - Rotor

34 –Power spreader

Overview: Rotary

6

Overview Walkers

1 - Cutterbar

2 - Crop divider

3 - Crop lifter

4 - Reel

5 - Table auger

6 - Feed rake conveyor

7 - Stone trap

8 - APS Drum

9 - APS concave

10 - Threshing drum

11 - Main concave

12 - Impeller

15 - Return floor

16 - Preparation floor

17 - Upper sieve

18 - Lower sieve

19 - Clean grain cross auger

20 - Returns cross auger

21 - Cleaning fan

22 - Air duct

23 - Radial spreader

24 - Straw chopper

26 - Returns elevator

27 - Clean grain elevator

28 - Grain tank

29 - Bubble-up auger

30 - Unloading auger

31 - Gearbox

32 - Rotor concave

33 - Rotor

34 - Chaff spreader

Overview: Straw Walker

7

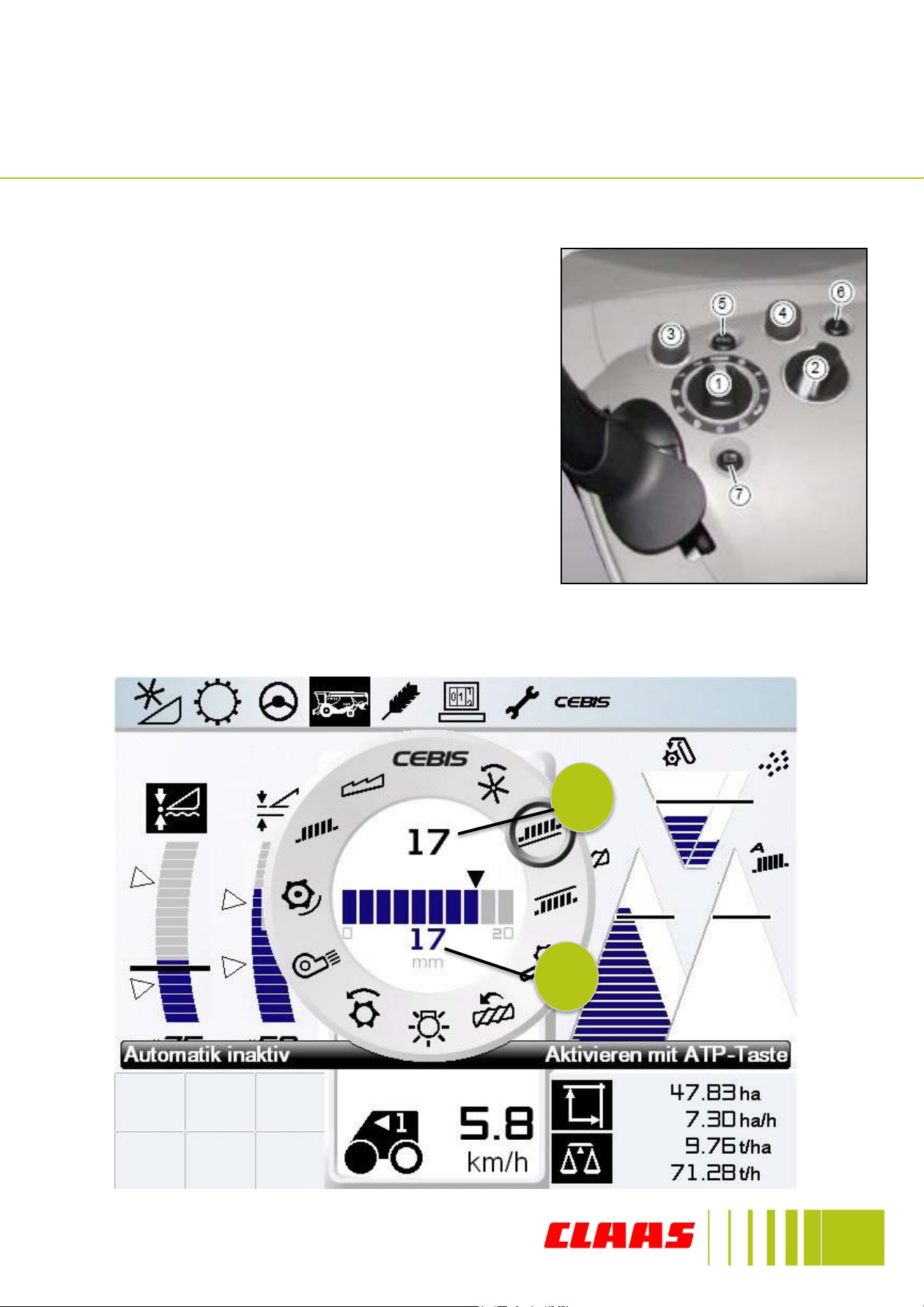

Right Hand Console

1. CEBIS rotary switch

2. HOTKEY rotary switch

3. Main menu rotary switch

4. Value select rotary switch

5. ESC button

6. Information button

7. Quick access button

8. Front Attachment Engagement

9. Threshing Engagement

10. Front Attachment reverser

11. Left hand rape knife switch

12. Front attachment cross levelling

/ VARIO length adjustment/Hotkey

13. Gear Selection switch

14. Not Used

15. Park Brake

16. LASER PILOT left & right

selector switch

17. Not Used

18. Not Used

19. Not Used

20. POWER TRAC switch

21. Engine speed switch

22. Not Used

23. Grain tank extension

8

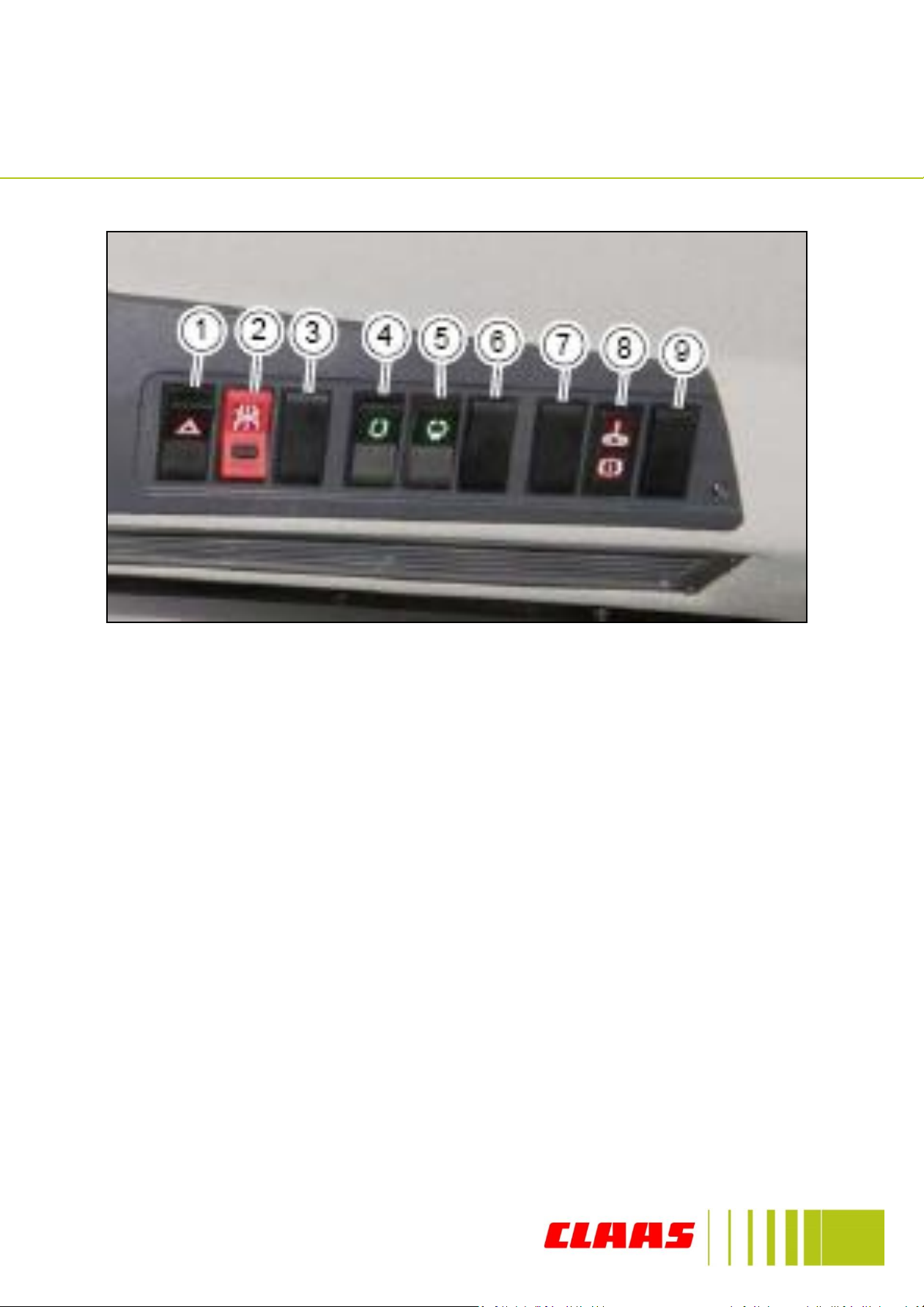

