Clare Instruments Inc. Safe Check 5s User manual

Rental Industry Safety Tester

Safe Check 5s

Feb 2006 © 2006 Clare Instruments Inc.

Issue 2.0 Firmware Version : 1.2a

Your Safety Tester

i

Limited Warranty & Limitation of Liability

Clare Instruments Inc, guarantees this product for a period of one year. The

period of warranty will be effective at the day of delivery.

In order to ensure the continued performance of this product Clare

recommends that this tester be serviced and calibrated on an annual basis,

by Clare Instruments Inc. or any of Clare’s authorised service center using

Clare’s approved parts and components.

Any unauthorised modifications, tampering or physical damage sustained

through negligent use or handling will void your warranty.

© Copyright 2005

All rights reserved. Nothing from this edition may be copied for reproduction,

or made public in any form or manner, either electronically, mechanically, by

photocopying, recording, or in any manner, without prior written consent

from Clare Instruments Inc. This also applies to accompanying drawings

and diagrams.

Due to a policy of continuous development Clare Instruments Inc. reserves

the right to alter the equipment specification and description outlined in this

publication without prior notice and no part of this publication shall be

deemed to be part of any contract for the equipment unless specifically

referred to as an inclusion within such contract.

Your Safety Tester

ii

Table of Contents

BEFORE STARTING.......................................................2

SAFETY...........................................................................3

WARNING .......................................................................4

INTRODUCING THE TESTER.........................................5

Introduction................................................................................5

Standard Accessories................................................................5

Optional Accessories.................................................................5

SPECIFICATIONS...........................................................6

Input Rating ...............................................................................6

Ground Bond Test .....................................................................6

Short to Case Test.....................................................................6

Short to Line Test ......................................................................6

Leakage Test.............................................................................6

PURPOSE OF THE TESTS.............................................7

Ground Bond Test .....................................................................7

Short to Case Test.....................................................................7

Short to Line Test ......................................................................7

Leakage Test.............................................................................7

Extension Cord Test..................................................................7

DEFINITIONS ..................................................................8

SWITCHING ON THE TESTER.......................................8

Your Safety Tester

iii

SUPPLY POWER OUTLET FAULTS..............................8

USING THE TESTER ......................................................9

Testing Metal Case (Class 1) Products.....................................9

Testing Double Insulated (Class 2) Products............................9

Testing Extension Cords .........................................................10

RUN/LEAKAGE Test – Self Test Facility ................................10

REPAIR AND CALIBRATION.......................................11

MAINTAINING THE TESTER........................................ 12

Cleaning the Tester.................................................................12

User Maintenance ...................................................................12

NOTES...........................................................................13

Your Safety Tester

1

DECLARATION OF CONFORMITY

for the

Clare Safe Check 5s

Manufactured by:

Seaward Electronic Ltd., Bracken Hill, Peterlee

County Durham. SR8 2SW England

Millennium Statement

This product is Millennium compliant, and conforms fully to the document

BSI DISC PD2000-1.

Statement of Conformity

Based on test results using appropriate standards, the product is in

conformity with Electromagnetic Compatibility Directive 89/336/EEC and

Low Voltage Directive 73/23/EEC

Standards used:

EN 61010-1 (2001) Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use.

EN 61326: (1998) Class A. Electrical equipment for measurement, control

and laboratory use – EMC requirements.

The tests have been performed in a typical configuration.

This Conformity is indicated by the symbol ,

i.e. “Conformité Européenne

Your Safety Tester

2

Before Starting

Upon receipt of your Tester:

1. Check that all the component parts are present:

• Safe Check 5s Tester

• Instruction Manual

2. Read the operating instructions fully before conducting any

tests.

3. Contact Clare Instruments if you need information on

training in Electrical Safety Testing. Courses can be

arranged at Clare, or at the customer location.

4. Clare Instruments reserve the right to update the software in

any instruments returned to them for repair or otherwise,

without notifying the customer previously.

