Clack WS CI Series Owner's manual

Installation, Operation

& Maintenance Guide

Clack WS CI & TC

Filter Systems

Including Birm, Filox, pH,

Sediment, Carbon &

Arsenic Removal Filters

WS CI

WS1TC

Manual 018.0

2

Contents

Accessories

1. Unpacking Instructions

2. Installation

Pre-installation checks

Fitting the bottom distribution system

Adding the media

Fitting the valve

DLFC (drain line flow control)

Electrical Connections

Programming the valve

3. Commissioning

Introduction

Backwash

Service

4. Routine Maintenance

Weekly

Monthly

5. Technical Information

Identifying your system

Programming details

Process and operating details

Hydraulic connections

Weights & Dimensions

Accessories

5303024075 Bypass (suitable for 1” connections)

5303024084 Auxiliary Micro Switch (for 1” & 1.25” valves)

5303020005 Auxiliary Micro Switch (for 1.5” & 2” valves)

5303028632 Service Wrench

5303024087 Vertical Adaptor Assy (1” connections up to 14” vessel) (CI only)

5303020765 No untreated water bypass 1” & 1.25” valves (CI only)

5303020763 Motorized Alternating Valve 1” & 1.25” valves (CI only)

5302036536 Motorised Alt Valve 1.5” valve (can use as no untreated water bypass)(CI only)

5303028622 Motorised Alt Valve 2” valve (can used as no untreated water bypass) (CI only)

5303027234 2” Meter Assy (CI only)

3

Thank you for purchasing this Filter System. We are sure that it will provide you with trouble

free service for many years to come. Please use the following pages to assist you with the

assembly and installation of your new system.

1. Unpacking

PLEASE USE THE ACCOMPANYING PACKING DOCUMENTS TO CHECK THAT ALL

ITEMS ARE PRESENT AND CORRECT.

If any item is missing or damaged your carrier and supplier must be notified within 2 days of

receipt if a claim is to be made.

The main parts of the system include:

Riser tube

Lower screen

Optional adaptor

Valve

valve

Vessel

Base

Inlet, Outlet and Drain & DLFC

Gravel

well

Filter Media

Optional upper screen

Optional dome hole

4

2. Installation

Please observe the regulations concerning the installation of your filter system. Check that

you have allowed space for access to the unit for possible future maintenance. This

installation may require plumbing work and will require an electrical outlet to be fitted near the

system. Only attempt this if you have the necessary skills.

2.1 Pre-installation checks

The area needs to be level, frost free, have access to electricity and an open drain. Check the

incoming water quality is within any parameters specified for that media (see technical

information later in the manual). In addition to this check the incoming water pressure is

between 2 and 8 bar (preferably approx. 4 bar) and the water temperature is between 3ºC

and 45ºC.

2.2 Fitting the Distribution System

Fit the bottom distribution system into the vessel – the bottom screen should been pre glued

to the riser tube (fig A.1) (smaller systems). Alternatively if the system uses bottom laterals

these need to be assembled inside the vessel (fig A.2), Move the vessel in its final position as

it will be difficult to move once the media has been added.