Roof console

1. Hazard warning lights

2. Road travel switch

3. Not used

4. Not used

5. Front attachment folding

6. Not used

7. Not used

8. Track tension/Montana brake warning

9. Emergency steering indicator

9

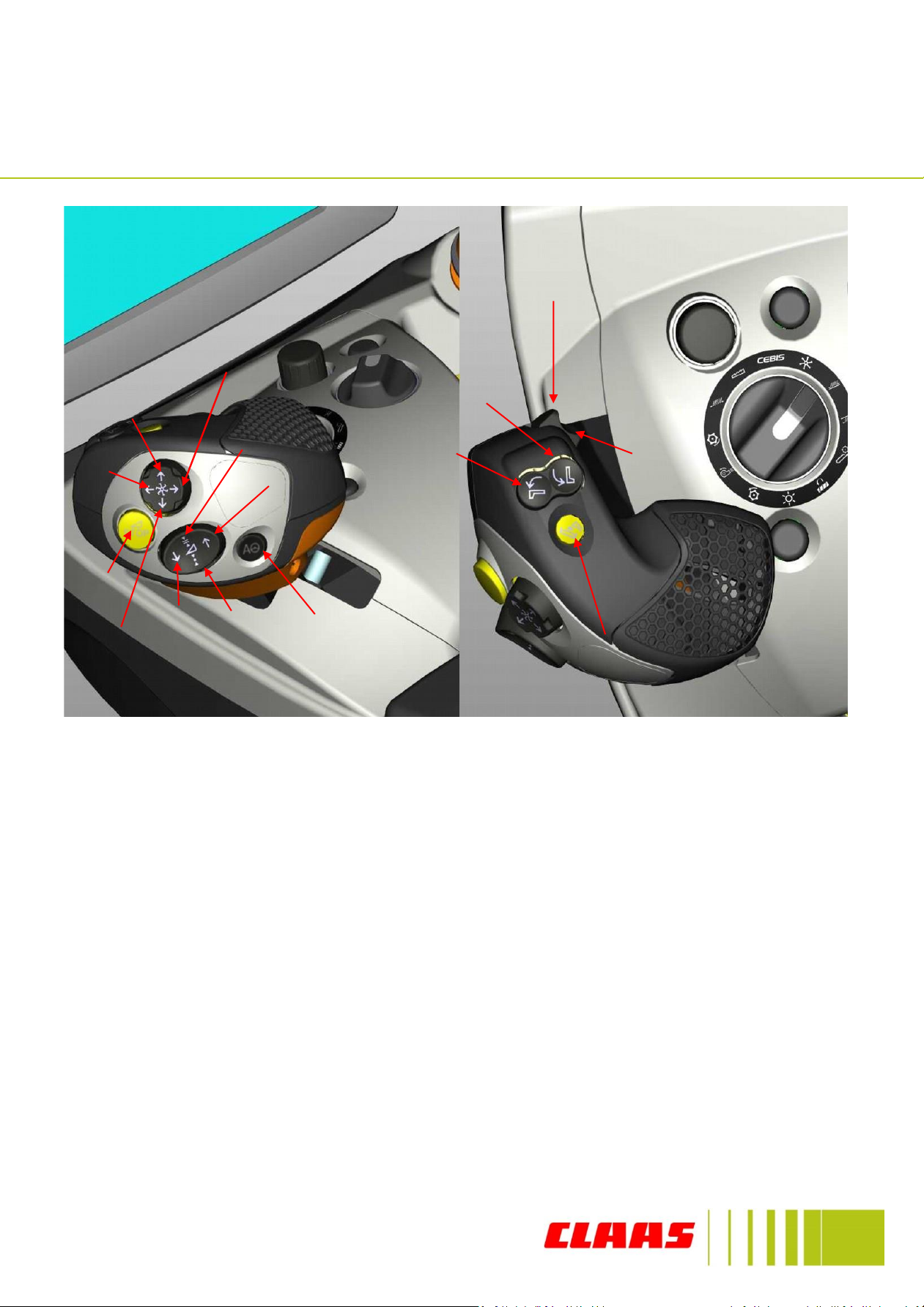

C-MOTION Multifunction lever

1b 2

3a

3b

1a

1d

1c

5

4a

4b

4c

4d

6

7H

7S

1a. Raise front attachment (2 speed) 4d. Reel aft

1b. Lower front attachment (2 speed) 5. Front attachment stop

1c. Cutting height pre-selection 6. Grain tank unloading on/off

1d. Cutterbar ground pressure 7H Extend vario table/Cross

2. Auto pilot/Laser pilot/Cruise pilot/CEMOS levelling left/hotkey

