Project Specications

6

United Industries, Inc.

P.O. Box 58

Sterling, KS 67579

800-835-3272 • 620-278-3160

Fax 800-500-3115 • 620-278-3115

www.towerflo.com

Form TFH-PSP-1/3:2/17

Data presented here is the best available at the

time of publicaton. United Industries and/or its

representatives assume no liability for its use.

Series

TFH

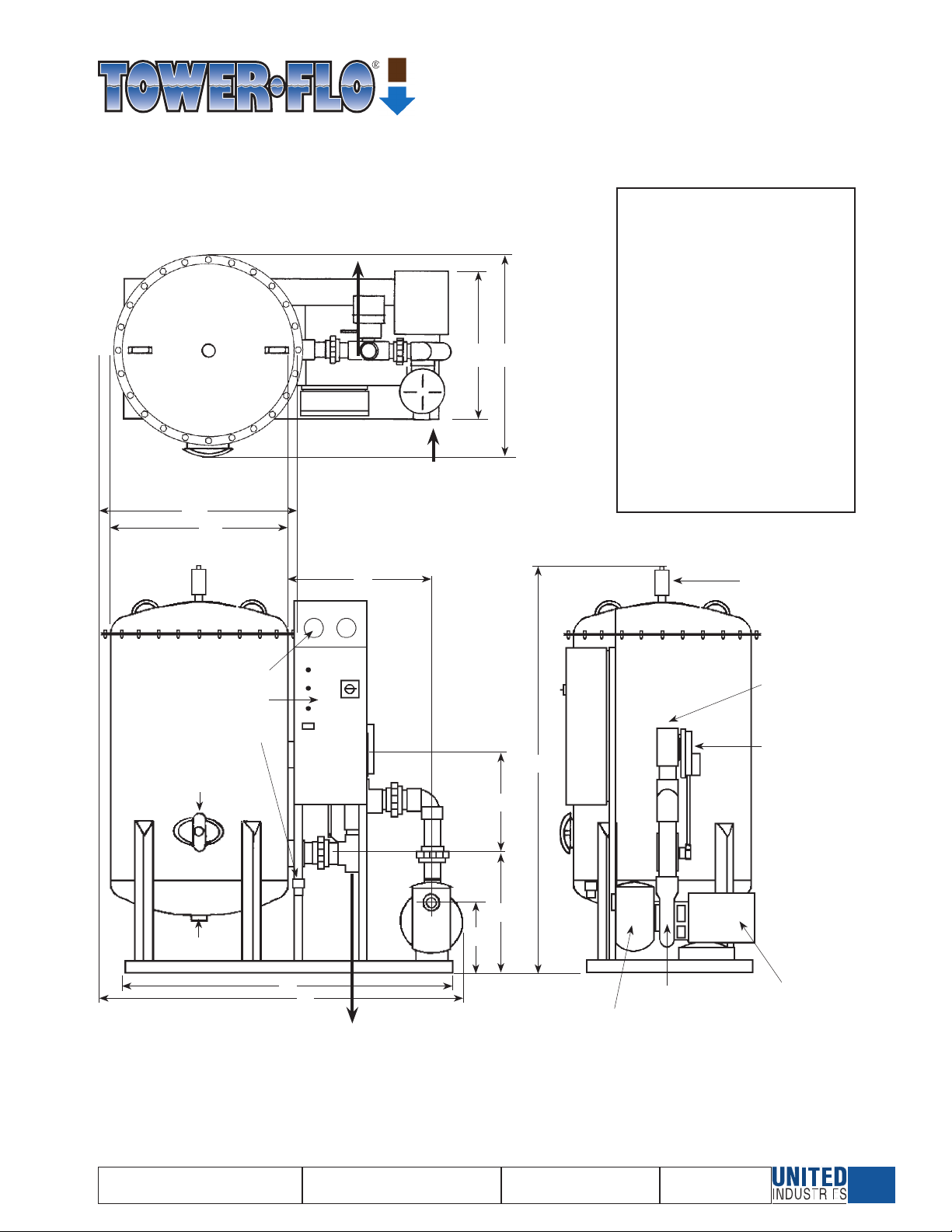