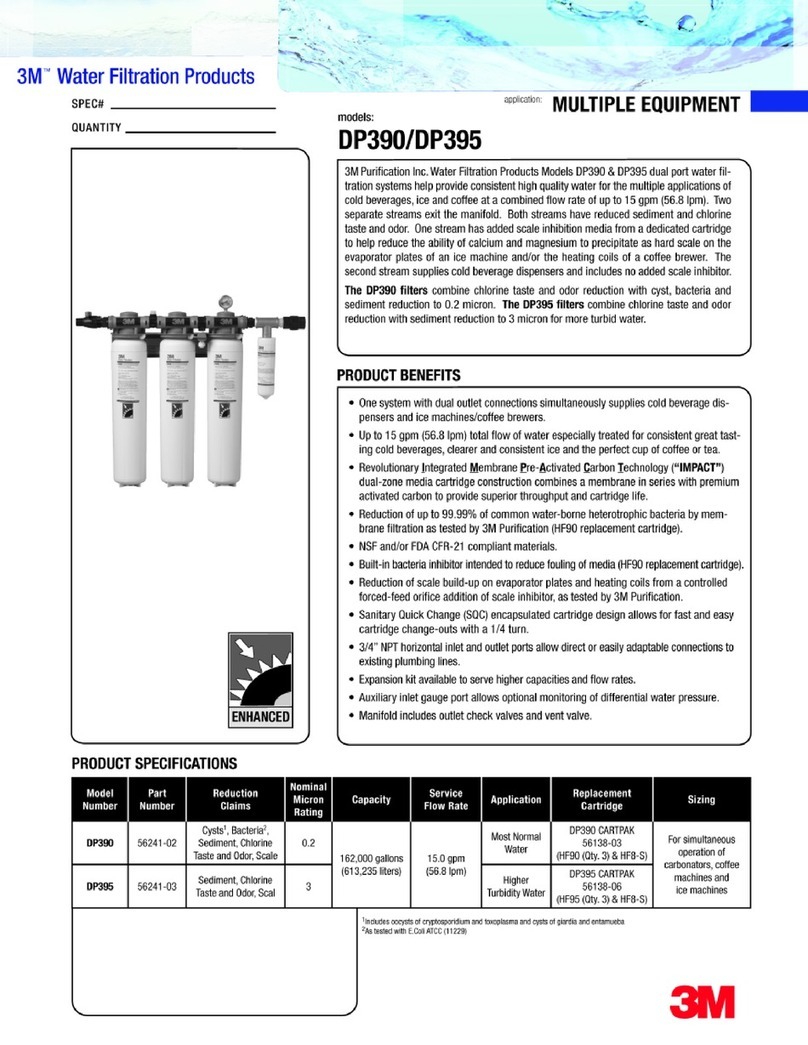

Fig A.1 Fig A.2 Fig A.3

2.3 Adding the Media

Block the top of the riser tube to stop media getting down the tube.(see fig A.3). Add about

1/3 by volume of water to the vessel so when the media is poured in it doesn’t damage the

bottom distribution system. If you have been supplied gravel with your kit this should be

added first so it covers the bottom distribution system. Add the other media supplied but make

sure there is 30%. free space left above the media so when the system is backwashed the

media can expand into the space and the sediment and contaminants can be backwashed

away (there may be media left over). See section 5.4 for more information on the Medias.

Unblock the riser tube.

5

2.4 Fitting the Valve

Add a small amount of silicone grease to the valve outer and inner o-rings (fig A.4 & 5).

Fig A.4 Fig A.5

If a top screen is supplied this should be attached next. (Not always used)

Slide the valve onto the riser tube and gently push it down onto the vessel treads. Screw the

valve on until you start to squeeze the main O ring and then finally give the valve a final

tighten by tapping the rear side of the valve with the palm of your hand (fig A.6)

Fig A.6

2.5 DLFC (drain line flow control)

This is possibly one of the most important components to check has been installed; this will

control the backwash flow rate and ensure the system will continue to function correctly. The

DLFC will either be fitted inside the drain line elbow, the 1” adaptor or in an external housing.

The larger external DLFC may have more than one flow controls fitted to gain the required

flow rate. See below pictures of the drain line housings.

¾” Elbow

Insert

1” External Straight 1.½” External

6

2.6 Electrical connection

To connect the power cable you need to firstly remove the

cover then remove the drive bracket assembly by pressing

up on the drive brackets release tabs and pulling towards

you, the drive bracket including software can now be lifted

away to reveal the back plate (fig A.7). Fig A.7

When the drive plate has been removed, locate the knockout on the

backplate. You can use a punch or a Phillips screwdriver to do this.

(fig A.8)

You can now re install the drive bracket into its original position.

Please make sure that this has been replaced correctly as this

can cause problems at a later date. Fig A.8

Fig A.9 Fig A.10 Fig A.11

Remove the tabs at the bottom of the strain relief on the back side of the back plate (fig A.9).

You can now connect the power cable to the valve and any additional cables that may be

needed for no hard water bypass (CI only) or micro switch cables through the knockout. After

connecting the cables you can weave the wires through the strain relief (fig A.10) and fit the

cover supplied (fig A.11)

7

CI Valve connections.

Connect NHWB here marked Drive if

used.

Connect power here marked 12V DC

When all connections have been made

the power can be turned on and

programming can take place.

TC Valve connection.

Connect power here marked 12V DC

4202035013

SNo 08090137

Mis

0919-255-760

CI connection

TC connection

When all the connections have been made the power can be turned on and site programming

can take place.

2.7 Identifying your system.

Your Filter will have an identification label fixed to the control valve; this will look similar to the

picture shown here.

The information listed can be read as follows:

Stock Number: Manufacturers part number.

Serial No: Serial No.

Id Code: System type identification code.

Configuration: Vessel size, Valve type & Controller type.

Identify the settings from the charts in the programming section by looking at the vessel size

and controller type.

8

The valve is supplied pre programmed!

(Excluding settings that need to be done on site)

The settings are listed in case there is a need to re program the

unit.