Clare Instruments Inc. can be contacted at:

Clare Instruments U.S. Inc,

6304 Benjamin Road, Suite 506, Tampa, Florida.

Telephone: 813 886 2775

Fax: 813 886 2754

Email: [email protected]

Internet: www.clareinstruments.com

Your Safety Tester

3

Safety

Note:

Please read the following Safety Instructions before use!

Safety Precautions

The manual contains specific warning and caution statements.

A Warning will identify the conditions and actions that pose hazard(s)

to the user.

A caution will identify the conditions and actions that may damage the

Tester.

Symbols used within this manual and on the Tester are shown below:

Risk of electric shock

Warning of potential

hazard

Conformité Européenne

Use of the instrument in a manner not specified may impair safety. Read

the following safety information carefully before attempting to operate the

instrument.

Your Safety Tester

4

Warning

Due to the potential hazards associated with any electrical

circuit it is important that the user is familiar with the

instructions covering the capabilities and operation of this

instrument. The user should ensure that all reasonable safety

precautions are followed and if any doubt exists should seek

advice before proceeding.

This product is designed for use by suitably trained competent

personnel and should be operated strictly in accordance with

the instructions supplied.

Failure to comply with these instructions may expose the user to electrical

hazard.

This Tester performs a number of electrical tests, which involve supply

voltages and high currents. Never touch the Product being tested, or the

test leads, whilst a test is in progress. Never remove the cover and touch

any internal components whilst the tester is switched ON.

Always check all test leads for signs of damage prior to use. Never use

damaged or defective leads, to perform any test.

Always ensure the power outlet to the Tester provides an adequate Ground

connection.

This manual contains information and warnings, which must be adhered to,

to ensure operator safety during operation. It is essential that this manual

be read fully before proceeding to test.

Should the Tester behave abnormally do not continue with the testing.

Disconnect immediately and contact Clare Instruments for servicing (see

Chapter 5 - Maintaining the Tester).

Your Safety Tester

5

Introducing the Tester

Introduction

The Clare Safe Check 5s Tester is a powerful tool to assist in the

verification of the safety of electrical and electronic equipment. A range of

tests are provided, with innovative features to aid difficult test situations,

which allow testing of a wide variety of equipment.

The Tester is designed to be easy to use, and also includes the following

innovative features:

• Automatically checks supply power outlet for faults.

• Accurate Ground Bond, Short and Leakage Current measurements.

• Simple PASS – FAIL indication.

• Automatic selection of correct tests.

• Supply Input 120V AC 60Hz (GROUNDED).

• 20 Amp thermal circuit breaker (located on the rear of the Tester)

• Versatile range of test outputs:

• Self test facility

Standard Accessories

Accessory Part Number

Operating Manual

Quick Reference Guide

SC5s-OM

SC5s-QR

Optional Accessories

Accessory Part Number

Calibration Checkbox SC5-CB

Product Number Labels (250) CLARE-PNL

Pass Labels (500) CLARE-PL

Your Safety Tester

6

Specifications

Input Rating

Supply Voltage .............................................................. 120 Vac RMS

Frequency ..............................................................................50/60 Hz

Fuse ..................................................... 20 Amp thermal circuit breaker

Ground Bond Test

Test Voltage.................................................................6 Vac (Nominal)

Test Current....................................................................... 7A (Typical)

Fail Level ...................................................................................500mΩ

Short to Case Test

Test Voltage.................................................................6 Vac (Nominal)

Test Current........................................................... 20 μAmps (Typical)

Fail Level.....................................................................................150kΩ

Short to Line Test

Test Voltage.................................................................6 Vac (Nominal)

Test Current................................................................. 1 Amp (Typical)

Fail Level...........................................................................................3Ω

Leakage Test

Test Voltage............................................................................. 120 Vac

Fail Leakage Current .............................................................. 0.75 mA

Accuracy Levels +/-10% at 22 °C and 40% relative humidity.

