2 3

MA-EN-OSMOSIS XENA10.1-RO-0220-22-FLC-21-V01.0 MA-EN-OSMOSIS XENA10.1-RO-0220-22-FLC-21-V01.0

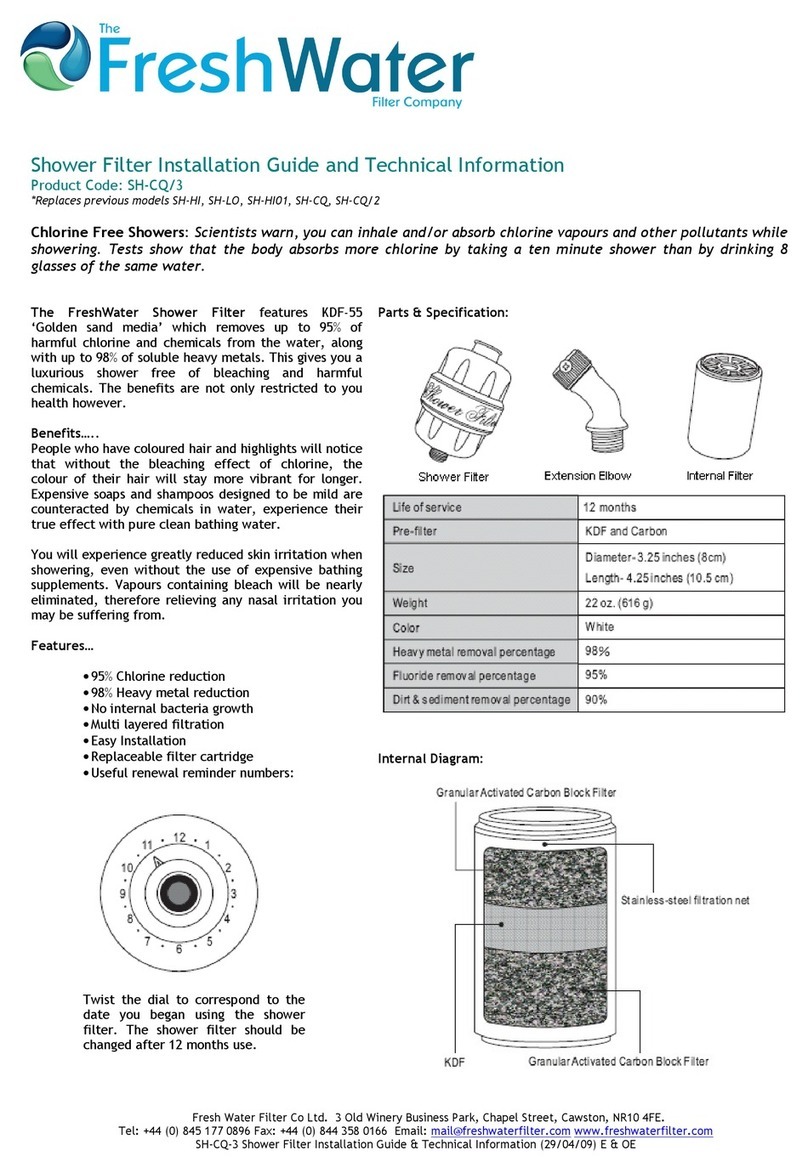

1.- INTRODUCTION

This manual explains the installation and operation of equipment for water treatment by reverse

osmosis for household use. The equipment has been designed to be connected to the housing facility.

It is easy installation and operation as it has already been semi-assembled. It requires very little

assembly as it is only necessary to connect the hydraulics, electrics and install the faucet as indicated

in point 4 of this manual.

In the absence of installation and maintenance as described in this manual by technically

qualied personnel to ensure the quality of water produced and proper installation, the

warranty is void.

2.- PRECAUTIONS AND WARNINGS

Please read this manual carefully following the warnings listed below before going ahead

with the installation and use of the XENA 10.1 osmosis system. If you have any doubts, please

contact your distributer.

• For the correct operation of osmosis systems with a pump, the pressure should be between

1 and 3 bars, for this reason a pressure regulator has been supplied with the system to

be installed at the system inlet. In doing so, this will avoid damaging the pump and other

components of the system.