If you have any concerns or worries following the setting procedure please contact your

supplier who will help you through the set up procedure.

Using the above information to identify your system you can then select the relevant setting

sheet from the following pages.

2.8 Programming the Valve (CI Only)

Should the programming have been lost in transit the following instructions in

conjunction with the setting sheet will allow you to re set them.

When the power has been connected the valve will display the software number and initialise

itself and then display TIME; you can then start to program the valve.

Selections are made using the UP and DOWN

buttons until the required setting is displayed;

after each setting press NEXT to continue.

Set the Time of Day (As above)

Step 1: Cycle Sequence.

Press NEXT and DOWN simultaneously for 3 seconds and release.

The screen will display SOFTENING flashing!

Press NEXT and DOWN simultaneously for 3 seconds.

The screen should display SET 25, adjust as necessary (see setting sheet page?) Press

NEXT and set each setting accordingly until the display returns to TIME. (See notes if fitting a

Motorised Alternating Valve or No Hard / untreated Water Bypass valve)

Step 2: System Setup.

Press NEXT and DOWN simultaneously for 3 seconds and release.

The screen will display SOFTENING flashing. Change this to FILTERING.

The screen should display CYCLE 1, adjust as necessary (see setting sheet page?) Press

NEXT and set each setting accordingly until the display returns to TIME.

Quick Start CI.

Set Time of Day.

Press SET CLOCK.

Adjust the hours and press NEXT to adjust the minutes, press NEXT to return to the

normal TIME display.

9

Clack WS / CI Valves Set up as Filters. pH, Sand, Turbidex, Aquamandix, Birm, Arsenic.

Please apply the settings in the following sequence.

Selections are made using the UP and DOWN buttonsuntil the required setting is displayed.

After each setting press NEXT to continue.

Vessel Size 1044 1054 1252 1354 1465 1665 1865 2160 2469 3072 3672

Media Vol (1/2 Cuft) Filox 2 3 4 6 8 10 12 16 22

Media Vol (Cuft) Birm 1.5 2 2.5 3 3.5 5 6.5 9 15 20

Media Vol (Cuft) Turbidex 1 2 2.5 4 5 7 8 11

Media Vol (Kg) Sand 32 50 37.5 100 125 150 225 250 400 625 900

Media Vol (Kg) pH 50 62.5 100 125 150 225 250 400 650 925

Media Vol (Kg) Bayoxide 15 30 45 60 75 105 150 225 300

Media Vol (Kg) Carbon 20 25 35 50 63 85 100 150 200 300

Valves 1" 1" 1" 1" 1" 1" 1"

1.25" 1.5" 1.5"

2" 2" 2"

Step 1, Cycle Sequence,

Press NEXT and DOWN simultaneously for 3 seconds and release.

Screen will display SOFTENING flashing.

Press NEXT and DOWN simultaneously for 3 seconds, the screen will display SET 1, Adjust to the turbine setting below.

Turbine Size WS1 1 1 1 1 1 1 1

Turbine Size WS1.25 1.25

Turbine Size WS1.5 1.5 1.5

Turbine Size WS2 2 2 2

Alternating

DP

Set Hardness

SET Cycle 1

SET Cycle 2

SET Cycle 3

SET Cycle 4

SET Cycle 5

Step 2, System Setup.

Press NEXT and DOWN simultaneously for 3 seconds and release.

Screen will display SOFTENING flashing. Change this to FILTERING.

Cycle 1 Backwash 5 5 5 5 5 5 5 5 5 5 5

Cycle 2 Rinse 3 3 3 3 3 3 3 3 3 3 3

Cycle 3 2nd Backwash 5 5 5 5 5 5 5 5 5 5 5

Cycle 4 2nd Rinse 3 3 3 3 3 3 3 3 3 3 3

Cycle 5 End

Set Regen

Set Time Regen

Set rLY1 (Relay 1)

Set rLY2 (Relay 2)

Step 3, Display Settings.

Press NEXT and UP simultaneously for 3 seconds and release.

Regen Day

Regen Day (Arsenic)

Set Time Regen Hrs

Set Time Regen Min

Step 4. Set time of day,

Press SET CLOCK

Set hours using the up and down buttons.

Set minutes using the up and down buttons.

Off

PPM

Backwash

Rinse

END

or (see note 5 for options)

or (see note 6 for options)

2nd Backwash

2nd Rinse

Default 2:

31/05/2017

Software version from 332.2

Off

or (see note 1 for options)

Off

or (see note 2 for options)

Off

or (see note 3 for options)

End

3

14

Default :00

(will not show if Off selected above)

or (see note 4 for options)

Off

Step 3: Display Settings.

