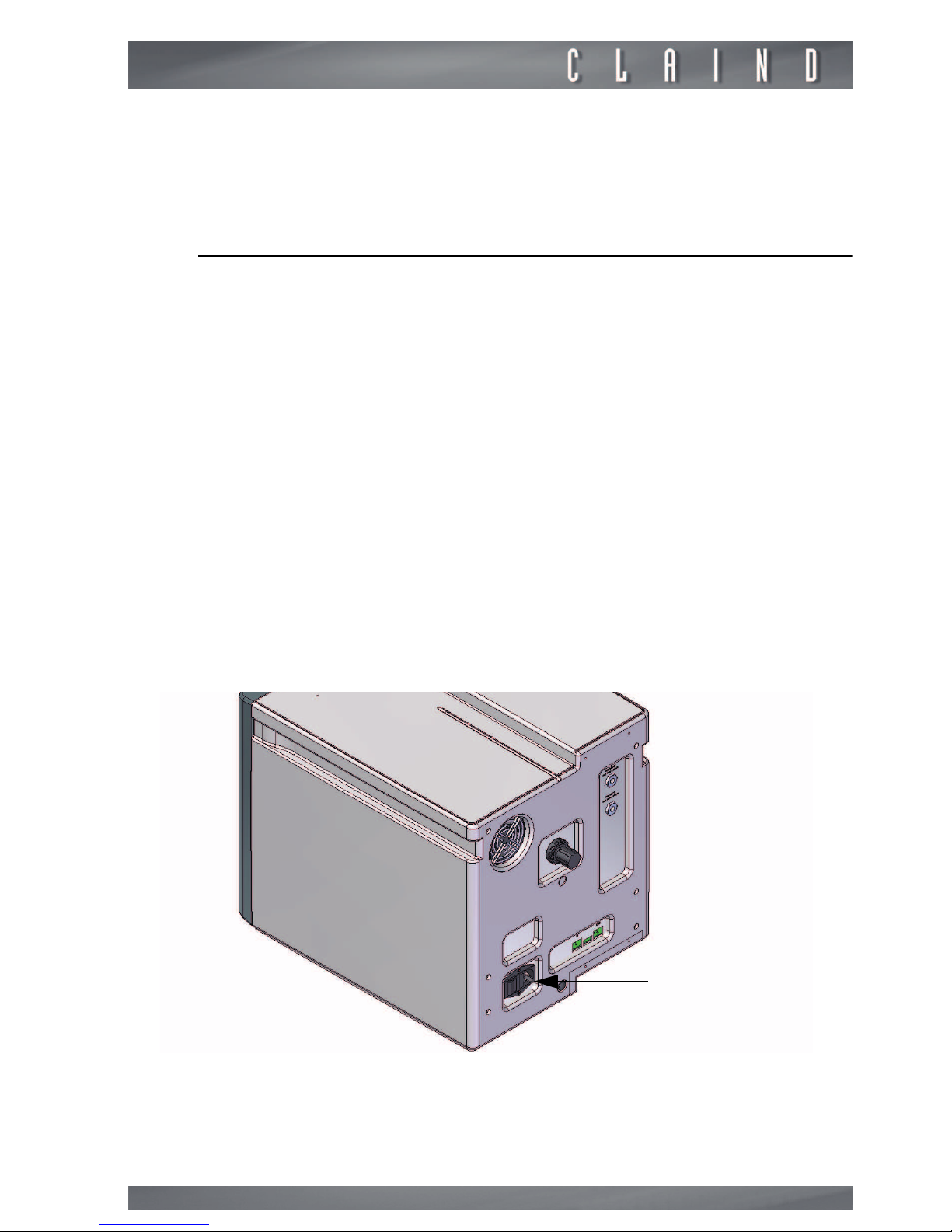

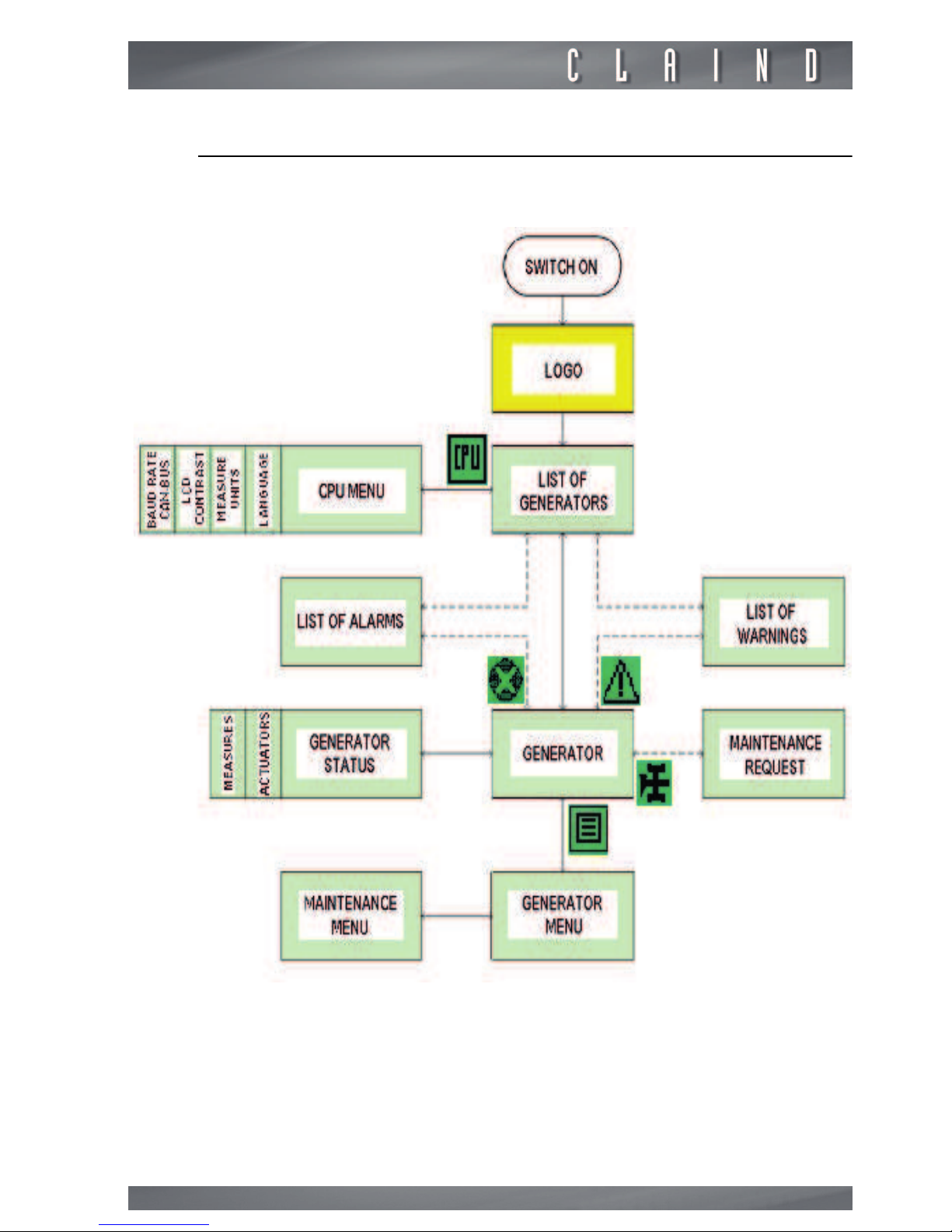

Claind NiGen GC User manual

This manual suits for next models

2

Table of contents

Popular Inverter manuals by other brands

APsmart

APsmart RSD-D Quick installation guide

Chicago Electric

Chicago Electric 93096 Assembly and operating instructions

Rowan Elettronica

Rowan Elettronica C350 Series Safety manual

Roger Technology