• The temperature of the water to be treated should not be below 5ºC nor above 35ºC to avoid

damaging the system.

• The osmosis system is designed to treat tap water with a maximum salinity of 1000 ppm. Do not use

in places where the water is not microbiologically safe or has an unknown quality. For water with a

greater salinity level, please contact your distributor.

• It is advisable that the water to be treated has been softened or with a maximum hardness of

15ºHF for optimum performance. Water with a hardness greater than 15ºHF will shorten the life

of the membrane.

• If the water has a high concentration of iron or magnesium, nitrate concentration greater than 100

ppm, sulphate concentrations greater than 250 ppm, more than 3 NTU turbidity and/or prolonged

use of high chlorine levels, please contact your distributor to suggest an appropriate pre-treatment

system to ensure the correct operation of the system.

• The osmosis system reduces the level of the following elements; aluminium, ar-senic, bromoform,

chlorine, chlorides, copper, conductivity, chrome, dibromo-chloromethane, uorides, nitrates,

oxidability, pH, selenium, sodium, sulphates, PAHs, trihalomethanes and other dissolved solids.

• If the osmosis system is not going to be used for a long period of time, close the water passage.

• Install the system on a at surface.

• Do not expose the system to direct sunlight or install it outdoors.

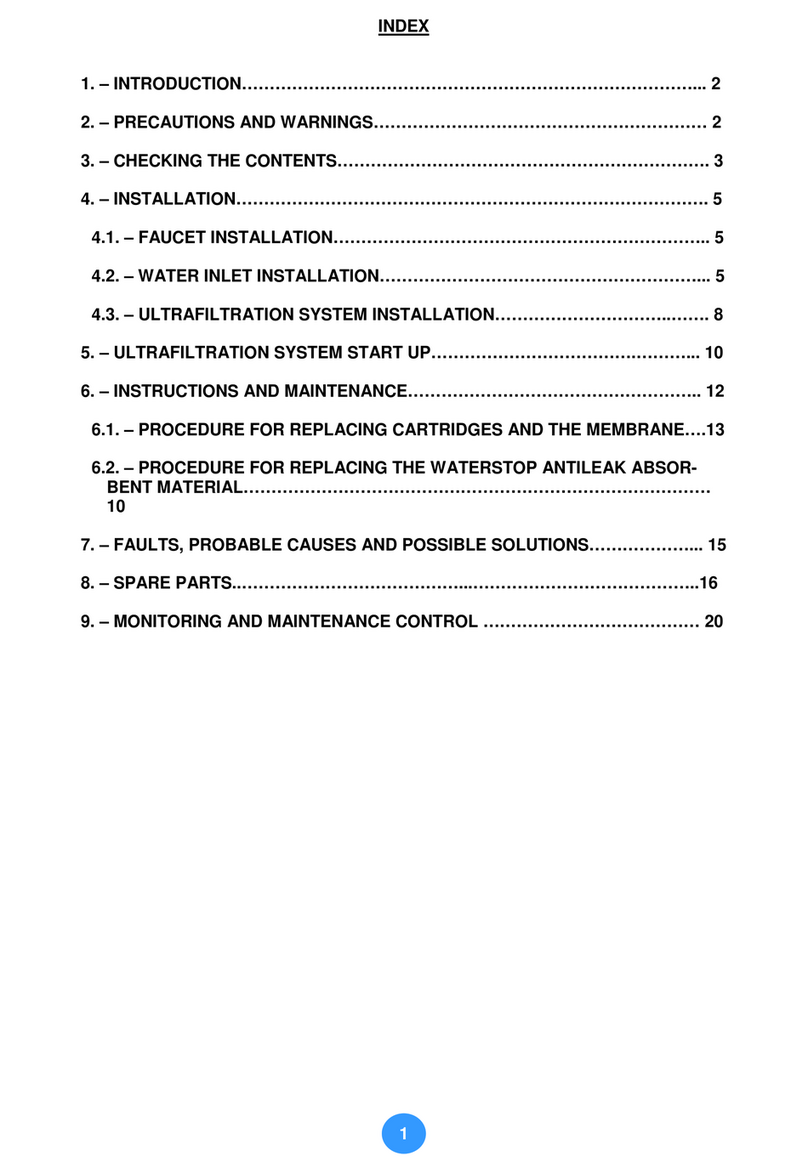

INDEX

1.- INTRODUCTION..........................................................................................................3