Press NEXT and UP simultaneously for 3 seconds and release.

HARDNESS with –nA- should appear on screen. Adjust as necessary (see setting sheet

page?) Press NEXT and set each setting accordingly; please pay particular attention to the

Regen Day and Regen Time settings, the display will return to the time of day after setting the

regen time (minutes) has been set.

The valves are supplied pre programmed. Listed below are the settings in case

there is a need to re program the unit.

10

Notes for CI valves software version 332.2

Starting a manual Regeneration Press and hold the REGEN button until the motor starts.

Set a delayed regeneration Press the REGEN button (REGEN TODAY) will flash on screen) press

the REGEN button again to clear.

Advancing through a regeneration Press the REGEN button to move to the next stage of regeneration.

Doing a soft reset Press & Hold REGEB & NEXT for 3 seconds. (resets valve in error).

Doing a total reset Press & Hold REGEB & NEXT for 3 seconds, then press & hold the

UP & DOWN buttons togeter for 3 seconds. (resets valves history).

Changing the service display Press NEXT to toggle to the next available display.

Note Options

1Off

ALT A

ALT B

SYS

SEPS

nHbP

2Off

dpon0

dPdEL

Hold

3Auto

OFF

M³

4NORMAL

On 0

Normal on 0

5OFF

Time on

L Softening on

6OFF

Time on

L Softening on

Error

7

8OFF

Delay

8a PrE

9PrE

Feature not used (standard setting)

Set on primary valve is using a standard duplex alternating systen (Duplex only)

Secondary valve if using a standard duplex alternating system (Duplex only)

If being used with a system controller.

Used if a separate source MAV is being fitted (requires 3 way Mav valve)

Used if a No Untreated Water valve is being fitted (no untreated water during regen)

Feature not used (standard setting) If used the following options are available)

If the contact is closed it will initiate an immediate regeneration.

If the contact is closed it will initiate a delayed regeneration.

If the contact is closed a regeneration will be prevented.

Activates after a set time from the start of a regeneration for a set period of time.

Capacity is automatically calculated and a reserve will be estimated.

Regenerations will be controlled from the day override setting (user settings)

Regeneration will occur immediately when the set capacity has expired.

If off or M³ is selected the hardness setting will not display in settings.

Regenerations will occur at the pre set time. (not available on alternating duplex)

Regenerations will occur immediately when capacity reaches zero.

Regeneration will occur at the preset time when volume is below the reserve or if

volume is below the reserve after 10 minutes of no water usage.

Feature not used.

Activates in service after a set number of litres for a set time and deactivates after

a set period of flow stops.

As above but during regeneration.

Feature not used.

L Softening Regen on

Activates in service after a set number of litres for a set time and deactivates after

a set period of flow stops.

As above but during regeneration.

Activates whenever the valve enters an error mode.

Activates after a set time from the start of a regeneration for a set period of time.

Add the KG of salt added to the brine bin each fill, doe's not show for 1.5 & 2" valves.

L Softening Regen on

Standard setting.

The last two cycles can be delayed (Rinse & Fill) this delays untl the on line unit is

depleted to 10%.

A pre sinse can be set to rinse the next cylinder before going into service (1" 2" & 1" TT)

A pre rinse can be set if required of up to 20 min duration.

Notes:

11

Programming the Valve (TC Only)

Should the programming have been lost in transit the following instructions in

conjunction with the setting sheet will allow you to re set them.

When the power has been connected the valve will display the software number and initialise

itself and then display TIME; you can then start to program the valve.

Selections are made using the UP and DOWN buttons until

the required setting is displayed; after each setting press

SET HOUR to continue.

Step 1: System Setup.

Press SET HOUR + UP button simultaneously for three seconds and release.

Then press SET HOUR + UP button simultaneously for three seconds and release.

Select the chosen program P7 to P9 (see setting sheet) two dashes with an arrow pointing

towards Min Fill will display; press SET HOUR to continue.

99 with an arrow pointing to Days to Regen will now flash select 99 and continue SET HOUR.

50 with three arrows each side will now flash select 50 and continue SET HOUR this

represents 50Hz frequency..

dp will now display; standard systems are not fitted with a dp switch and consequently this

setting is ignored.

Step 2: Display Settings.

Press SET HOUR + UP button simultaneously for three seconds and release.

The REGENERTION / BACKWASH time is now showing; use the UP and DOWN buttons to

adjust to the hour required (default 2am).

