Clack WS1 Series Instruction manual

WS1”, 1.5” & 2” Series Watersoftener

Installation Operation Maintenance Manual

SIMPWS1 REV3 13/07/11 PAGE 1 OF27

Installation

Operation

Maintenance

Manual

Simplex Water Softeners

With WS1”, 1.5” & 2” Series Valve

Models 20 ltr - 750 ltr

WS1”, 1.5” & 2” Series Watersoftener

Installation Operation Maintenance Manual

SIMPWS1 REV3 13/07/11 PAGE 2 OF27

1.0 PARTS LIST

..................................................................................................................................3

1.1 BASIC PARTS LIST.....................................................................................................................3

1.2 MISSING OR DAMAGED GOODS..............................................................................................3

2.0 TEMPORARY STORAGE

..............................................................................................................3

3.0 REGENERATION

..........................................................................................................................3

3.1 The Regeneration Process....................................................................................................3

3.2 METER CONTROL OF REGENERATION.....................................................................................4

3.3 TIME CLOCK CONTROL OF REGENERATION INITIATION..........................................................4

4.0 PRE-INSTALLATION CHECKS

......................................................................................................4

4.1 MECHANICAL...........................................................................................................................4

4.1.1 Foundation/Drainage .......................................................................................................4

4.1.2 Operating Space ...............................................................................................................5

4.1.3 Incoming Water................................................................................................................5

4.1.4 Pipework...........................................................................................................................5

4.1.5 Water Supply Company Requirements ............................................................................5

4.2 ELECTRICAL ..............................................................................................................................6

5.0 ASSEMBLY/INSTALLATION

........................................................................................................6

5.1 MECHANICAL...........................................................................................................................6

5.1.1 Pipework...........................................................................................................................6

5.1.2 Assembly...........................................................................................................................6

5.2 Options ....................................................................................................................................7

5.2.1 No Hard Water Bypass .....................................................................................................7

5.2.2 Differential Pressure Switch (dP)......................................................................................8

6.0 PROGRAMMING

.........................................................................................................................8

6.1 INTRODUCTION .......................................................................................................................8

6.2 CONTROLLER SETTING.............................................................................................................8

6.2.1 Setting the Time of Day ....................................................................................................9

6.3 Factory Programming

..........................................................................................................10

7.0 COMMISIONING ....................................................................................................................13

8.0 ROUTINE MONITORING.............................................................................................................14

9.0 FAULT FINDING AND RECTIFICATION ........................................................................................15

9.1 NO FLOW TO SERVICE ...........................................................................................................15

9.2 POOR TREATED WATER QUALITY..........................................................................................15

9.3 NO REGENERATION ...............................................................................................................16

9.4 UNSATISFACTORY CAPACITY BETWEEN REGENERATIONS....................................................16

10.0 WARRANTY AND SERVICE ...................................................................................................16

10.1 AFTER SALE WARRANTY ......................................................................................................16

11.0 Technical Data

........................................................................................................................17

11.1 Process and Operating Data

........................................................................................17

11.1.1 WS1 20-80 L...........................................................................................................17

11.1.2 WS1 100-350 L.......................................................................................................18

11.1.3 WS1.5 100-500 L....................................................................................................19

11.1.4 WS2 150-750 L.......................................................................................................20

11.2 ENGINEERING DATA

.....................................................................................................21

11.2.1 WS1 20-80 L...........................................................................................................21

11.2.2 WS1 100-350 L.......................................................................................................22

11.2.3 WS1.5 100-500 L....................................................................................................23

11.2.4 WS2 150-750 L.......................................................................................................24

12.0 FACTORY PROGRAM................................................................................................................25

13.0 CE Certificate

..........................................................................................................................27

WS1”, 1.5” & 2” Series Watersoftener

Installation Operation Maintenance Manual

SIMPWS1 REV3 13/07/11 PAGE 3 OF27

1.0 PARTS LIST

1.1 BASIC PARTS LIST

1. WS1 VALVE C/W TRANSFORMER

2. VESSEL & RISER

3. BRINE TANK

4. INSTRUCTIONS

5. REDUCER (if required)

6. RESIN

1.2 MISSING OR DAMAGED GOODS

Immediately on receipt of the goods, it is advisable to check that all items

ordered have been received. If you have any doubt that goods have been

supplied as requested, please contact your supplier immediately. If any

items are missing or damaged, the carrier and your supplier must be notified

within 2 days of receipt if a claim is to be made.

