CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual Page 19

CLARKETECHNOLOGY Model SPS-28

Engine, Dust Control & Handle Assembly 4/99

Ref # Part No. Description Qty

1 60072A Frame, Main 1

2u792920 Engine, 5 H.P. Briggs and Stratton 1

3 285161 Label, Gasoline 1

4 722824 Elbow, ¼ x 45° Street Brass 1

5 755721 Nipple, ¼ x 2½" Brass 1

6 822806 Elbow, ¼ x 90° Brass 1

7 Drain Plug - Part of Engine

8 822806 Washer 5/16 Lock 8

9 196157 Screw, 5/16 -18 x 1¼ Hex 4

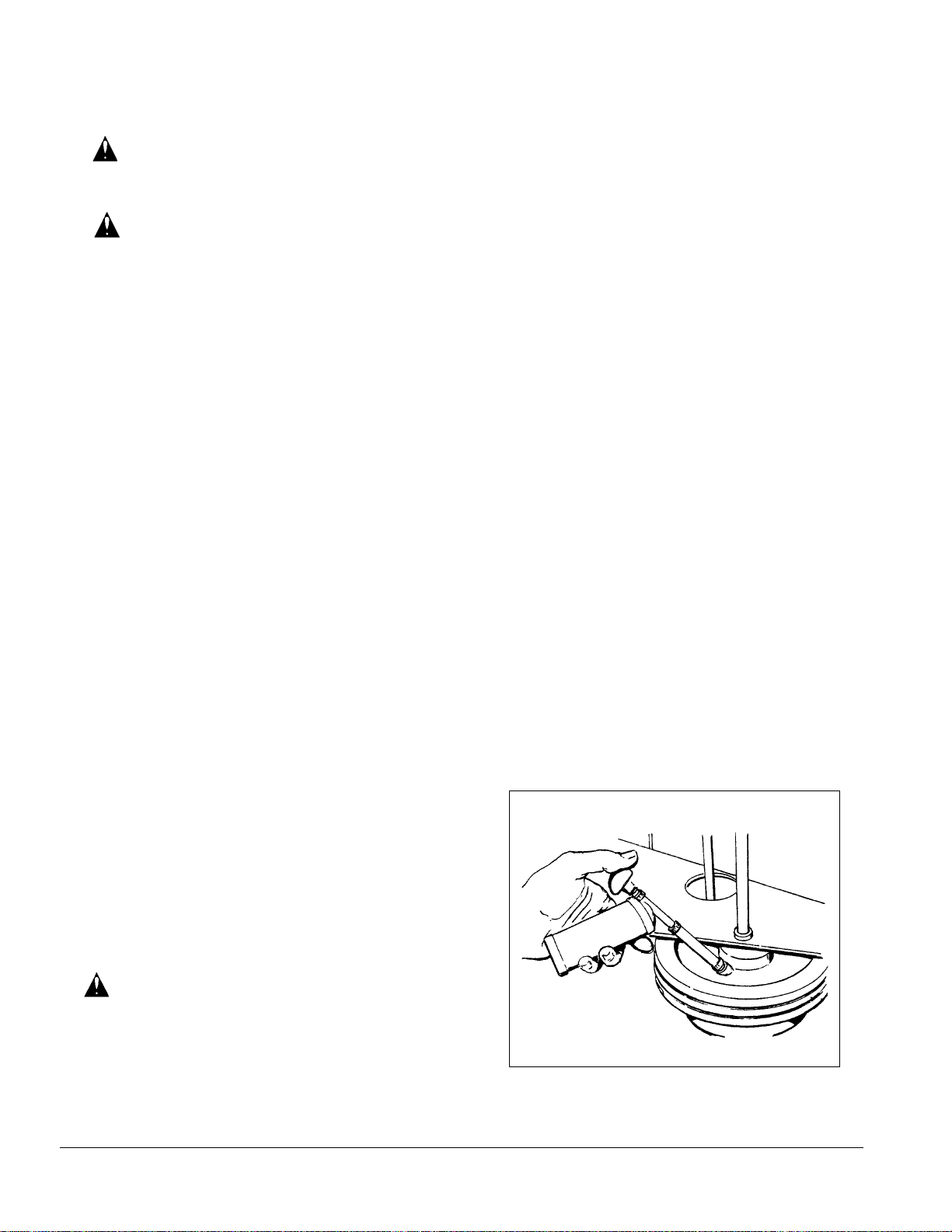

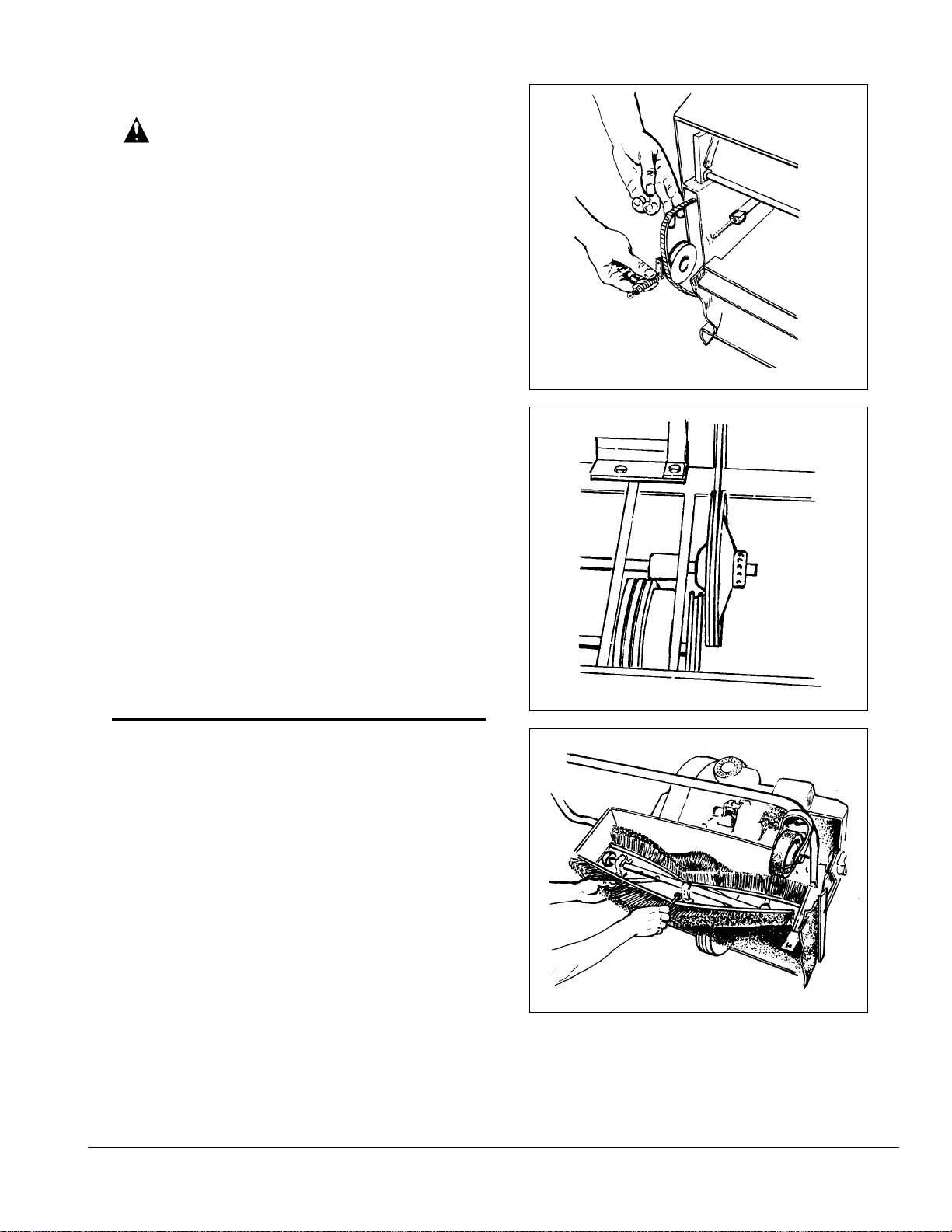

10 796924 Pulley, Engine 1

11 962103 Screw, 5/16 -18 x 3/8Set 8

12 915044 Key 3/16 x 3/16 x 1" Square 1

13 790335 Arm, Assembly 1

14 798231 Spacer, Parallel Arm Rear 1