Days between REGEN / BACKWASH is now showing; use the UP and DOWN buttons to

adjust to the days required (default 3).

The valve can be set to regenerate on specific days; information is supplied in the full valve

manual (available on request)

Quick Start.

Set Time of Day.

Press SET HOUR and adjust time using the UP or DOWN buttons.

12

The valves are supplied pre programmed. Listed below are the settings in case there is a

need to re programme the unit.

13

3. Commissioning the Filter

3.1 Introduction

With the system fully plumbed (see below) and the valve programmed commissioning can

start.

3.2 Backwash

When the system is fully functional the backwash will happen at the pre-set time (see

programming the valve section). However, running a manual backwash during commissioning

is the best way of removing air from the system, bedding in the media and flushing the

system.

Make sure the water inlet and outlet are closed. Press and hold the regeneration button for 5

seconds. The motor will turn and the piston will move to the backwash position. Slowly half

open the water inlet to the system, and then slowly open the outlet to allow the air to be

purged from the system. Once this has been done you can fully open the inlet and outlet and

allow the system to continue through the backwash cycle, this will allow you to check for leaks

and also purge any remaining air from the system. After a backwash the system will move

through a short rinse cycle and then stop in the service position.

For new systems or after a media change it maybe necessary to run two backwashes to fully

wash the media (check the water at the end of the backwash is running clear).

For TURBIDEX please see below.

Initial backwash instructions for Turbidex filtration media.

Due to the naturally occurring dust and fine particles found in zeolites it is important to

thoroughly clean the new bed to prevent plugging of the distributor slots. Zeolite fines are

crystalline in structure and may get wedged in the slots, becoming very difficult to remove.

Important: Throughout this procedure, do not place the unit into rinse or service until you are

sure the bed has been cleaned of fines.

Always start the unit in backwash and slowly open the by-pass valve until the unit is full of

water (as evidenced by a gradual flow to drain). Shut off the by-pass and allow the unit to

Pressure

tank to

control

pump

Filter

sampling

point

OUTLET

Drain

Pump

Bypass

14

saturate for a minimum of one half hour for filters below 16”, one hour for 18” to 30”, 2 hours

for 36” to 48” and a minimum of 3 hours for larger vessels.

After the media has been fully saturated, open the by-pass until the full backwash flow is

reached. Inspect the water going to drain for evidence of the water being milky in colour.

Once the water going to drain begins to run clear, close the by-pass and allow the unit to

settle for 5 minutes.

Open the by-pass again and inspect the water going to drain, again you will notice a milky

colour in the water.

Repeat this procedure until there is no longer any colour in the water going to drain.

At this point you may rinse the filter for 10 to 30 minutes depending on the size and then

place the valve into the service position.

Note

Check the service and backwash flow rates (see technical information). If the service

flow rates are exceeded or the backwash flow rate is not correct then the filter may not

work correctly.

If during a backwash cycle you need to skip through the cycle this can be done in the

following way. To skip to the next stage press the REGEN button.

3.3 Service

Water flows into the valve at the top, down through the media and then up through the ‘riser’

tube in the middle of the vessel. As the water travels through the media the contaminants are

removed. The timer options are set to automatically self clean (backwash) and wash away any

of the accumulated contaminants.

4.Routine Maintenance

The filter system is designed to run with the minimum of maintenance and does not normally

require much adjustment.

Monthly

Check there is no sign of damage or leaks, check drain lines and power cables are still

in good condition and not kinked.

Yearly

We recommend that a competent service engineer checks the system annually. The

inlet and outlet pipes need to be rinsed, the drain line checked for degradation, and the

system flushed through. The media should be checked, if pH it probably needs to be

topped up.

The quality of the treated water needs to be checked regularly. How regularly depends on

what the water is being used for eg drinking water or irrigation etc. If the water is being used

for drinking water then it needs to be checked more regularly and the relevant Private Water

regulations covers the sampling and testing routines for England this is “The Private Water

Supplies Regulations 2009” No. 3101. However it is sensible to at least partially test the

treated water every 3 months or so and certainly every 6 months to look for compliance. A

competent water treatment company can help with this.

15

5. Technical Information

Note: Check the service and backwash flow rates (see technical information). If the

service flow rates are exceeded or the backwash flow rate is not correct then the filter

may not work correctly.