2.0 TEMPORARY STORAGE

If installation is not to start immediately after delivery, the equipment should

be stored in a clean dry area, where it will not be damaged, or be subjected

to temperatures below freezing.

3.0 REGENERATION

3.1 The Regeneration Process

The regeneration process consists of six stages:-

1. Backwash

- Water flows upwards through the resin bed, and out to a

drain. As it does so, it loosens the ion exchange beads, removes any resin

'fines' (i.e. small pieces of broken beads etc.) and cleans off any particles of

dirt or pipework corrosion products which may have accumulated during the

service cycle.

2/3. Brine/Slow Rinse

- During the first part of this stage, the

concentrated salt -solution is drawn from the brine tank, blended with water to

reduce the concentration to the correct level, and passed down through the

resin. When the required quantity of brine has been drawn in, the water flows

alone to push the remaining brine through the resin at the correct rate, and

ensure that all of the resin sees the right amount of regenerant.

WS1”, 1.5” & 2” Series Watersoftener

Installation Operation Maintenance Manual

SIMPWS1 REV3 13/07/11 PAGE 4 OF27

4. Backwash (2nd)

- This valve has the unique facility of performing a second

backwash allowing for optimum regeneration, efficiency and cleaning of the

resin bed. Water flows as in the first backwash cycle.

5. Fast Rinse

- This follows the brine and slow rinse cycle, and entails rinsing

away the residual brine and Calcium and Magnesium salts from the resin and

re-packing the resin bed. This is carried out down flow with water flowing

through the resin in the direction of service.

6. Salt Tank Refill

- Following the fast rinse, a quantity of water

sufficient to dissolve the correct amount of salt for the next

regeneration is returned to the salt tank. When this has finished, the unit

automatically returns to service.

3.2 METER CONTROL OF REGENERATION

On meter controlled valves a water meter is installed in the outlet from the

softener, to measure the volume of water which passes to service. The

internal turbine rotates with the flow of water and reports its rate of rotation

through Hall-effect circuitry to the printed circuit board. When the reading

reaches zero the valve will automatically regenerate that night at 2 am for

delayed regeneration softeners or immediately for immediate regeneration

softeners.

3.3 TIME CLOCK CONTROL OF REGENERATION INITIATION

Time clock configuration valves initiate regeneration at a pre-set time after

a pre-set number of days. The frequency of regenerations are adjustable

on programming the timer (Regeneration control).

4.0 PRE-INSTALLATION CHECKS

4.1 MECHANICAL

4.1.1 Foundation/Drainage

The softener will not require any special foundations, provided that a firm,

level area which is capable of supporting the working weight is available.

(See Engineering Data, Section 11.2)

Unwanted water from the regeneration process must flow to drain, and so

an open drain or gully, capable of passing the necessary flow is required

(see Process and Operating Data, 11.1, for relevant flows). The total flow

of water to drain depends on site conditions, but will be approximately 6

times the resin volume. Preferably the drain should be level with or no higher

than 500mm above the softener valve.

A second drain is required for the brine tank overflow. This is a safety drain

which will only discharge water if there is a malfunction in the control

WS1”, 1.5” & 2” Series Watersoftener

Installation Operation Maintenance Manual

SIMPWS1 REV3 13/07/11 PAGE 5 OF27

valve. Where possible this should be installed through an outside wall

like a cistern overflow, where it will give a visual indication of any failure.

4.1.2 Operating Space

The space occupied by the softener can be found in the Engineering Data

(Section 11.2).

Access will be required to refill the salt tank, and to carry out

adjustments or maintenance on the equipment. It is therefore

recommended that a minimum of 500mm clearance be allowed in front of

the unit for this purpose.

4.1.3 Incoming Water

The raw water to be fed to the softener must comply with the

following:-

1. Available at all times at a flow equal to or greater than

the required service flow

2. At a pressure between 1.7 and 8.0 bar

3. Temperature between 4 and 38oC

4. Suspended solids less than 1 ppm

5. Iron less than 0.2 ppm, Manganese less than 0.1 ppm,

Free Chlorine less than 1 ppm if temperature is less than

15oC, less than 0.3 ppm if temperature higher (up to 30oC)

4.1.4 Pipework

Pipework to be connected to the softener should not have an

excessive amount of hardness scale deposit. Piping that is heavily built up

with scale (or Iron deposits) should be replaced.