15 987013 Wrench, Allen 5/32"1

16 962216 Screw, 3/8x 16 x 1" Hex 1

17 793624 Guard, Gas Tank 1

18 796925 Pulley, Idler 1

19 902659 Bearing 1

20 857301 Retaining Ring 1

21 962454 Screw, ¼-20 x 1" 1

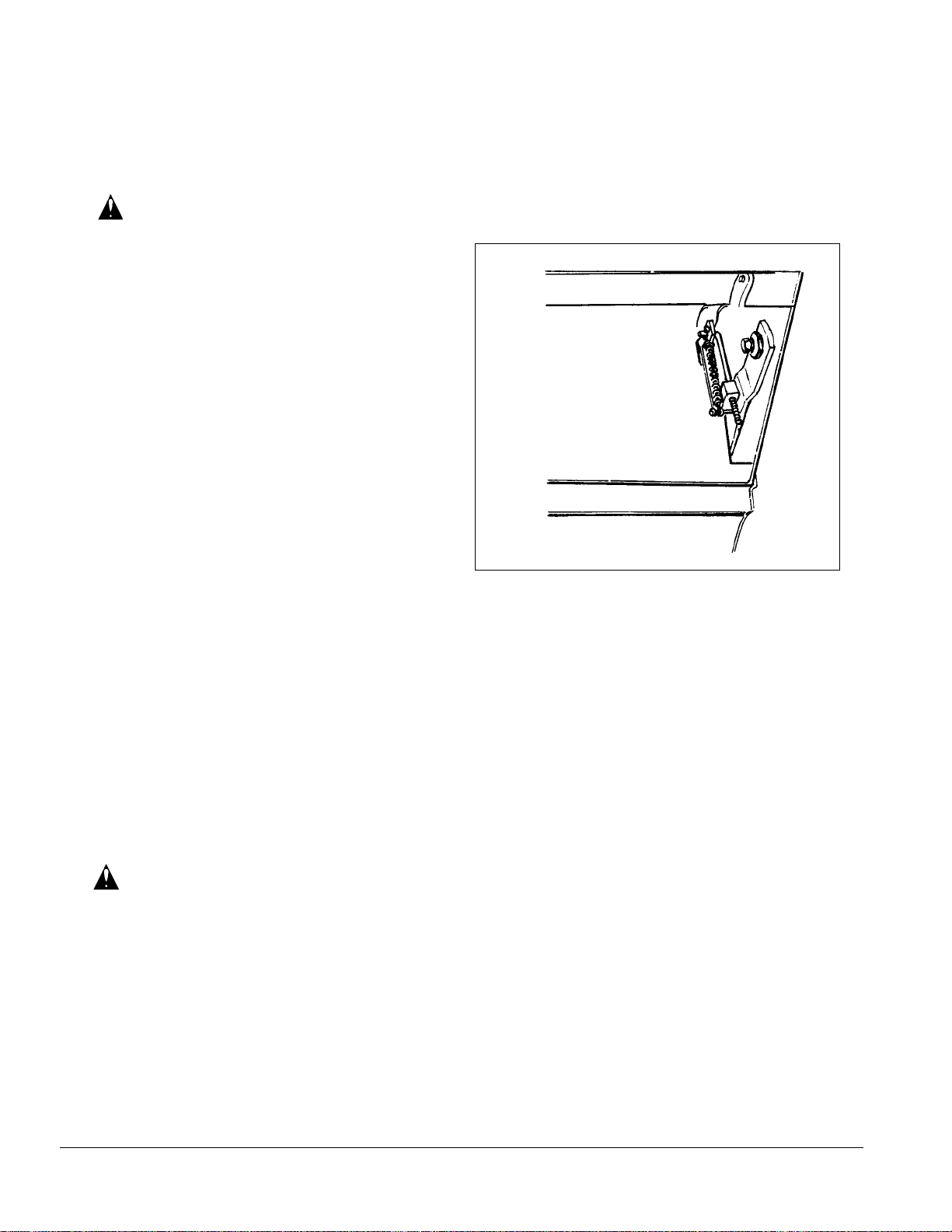

22 60073A Housing Assembly, Blower 1

23 793424 Gasket, Duct to Filter 1

24 791221 Bumper, Dust Hopper 1

25 793423 Gasket, Duct to Frame 1

26 962709 Screw ½ Sems 20

27 980657 Washer ¼ Lock 4

28 920110 Nut, 5/16 -18 Elastic Stop 1

29 980210 Washer, Impeller 1

30 614820 Impeller 1

31 915044 Key, 3/16 x 3/16 x 1" Square 1

32 793420 Gasket, Blower Mounting Adapter 1

33 790221 Adapter Assembly, Blower Mounting 1

34 962835 Screw, 10 x 24 x ½ Hx St.Typ F 6