5.1 Process and Operating Data.

Birm

Vessel size

C1054

C1248

C1354

C1465

C1665

C1865

C2160

C2469

C3072

C3672

Service flow rate - m3/hr

0.6

0.9

1.0

1.2

1.6

2.0

2.7

3.6

5.6

8.0

Backwash flow rate - m3/hr

1.1

1.8

2.0

2.3

3.4

3.9

5.7

6.8

11.4

17.1

Birm can be used for iron and manganese removal by oxidation (up to 15ppm). It requires a

pH of 7 or more for iron removal and pH 8 for manganese removal (it uses dissolved oxygen

in the water to oxidise the metal). As it acts a catalyst it is not consumed so Birm doesn’t

require regenerating or topping up (does require backwashing). Birm also has the advantage

of acting as a filter removing relatively high levels of turbidity. It is advised not to use Birm in

combination with chlorination and the water should be free of oil, polyphosphates and

hydrogen sulphide. Alkalinity should be greater than twice the sulphate and chloride level and

the organic loading should be below 5ppm. If the pH of the water is too low pH correction

maybe required by adding a pH correction media such as Juraperle or Corrosex. Birm

requires a dissolved oxygen of at least 15% of the iron and manganese content to work..

Freeboard 30% to 50%

Filox

Vessel size

C1054

C1252

C1354

C1465

C1665

C1865

C2160

Service flow rate - m3/hr

2.0

2.7

3.3

4.0

5.3

5.7

6.1

Backwash flow rate - m3/hr

1.8

2.3

3.1

3.7

4.7

5.4

5.7

Filox can be used for iron and manganese and hydrogen sulphide removal by oxidation. It

requires a pH of 7 or more for iron removal and pH 8 for manganese removal plus a dissolved

oxygen level of at least 15% of the iron and manganese content. It needs a high backwash

flow rate to remove the oxidised iron and manganese but can cope with high service flow

rates. Filox can also cope with chlorinated water. NSF certified, Freeboard 30% to 50%

pH Media

Vessel size

C1054

C1248

C1354

C1465

C1665

C1865

C2160

C2469

C3072

C3672

Service flow rate - m3/hr

0.6

0.9

1.0

1.2

1.6

2.0

2.7

3.6

5.6

8.0

Backwash flow rate - m3/hr

1.1

1.8

2.0

2.3

3.4

3.9

5.7

6.8

11.4

17.1

Water with a pH below 7 is acidic and can damage copper pipe-work and heating systems.

Raising the pH will neutralise the water stopping the corrosivity, removing the metallic taste.

The pH is raised by passing the water through a vessel containing slowly dissolving calcium

and magnesium salts. These salts slowly dissolve into the water 're-mineralising’ the water

and naturally raising the pH. Make sure that there is 30% freeboard.

Juraperle: a granular media made up of 99.4% calcium carbonate. It has a superior

performance to limestone due to its micro-crystalline structure and dissolves very

slowly. Juraperle is consumed and from time to time new media should be added.

16

Corrosex: a highly magnesium oxide salt and is used most effectively where the pH

correction is substantial or the flow rate is high. In reality for a pH of less than 6 a 25%

Corrosex, 75% Juraperle mix is ideal.

Sediment filters:

Sand, Filter Ag & Turbidex

Vessel size

C1054

C1248

C1354

C1465

C1665

C1865

C2160

C2469

C3072

C3672

Service flow rate - m3/hr

0.6

0.9

1.0

1.2

1.6

2.0

2.7

3.6

5.6

8.0

Backwash flow rate - m3/hr

1.1

1.8

2.0

2.3

3.4

3.9

5.7

6.8

11.4

17.1

Sediment filters are needed when the water supply is cloudy or turbid. The particles in the

water will block plumbing systems, leave unsightly staining, may contain toxic chemicals or

bacteria. The easiest way to remove the particles is by passing the water through a media

where the particles get stuck and allowing clear water to flow through. The particles can be

periodically ‘backwashed’ away to drain.

Sand: The grade of sand is tightly controlled so only highest quality; triple washed 0.5 to

1mm size water treatment grade sand is used. Particles above 40 micron are typically

trapped.

Filter Ag: Has a high surface area and complex flow path for a more efficient removal of

suspended matter. Filter Ag is also lighter in weight than sand which reduces backwash flow

rate. Particles down to 20 micron can be trapped. Filter Ag should be soaked for 24 hours

before use.

Turbidex

Vessel size

C844

C1054

C1248

C1354

C1465

C1665

C1865

C2160

C2469

C3072

Service flow rate - m3/hr

0.9

1.5

2.19

2.50

2.9

3.8

4.8

6.6

8.6

13

Backwash flow rate m3/hr

1.2

1.9

2.7

3.1

3.6

4.8

5.7

8.2

10.7

17.4

Turbidex: A natural ore that has a more irregular surface than sand. Giving more efficient

removal of suspended matter and means the equipment can be smaller. Particles down to 5

micron are typically removed. Turbidex has a different commissioning process!