Make sure that the pipework can be connected to the softener in such a

way as to impose no stresses on the control valve, and that it is properly

aligned and supported.

A system for the complete by-passing and isolation of the softener should

be installed.

4.1.5 Water Supply Company Requirements

It is essential that if the equipment is to be connected directly to a mains

water supply, the local bylaws must be adhered to. These cover both

plumbing and the prevention of backflow into the mains. If there is any

doubt, the local water inspector should be consulted, but in general, the

installation of a 'Double check valve assembly' conforming to BS6282 part 2

will be required in the feed pipework to the softener.

If the pressure available from the mains is not adequate it will be

necessary to install a booster pump arrangement. Such a system would

WS1”, 1.5” & 2” Series Watersoftener

Installation Operation Maintenance Manual

SIMPWS1 REV3 13/07/11 PAGE 6 OF27

be covered by additional bylaws, and the water storage tank needed must

comply with these.

4.2 ELECTRICAL

A continuous supply of 240v, 5 VA is required. The softener itself is 12 volt

but a plug in 240v/12v transformer is supplied and should be connected

to an uninterrupted mains supply, which is separately 1 Amp fused, and

does not have any additional switch.

5.0 ASSEMBLY/INSTALLATION

5.1 MECHANICAL

Check all the items against the parts list and shipping documents, and

ensure you have them all before starting work. In addition to the

softener you will require installation materials and basic tools, (i.e.,

spanners, screwdrivers etc., and PTFE tape)

5.1.1 Pipework

Pipework should be assembled incorporating the features shown in the

Installation Diagram, Section 14.1. It is essential that inlet and outlet

isolating valves and a by-pass valve are provided, and that the water main

is protected by a double check valve where appropriate (see Local Water

Bye-laws).

Pipework can be constructed from any normally acceptable material

(Copper, Galvanised, Plastic), provided it is properly supported and

aligned. Ensure that the pipe is sufficiently large to accommodate the flow

of water required, making due allowance for the pressure drop between

the softener and the point of discharge of soft water.

NOTE: IF BRAZED OR SOLDERED FITTINGS ARE TO BE USED, THE

PIPE WORK MUST BE DISCONNECTED FROM THE VALVE DURING

HEATING AND COOLING. EXCESS HEAT CAN CAUSE PERMANENT

DAMAGE TOSOME OF THE VALVE COMPONENTS.

5.1.2 Assembly

If possible place the pressure vessel on its final location before filling. Check

that the distributor tube, with its yellow top cover, is in place and using a

funnel slowly pour in the resin taking care not to spill any on the floor. Ensure

that the distributor tube remains central in the vessel during filling. After

emptying all the bags, the vessel should be almost 75-80% full. This is to

allow for the rising of the resin bed during backwash. Once the vessel is

filled, immediately sweep up any spilled resin.

WS1”, 1.5” & 2” Series Watersoftener

Installation Operation Maintenance Manual

SIMPWS1 REV3 13/07/11 PAGE 7 OF27

Remove cover from distributor tube and brush any beads of resin out of

the threads in the neck of the vessel.

Unpack valve and skip down over the distributor tube. Screw the valve in to

the resin vessel, taking care not to cross the threads. Excessive force

should not be needed as the valve is running in to the vessel. Finally

tighten to approximately 20 ft/lbs torque. Adjust position of vessel to line

up piepwork connections, not the position of the valve on the vessel.

Position the brine tank and connect brine line to the bulkhead

connector above the overflow (3/8”). Ensure that a brass insert is

placed

inside the brine line before connecting.

Connect inlet and outlet pipework

to the valve (1” BSP 90 deg or straight

male

threaded elbows at rear of valve) using flexibles where possible or rigid

high pressure pipe and socket unions. Some felxible pipework is

advisable to prevent stress on the vessel as it cycles during service, since

it will expand and contract longitudinally.

Connect drain line to the drain outlet (3/4” male threaded elbow on top

of

valve). Ensure that there is an air break in the drain line at the same height as

the valves to prevent negative pressure on the vessel.