3a. Swing out unloading tube 7S. Retract vario table/Cross

3b. Swing in unloading tube levelling right/hotkey

4a. Reel lower

4b. Reel raise

4c. Reel forward

10

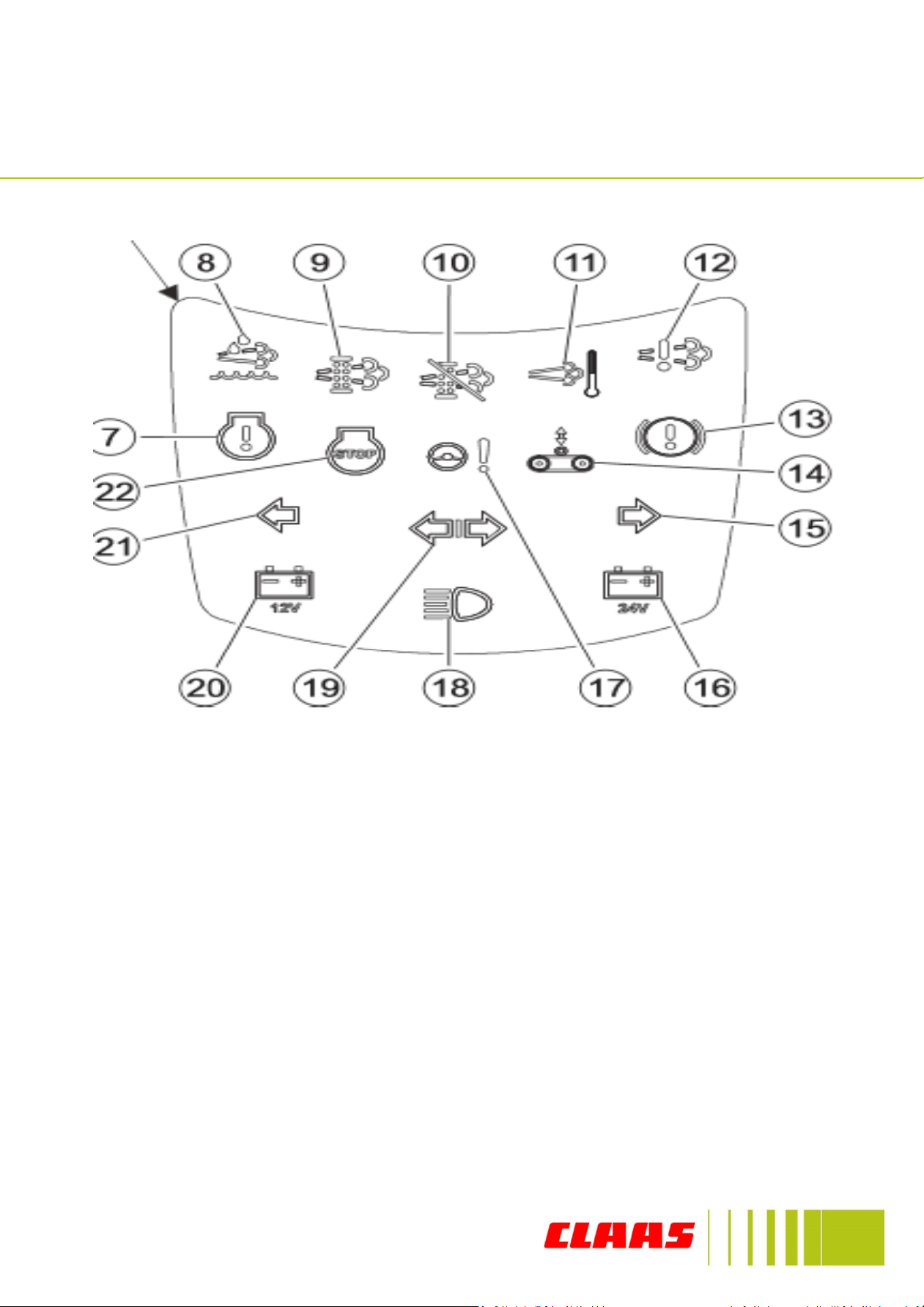

Steering column perkins

7. Engine fault indicator

8. Urea level

9. Exhaust filter loading

10. Regen deactivated

11. High exhaust temp

12. After treatment fault

13. Brake pressure warning

14. Track tension warning

15. Right indicator

16. 24v charging light

17. Emergency steering pump

18. Main beam

19. Trailer indicator

20. 12v charging light

21. Left indicator

22. Stop engine light

11

Steering column Mercedes

7. Engine fault indicator

8. Urea level

9. Not used

10. Engine de-rate