2.- PRECAUTIONS AND WARNINGS ............................................................................3

3.- CHECKING THE CONTENTS ....................................................................................4

4.- INSTALLATION...........................................................................................................6

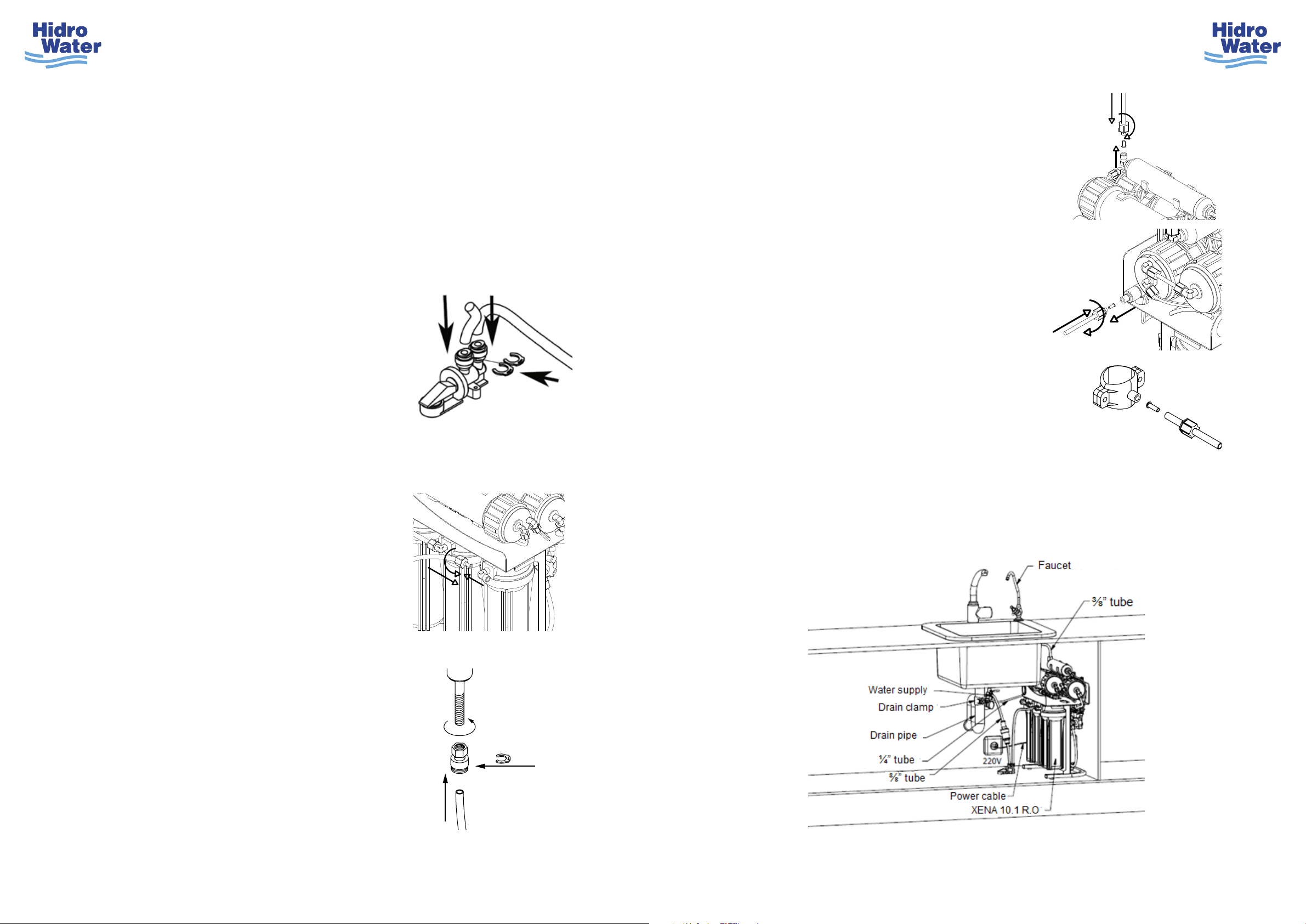

4.1.- Faucet installation (Figure-3)....................................................................................................... 6