Connect brine line to the brine connection on the valve. Again ensure that a

brass insert is placed inside the brine line before connecting.

Connect power supply to valve and commission.

5.2 Options

5.2.1 No Hard Water Bypass

All Clack valves are fitted with Bypass pistons, they will pass regeneration

water to service if there is a demand during regeneration. If this is a potential

problem then it can be resolved by fitting a Motorised Alterating Valve (MAV)

with one port block or a No Hard Water Bypass Valve (NHWBV) on the outlet

of the valve. The two pin connector from the MAV or NHWBV has to be

connected to the ALTERNATOR DRIVE pin of the Clack valve and step 3CS

in the OEM programming level has to be set to nHbP. The MAV or NHWBV

will be driven to close before the first regeneration cycle that is not FILL or

SOFTENING or FILTERING and be driven open after the last regeneration

cycle that is not FILL.

WS1”, 1.5” & 2” Series Watersoftener

Installation Operation Maintenance Manual

SIMPWS1 REV3 13/07/11 PAGE 8 OF27

5.2.2 Differential Pressure Switch (dP)

There is a dP input on Clack valves that can be used to carry out the following

functions depending upon the setting of step 4CS in the OEM programming

level

4CS set to OFF no function

4CS set to dPon0 if the dp switch is closed for an accumulative time of

2 minutes a regeneration will occur immediately

4CS set to dPdEL if the dp switch is closed for an accumulative time of

2 minutes a regeneration will occur at the scheduled regeneration time

4CS set to HoLD if the dp switch is closed a regeneration will be

preventing from occurring.

6.0 PROGRAMMING

6.1 INTRODUCTION

It is recommended that the commissioning of the plant is undertaken by a

trained service engineer, who will be able to put the plant into service

quickly, and most efficiently. However, if the services of an experienced

engineer are not available, following the steps outlined below will result in

the system being properly commissioned.

6.2 CONTROLLER SETTING - Site programming mode

All controller settings will require the valve to have the mains supply

switched on. The valve must not be regenerating when controller

settings are adjusted.

WS1”, 1.5” & 2” Series Watersoftener

Installation Operation Maintenance Manual

SIMPWS1 REV3 13/07/11 PAGE 9 OF27

2. Adjust hours with UP and

DOWN arrows

3. Press NEXT

4.Adjustminuteswith UP

and DOWN arrows.

5.Press NEXT to returnto

normal operation

6.2.1 Setting the Time of Day

1. Press SET CLOCK

The softener regeneration cycles have been factory programed. On

metered softeners the volume capacity of the resin in litres has also been

entered on a default hardness of 300ppm and a reserve capacity of

33%. This may need to be altered based on local water hardness and

reserve required for the site (see section 13.1) The time of day for

WS1”, 1.5” & 2” Series Watersoftener

Installation Operation Maintenance Manual

SIMPWS1 REV3 13/07/11 PAGE 10 OF27

NEXT

NEXT

NEXT

NEXT

NEXT

NEXT

regeneration has been entered as 2 AM, this can be changed if

necessary.

6.3 Factory Programming

Regeneration Programming

(All programming below is Factory set)

To alter settings – Press “↑” and “↓” keys To back up at any stage – Press

“REGEN” To save any changes – Press “SET CLOCK”

Press and hold together for 5 seconds

“Softening” will be flashing in top left corner

Set 1

st

cycle time in minutes – BACKWASH

Set 2

nd

cycle time in minutes – BRINE & SLOW

RINSE

Set 3

rd

cycle time in minutes – BACKWASH 2

Set 4

th

cycle time in minutes – FAST RINSE

Set 5

th

cycle time in kilos of salt required per regeneration

– BRINE REFILL except WS2 which is in minutes

WS1”, 1.5” & 2” Series Watersoftener

Installation Operation Maintenance Manual

SIMPWS1 REV3 13/07/11 PAGE 11 OF27

NEXT

NEXT

NEXT

NEXT

NEXT

NEXT

Capacity in Kilograms-Set according to Softener Size in

Technical data if metered, ignore if timeclock

Set Auto if metered, off if timeclock

Set type of regeneration required:-

“NORMAL” –

Delayed Regeneration

“on 0” –

Immediate Regeneration

“NORMAL + on 0” –

Either Delayed or Immediate Regeneration, whichever

occurs first

Set Salt to Off

Programming Finished

–

Return to time of day

User Programming

To alter settings

– Press

“↑” and “↓”

keys

To back up at any stage

– Press

“REGEN”