35 618220 Spacer, Impeller 1

36 067304 Snap Ring 1

37 902550 Bearing 2

38 617704 Shaft, Impeller 1

39 794224 Housing, Bearing 1

40 856702 Pin, Hair Cotter 2

41 796923 Pulley, Blower 1

42 793620 Guard, Belt 1

43 790830 Bracket, Lift Shaft 2

44 797726 Shaft Assembly 1

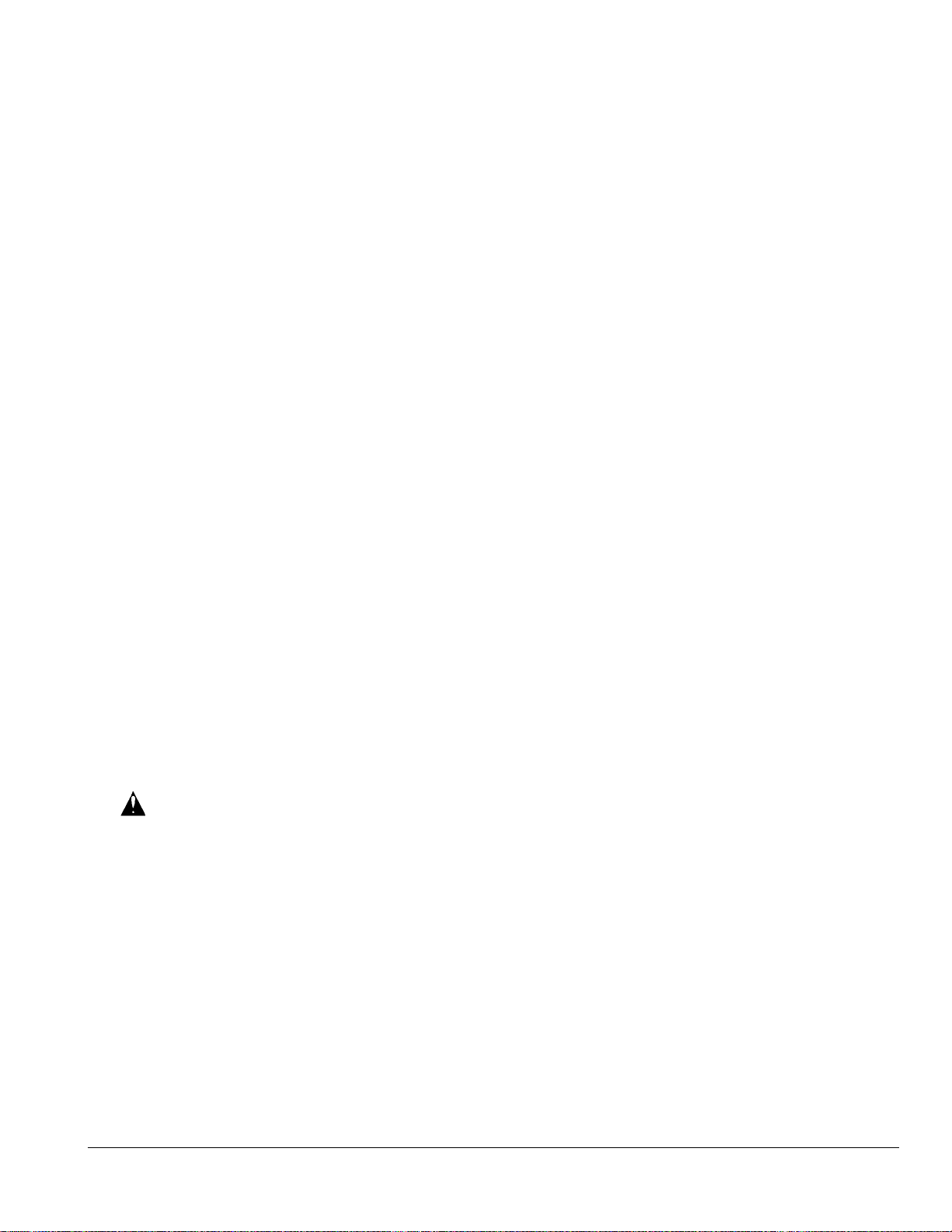

45 920993 Nut, 3/16 -18 Panel 6

46 60074A Cover, Filter 1

47 793320 Filter, Dust 1

48 15724A Housing Asm., Dust Chamber 1

49 793422 Gasket, Dust Chamber 4

50 793421 Gasket, Dust Chamber Top 2

Ref # Part No. Description Qty

51 793820 Guide, Dust Hopper 2

52 682006 Clamp Assembly, Lid 2

53 930086 Rivet, 3/16 x .450 Long 10

54 285102 Latch, Inspection Door 3

55 60070A Hopper, Dust 1