4.2.- Water inlet installation (Figure-8 & Figure-9).............................................................................. 6

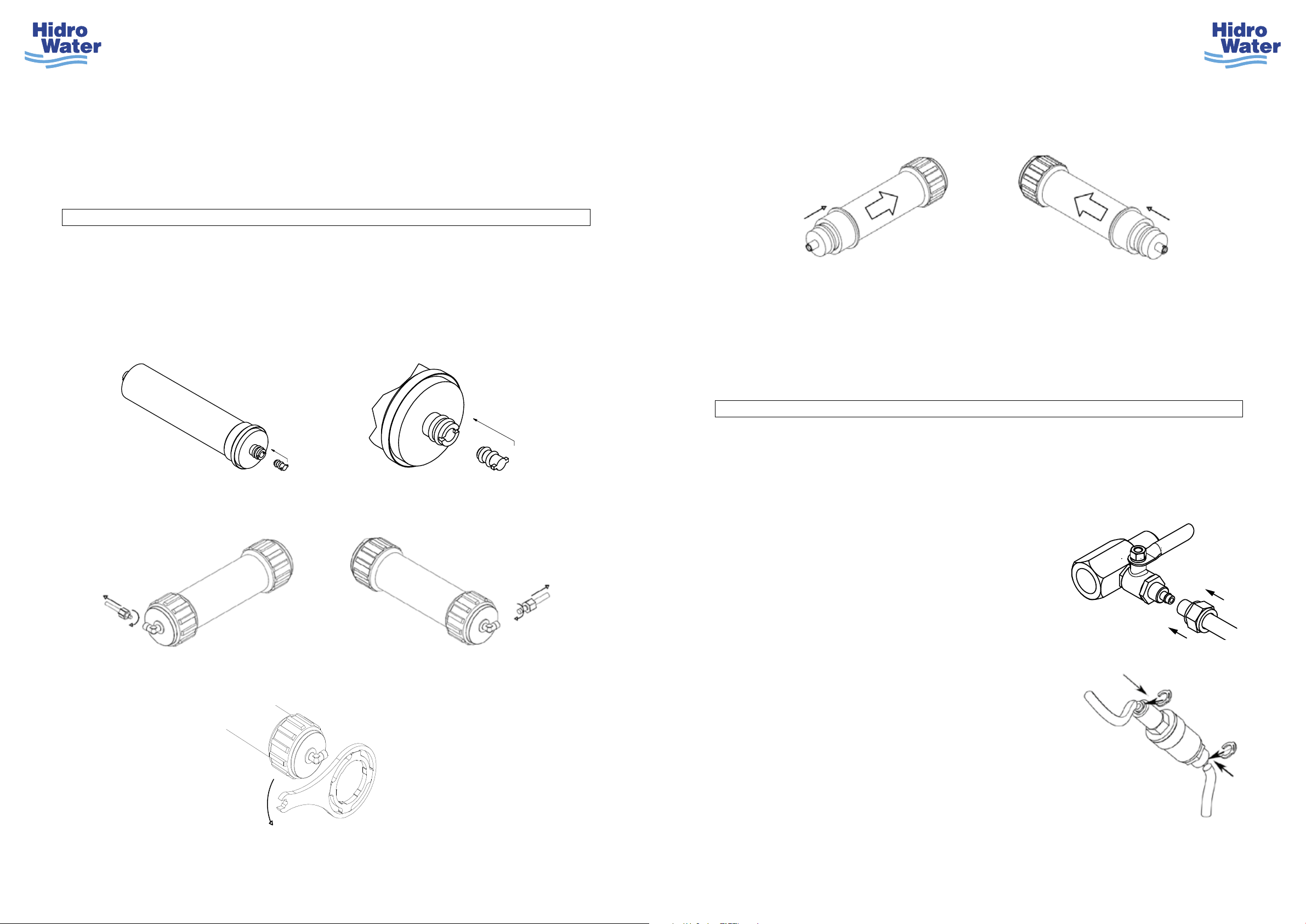

4.3.- Drain clamp installation (Figure-7) .............................................................................................. 7