To save any changes

– Press “SET CLOCK”

Press together and hold for 5 seconds

Set Influent Hardness in ppm if metered, nA if

timeclock

WS1”, 1.5” & 2” Series Watersoftener

Installation Operation Maintenance Manual

SIMPWS1 REV3 13/07/11 PAGE 12 OF27

NEXT

NEXT

NEXT

NEXT

Set effluent hardness in ppm if mixing valve fitted, if

no mixing valve fitted then set to 0 if metered. NA if

timeclock.

Set day regeneration override for metered softeners

OR set frequency of regenerations for Timeclock

valves (1-28 days)

Set time for regeneration hours. Time for Immediate

regeneration valves cannot be altered and will show “on

0”

Returns to time of day

WS1”, 1.5” & 2” Series Watersoftener

Installation Operation Maintenance Manual

SIMPWS1 REV3 13/07/11 PAGE 13 OF27

7.0 COMMISIONING

The objective of commisioning is to fill the softener and brine tank with

water, check for leaks and prepare it for service. The simplest way to

commission the unit is to initiate a regeneration. This will eliminate the

air from the system and flush the resin prior to use.

Manually add water to the brine tank until it is filled approximately 6”

(100mm) from the bottom of the tank.

Before opening the inlet water supply, ensure that the outlet is shut and

switch on the power supply and press the “REGEN” button on the

valve. “Regen today” will appear at the bottom left of the timer, by

continuing to press the “REGEN” button the motor will power up and

move the valve into the backwash position. Slowly open the inlet valve.

At first, air will be expelled from the drain line, followed by water once

the vessel is full. The first quantity of water will have a tan colouration

which is perfectly normal. Allow water to run to drain until the water is

clear.

Next, press the “Regen” button and the motor will move the valve into

the brine and slow rinse position. Ensure that the water level in the

brine tank drops as water is drawn in. During brine and slow rinse

water will slowly run to drain.

Press the “Regen” button 3 more times (after pressing the button once,

wait for the motor to stop before pressing it again) until the valve

reaches the refill stage. Ensure that water is now refilling the brine

tank. Leave to fill for full duration of the cycle and add salt to the brine

tank. The level the water will reach depends on the type of salt used

and the resin volume of the softener

At the end of the refill cycle the motor will automatically move the valve

back into the service position. The softener is now commissioned.

Open the outlet from the softener to run water to service.

Add salt to the brine tank. If tablet salt is used (recommended) then

the cabinet can be filled to the top. If granular salt is used then the

cabinet must only be 3/4 full.

WS1”, 1.5” & 2” Series Watersoftener

Installation Operation Maintenance Manual

SIMPWS1 REV3 13/07/11 PAGE 14 OF27

8.0 ROUTINE MONITORING

The following recommendations are made to help the user of the

softener confirm that it is performing as required, and to give early

warning of possible problems. The operation of the softener is

completely automatic, and should not require adjustment.

Weekly

Check the treated water hardness with a hardness test kit.

Inspect the level of salt in the salt tank and refill if necessary.

Monthly

Check raw water hardness, and record. Compare with original

hardness and adjust volume capacity setting if required (see Section

12.0).

Annually

Inspect and clean/replace as necessary the brine injector, brine screen

and the inernal disc/flapper set. This should be performed by a

competent engineer familiar with the WS1 valve.

WS1”, 1.5” & 2” Series Watersoftener

Installation Operation Maintenance Manual

SIMPWS1 REV3 13/07/11 PAGE 15 OF27

9.0 FAULT FINDING AND RECTIFICATION

Modern water softeners are extremely reliable and unlikely to give any

problems if they are installed and operated correctly.

9.1 NO FLOW TO SERVICE

Check mains pressure is above 1.7 bar.

Check inlet and outlet isolating valves are open.

Check service outlet valve is open.

Check pressure drop across resin. If excessive, resin may be fouled,

or internals blocked. Initiate a regeneration. If this does not free up

the resin the softener will need to be inspected and serviced by a

competent engineer.