This product is IP40 rated.

Your Safety Tester

7

Purpose of the Tests

Ground Bond Test

This test is to ensure the connection between the ground wire and ground

pin in the power cord of the product and the metal casing are connected by

a sufficiently low impedance.

A test current is applied between the ground pin of the power cord and the

ground clip.

A high current is normally used to stress the connection to a fault condition.

The length of the test is limited to prevent damage due to overheating.

Short to Case Test

A low voltage test to ensure there is no short present between the line

conductor and the case.

Short to Line Test

A low voltage test to ensure there is no short between the line and neutral

conductors.

Leakage Test

A supply voltage test to ensure there is no harmful leakage in the equipment

under test.

Extension Cord Test

This test confirms the safety and integrity of 120V power cords.

The cord test performs a ground bond test on the ground wire and then

does continuity and polarity checks on the Line and Neutral conductors,

between the plug and socket of the extension cord.

Your Safety Tester

8

Definitions

• Equipment Under Test - the electrical / electronic apparatus (EUT)

which is the subject of testing.

• Tester - the Clare Safe Check 5s tester.

• Un-powered Tests - the EUT is the subject of electrical tests using

stimuli generated within the Tester.

• User - The test operative using the Tester to perform tests on an EUT

Switching on the Tester

• Connect the power cord to a 120 Volt 60Hz Grounded supply.

• Switch on the Tester.

• The amber test indicators should illuminate.

• If the Green PASS and Red FAIL indicators illuminate there is a fault.

Supply Power Outlet faults

• If a fault is detected, indicated by the Green PASS and Red FAIL

indicators, switch the tester off immediately and correct the fault. Seek

assistance if you are unsure how to proceed.

• The tester will not allow you to perform any tests while a fault is present.

• The type of fault can be determined by the buzzer.

o Buzzer Continuous – Mains power has been connected to

the male test plug. Remove any power cords connected to

the tests connectors

o Short beeps (0.2s duration) – Supply Ground fault. The

installation ground has a fault. Consult a qualified

electrician.

o Long beeps (0.5s duration) – Line/Neutral fault. The

installation line and neutral connections are crossed.

Consult a qualified electrician.

Your Safety Tester

9

Using the Tester

WARNING - do not touch or hold the EUT during testing. Ensure the EUT

cannot move when under test.

Testing Metal Case (Class 1) Products

• Before connecting to the Tester a visual inspection must be carried out

to ensure the EUT has no loose cables on plugs or cable entries, and to

verify the condition of the supply cord.

• Connect the EUT to the appropriate test output socket.

• Ensure the EUT is switched on and properly supported.

• Connect the ground clip to a metal part on the body of EUT.

• WARNING During LEAKAGE tests the product will be powered at line

voltage and will operate. Make sure the ground clip is not connected to

moving parts.

• Press and hold the TEST button to begin test sequence. If the TEST

button is released at any time the sequence will be aborted.

• If any test fails all outputs are switched off and the FAIL indicator will

flash for 3 seconds accompanied by the buzzer sounding.

• As each test is performed the indicator will flash. When a test is

complete the next test in the sequence will start automatically.

• After the SHORT to LINE test has finished the LEAKAGE test will not

start until the TEST button has been released and the RUN/LEAKAGE

button has been pushed.

• Press and hold the RUN/LEAKAGE button to start the LEAKAGE test. If

the RUN/LEAKAGE button is released at any time the test sequence will

abort.

• WARNING During LEAKAGE tests hazardous voltages may be

present. Do not touch the EUT during LEAKAGE tests.

• When all tests are successfully completed the PASS indicator will flash

for 3 seconds.

Testing Double Insulated (Class 2) Products

• Before connecting to the Tester a visual inspection must be made to

ensure the EUT has no loose cables on plugs or entries, and to verify

the condition of the supply cord.

