ENGLISH

Operator’s Manual - RSW 37 1

TABLE OF CONTENTS

INTRODUCTION......................................................................................................................................................... 2

MANUAL PURPOSE AND CONTENTS .....................................................................................................................................2

TARGET......................................................................................................................................................................................2

HOW TO KEEP THIS MANUAL..................................................................................................................................................2

IDENTIFICATION DATA..............................................................................................................................................................2

OTHER REFERENCE MANUALS..............................................................................................................................................2

SPARE PARTS AND MAINTENANCE........................................................................................................................................2

CHANGES AND IMPROVEMENTS ...........................................................................................................................................2

OPERATION CAPABILITIES......................................................................................................................................................2

CONVENTIONS .........................................................................................................................................................................2

UNPACKING/DELIVERY ............................................................................................................................................ 3

SAFETY ...................................................................................................................................................................... 3

SYMBOLS ..................................................................................................................................................................................3

GENERAL INSTRUCTIONS.......................................................................................................................................................3

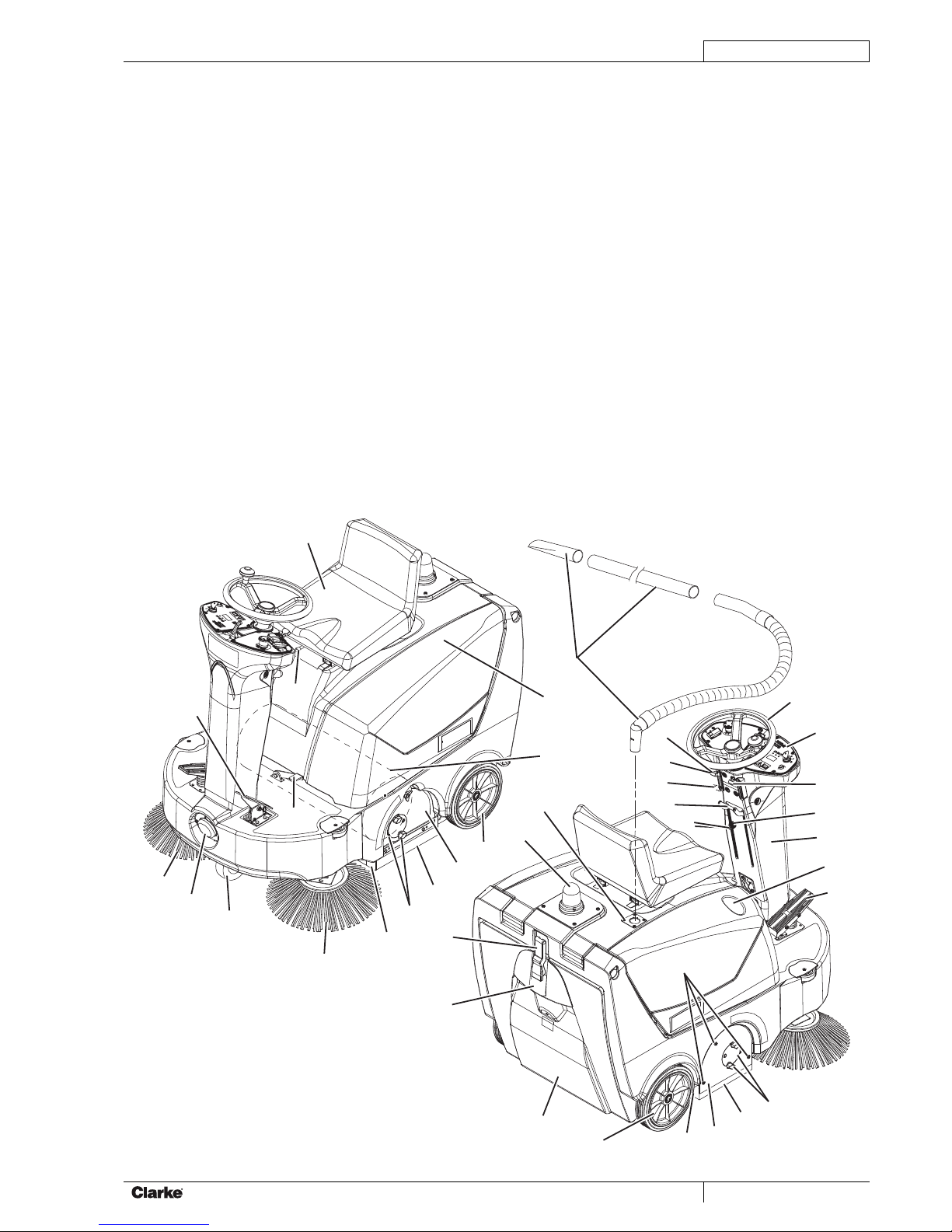

MACHINE DESCRIPTION .......................................................................................................................................... 5