Roger Technology B71/PBX Instruction and warnings for the installer

EAS Electric

EAS Electric EINSOLAR36Y Quick installation guide

Xantrex

Xantrex PowerHub PH1800 Operator's guide

Mastervolt

Mastervolt whisper 3.5m installation manual

Siemens

Siemens MICROMASTER 430 operating instructions

Generac Power Systems

Generac Power Systems G0065510 owner's manual

SMA

SMA SUNNY TRIPOWER CORE1 Quick reference guide

Duratech

Duratech DURAFLOW DFI-150 manual

Fimer

Fimer UNO-DM-1.2 Quick installation guide

Atlas Copco

Atlas Copco QAS108 Pd(S) Mk II instruction manual

SAJ

SAJ R6 Series user manual

ZIEHL-ABEGG

ZIEHL-ABEGG ZA dyn 4C Original operating instructions

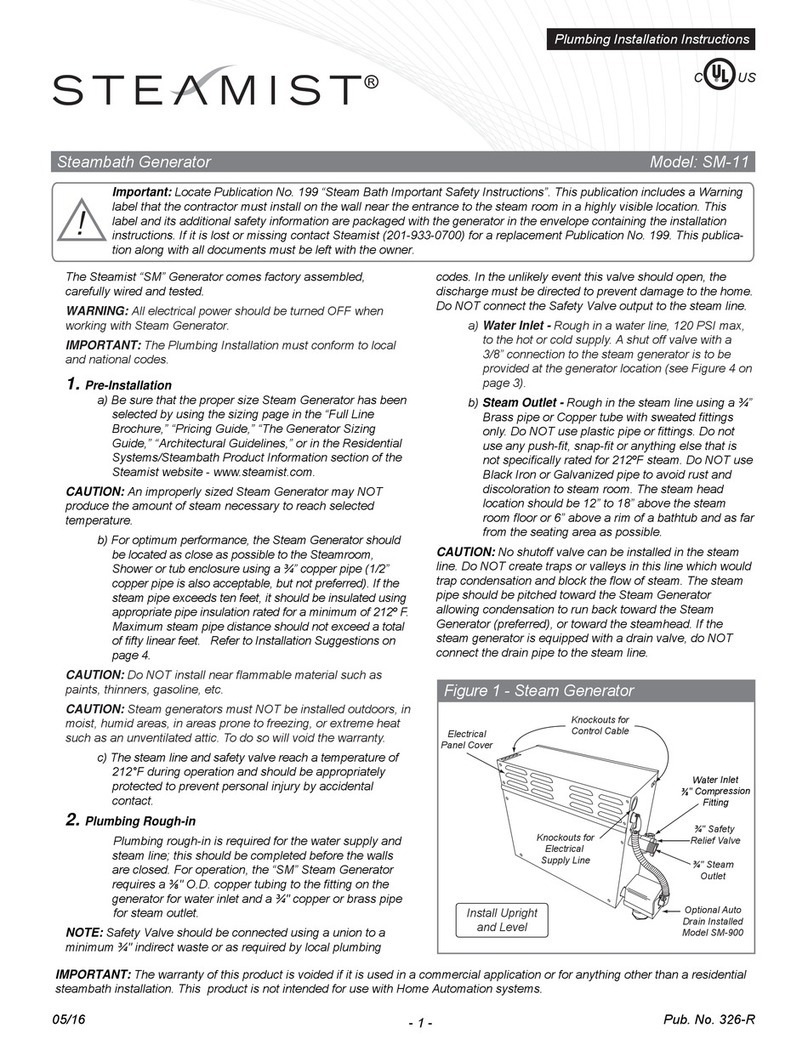

Steamist

Steamist Plumbing Installation Instructions Plumbing installation instructions

GYS

GYS PSW 601 W manual

Agilent Technologies

Agilent Technologies E4428C Configuration guide