Arsenic Removal Media

Vessel size

C1054

C1248

C1354

C1465

C1665

C1865

C2160

C2469

C3072

C3672

Service flow rate - m3/hr

1.1

1.5

1.8

2.0

2.6

3.2

4.5

5.9

9.2

13.5

Backwash flow rate m3/hr

1.3

1.9

2.2

2.4

3.3

4.2

5.6

7.3

11.5

16.5

Severn Trent worked to develop an arsenic removal media formulated to give a high arsenic

removal capacity. The media is strong, reliable and easy to handle. Arsenic is trapped within

the media and held even when it is backwashed. Typical life time of the media depends on

arsenic levels and the amount of water used. A 1054 system with 1 bag of media (15 Kg) can

typically be expected to treat 1500m3 of water at 50ug/l Arsenic .For a family of 4 the media

should last about 6 years.

Pre-treatment may be necessary as the raw water must contain: Iron <200ug/l, Manganese:

<50ug/l, Silica (SiO2) <40mg/l, Phosphate: <200ug/l, pH: 6.5 to 8.5, suspended

solids:<10mg/l.

Backwash frequency 14-28 days.

17

WS1 TC WS1 CI WS1.25 CI WS1.5 CI WS2CI WS1 TC WS1CI WS1.25CI WS1.5 CI WS2 CI

Vessel Vessel

1044 1865

WxDxH cm 26x32x131 WxDxHcm 46x46x198 46x46x198 46x46x198

46x46x198

46x46x201

Weight Kg 66 Weight Kg 312 312 312 320 324

1054 2160

WxDxH cm 26x32x156 26x32x156 26x32x156 WxDxHcm 54x54x182 54x54x182 54x54x182

54x54x182

54x54x185

Weight Kg 68 68 68 Weight Kg 336 336 336 344 348

1248 2469

WxDxH cm 31x32x141 31x32x141 31x32x141 31x31x141 31x38x144 WxDxHcm 61x61x207

61x61x207

61x61x210

Weight Kg 77 77 77 85 218 Weight Kg 498 506 510

1354 3072

WxDxH 33x33x156 33x33x156 33x33x156 33x33x156 33x38x159 WxDxHcm

76x76x223

76x76x226

Weight Kg 129 129 129 137 141 Weight Kg 799 804

1465 3672

WxDxH cm 36x36x185 36x36x185 36x36x185 36x36x185 36x38x188 WxDxHcm

92x92x230

92x92x233

Weight Kg 170 170 170 178 182 Weight Kg 1115 1121

1665 Weight based on Sand asmedia

WxDxH cm 41x41x186 41x41x186 41x41x186 41x41x186 41x41x189

Weight Kg 205 205 205 213 217

Valve Fitted

Valve Fitted

Activated Carbon

Vessel size

C1054

C1248

C1354

C1465

C1665

C1865

C2160

C2469

C3072

C3672

Service flow rate - m3/hr

1.1

1.5

1.8

2.0

2.6

3.2

4.5

5.9

9.2

13.5

Backwash flow rate m3/hr

1.3

1.9

2.2

2.4

3.3

4.2

5.6

7.3

11.5

16.5

Activated carbon (GAC) works by absorbing soluble pollutants onto its surface and holding

them. Eventually all the pores are filled and the carbon needs to be replaced. GAC is used to

reduce chlorine, natural colours and odours from water.

5.2 Standard Hydraulic Connections (BSP).

Valve

WS1 CI/TC

WS1.25 CI

WS1.5 CI

WS2 CI

Inlet

1”

1.25”

1.5”

2”

Outlet

1”

1.25”

1.5”

2”

Drain

.75”

.75”

.75”

1.5”