9.2 POOR TREATED WATER QUALITY

Check manual by-pass closed.

Check salt level in salt tank. Refill if necessary.

Trickle flow through conventional ball valve in storage tank. Replace

with Torbeck or Fluidmaster servo valve.

Check raw water pressure above minimum. If flow is less than

minimum, channelling of water can occur in resin. which results in

inadequate treatment.

Check injector strainer and injector not blocked (see Appendix for

drawings). Clean if necessary.

Check brine pick-up screen not blocked. Clean if necessary.

Check brine line not split. Replace if necessary.

Check raw water hardness, and then check if capacity setting is correct

for this hardness (see Section 12.0)

WS1”, 1.5” & 2” Series Watersoftener

Installation Operation Maintenance Manual

SIMPWS1 REV3 13/07/11 PAGE 16 OF27

9.3 NO REGENERATION

Check electrical supply, fuses etc. satisfactory.

Check control head motor runs by initiating a manual regeneration

(Press “REGEN” button for 5s and then again for a further 5s), listening

for drive motor ‘whirring' as it advances between cycles. Replace if

necessary.

Check internal meter running freely (if fitted) indicated by small black

dot in center of display flashing.

9.4 UNSATISFACTORY CAPACITY BETWEEN

REGENERATIONS

Check condition of resin. It may have become fouled, inhibiting the

regeneration process. If fouled, it should be cleaned or replaced.

Check incoming water for presence of Chlorine. If high, the resin may

have been degraded.

Check raw water pressure. Too high pressure may mean the brine

draw stage of regeneration is not effective

10.0 WARRANTY AND SERVICE

10.1 AFTER SALE WARRANTY

Your softener is covered by a parts warranty for a period of one year

from installation or 14 months from purchase.

Should you have any problems with your softener or require a routine

service, please contact your supplier.

WS1”, 1.5” & 2” Series Watersoftener

Installation Operation Maintenance Manual

SIMPWS1 REV3 13/07/11 PAGE 17 OF27

11.0 Technical Data

11.1 Process and Operating Data

11.1.1 WS1 20-80 L

PARAMETER UNITS 25L 30L 40L 50L 60L 80L

MAX.SERVICE

FLOW M3/hr 1 1.2 1.6 2 2.4 3.2

SYSTEM CAPACITY Kg

CaCO3 1.25 1.5 2 2.5 3 4

CAPACITY @

300PPM M3 4.1 5 6.6 8.3 10 13.3

SALT USED PER

REGEN Kg 3.5 4.2 5.6 7 8.4 11.2

REGENERATION

TIME MIN 48 68 72 72 72 72

SALT STORAGE

CAPACITY Kg 60 60 100 130 130 130

MAX OPERATING

TEMP

OC 50 50 50 50 50 50

MAX FLOW TO

DRAIN LIT/MIN 5.7 9 9 9 15.14 15.14

IMPORTANT NOTES

Much of the data quoted in the above table is affected by the inlet pressure,

and so should be regarded as nominal only.

Total flow to drain will be similarly affected and is therefore not quoted, but

will be about 6 times the resin volume.

WS1”, 1.5” & 2” Series Watersoftener

Installation Operation Maintenance Manual

SIMPWS1 REV3 13/07/11 PAGE 18 OF27

11.1.2 WS1 100-350 L

PARAMETER UNITS 100L 120L 150L 250L 350L

MAX.SERVICE

FLOW M3/hr 4 4.3 6 6 6

SYSTEM CAPACITY Kg

CaCO3 5 6 7.5 12.5 17.5

CAPACITY @

300PPM M3 16.7 20 25 41.75 58.45

SALT USED PER

REGEN Kg 14 16.8 21 35 49

REGENERATION

TIME MIN 96 96 96 120 140

SALT STORAGE

CAPACITY Kg 160 160 300 400 500

MAX OPERATING

TEMP

OC 50 50 50 50 50

MAX FLOW TO

DRAIN LIT/MIN 19 19 26 37 57

IMPORTANT NOTES

Much of the data quoted in the above table is affected by the inlet pressure,

and so should be regarded as nominal only.

Total flow to drain will be similarly affected and is therefore not quoted, but

will be about 6 times the resin volume.