11. Not used

12. Not used

13. Brake pressure warning

14. Track tension warning

15. Right indicator

16. 24v charging light

17. Emergency steering pump

18. Main beam

19. Trailer indicator

20. 12v charging light

21. Left indicator

22. Stop engine light

12

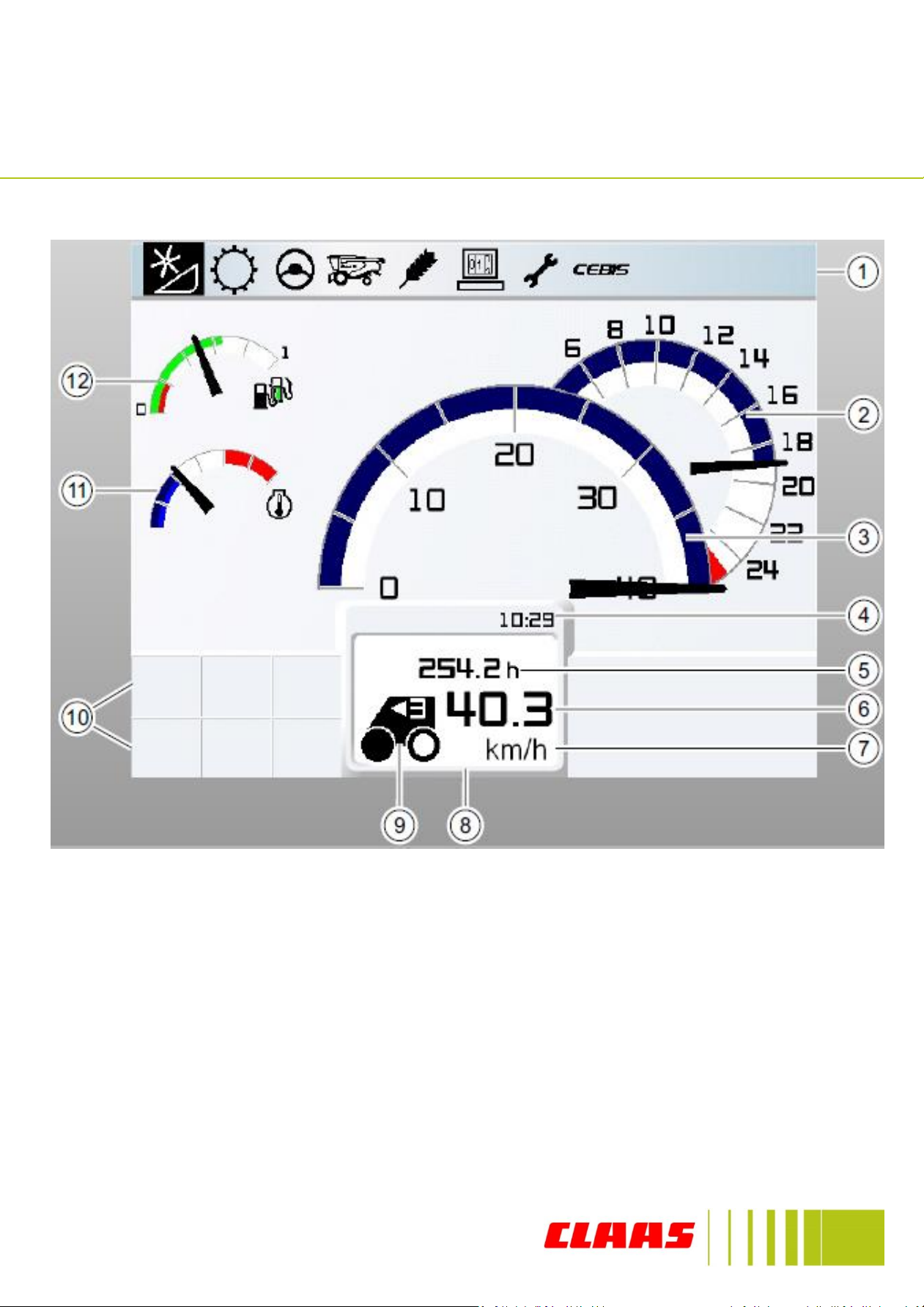

CEBIS

Road travel display Mercedes

1. Main menu

2. Engine RPM

3. Speedometer

4. Time

5. Operating hours

6. Ground speed

7. Ground speed units

8. Vehicle control display

9. Drive status

10. Message fields

11. Coolant temperature

12. Fuel (pointer)/ urea level*(green bar)

*Engine HP is reduced if urea tank is below

20%

13

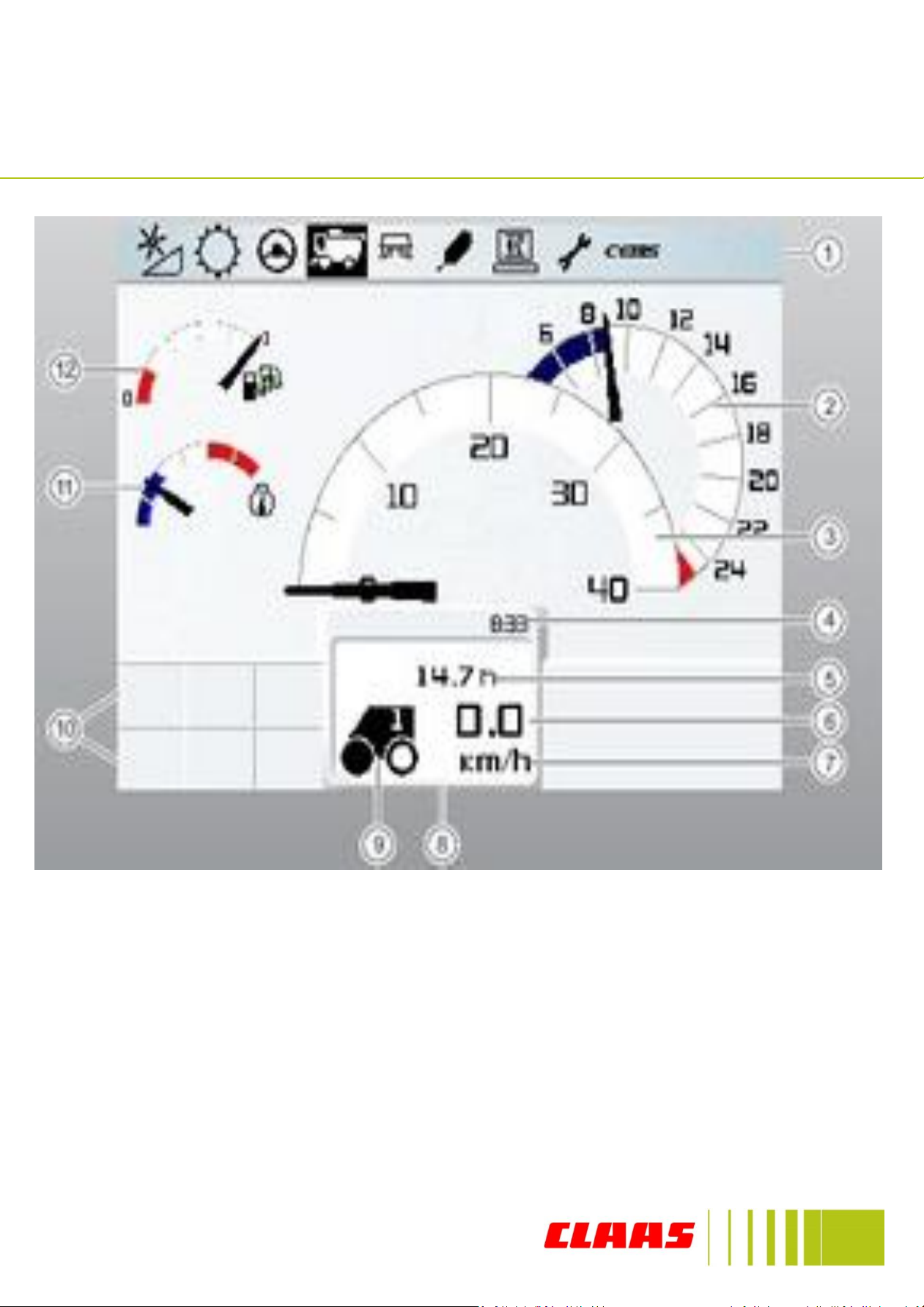