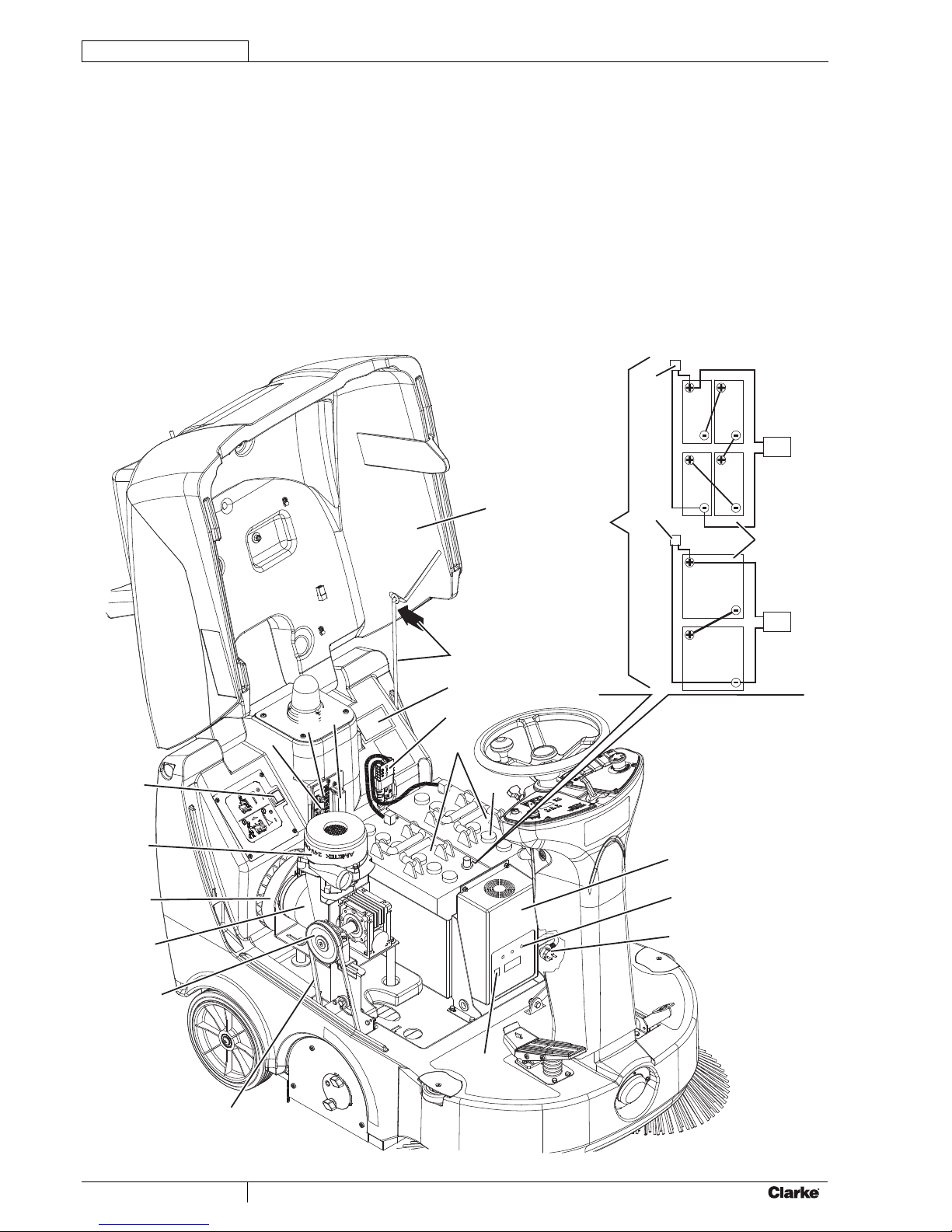

MACHINE STRUCTURE ............................................................................................................................................................5

CONTROL PANEL......................................................................................................................................................................7

ACCESSORIES/OPTIONS........................................................................................................................................................7

TECHNICAL DATA......................................................................................................................................................................8

WIRING DIAGRAM.....................................................................................................................................................................9

USE ........................................................................................................................................................................... 10

BATTERY CHECK/SETTING ON A NEW MACHINE...............................................................................................................10

WET OR GEL BATTERY SETTING..........................................................................................................................................11

BEFORE START-UP.................................................................................................................................................................11

MACHINE START AND STOP..................................................................................................................................................12

PARKING BRAKE.....................................................................................................................................................................12

MACHINE OPERATION ...........................................................................................................................................................13

HOPPER EMPTYING...............................................................................................................................................................13

AFTER USING THE MACHINE................................................................................................................................................13

PUSHING/TOWING THE MACHINE........................................................................................................................................13

MACHINE LONG INACTIVITY .................................................................................................................................................13

FIRST PERIOD OF USE ..........................................................................................................................................................13

MAINTENANCE........................................................................................................................................................ 14

SCHEDULED MAINTENANCE TABLE ....................................................................................................................................14

MAIN BROOM HEIGHT CHECK AND ADJUSTMENT.............................................................................................................15

MAIN BROOM REPLACEMENT ..............................................................................................................................................16

SIDE BROOM HEIGHT CHECK AND ADJUSTMENT .............................................................................................................17

SIDE BROOM REPLACEMENT...............................................................................................................................................17

DUST FILTER CLEANING AND INTEGRITY CHECK .............................................................................................................18

SKIRT HEIGHT AND OPERATION CHECK.............................................................................................................................19

HOOD SAFETY SWITCH OPERATION CHECK .....................................................................................................................20

BATTERY CHARGING .............................................................................................................................................................21

FUSE CHECK/REPLACEMENT/RESET..................................................................................................................................22

SAFETY FUNCTIONS .............................................................................................................................................. 23

EMERGENCY PUSH-BUTTON................................................................................................................................................23

HOOD SAFETY SWITCH.........................................................................................................................................................23

DRIVER SEAT MICROSWITCH...............................................................................................................................................23

TROUBLESHOOTING.............................................................................................................................................. 23

SCRAPPING ............................................................................................................................................................. 24

PART LIST ................................................................................................................................................................ 73