WS1”, 1.5” & 2” Series Watersoftener

Installation Operation Maintenance Manual

SIMPWS1 REV3 13/07/11 PAGE 19 OF27

11.1.3 WS1.5 100-500 L

PARAMETER UNITS 100L 120L 150L 250L 350L 500L

MAX.SERVICE

FLOW M3/hr 4 4.8 6 10 11.6 11.6

SYSTEM CAPACITY Kg

CaCO3 5 6 7.5 12.5 17.5 25

CAPACITY @

300PPM M3 16.7 20 25 41.75 58.45 83.5

SALT USED PER

REGEN Kg 14 16.8 21 35 49 70

REGENERATION

TIME MIN 96 96 96 120 140 140

SALT STORAGE

CAPACITY Kg 160 160 300 400 500 750

MAX OPERATING

TEMP

OC 50 50 50 50 50 50

MAX FLOW TO

DRAIN LIT/MIN 19 19 26 37 56 94

IMPORTANT NOTES

Much of the data quoted in the above table is affected by the inlet pressure,

and so should be regarded as nominal only.

Total flow to drain will be similarly affected and is therefore not quoted, but

will be about 6 times the resin volume.

WS1”, 1.5” & 2” Series Watersoftener

Installation Operation Maintenance Manual

SIMPWS1 REV3 13/07/11 PAGE 20 OF27

11.1.4 WS2 150-750 L

PARAMETER UNITS 150L 200L 250L 300L 350L 500L 750L

MAX.SERVICE

FLOW M3/hr 6 8 10 12 14 20 24

SYSTEM

CAPACITY Kg

CaCO3 7.5 10 12.5 15 17.5 25 37.5

CAPACITY @

300PPM M3 25 33.4 41.75 50.1 58.45 83.5 125.2

5

SALT USED

PER REGEN Kg 21 28 35 42 49 70 105

REGENERATIO

N TIME MIN 96 120 120 140 140 140 140

SALT STORAGE

CAPACITY Kg 300 400 500 500 750 750 1000

MAX

OPERATING

TEMP

OC 50 50 50 50 50 50 50

MAX FLOW TO

DRAIN LIT/MIN 26.5 37.85 37.85 56.78 56.78 94.63 132.4

8

IMPORTANT NOTES

Much of the data quoted in the above table is affected by the inlet pressure,

and so should be regarded as nominal only.

Total flow to drain will be similarly affected and is therefore not quoted, but

will be about 6 times the resin volume.