CEBIS

Road travel display Perkins

1. Main menu

2. Engine rpm

3. Speedometer

4. Time display

5. Operating hours

6. Ground speed

7. Ground speed units

8. Vehicle Control display

9. Drive status

10. Message fields

11. Coolant temperature

12. Fuel level

14

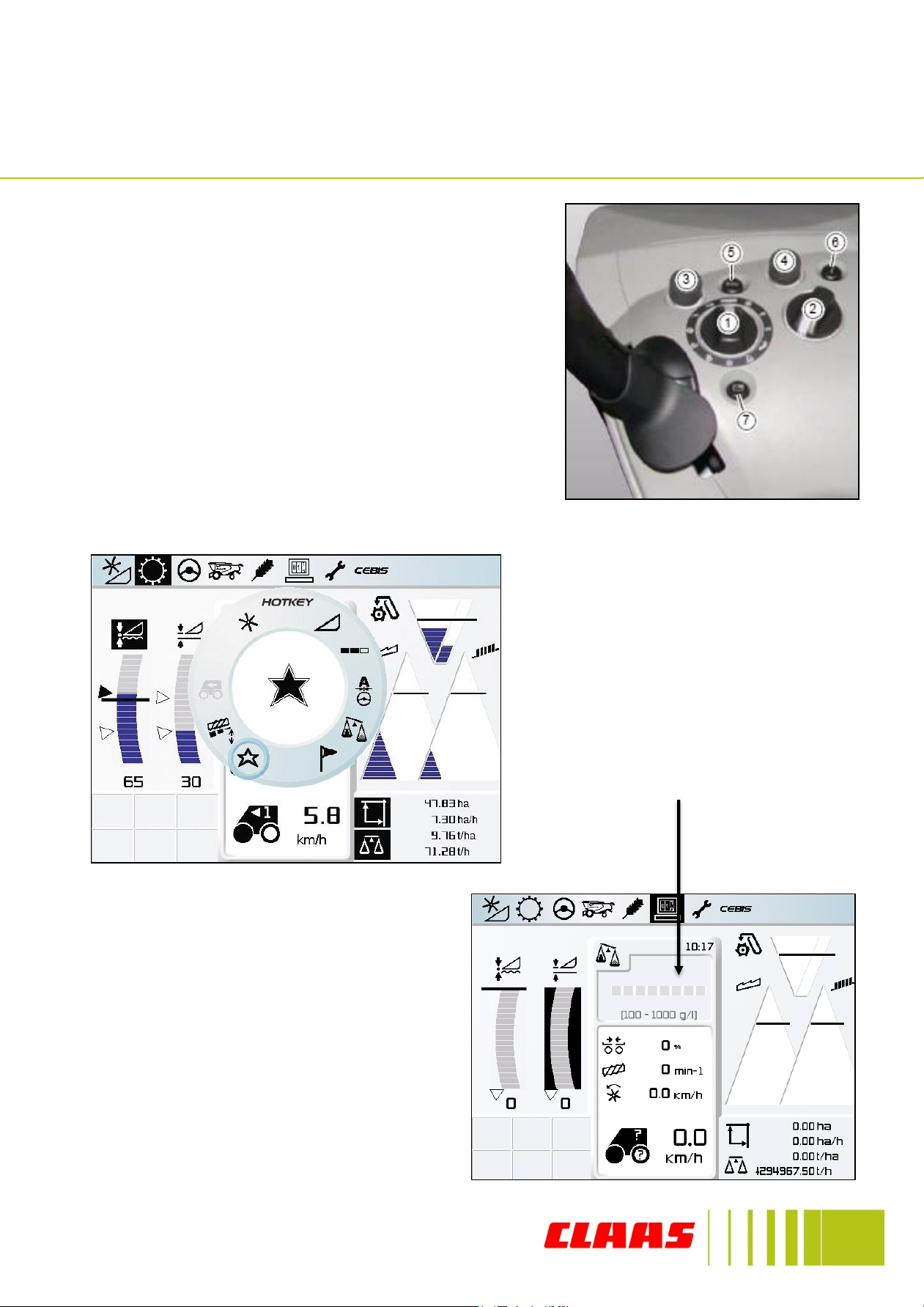

CEBIS –Harvest display

1. Main Menus

2. Broken grain

3. Non-Grain

4. Returns meter

5. Grain in returns

6. Separation monitor

7. Cleaning monitor

8. Area counter

9. Area/hour counter

10. Yield counter

11. Yield/hour counter

12. Harvest display

13. Ground speed display

14. Ground speed unit

15. Drive direction

16-18 Variable display

19. Message display

20. Cutting height control

21. Pre-set cutting height

22-23 Variable display

24. Time

15

CEBIS Keys

CEBIS

Using the CEBIS rotary switch (1) the combine

settings can be adjusted. The picture below

shows the operating settings that can be

adjusted. To navigate through the settings turn

the CEBIS rotary switch (1).

Inside the CEBIS display there are 2 large

numbers, the top number (7) shows the

desired value and the lower number (8) shows

the actual value.

To adjust the value turn switch (3) left or right

to increase or decrease, after the required

setting is completed turn the CEBIS rotary

switch (1) back to the CEBIS icon on the display

screen (12 o’clock).