• Connect the EUT to the appropriate test output socket.

• Ensure the EUT is switched on and properly supported.

• Connect the ground clip to body of EUT.

Your Safety Tester

10

• Press and hold the TEST button to begin. If the TEST button is

released at any time the sequence will abort.

• If any test fails all outputs are switched off and the FAIL indicator will

flash for 3 seconds accompanied by the buzzer.

• As the SHORT to LINE test is performed the indicator will flash.

• After the SHORT to LINE test has finished the LEAKAGE test will not

start until the TEST button has been released and the RUN/LEAKAGE

button has been pushed.

• Press and hold the RUN/LEAKAGE button to start the LEAKAGE test. If

the RUN/LEAKAGE button is released at any time the test sequence

will abort.

• WARNING During LEAKAGE tests hazardous voltages may be present.

Do not touch the EUT during LEAKAGE tests.

Testing Extension Cords

• Before connecting to the Tester a visual inspection must be made to

ensure the EUT(in this case the extension cord set) has no loose cables

on plugs or sockets, and to verify the condition of the supply cord.

• Connect the socket end of the EUT to the Tester output plug (male) and

the plug end of the EUT to the appropriate test socket output.

• Press and hold the TEST button to begin the tests (three stages). If the

TEST button is released at any time the sequence will abort.

• As the CORD TEST is performed the indicator will flash to indicate that

the Ground bond test (1st stage), then the continuity & polarity tests (2nd

stage), then the line/neutral short test (3rd stage) are being performed

respectively.

• If any test fails all outputs are switched off and the FAIL indicator will

flash for 3 seconds accompanied by the buzzer.

• When all tests are successfully completed the PASS indicator will flash

for 3 seconds.

RUN/LEAKAGE Test – Self Test Facility

• Ensure there are no EUTs connected to the tester.

• Select CLASS 2 Double Insulated – using the rotary switch.

• Press and hold the TEST button to begin. If the TEST button is

released at any time the sequence will abort.

• After the SHORT to LINE test has finished the LEAKAGE test will not

start until the TEST button has been released and the RUN/LEAKAGE

button has been pushed.

Your Safety Tester

11

• Before beginning the LEAKAGE test press the Leakage Self Test button

on the rear of the tester

• Press and hold the RUN/LEAKAGE button to start the LEAKAGE test. If

the RUN/LEAKAGE button is released at any time the test sequence

will abort.

• The LEAKAGE test should fail Note: the Leakage Self Test button must

be pressed for the full duration of the LEAKAGE test

• If the LEAKAGE test does not fail, contact Clare Instruments Inc. for

service

Repair and Calibration

Please return with a detailed fault report to:

Clare Instruments U.S. Inc,

6304 Benjamin Road, Suite 506, Tampa, Florida

Telephone: 813 886 2775

Fax: 813 886 2754

Email: [email protected]

Internet : www.clareinstruments.com

Your Safety Tester

12

Maintaining the Tester

Cleaning the Tester

The Tester case can be cleaned with a damp cloth and a small amount of

mild detergent. Prevent excessive moisture around the socket panel or at

the rear of the unit.

Do not allow liquids to ingress into the Tester, or around the socket panel.

Do not use abrasives, solvents, or alcohol to clean.

If any liquid is spilt onto the Tester case, the Tester should be returned for

inspection, stating the cause of the defect.

User Maintenance

The Tester is a rugged quality instrument. However, care should always be

taken when using, transporting and storing this type of equipment. Failure

to treat the product with care will reduce both the life of the instrument and

its reliability.

If the Tester is subject to condensation, allow the Tester too completely dry

before use.

• Always check the Tester and all the test leads for signs of damage and

wear before use.

• Do not open the Tester under any circumstances.

• Keep the instrument clean and dry.

• Avoid testing in conditions of high electrostatic or electromagnetic fields.

• Maintenance should only be performed by authorized personnel.