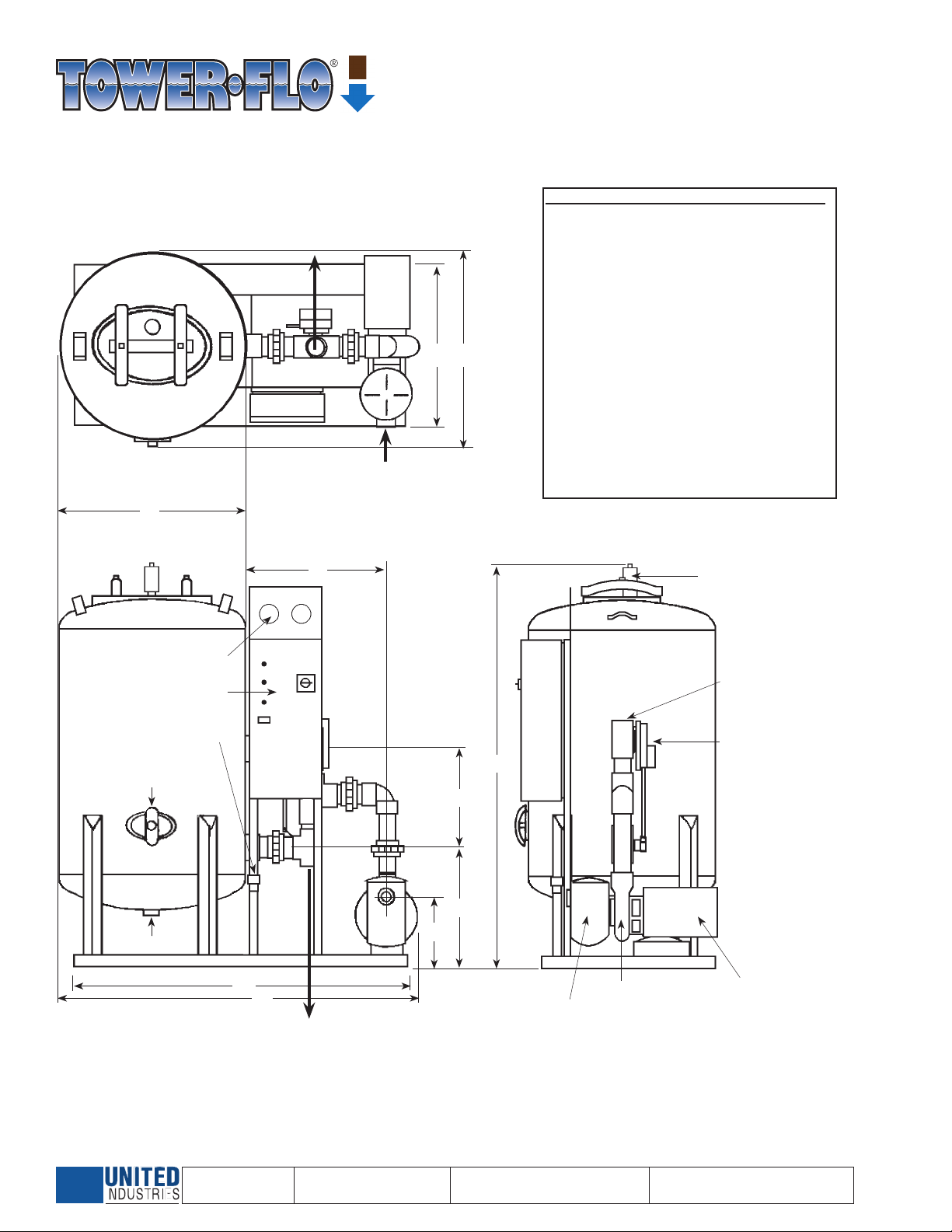

TOWER-FLO® Series TFH self-contained filter plants shall consist of the following major components: base, pump, motor,

strainer, facepiping, valve, controls, and filter vessel. The system shall be shipped as a complete factory assembled and tested

unit. Filter media shall be shipped with the unit for field installation.