7

8

16

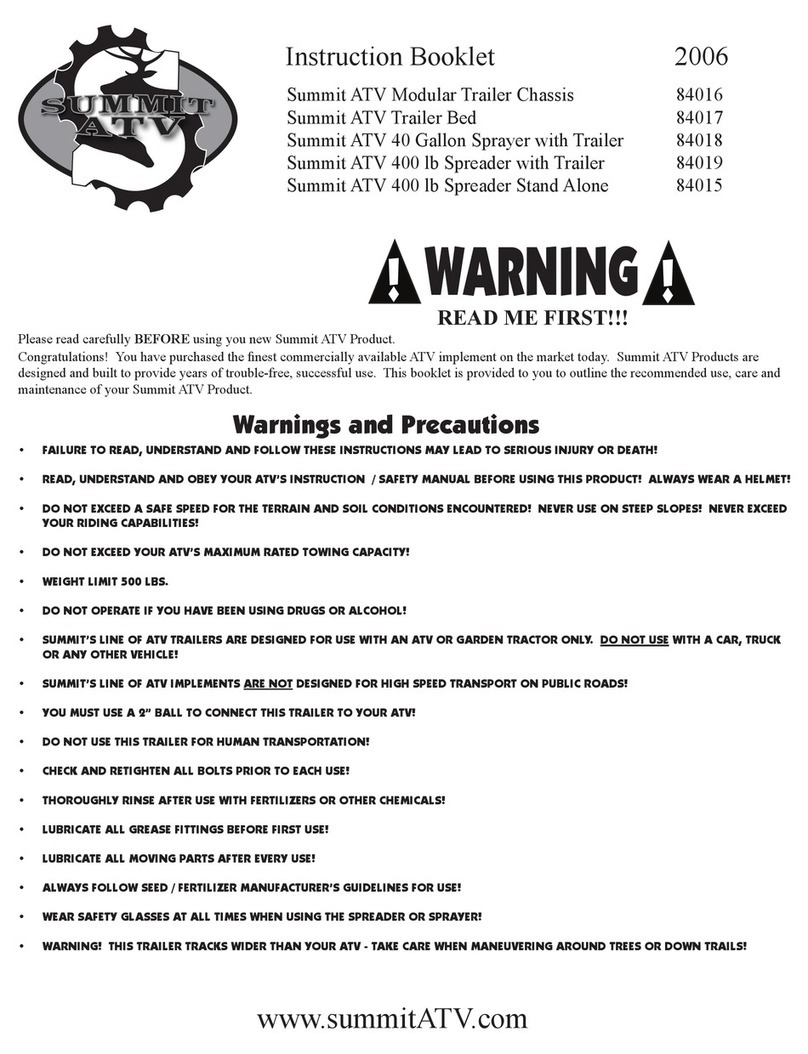

HOTKEY

HOTKEY

The HOTKEY (2) is used to adjust the more

frequently changing settings on the Combine

for example straw chopper or LASER PILOT

bias.

To adjust any of the HOTKEY values turn the

rotary switch (2) and the HOTKEY dial will

appear on CEBIS which is shown in the picture

below. Turn the dial to select the required icon

to make any adjustments.

After 5 seconds the HOTKEY dial

will disappear from CEBIS and the

settings will be displayed in the

window shown below. To change

the HOTKEY setting value turn

switch (4) either left or right to

either increase or decrease the

value.

To remove the adjusted settings

from the window turn the

HOTKEY switch (2) back to the

CEBIS (12 o’clock) position and

the previous settings will be

displayed.

17

CEBIS Symbols

Exits the menu and returns to CEBIS

Manual reel speed adjustment

Top sieve adjustment

Bottom sieve adjustment

Front attachment speed adjustment (if fitted)

Rotor speed adjustment

CEBIS screen brightness adjustment

Drum speed adjustment

Fan speed adjustment

Concave clearance adjustment

Cleaning performance monitor adjustment (Sieve loss)

Separation performance monitor adjustments (Walker/rotor loss)

18

HOTKEY Symbols

LASER PILOT adjustment

Hectolitre weight adjustment

Flagging function for yield mapping

Left / Right chopper bias, Working width, Central overlap, (only with

power spreader) and crosswind compensation if fitted

Favourite crop settings

CRUISE PILOT

Automatic Reel speed, Reel height, Reel fore & aft position

Cutting height, VARIO length, End snapping plate adjustment

Partial working width adjustment

19

CEBIS Menu Navigation

To navigate through the CEBIS menu turn the switch (3) shown below and the

different icons at the top of the CEBIS screen will be highlighted in black (8).

When the desired menu is highlighted push switch (3) to enter it, with any menu

turn switch (3) to select the required section and push it to enter it. If a value needs

to be changed within a menu push the switch (3) to display the + - signs and turn

the switch the correct value and push it again to enter and save the value as shown

in the picture below.

To exit any of the menu within

CEBIS use the ESC button (5),

this will return the screen back

to the previous menu.

8

Table of contents

Other Claas Utility Vehicle manuals

Popular Utility Vehicle manuals by other brands

Century

Century 974W25 Installation, operation, maintenance, parts

Floe

Floe CargoMax XRT owner's manual

Mi-T-M

Mi-T-M HMT-4004-0MGH Operator's manual

Summit

Summit 84015 Instruction booklet

Yamaha

Yamaha YUM1A UMAX RALLY 2021 Owner's/operator's manual

MULTIQUIP

MULTIQUIP Whiteman series Operation and parts manual

Taylor-Dunn

Taylor-Dunn SC-100-24 Service and Replacement Parts Manual

SnowEx

SnowEx V-Maxx G2 VX-2200 Installation instructions manual

Toro

Toro 7213 Operator's manual

Jungheinrich

Jungheinrich ESD 220 operating instructions

Polaris

Polaris RANGER 570 Full Size 2016 owner's manual

Yamaha

Yamaha Yamaha Rhino 660 owner's manual