• There are no user replaceable parts within the Tester.

• The unit should be regularly calibrated (at least annually).

Your Safety Tester

13

Notes

Table of contents

Popular Test Equipment manuals by other brands

Kusam-meco

Kusam-meco KM 7016 IN instruction manual

Agilent Technologies

Agilent Technologies J-BERT N4903 user guide

SIGLENT TECHNOLOGIES

SIGLENT TECHNOLOGIES SDS1000X-E Series user manual

SubSurface Instruments

SubSurface Instruments ML-1M instruction manual

Fluke

Fluke BT5300 Series user manual

Vanguard Instruments

Vanguard Instruments EZCT S2 user manual

Myron L

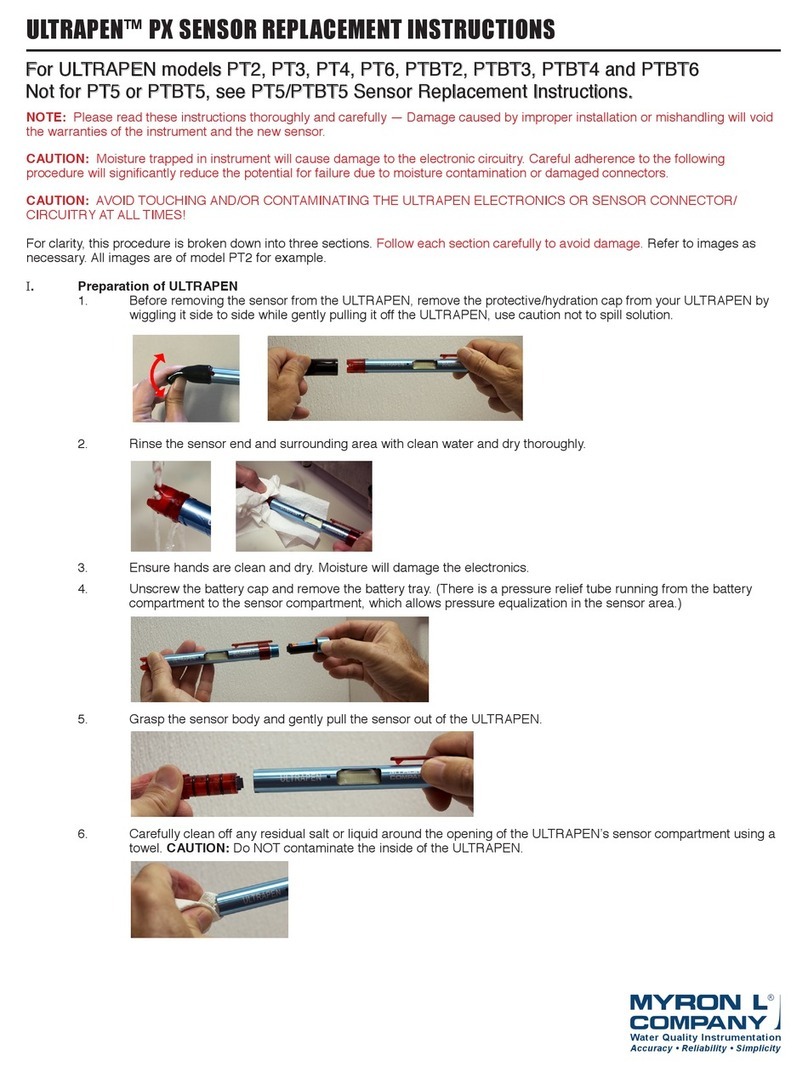

Myron L ULTRAPEN PTBT2 Replacement instructions

Hanna Instruments

Hanna Instruments HI 95711C instruction manual

Amprobe

Amprobe VP-700-E instruction manual

tCheck

tCheck tCheck user manual

Velleman Instruments

Velleman Instruments VPS10 Technical Doc

Extech Instruments

Extech Instruments 380375 user manual