5.3 Approximate dimensions and weight for a single unit.

18

5.4 Installation Layout

Pressure

tank to

control

pump

Filter

sampling

point

OUTLET

Drain

Pump

Bypass

19

Troubleshooting

20

Other manuals for WS CI Series

1

This manual suits for next models

6

Table of contents

Other Clack Water Filtration System manuals

Popular Water Filtration System manuals by other brands

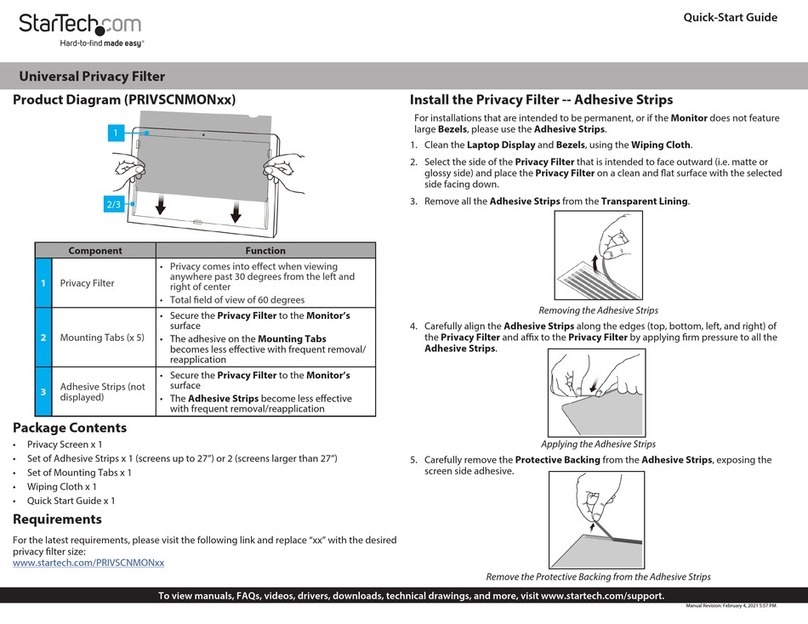

StarTech.com

StarTech.com PRIVSCNMON Series quick start guide

HoMedics

HoMedics AP-T10FL Replacement

Clear2O

Clear2O CAB350BL use and care manual

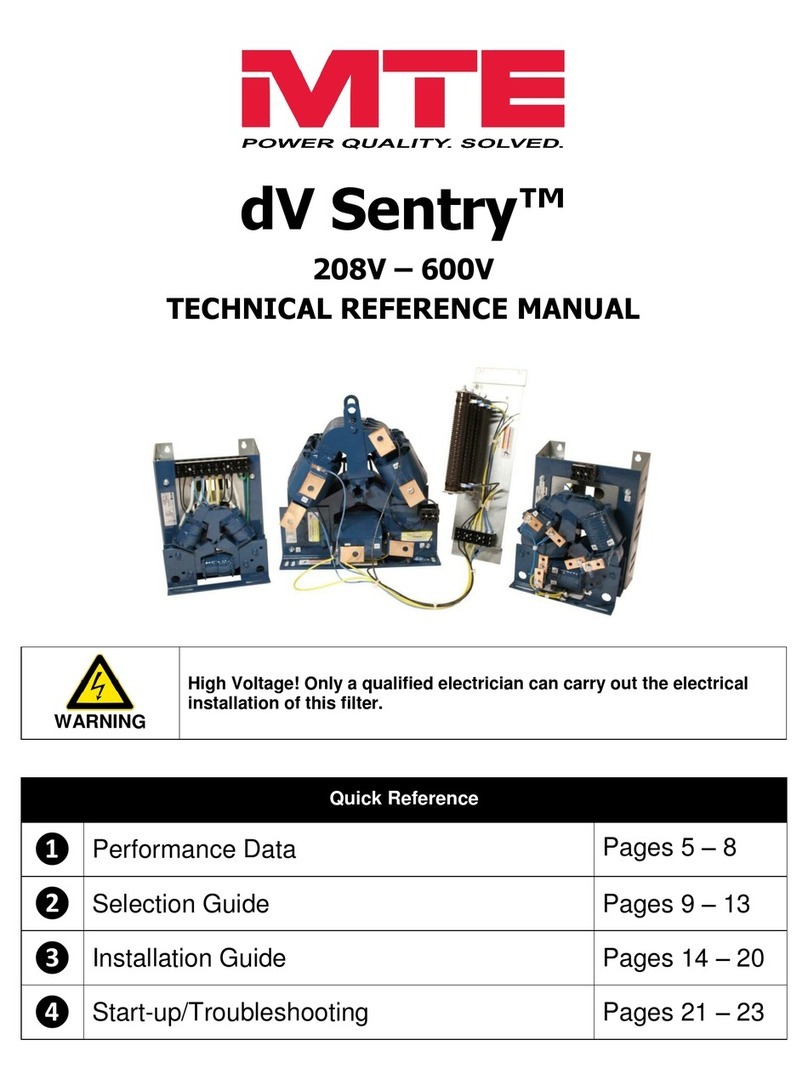

MTE

MTE dV Sentry Technical reference manual

UNITED

UNITED Tower-Flo TFH Series Engineering, Installation, Operation & Maintenance

Hamilton Beach

Hamilton Beach Brita Hub manual