56 797226 Retainer, Dust Hopper 2

57 962385 Screw 10- 24 x ½ Bdg. Hd. 4

58 920200 Nut, 10 - 24 Hex 4

59 790832 Bracket, Dust Housing Support 1

60 53038A Spring 1

61 793425 Gasket, Dust chamber Bottom 2

62 Serial No. Plate - Gasoline (Blank) 1

Serial No. Plate - Battery (Blank) 1

63 215104 Label, Warning 1

64 755129 Label, Patent Pending 1

65 795120 Label, Instruction 1

66 793920 Handle, Upper 1

67 790825 Bracket, Handle Pivot 2

68 806705 Pin 1

69 790824 Bracket, Handle 2

70 796721 Pin, Handle Pivot 2

71 925004 Pin, 1/16 x ½ Cotter 2

72 85818A Screw, 5/16 - 18 x 2½ Hex 4

73 796720 Pin Assembly, Handle Release 2

74 85392A Screw 6-32 x 3/8Pan Hd 2

75 793922 Handle, Lower 2

76 798524 Support, Handle 2

77 962894 Screw, 5/16 - 18 x 2½ 4

78 920160 Nut, 5/16 - 18 Jam 4

79 797420 Rod, Traverse 1

80 920329 Nut, 5/16 -24 Hex 1

81 809904 Yoke 1

82 62665A Cover, Frame 2

83 980646 Washer, ¼ Plain 7

84 796631 Plate, Stabilizer Whl. Stiffner 2

85 798537 Support, Rear Wheel 2

86 419702 Wheel 2

87 796722 Pin, Wheel Support 2

88 925036 Pin, 3/32 x ¾ Cotter 4

89 799724 Wheel Assembly, Stabilizer 2

90 798230 Spacer, Idler Pulley 1

91 962086 Screw, ¼-20 x ¾ Hx Hd. 2

92 962799 Screw, ¼-20 x 3/8Soc. Cap 1

93 920148 Nut, 3/8-16 Hex Jam 1

94 790846 Bracket, Idler Arm 1

95 980202 Washer Wave 1

96

97 170266 Coupling 1

NOTE: uindicates a change has taken place since

last publication of this manual.