4.4.- Cartridge installation.................................................................................................................... 7

4.5.- Membrane installation.................................................................................................................. 8

4.6.- Osmosis system installation ....................................................................................................... 9

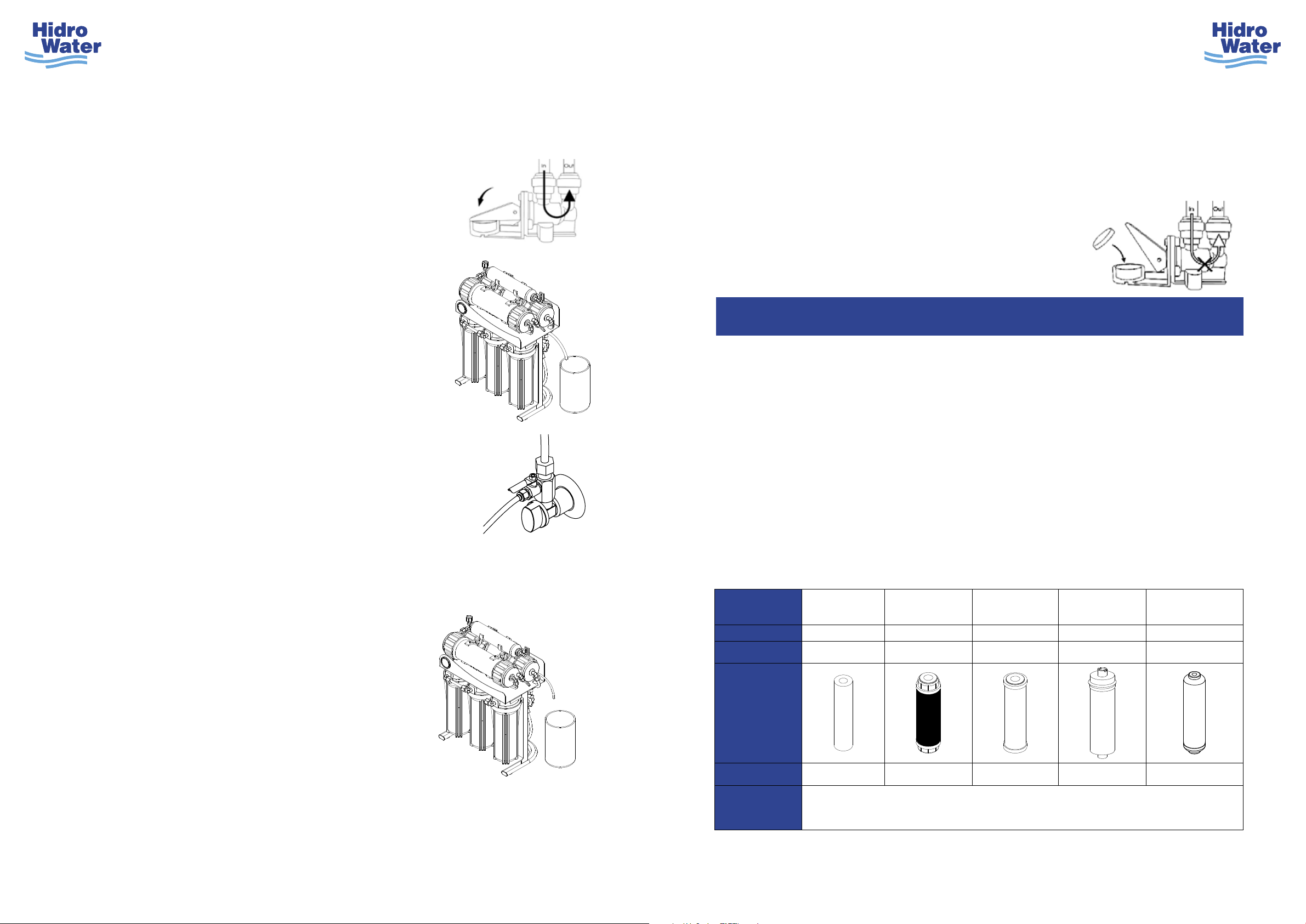

5.- OSMOSIS SYSTEM START-UP...............................................................................12

6.- INSTALLATION AND MAINTENANCE...................................................................13

6.1.- Procedure for replacing cartridges and the membrane............................................................ 14