Project: ________________________________________________________ Date: ______________________

The TOWER-FLO Series TFH Model being specified for this project is a TFH-____ with a maximum filter rate of _____ GPM.

___ unit(s) is(are) specified and each unit shall be equipped with the following components:

COMPONENT SPECIFICATION

BASE ___ Standard: Structural steel channel and plate, primed and coated.

PUMP ___ Standard: TFH-18, -24, -30: Self-priming, close grain cast and machined brass volute, impeller, and pump-to-

motor coupling; close coupled to the motor; and capable of ____ GPM at ____ feet TDH.

___ Standard: TFH-36: Flooded suction, machined cast iron volute, bronze fitted, close coupled to the motor

and capable of ____ GPM at ____ feet TDH.

___ Option: TFH-36: Self-priming pump, machined cast iron volute, bronze fitted, close coupled to the motor

and capable of ____ GPM at ____ feet TDH.

MOTOR ___ Standard: TFH-18, -24, -30: TEFC, heavy gauge rolled steel case, NEMA 56C frame, Class F insulation,

double shielded prelubricated ball bearings; UL®and CSA®listed; ____ HP; and at the follow-

ing VAC, phase and Hz: ___________________.

___ Standard: TFH-36: TEFC, heavy gauge rolled steel case, NEMA 145JM frame, Class F insulation, double

shielded prelubricated ball bearings; UL®and CSA® listed; ____ HP; and at the following VAC,

phase and Hz: ___________________.

___ Option: 575V.

STRAINER ___ Standard: TFH-18, -24, -30: Basket type, brass body, ABS basket, brass cover with o-ring, held in place

by two brass lockhandles.

___ Option: TFH-18, -24, -30: Delete strainer on installations where inlet pressure exceeds 30PSI.

___ Standard: TFH-36: Cast iron body; stainless steel basket; cast iron cover with gasket, held in place with a

yoke and bolt clamp (60 PSI @ 150˚ F).

FACEPIPING ___ Standard: Steel; backwash sight glass; influent / effluent pressure gauges, 0-160 psi, liquid-filled

___ Option: Type 304 Stainless Steel (with brass or stainless steel valves).

___ Option: Fresh water backwash from municipal water supply; includes facepiping modifications, flow

control valve for field installation; end-user responsible for the addition of pressure regulator

(maximum 30 psi) and/or backflow preventer, if required.

___ Option: Fresh water backwash from static water supply using pump to assist.

VALVES ___ Standard: Brass, 3-way ball valves, with electric actuation.

___ Option: Stainless steel (with steel or stainless steel facepiping).

141 GPM MAX FLOW RATE 100 PSI WORKING PRESSURE

Model Base HP Max TDH Full Load Amp Draw Media Operating

Number Dimensions GPM Ft. Single Phase Three Phase Area Vol Weight

S.F. 115V 208V 230V S.F. 208V 230V 460V SqFt CuFt* in Lbs

TFH-18 16.75" x 38" 1 35 65 1.15 12.0 6.6 6.0 1.15 3.2 3.6 1.8 1.8 4.0

TFH-24 22" X 46" 1.5 65 50 1.0 17.0 8.8 8.5 1.15 4.4 4.2 2.1 3.14 7.0 2488

TFH-30 26" X 52" 3 100 45 1.0 - 14.0 14.2 1.15 8.1 8.0 4.0 5.0 9.0 2957

TFH-36 30" X 58" 3 141 45 1.15 - - - 1.15 9.1 8.3 4.1 7.0 14.0 3910

*1 Cubic foot of media = 100 lbs.