Other manuals for WS1 Series

4

This manual suits for next models

2

Table of contents

Other Clack Water Dispenser manuals

Popular Water Dispenser manuals by other brands

Water Care

Water Care TotalCare Series Installation instructions & owner's manual

Spring Well

Spring Well SS+ installation instructions

Black & Decker

Black & Decker 900149 user manual

Elkay

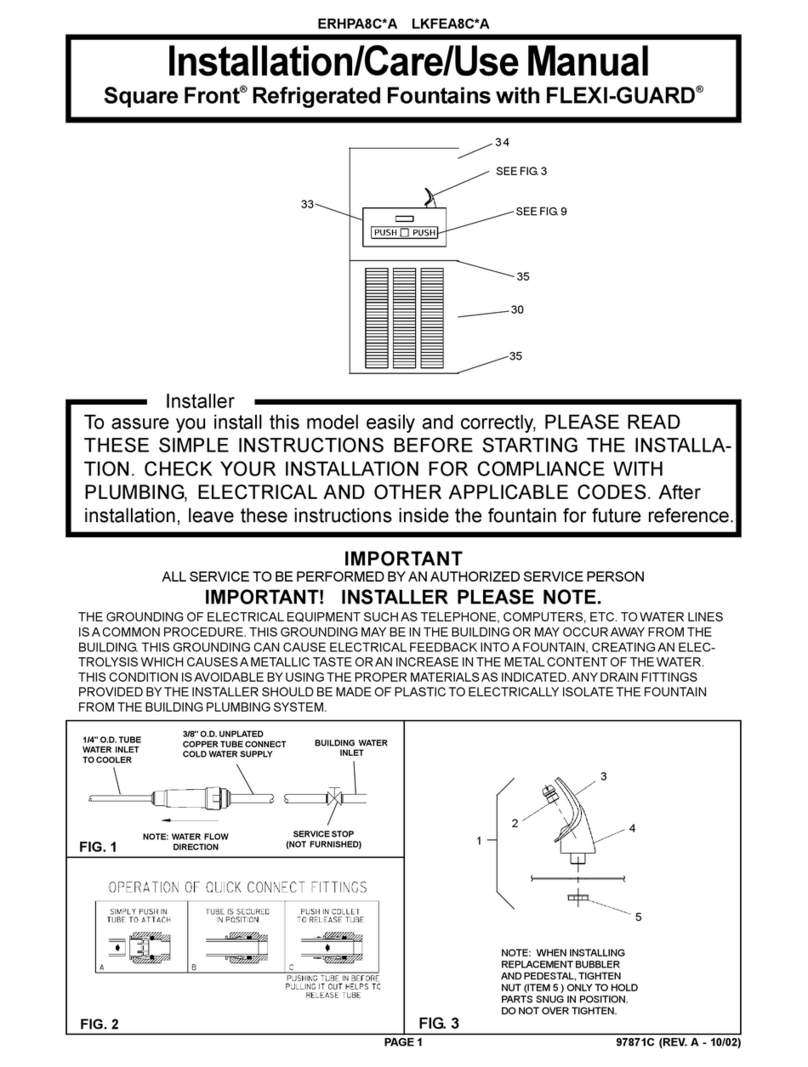

Elkay Square Front LKFEA8C A Series Installation, care & use manual

Franklin

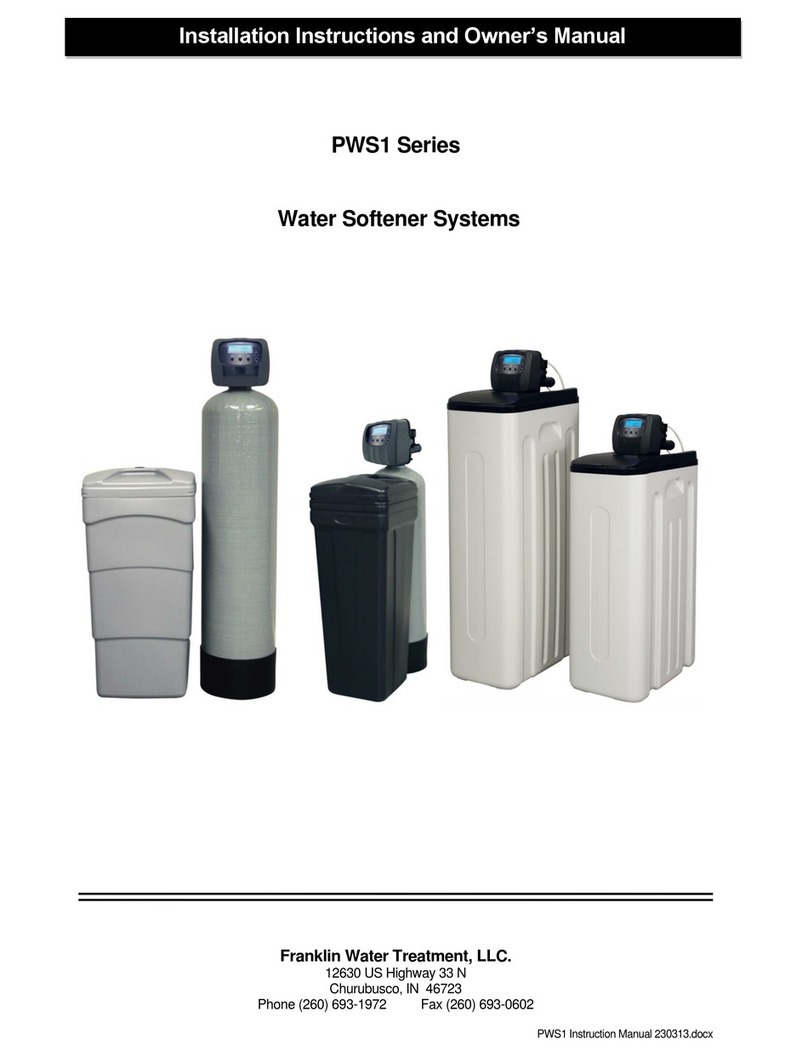

Franklin PWS1 Series Installation instructions and owner's manual

vitapur

vitapur VWD1076BLST Use & care guide