7.- FAULTS, PROBABLE CAUSES AND POSSIBLE SOLUTIONS...........................16

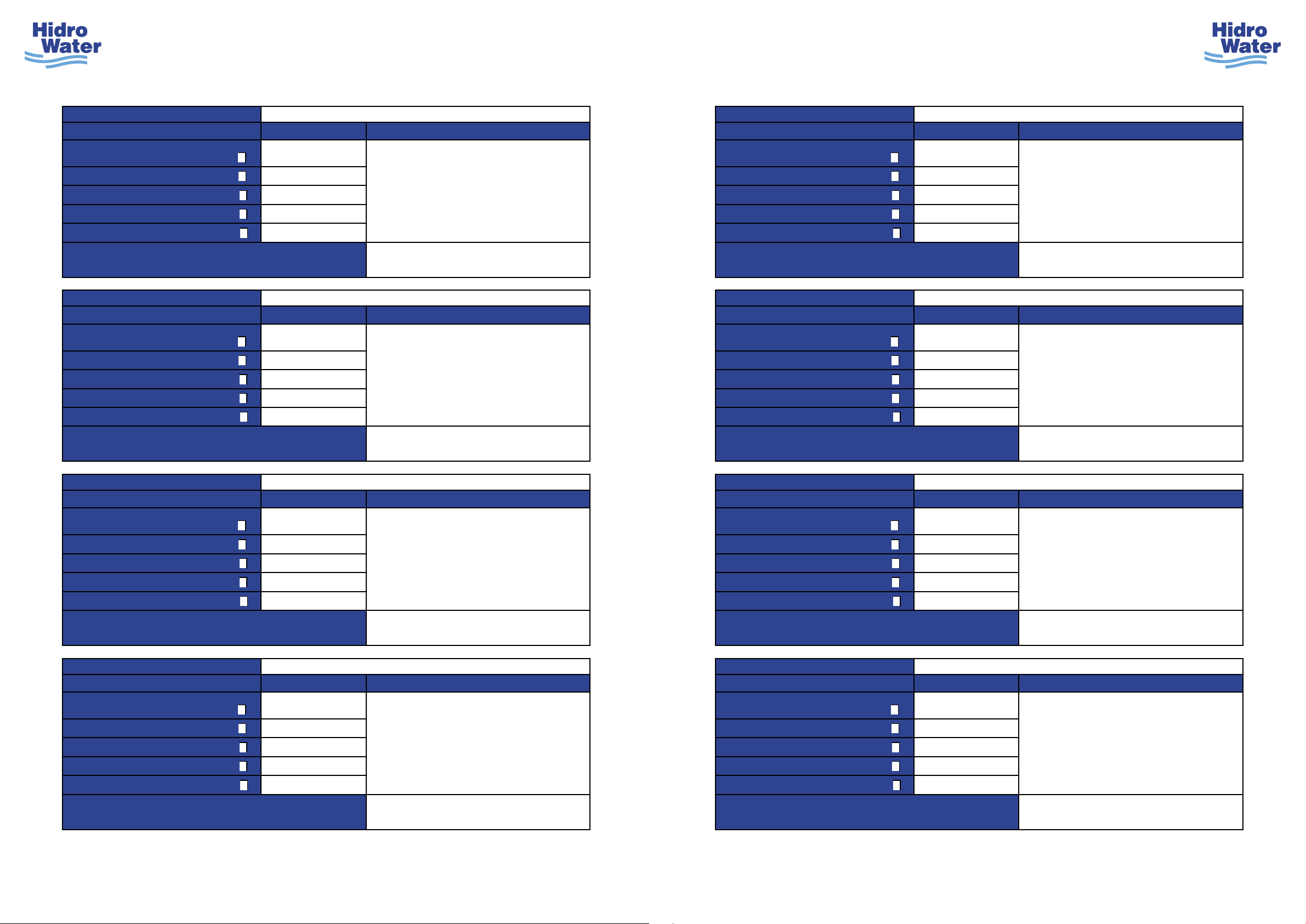

8.- MONITORING AND MAINTENANCE CONTROL ..................................................18

9.- SPARE PARTS ..........................................................................................................20